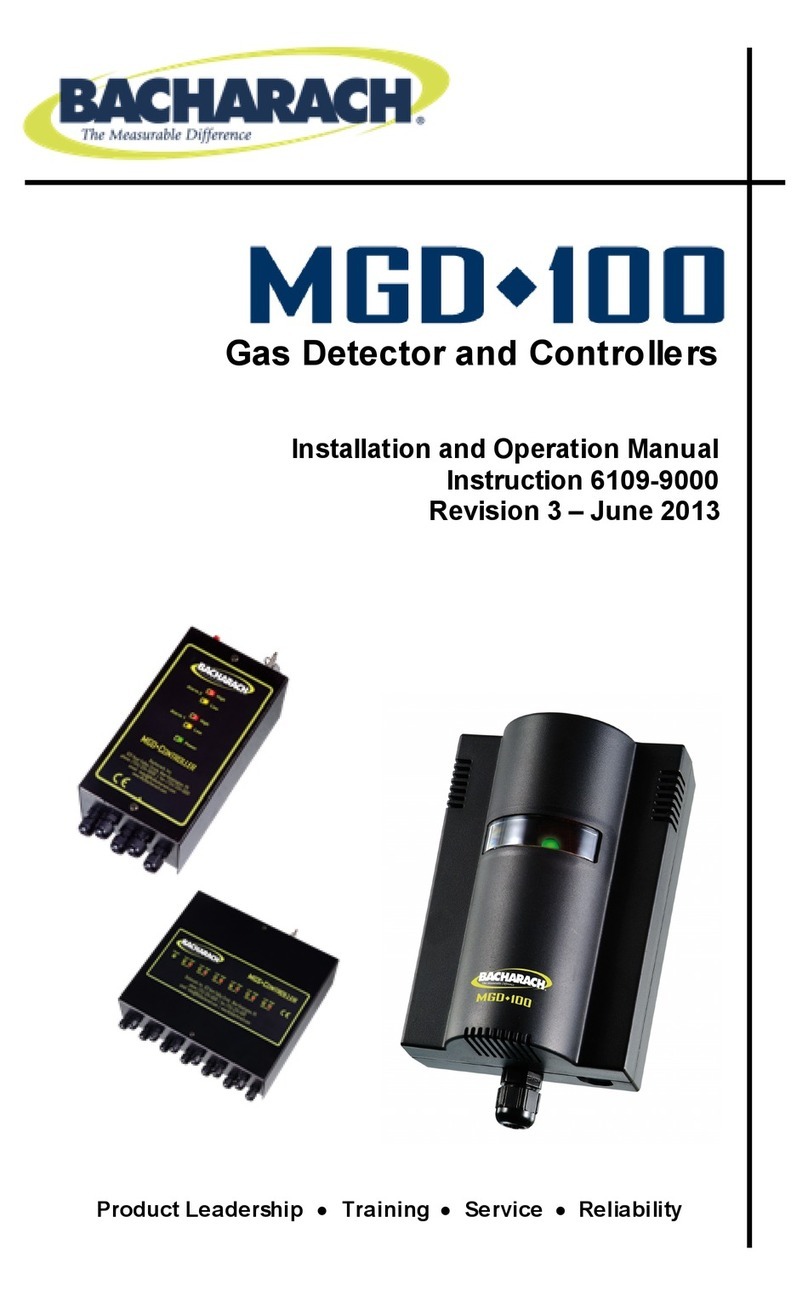

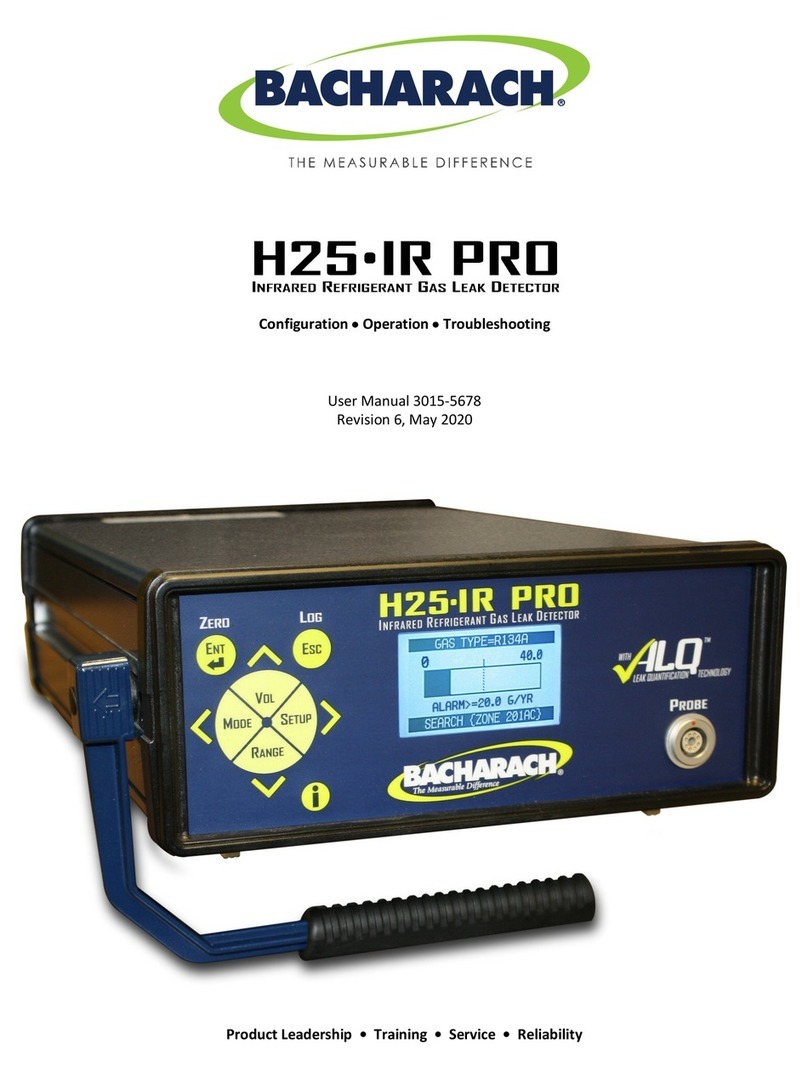

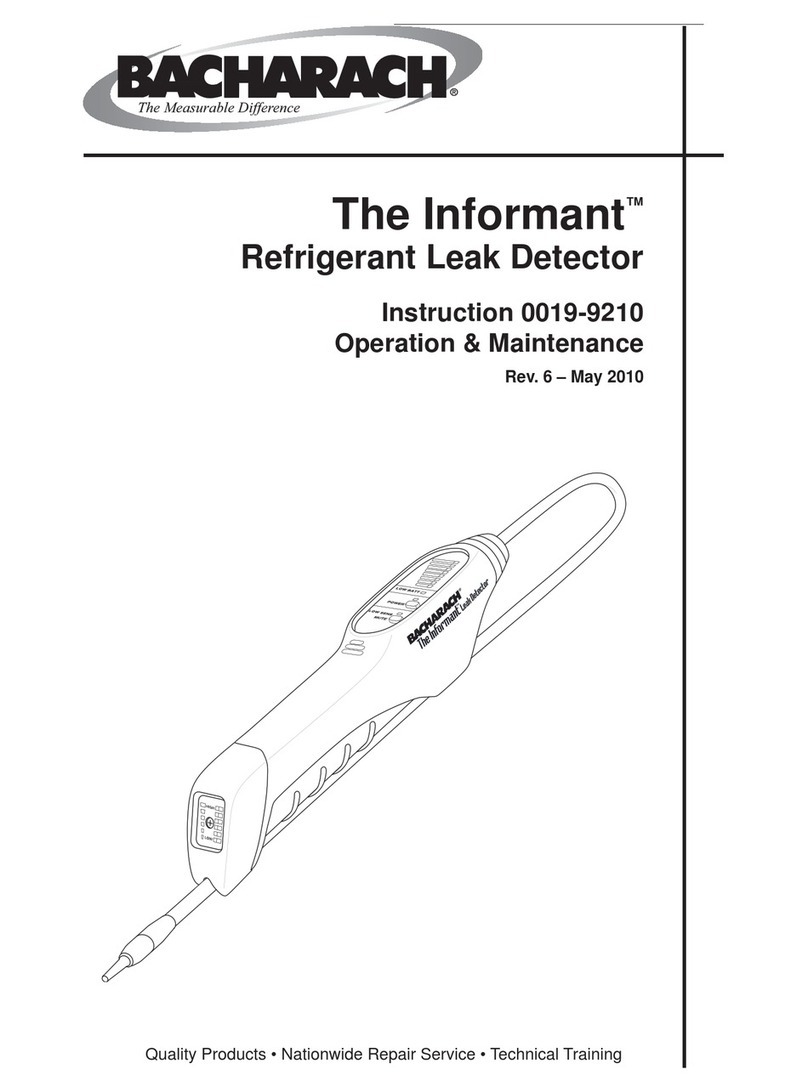

1: OVERVIEW

The Bacharach MVR-300 detects refrigerant leaks in occupied

spaces.

3: SAFETY INSTRUCTIONS

CODE COMPLIANCE: Comply with all local and naonal

laws, rules and regulaons associated with this equipment.

TECHNICIAN USE ONLY: This unit must be installed by a

suitably qualified technician who will install this unit in

accordance with these instrucons and the standards in his

parcular industry/country. Operators of the unit should be

aware of the regulaons and standards in their indus-

try/country for the operaon of this unit. These notes are

only intended as a guide and the manufacturer bears no

responsibility for the installaon or operaon of this unit.

Failure to install and operate the unit in accordance with

these instrucons and with industry guidelines may cause

serious injury including death and the manufacturer will not

be held responsible in this regard.

SAFE MOUNTING: This detector must be connected by a

marked, suitably located and easily reached switch or

circuit-breaker as means of disconnecon.

CAUTION: DO NOT MOUNT the MVR-300 in an

area that may contain flammable liquids or

vapors. Operaon of electrical equipment in

such an area constutes a safety hazard.

CAUTION: The use of MVR-300 in ceiling voids

in a hotel room would not strictly comply with

EN378.

IMPORTANT: Mount in-room sensors at less

than the normal heights of the occupants. E.g.,

in a hotel room this is less than bed height

(between 100 and 150 mm [4 and 6 inches] off

the floor). Avoid dras and heat sources (like

radiators), and avoid sources of steam.

P/N: 6203-9001

Revision 1

August 2016

INSTALLATION GUIDE

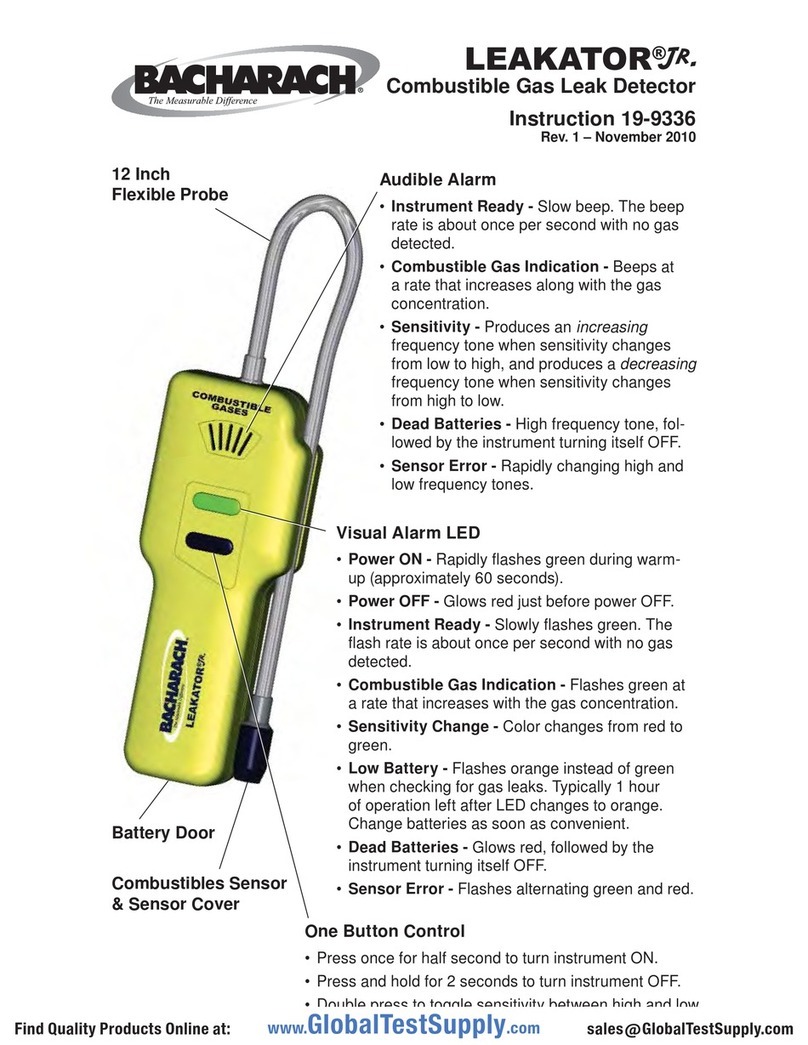

Magnec

Wand

Grill Decorave

Bezel

Tri-color

Status LED

Magnec

Switch B (••)

MVR-300 Proper vs. Improper Placement Locaons

AIR CONDITIONER

6: INSTALLATION

REFRIGERANT

GAS DETECTOR

Magnec

Switch A (•)

For more detailed informaon, scan

here or visit www.MyBacharach.com to

access the MVR-300 User Manual (P/N

6203-9000).

Coin Slot

for Bezel

Release

CAUTION: Ensure all wiring

connecons are made before

applying power.

ENVIRONMENTAL CONSIDERATIONS: Carefully

consider the full range of environmental condions

to which the instruments will be exposed.

TARGET GAS CONSIDERATIONS: The physical data of

the gas or vapor to be detected must be observed.

APPLICATION CONSIDERATIONS: The specifics of the

applicaon (for example, possible leaks, air move-

ment/dra, etc.) must be observed.

ACCESSIBILITY CONSIDERATIONS: The degree of

accessibility required for maintenance purposes

must be granted.

ELECTRONIC CONSIDERATIONS: The system contains

sensive electronic components that can be easily

damaged. Do not touch nor disturb any of these

components.

2: MOUNTING CONSIDERATIONS

Mount the MVR-300 according to the above consideraons,

product dimensions, and maximum wiring lengths.

4: SPECIFICATIONS

Size (HxWxD): 150 x 105 x 45 mm including bezel

(6.0” x 4.1” x 1.75”)

Depth of bezel: 10 mm (0.39 “)

Weight: 230 grams (8 ounces)

Indicators: Mul-color status LED

Internal alarm buzzer; 85 dB @ 30 cm (12’)

Alarm Delay: Selectable (0, 5, 10, 15 minutes)

Inputs: Magnec switches (2)

Power terminal block

Configuraon DIP switch block

Gas sensor (refrigerant)

Outputs: Relay outputs (2)

2 SPDT, 1 A at 30 VDC,

1 A at 125 and 240 VAC, resisve load

Modbus: Connecon: RS-485 terminal block

Baud rate: 9600 or 19200 (selectable)

Default baud: 9600

Start bits: 1

Data bits: 8

Parity: None (default), odd, even (selectable)

Stop bits: 1 (default) or 2 (selectable)

Retry me: 500 ms (min) between retries

End of msg: Silent 3.5 characters

Power: 100 to 230 VAC, 50/60 Hz, 4 W

Wiring Power: 3-core cable, 14 to 20 AWG (0.5 to 2.0 mm2)

Wiring Relays: 3-core cable, 18 to 20 AWG (0.5 to 1.0 mm2)

Wiring Modbus: 2-core twisted pair shielded cable

18 to 24 AWG (0.2 to 1 mm2) with 120 Ω

characterisc impedance

Enclosure: Material: ABS; Protecon: IP41, NEMA 1

Temperature: Operaon: 32 to 120�F (0 to 50�C)

Storage: - 5 to 100�F (- 20 to 40�C)

Humidity: 5 to 90 %RH, non-condensing

Pressure: 23.6 to 32.5 in. of Hg (800 to 1100 hPa)

Elevaon: 0 to 6,560 . (2000 m) altude

Gas Detecon: R-22, R-32, R-134a, R-404a, R-407c, R-410a

Detect Range: 0 to 2,500, 5,000, 10,000 ppm

Sensor Life: 5 to 8 years (typical)

NOTE: The MVR-300 is designed for use in 2-gang

wall boxes with a minimum depth of 50 mm (2”).

Low

Gas

Alarm

High Gas

Alarm

or Fault

The detector can be calibrated and maintained non-intrusively

using a magnec wand.

The detector is for indoor applicaons. It is housed in an ABS

enclosure that fits into most 2-gang electrical back boxes (not

included).

5: CONFIGURATION

1 Restart

On = Restart MVR-300

Off = Normal Operaon

(Default)

2,3 Alarm ON Delay

Off, Off = No delay (Default)

Off, On = 5 minute delay

On, Off = 10 minute delay

On, On = 15 minute delay

4 Failsafe Relay Selecon

On = Failsafe Relay Operaon

Off = Normal Relay Operaon

(Default)

8 = Reserved

When inserng the wire into the terminal,

release the spring clamp by pushing back

the release latch.

Push to release

1234

ON

5678

Gas alarms and status messages are indicated visually by a

3-colored LED and audibly by a buzzer. In case of an alarm

and/or fault, relays switch (for example, shut-off valves or alarm

devices).

Power

Relay #2

NC NOCOM

Relay #1

NC NOCOM

Modbus

AGB

5 Relay 2 Fault Indicaon

On = High Alarm Only

Off = High Alarm or Fault

(Default)

6 Alarm Latching

On = Alarms latch and

require manual reset

Off = Alarms automacally

reset (Default)

7 Buzzer Disable

On = Buzzer disabled

Off = Buzzer enabled

(Default)

NOTE: Before installing the MVR-300, refer to the

calibraon gas concentraon label and record the

value for use in step 15 of the calibraon procedure.

MVR-300 is a trademark of Bacharach, Inc. All rights reserved.