Copyright © 2020 by Cool Air Incorporated. All rights reserved.

PROGRAMMING AND OPERATION ................................................

PROGRAMMING THE AMMONIA HI-ALARM AND LOW ALARM SET

POINTS ...................................................................................................

PROGRAMMING THE 4-20 MARANGE ...................................................

SETTING THE SERVICE MODE TIMEOUT ..............................................

SETTING THE AUXILIARY RELAY PAIRING...........................................

SETTING THE RELAY LATCHING............................................................

RE-SETTING A LATCHED RELAY ...........................................................

SPECIFICATIONS ................................................................................... 2

IMPORTANT—READ THIS FIRST ...................................................... 3

CAUTIONS ................................................................................................ 3

INTRODUCTION ..................................................................................... 3

STANDARD FEATURES ......................................................................... 4

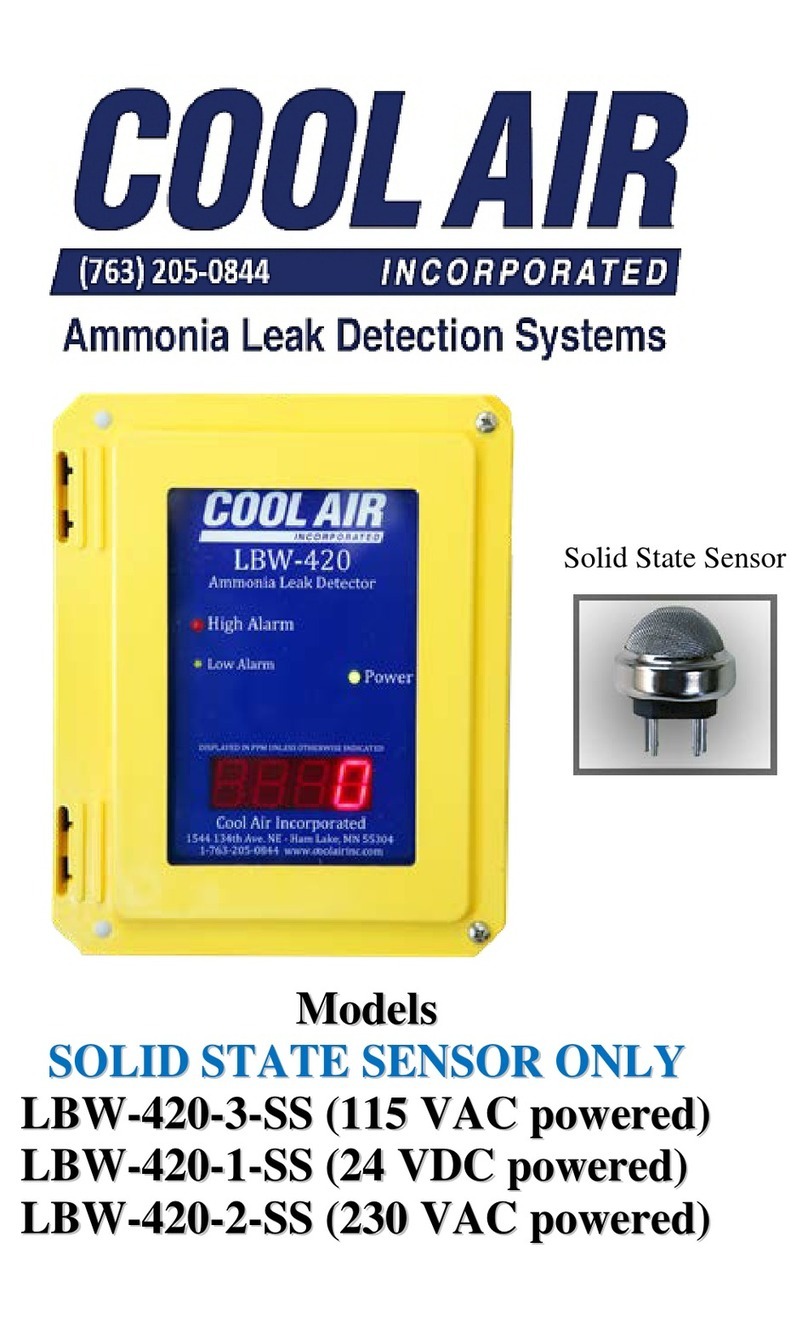

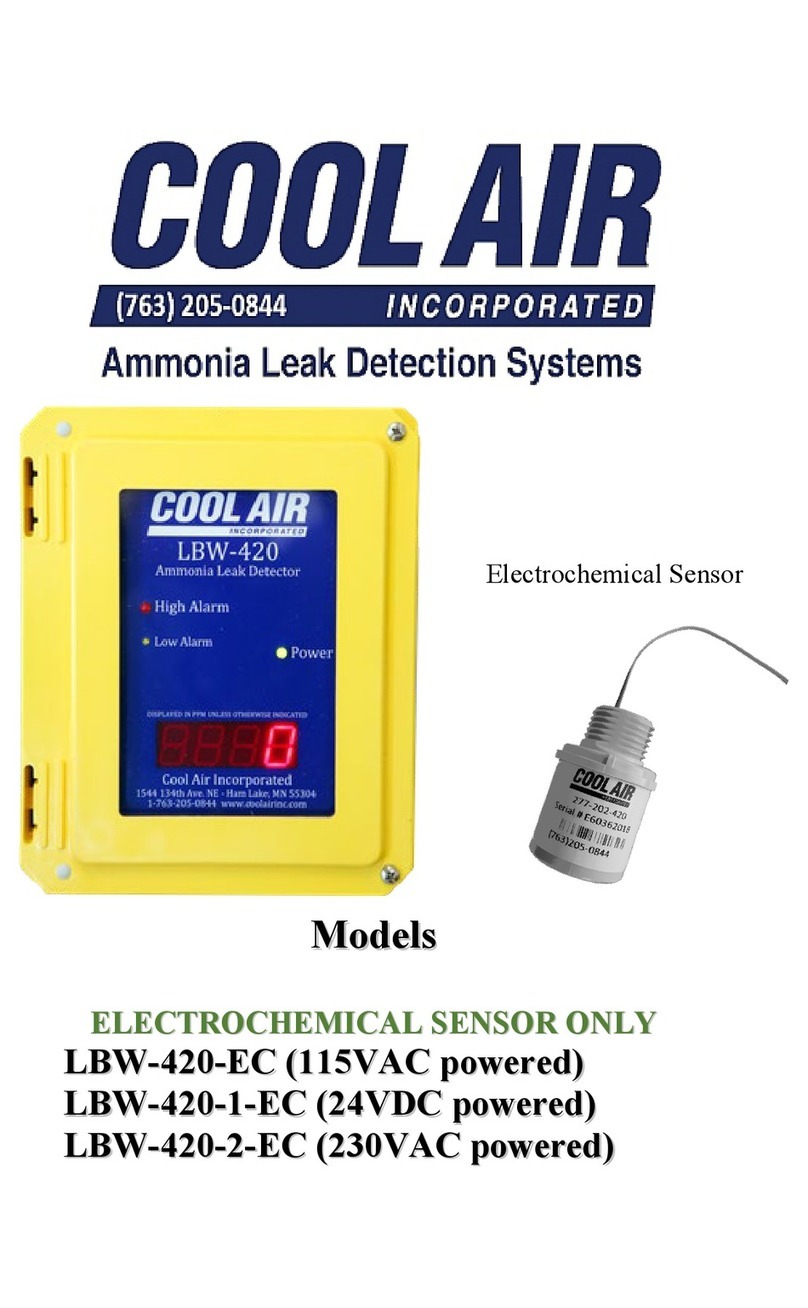

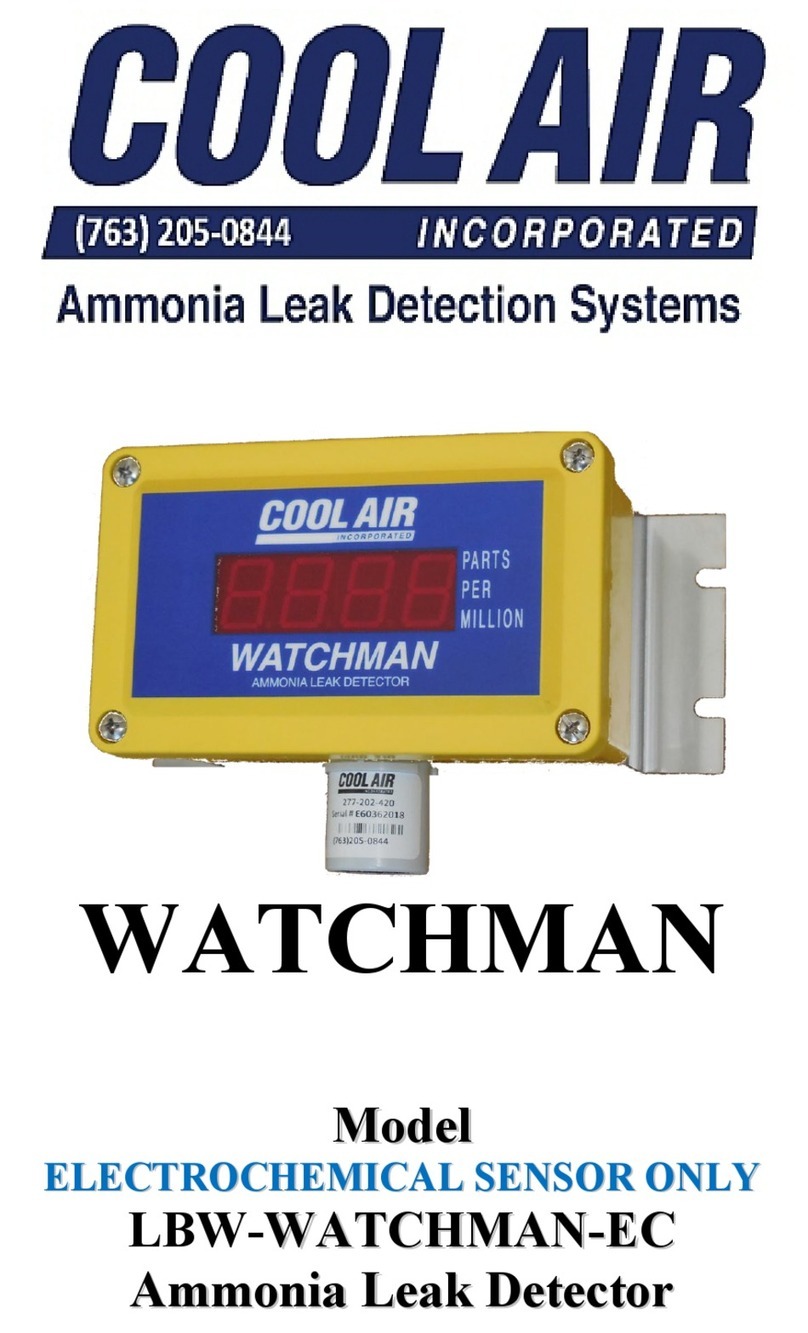

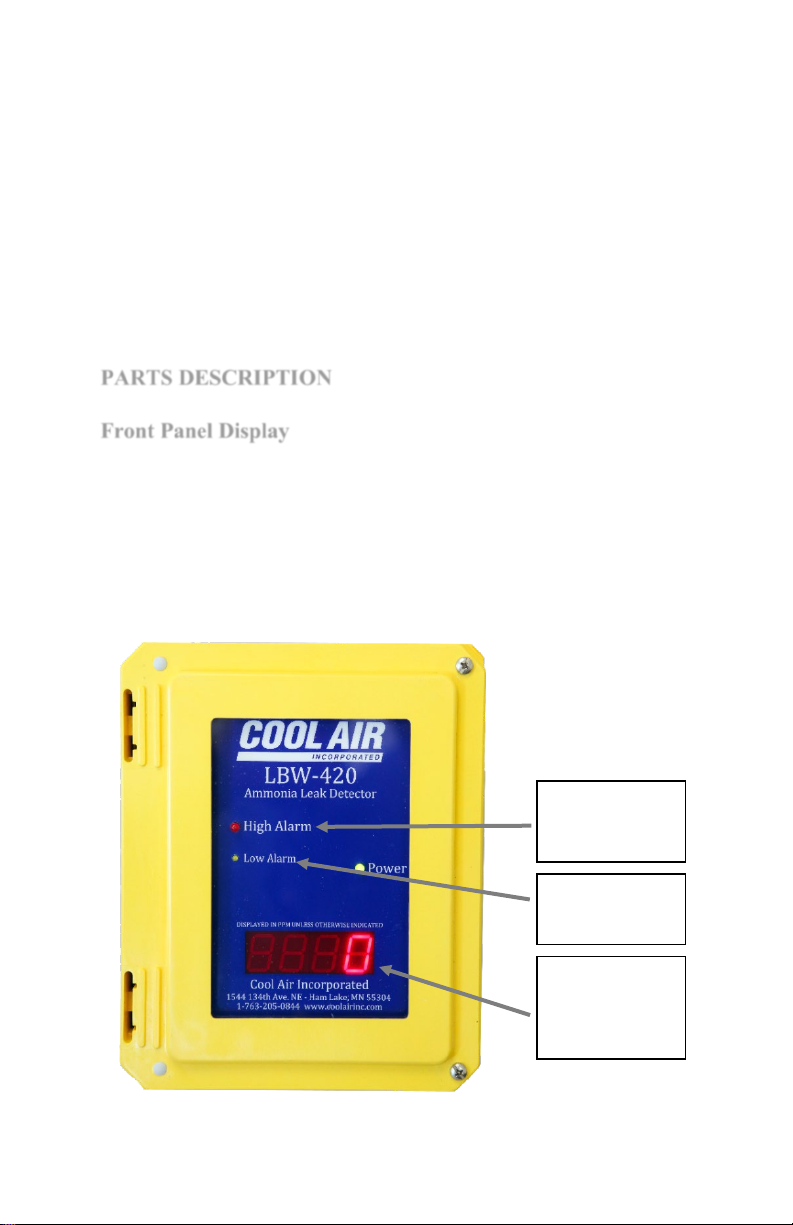

PARTS DESCRIPTION............................................................................ 5

FRONT PANEL DISPLAY .......................................................................... 5

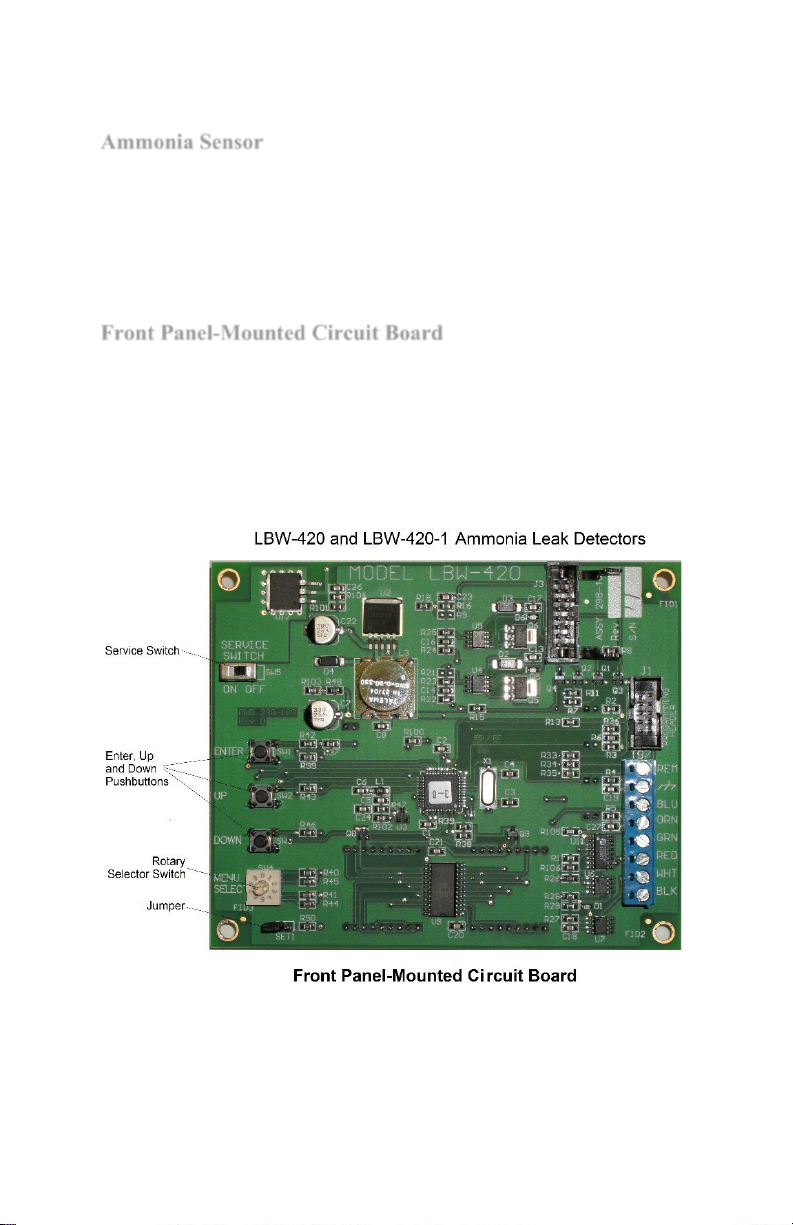

AMMONIA SENSOR .................................................................................. 6

FRONT PANEL-MOUNTED CIRCUIT BOARD ........................................... 6

SERVICE SWITCH (SERVICE MODE) ....................................................... 7

THE “ENTER”, “UP”, AND “DOWN” PUSHBUTTONS................................. 7

ROTARY SELECTOR SWITCH .................................................................. 7

ENCLOSURE-MOUNTED CIRCUIT BOARD............................................. 10

POWER (LBW-420) ............................................................................... 10

JUMPER J3, AMMONIA SIGNAL (LBW-420-1 ONLY)............................. 10

RELAYS.................................................................................................. 11

RELAY STATUS LEDS............................................................................ 11

EXTERNAL CONNECTIONS .................................................................... 11

4–20 MAANALOG OUTPUT ................................................................... 12

INSTALLATION AND SETUP ............................................................. 15

TABLE OF CONTENTS