MGS-550 Fixed Gas Detector

P/N: 1100-1000 Version 1 3

TABLE OF CONTENTS

SECTION 1. SAFETY ............................................................................................................................5

1.1 Definition of Alert Icons..............................................................................................................5

1.2 General Safety Statements .......................................................................................................5

1.3 Safe Connection of Electrical Devices ......................................................................................5

SECTION 2. DESCRIPTION..................................................................................................................6

2.1 Product Overview ......................................................................................................................6

2.2 Key Product Features................................................................................................................7

2.3 General Purpose Option............................................................................................................8

2.4 Explosion Proof Option..............................................................................................................9

2.5 Sensor Styles...........................................................................................................................10

SECTION 3. INSTALLATION..............................................................................................................11

3.1 General Information for Installation .........................................................................................11

3.2 Installation Restrictions............................................................................................................11

3.3 Mechanical Installation ............................................................................................................12

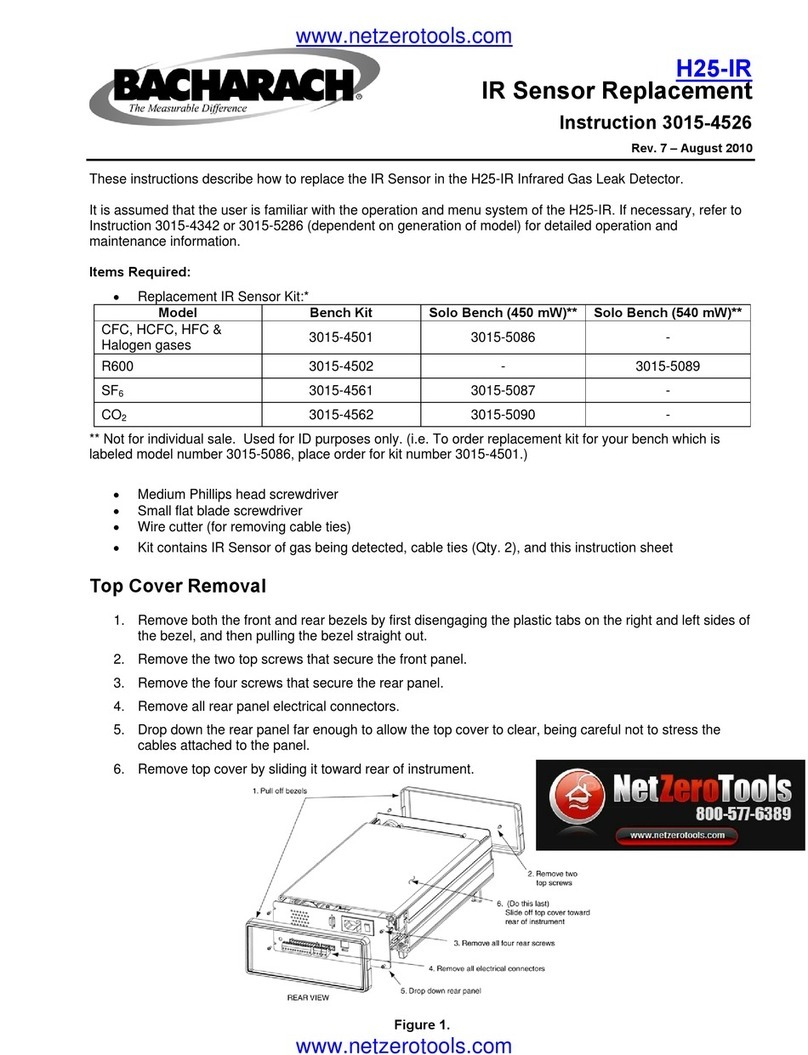

3.4 Electrical Installation................................................................................................................12

3.4.1 Preparations ...............................................................................................................12

3.4.2 Power and Signal Wiring............................................................................................14

3.4.3 Relay Wiring ...............................................................................................................15

3.4.4 Installation of Remote Sensing Head.........................................................................16

3.4.5 Connecting One or More MGS-550s to a Bacharach Controller................................17

3.4.6 Modbus RTU Interface ...............................................................................................17

3.4.7 Conclusion..................................................................................................................17

SECTION 4. OPERATION...................................................................................................................18

4.1 Overview of Normal Operation................................................................................................18

4.1.1 Applying Power and the Start-up Sequence ..............................................................18

4.1.2 Verifying Analog Signals.............................................................................................19

4.1.3 Verifying the Digital Modbus Signal............................................................................19

4.1.4 The 5-Digit Display and LEDs ....................................................................................19

4.2 Menus......................................................................................................................................21

4.2.1 General Navigation.....................................................................................................21

4.2.2 Checking Status and Changing Parameter Values....................................................22

4.2.3 Exiting the Menu.........................................................................................................22

4.2.4 Menu Overview...........................................................................................................23

4.3 Functions.................................................................................................................................25

4.3.1 Offline Mode (F-01) ....................................................................................................25

4.3.2 Zero Adjustment (F-02) ..............................................................................................25

4.3.3 Span Adjustment (F-03) .............................................................................................25

4.3.4 Instrument Test (F-04)................................................................................................25

4.3.5 Parameter Menu (F-05)..............................................................................................26

4.3.6 Register Sensor (F-06)...............................................................................................26

4.3.7 De-register One Sensor (F-07)...................................................................................27

4.3.8 De-register All Sensors and Reset Node Address (F-08) ..........................................27

4.3.9 Diagnostics, System Information and Fault Data (F-09) ............................................28

4.3.10 Reset System to Factory Default Setting (F-10) ........................................................28

4.4 Parameters..............................................................................................................................29

4.4.1 Sensor 1 Settings (S1-xx) and Sensor 2 Settings (S2-xx) if Connected....................29

4.4.2 Relay Designation (RX-xx).........................................................................................32

4.4.3 Alarm Configuration (AF-xx).......................................................................................33

4.4.4 Analog Output Configuration (AX-xx).........................................................................34

4.4.5 Modbus Configuration (MB-xx)...................................................................................35

4.4.6 Display Mode (P1-01).................................................................................................35

4.4.7 Buzzer Designation (B1-xx)........................................................................................35

SECTION 5. MAINTENANCE..............................................................................................................36

5.1 Maintenance Intervals .............................................................................................................36

www. .com information@itm.com1.800.561.8187