Bacharach H-10PM User manual

Other Bacharach Security Sensor manuals

Bacharach

Bacharach GDC-350 User manual

Bacharach

Bacharach H-10PA User manual

Bacharach

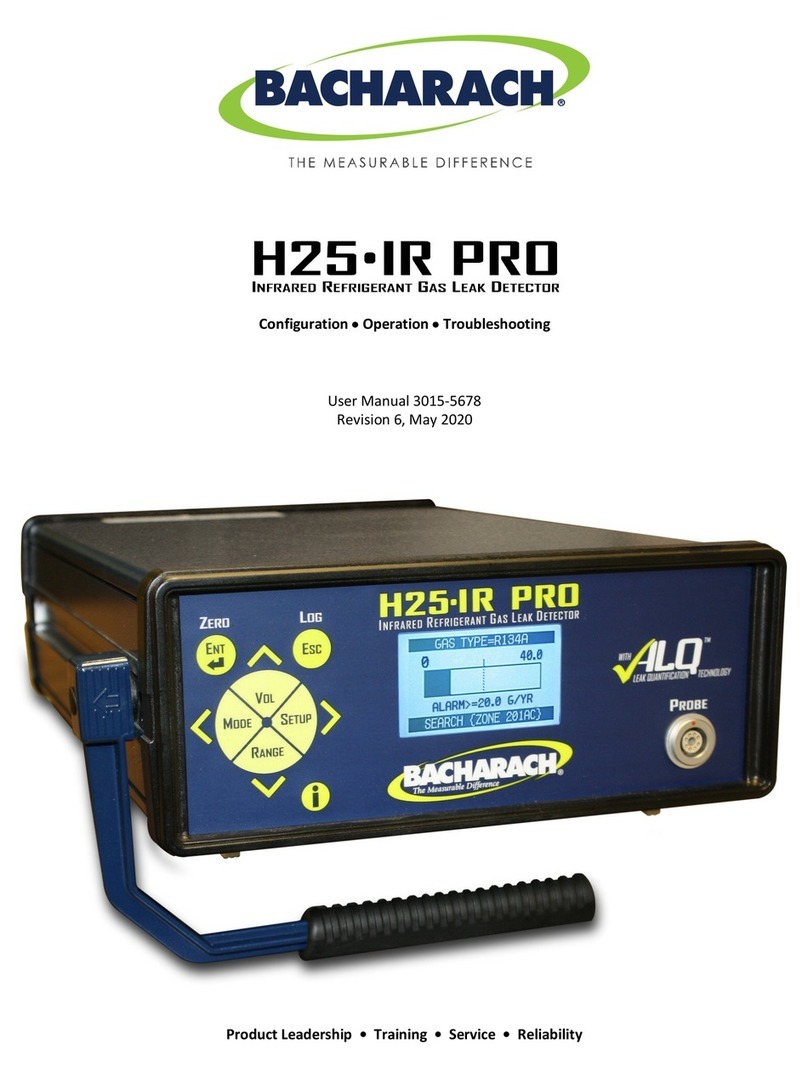

Bacharach H25-IR PRO User manual

Bacharach

Bacharach N2O Portable Monitor User manual

Bacharach

Bacharach H-25C User manual

Bacharach

Bacharach H-10 PRO User manual

Bacharach

Bacharach H-10 PRO User manual

Bacharach

Bacharach Tru Pointe 2100 Instruction Manual

Bacharach

Bacharach MGD-100 User manual

Bacharach

Bacharach 6401-0500 User manual

Bacharach

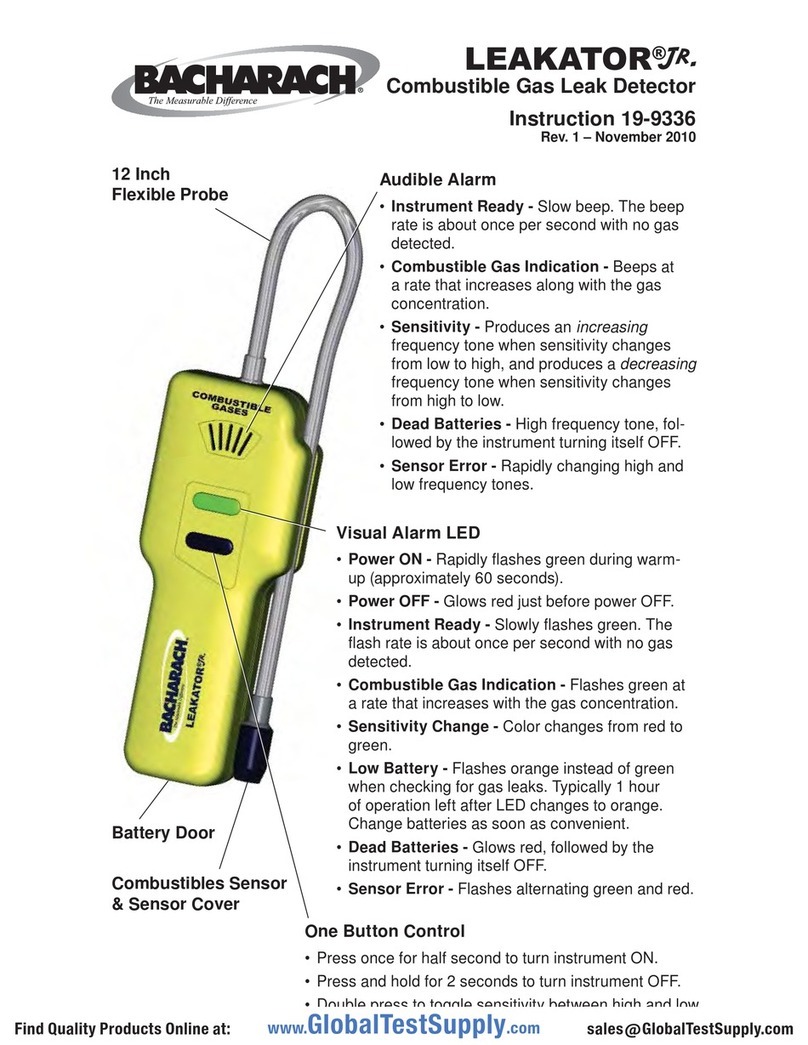

Bacharach Leakator Jr. User manual

Bacharach

Bacharach MVR-300 User manual

Bacharach

Bacharach MGS-150 User manual

Bacharach

Bacharach Tru Pointe Ultra HD Instruction Manual

Bacharach

Bacharach Informant Leak Detector User manual

Bacharach

Bacharach MGD-100 User manual

Bacharach

Bacharach MGS-150 User manual

Popular Security Sensor manuals by other brands

Shinko

Shinko SE2EA-1-0-0 instruction manual

Det-Tronics

Det-Tronics X Series instructions

ACR Electronics

ACR Electronics COBHAM RCL-300A Product support manual

TOOLCRAFT

TOOLCRAFT 1712612 operating instructions

Elkron

Elkron IM600 Installation, programming and functions manual

Bosch

Bosch WEU PDO 6 Original instructions