GasDog 41547 User manual

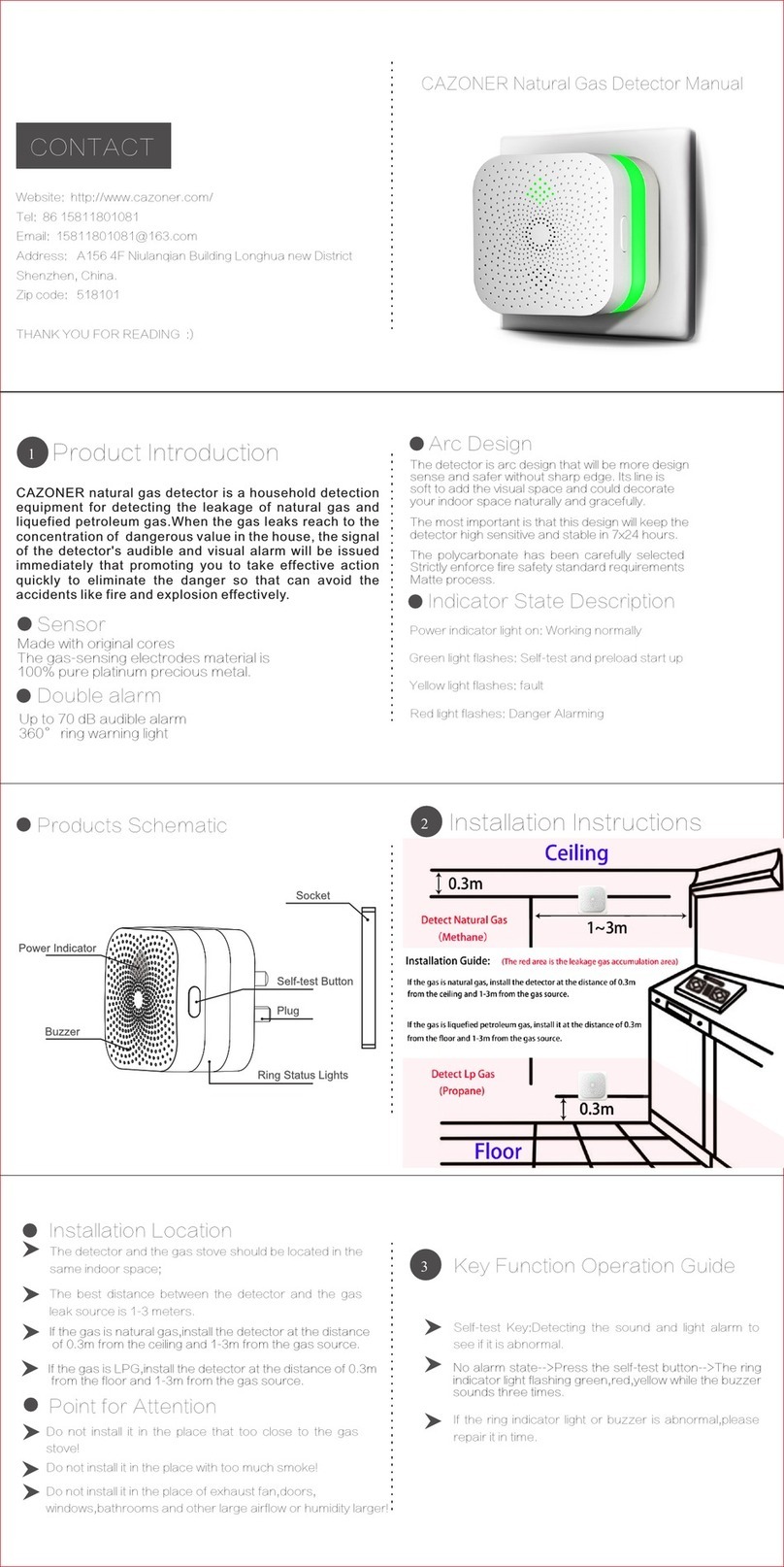

Product Overview

GD300 concentration in different kinds of situations or pipelines 24h

continuously wall mounted type gas detector. Using world first

brand sensors, and advanced micro-process technology, with data

display, fast response, high preci-sion and good stability. Powered by

24V DC, with 4-20mA, RS485, relay signal output. Explosion proof,

suitable for different kinds of situations.

GD300

Online Fixed Gas Detector

GD300

online fixed gas detector

1

GD300

online fixed gas detector

Employing overseas original sensor.

tandard equipped with three-wire system 4-20mA analog output;

relay output; RS485 output (optional)

Unique infrared ray control function, which can non-contacted control the

device. Being compatible with all kinds of controlled alarms, PLC, DCS and

other control system, can be remote monitored.

Alarm mode: Sound and light, alarm value is settable(Optional)

Explosion-proof design, fast, reliable and stable.

Explosion-proof grade: II 2G Ex db IIC T6 Gb IP65

With self-calibration function and three standard keys will be used

to realize on-site maintenance.

Monitor the specific gas concentration in environment or pipeline

and alarm.

With self-calibration and zero calibration function,

makes the detection more accurate and reliable.

With temperature compensation, this is able to realize gas

concentration compensation under conditions of different temperatures.

Infrared ray controller can remote control alarm point settings,

zero calibration, and address modification.

Can output one or two on-off signals, can drive ventilator or

solenoid valve and other external devices.

Working Voltage:12-36V DC

Case:die-cast aluminum

Product advantages

Features

Application

Petrochemical & Chemcial Industry Municipal Engineering & Utilities Agricultral & Environmental Protection

Electronic Food & Pharmaceutical Industry Other Industries

Product Advantages

2

Gas Measure range Optional

Normal gas types and paramaters (Other gases are not listed can be customized)

Resolution Response time

GD300 online fixed gas detector

Gas Detected

Detection Principle

Install Method

Measure Range

Resolution

Precision

Output signal

Response Time

Repeatability

Zero shift

Connection mode

Temperature

Explosion-Proof

Power

Dimensions

Recovery Time

Linearity error

Relay output

Thread Size

Humidity

Degree of protection

Operating time

Weight

Flammable gas(EX)

Oxygen(O2)

Carbon monoxide(CO)

Hydrogen sulfide(H2S)

Methane(CH4)

Ammonia(NH3)

Chlorine(CL2)

Hydrogen Chloride(HCL)

Hydrogen (H2)

Nitric oxide(NO)

Nitrogen dioxide(NO2)

Nitrous Oxides(NOX)

formaldehyde(CH2O)

Ozone(O3)

Carbon dioxide(CO2)

sulfur dioxide(SO2)

Ethylene oxide(ETO)

Phosphine(PH3)

Hydrogen cyanide(HCN)

Nitrogen(N2)

Hydrogen fluoride(HF)

0-100%LEL

0-30%VOL

0-1000ppm

0-100ppm

0-4%VOL

0-100ppm

0-10ppm

0-20ppm

0-1000ppm

0-100ppm

0-20ppm

0-100ppm

0-10ppm

0-10ppm

0-2000ppm

0-20ppm

0-100ppm

0-10ppm

0-10ppm

0-100%VOL

0-10ppm

0-100%VOL

0-25%VOL

0-2000ppm

0-1000ppm

0-100%VOL

0-200ppm

0-100ppm

0-100ppm

0-40000ppm

0-250ppm

0-100ppm

0-2000ppm

0-100ppm

0-1000ppm

0-50000ppm

0-5000ppm

0-1000ppm

0-5000ppm

0-100ppm

0-90%VOL

0-50ppm

1%LEL/0.1%VOL

0.01%VOL/0.1%

VOL 0.1ppm/1ppm

0.01ppm/0.1ppm

0.01%VOL

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.1ppm/1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.01ppm/1ppm

0.01ppm/0.1ppm

0.01ppm/0.1ppm

0.1ppm/1ppm

0.01ppm/1ppm

0.01ppm/1ppm

0.01ppm/1ppm

0.01ppm

0.01%VOL

0.01ppm

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

≤10S

O2, N2, CO2, EX, VOC, PH3, etc. According to customers' requirements.

Electrochemistry, infrared ray, catalytic combustion, PID photo ionization (according to the target gas and sensor).

Wall-mounted, piping type, flow-type(according to the detected environment)

The range is optional, according to the target gas and the sensor.

According to sensor and measure range

According to sensor.

4-20mA, 0-5V, RS485, relay(optional)

≤5S

≤±1%

≤±1%(F.S/year)

G1/2 external thread explosion-proof flexible pipe

-20℃~50℃

II 2G Ex db IIC T6 Gb IP65

12-36V DC

180×150×90mm

≤10S

≤±1%

220V AC 3A (optional)

M45*2mm

0-95%RH

IP65

24h

≤1.6kg

Technical Specification

3

GD300

Used in steel mills, repair

shops,etc.

GD300

Used in warehouse, freezer,

etc.

GD300

Applied in power plant,

hazardous chemicals plant,

etc.

GD300

Application in sewage

treatment, refuse treatment

station, etc.

More Application

Furniture, Floor, Wallpaper, Coating, Gardening, Interior Decoration and Renovation, Dyestuff, Papermaking,

Pharmacy, Health Care, Foodstuff, Antiseptic.

Disinfection, Chemical Fertilizer, Resin, Adhesive, Pesticide, Raw Material, Sample, Technological Process,

Livestock Farm, Refuse Processing Plant, Perm Place.

Bio-pharmaceutical Plant, Green Household, Livestock Breeding, Green House Cultivating, Warehouse

Logistics, Brewing And Fermentation, Agricultural Production.

Project Cases

4

Matters need attention

A. Please read this instruction manual before using the detector.

B. The detector must be used in compliance with the designated procedures of our company. C. The warranty period of this transmitter

is 12months (starts from the date userget the detector).

Users should comply with the instructionsin the use of this detector. Any damages or malfunctions caused by improperoperation of users are

not within the scope of warranty.

D. Repairand replacement of any parts must be operated by trained staff under authorization of our company, using original spare part.

The operatoris responsible for the liability if users operate the repair of replacement by themselves.

E. There is acid solution inside the transmitter, please do not disassembleit. And pay attention not to damage the frontal membrane of

the transmitter. If the skin is stained with the acid solution. the right remedy is to flushing the stained skin continuously with clean water for

1 0minutes.

F. The detector must be calibrated for once each year. The explosion proof sheet parts of the transmitter need to be cleaned

regularly (blow with low pressure compressedair), otherwise the detection sensitivity will be affected by the dust and impurities clogging

protection hole.

Notice to Reader

Please read this instruction manual before using the detector

online fixed gas detector

GD300:XX

Instruction Manual

5

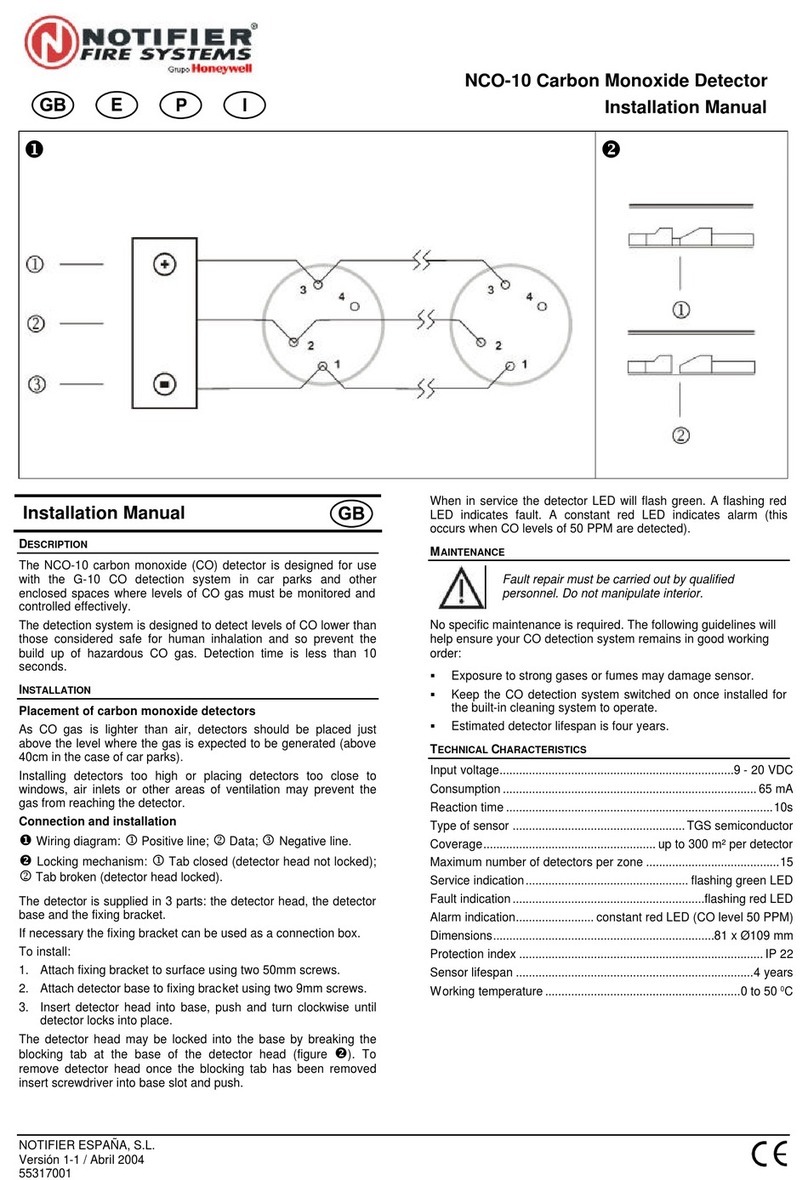

1.Power supply, signal line

2.Printed-circuit board

3.Terminal

4.Sound and tight alarm port

5.Air chamber of sensor

6.Sensor port

7.Main board connection

Ground

connection port

5

6

123

4

7

NC:Normally close

NO:Normally open

COM:Common

24V:24+,positive

GND:24-,negative

4~20mA:4~20mA analog signal

Low Alarm High Alarm

Relay Relay

Powered

Signal output

Motherboard connector Alarm

DDiiggiittaal pl prroobbe pe poorrtt

Port Instruction

6

1. Key Technical Indicator

Repeatability: <2%

Zero drift: < ± 2% (F•S) /6M

Operating temperature: -20~+50℃

Environment temperature: <90%RH

Working principle of the transmitter: electrochemical for oxygen and hazardous gases, catalytic

combustion for combustible gases

Lifespan of transmitter: 3years for combustible gas transmitter; 2years for hazardous gas transmitter

2. Other Technical Parameters

Inspection mode: diffusion

Working mode: fixed long-term continuous work Working voltage:

12-30V DC

Working current: oxygen and hazardous gas <50mA (Max)

combustible gas <150mA (Max)

Technical performance and parameters

Target gas Accuracy

O2<±2%(F.S)

H2S <±2%(F.S)

CO <±2%(F.S)

H2<±2%(F.S)

CO2<±2%(F.S)

C2H4<±2%(F.S)

NO2<±2%(F.S)

N2<±2%(F.S)

TVOC <±2%(F.S)

NH3<±2%(F.S)

ASH3<±2%(F.S)

C3H3N <±2%(F.S)

F2<±2%(F.S)

O3<±2%(F.S)

CL2<±2%(F.S)

BF3

Range

0-30%VOL

0-1000ppm

0-1000ppm

0-20000ppm

0-10000ppm

0-100ppm

0-20.0ppm

0-100%VOL

0-6000ppm

0-100ppm

0-10.00ppm

0-200.0ppm

0-10 ppm

0-5.00ppm

0-10.00ppm

0-10.00ppm <±2%(F.S)

least count

0.01%VOL

1ppm 1ppm

1ppm 1ppm

0.01ppm

0.1ppm

0.01%VOL

1ppm

0.01ppm

0.01ppm

0.1ppm

0.01ppm

0.01ppm

0.01ppm

0.01ppm

response time

≤15

≤15

≤25

≤15

≤40

≤60

≤25

≤40

≤60

≤40

≤30

≤40

≤25

≤50

≤60

≤60

l

Output signal: three-wire 4-20 mA standard signal output or RS485 signa output Exterior

structure: die-casting aluminum housing

Dimensions: 135 x 125 x 116mm (without mounting bracket)

167 x 145 x 126mm (with bracket)

Weight: without mounting brackets 1.2kg with brackets 1.6kg with stent

7

Connection cable (6 core cable) is defined as

follows: 4-20mA with RS485:

Red: positive-input of power (12 to 24V)/ 24V+ Black:

ground wire of power/24V

Yellow:4-20mA output.

Orange: RS485A

Blue: RS485B

Brown: Free

Connection distance: >1000m

Protection grade: IP65

Installation type: on wall

Type of explosion-proof: flame proof Explosion-proof

grade: Ex d IIC T6 Gb

Inlet port: hexagonal locknut

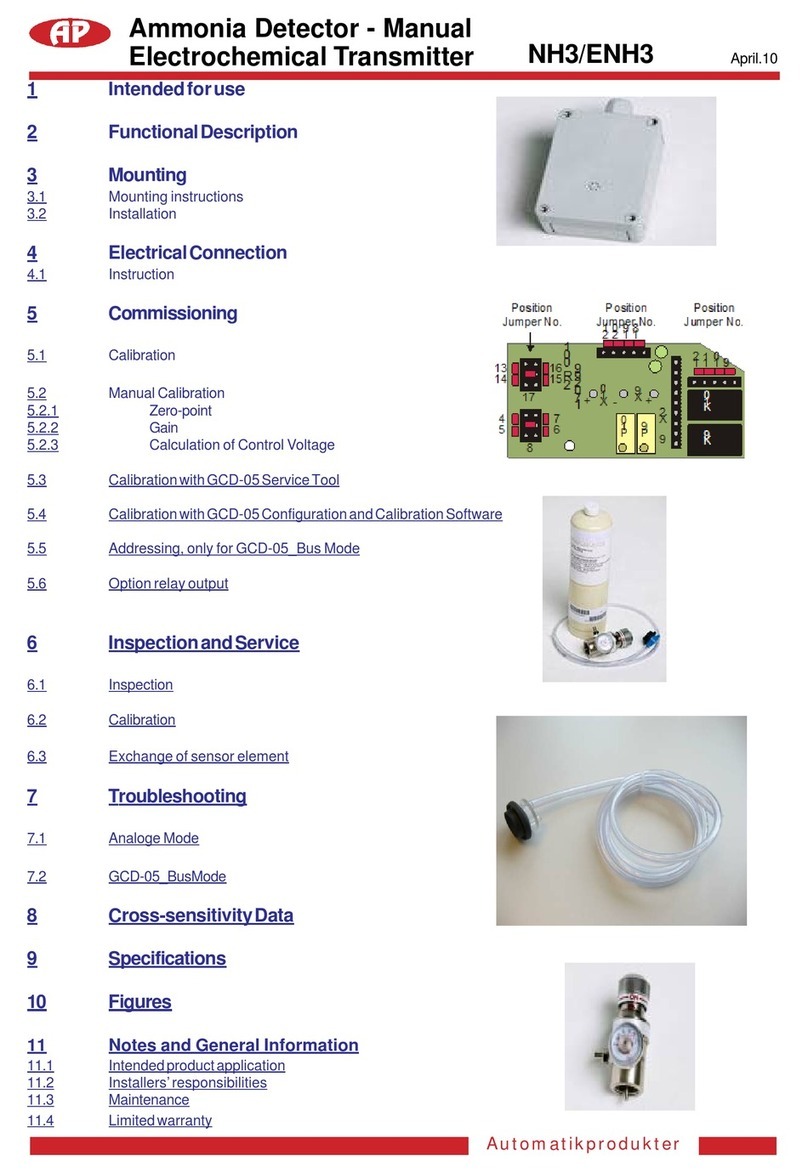

Settings of Remote Control

The remote control applied to all product type produced by Yuante.

1. Press "MENU" once to enter F01, address code setting menu. Press "OK" to modify, press"+""-

"to modify address code of the detector. Press "OK" to save settings and "BACK" to cancel.

2. Press "MENU", then press “+”to enter F02, minimum value setting menu of gas alarm, Press

"OK" to modify, press"+" "-"to modify the value. Press "OK" to save settings and "BACK" to cancel.

3. Continue to press "+"to enter F03, maximum value setting menu of gas alarm., Press "OK" to

modify, press"+" "-"to modify the value. Press "OK" to save settings and "BACK" to cancel. Same operation with

F04 (zero point calibration), F05 (range calibration), F06 (AD value).

4. Press "MENU" four times to enter a shift status, under this status:

Press "RESET" once, the data would be 255, one more it would be 0. Just press "RESET" to shift. When the

data is 0, press "+"or"-"to modify alarm point, the data difference would be only 1. When the data is 255, press

"+"or"-"to modify alarm point, the data difference would be 1000. "RESET" can also be used as mute button

when it is alarming.

MENU

RESET

OK

+

BACK

-

MENU button, from the measurement state into the functional state alarm

reset to eliminate alarm function

confirm button

plus

return

minus

Remote controller function

8

Function

introduction Controller

function introduction

F-01 Address, Range1-200

F-02 Low point alarm

F-03 High point alarm

F-04 Zero calibration

F-05 4mA offset correction

F-06 ADC check

F-07 Standard gas concentration

F-08 Calibration switch

F-09 Production date

F-10 Reserved function

F-11 Serial communication check. 0 no check, 1 odd check, 2 even check F-12

Arrangement mode of the floating-point data

0:DCBA

1:ABCD

2:CDAB

Need to press OK to save after all the above parameters are modified, which can take effect

immediately, power outage restart also valid.

Installation Instruction

1. Location Selection

The location selection of the gas detection transmitter is essential to achieve the best detection results. In

the selection of location, we need to consider the following factors: the density of gas in a leaking point,

proportion of target gas, the impact of surrounding buildings, condition of production equipment, wind direction

and annual meteorological conditions and even the location of windows and doors in an indoor environment.

We provide the following suggestions for your reference:

A. Maintain a proper distance between the detector and the possible gas leaking point. It would react too

fast or too frequent if the distance is not enough, which may paralyze people's mind.

B. The detector must be located in the downwind of the possible leaking point.

C. If installed indoor, but the source of the leak is outdoor, the detector must be installed at the air inlet.

D. Determine the height according to proportion of target gas in air.

E. Determine the quantity of detectors according to the condition of possible leaking point, frequency

of staff attendance and time of stay as well as the economic effect.

F. Consider to increase quantity of inspection point if the equipment is old.

G. Protect the detector from radiation of high temperature heart source. Environments of both

very high temperature and very low temperature will affect the result and lifespan of the detector.

9

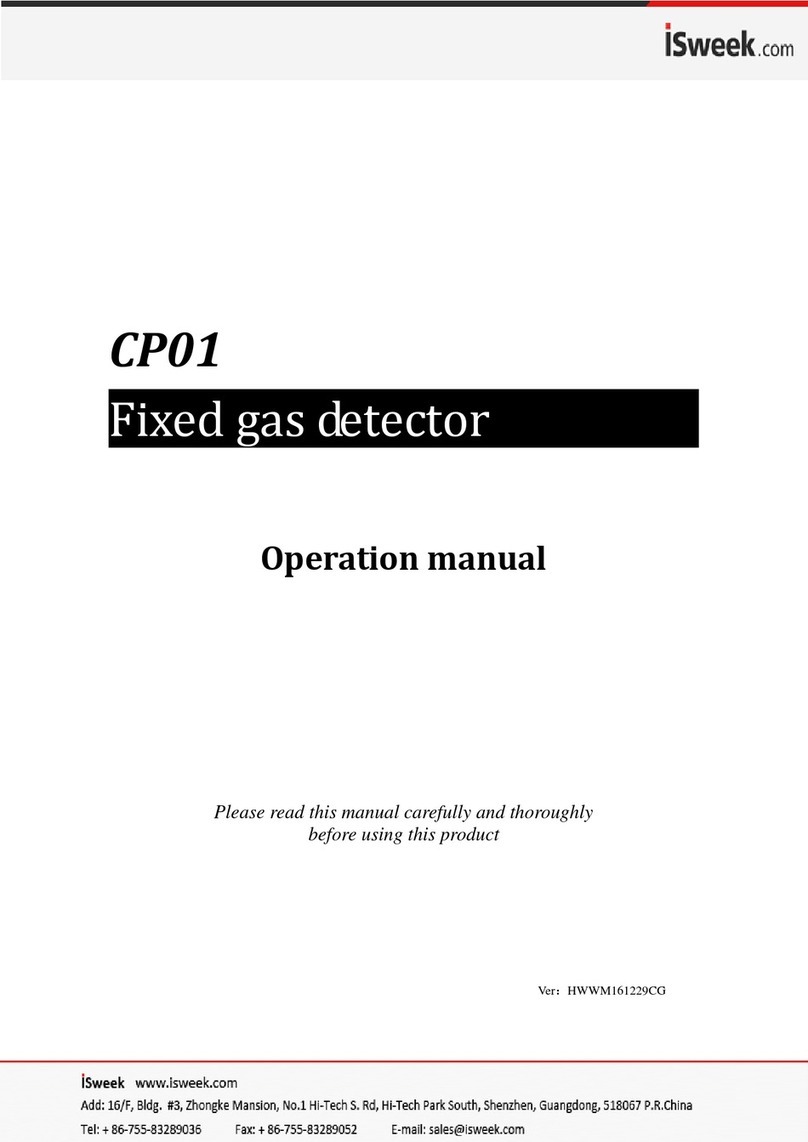

118.00

φ8.00

140.00

φ8.00 φ8.00

102.30

206.00

89.00

2. Steps of Installation

Connect wire to correspondent terminals. Don't work with power on. The arrangement of terminals

differs according to the type of transmitter. The definition of different wires:

Red: positive-input of power (12 to 24V)/24V+ Black:

ground wire of power/24V

Yellow:4-20mA output.

Orange: RS485A

Blue: RS485B

Brown: Free

Fix the detector on the wall with expansion bolt, make sure the transmitter is downward, or the detector

cannot work property. Users can also separate the bracket and transmitter according to the condition on

spot, fix the bracket before connection.

For the sake of safety and interference reduction, please connect the housing with reliable ground wire.

For the wire between the transmitter and the main engine, the shorter, the better. And protect the wire with

iron pipe.

Method of Calibration

To guarantee the measurement accuracy of the transmitter, regular calibration and maintaining

rigorous record is necessary.

Devices needed for calibration: a bottle of sample gas used for range calibration (60%F.S standard gas in

normal site),relief valve, flow meter of 0~1000ml/min, transparent and smooth conduit for gas, standard gas

housing, digital multimeter, stopwatch and etc.

Note: The value of transmitter WB (4mA) , WC (20mA) , Wz (zero potentiometer), WA (range

potentiometer, also known as calibration potentiometer) and host alarm has been set right before it leaves

the factory. User should not adjust casually. It is the value of zero potentiometer (Z) and calibration

potentiometer (S) needed to be set on spot.

10

1. Zero Point Calibration

Open the detector in clean air, if there is readings after counting down.

Press the button "MENU" of the remote controller, the detector displays "F-01", press"+" or"-", change

the function to "F-04", and click "OK". The detector value will be displayed as 0.

In the zero calibration of oxygen detection transmitter, we must use nitrogen of purity over

99.99%.

PRV

PTFE PIPE

Empty

Gas detector

Standard gas

Flowmeter

2. Range Calibration

1. Enter into "F-07"as the same way above . The

"F-07" value is the concentration of the standard gas,

initialized to half of the measure range. This value can

be modified through the"+" and"-" keys to make it

consistent with the standard gas concentration which

need to be calibrated. Press

"OK" to exit.

2. Enter into"F-08"to change 0 into 1,then back to

detection interface.

3. Connect the 200-400mL/min standard gas in

detection interface, when the detector value is stable,

press "OK" for 3 seconds, then the instrument will be

calibrated automatically. The measured concentration

value is consistent with the value set in "F-07".

4. After calibration, left the detector in the air for a

while. Shut off the power when the detector value is

close to zero.

Common Malfunction, Repair and Maintenance

Product component

Fixed Gas Detector

Instruction Manual

Qualification Certificate

Remote Control

one

one

one

one

Symptom

No output

for

transmitter

Reason

wrong connection

potential in reference point is not

correct

Too low

host

reading

Circuit fault

Value of S potentiometer

setting is too small

Too high

host

reading

Transmitter failure

Value of S potentiometer

setting is too large

Transmitter failure

Instable

host

reading

Heat settling time is not

enough

Transmitter failure

Circuit fault

Method to process

connect again

Adjust zero point gradually and then adjust potentiometer (4mA) Return to

Yuante for repair

Calibrate again

Get a new transmitter

Calibrate again

Get a new transmitter

Wait for starting up

Get a new transmitter

Return to Yuante for repair

11

Table of contents

Other GasDog Gas Detector manuals

Popular Gas Detector manuals by other brands

AP

AP NH3 manual

brennenstuhl

brennenstuhl BCN 1221 Directions for use

UE

UE VANGUARD WirelessHART TCD50H1A Installation and maintenance instructions

isweek

isweek CP01 Operation manual

Critical Environment Technologies

Critical Environment Technologies CGAS-AP installation manual

Gas Detection

Gas Detection GDA 3160 operating manual