CS-3 How can I prevent Carbon Monoxide

poisoning?

The best way to prevent Carbon Monoxide poisoning is

to make sure that your combustion equipment is func-

tioning properly. Combustion air openings (vents, flues,

exhausts and ducts) must be kept open, clean and free

of blockages such as dirt, dust, lint and trash.

Never obstruct a draft hood, wind cap or exhaust vent

on any combustion appliance. Don’t store anything

against or near the equipment that could restrict the air

flow.

In a private home or apartment, a roaring fireplace is

always nice on a cold day. But when combined with a

marginal air flow to the furnace room, the fireplace

might draw enough air to starve the furnace, producing

a potentially hazardous backdraft of Carbon Monoxide

in the living areas.

The best way to prevent CO poisoning is to be con-

stantly aware that CO is a deadly gas: testing is the

only way to detect its presence.

CS-4 What are the best ways to test for Carbon

Monoxide?

Because CO is colorless, tasteless, odorless and non-irri-

tating, the only way to detect its presence is to use a

testing device or instrument.

Electrochemical sensors make detection much faster

and easier and allow you to find fluctuating CO levels

which would be difficult or impossible to measure any

other way: changes as small as 1 ppm can be detected.

There are two types of chemical stain length tubes that

may be used. Indicating tubes give you a go/no go

reading and detect a wide range of CO concentrations.

Detector tubes allow you to make more accurate and

refined measurements which give you concentration

measurement in the 0-5,000 ppm range.

CS-5 If I do find dangerous levels of Carbon

Monoxide, how do I get rid of it?

If the level of CO is dangerous, evacuate the area

immediately and provide as much ventilation of fresh air

as possible to the area where the CO is concentrated.

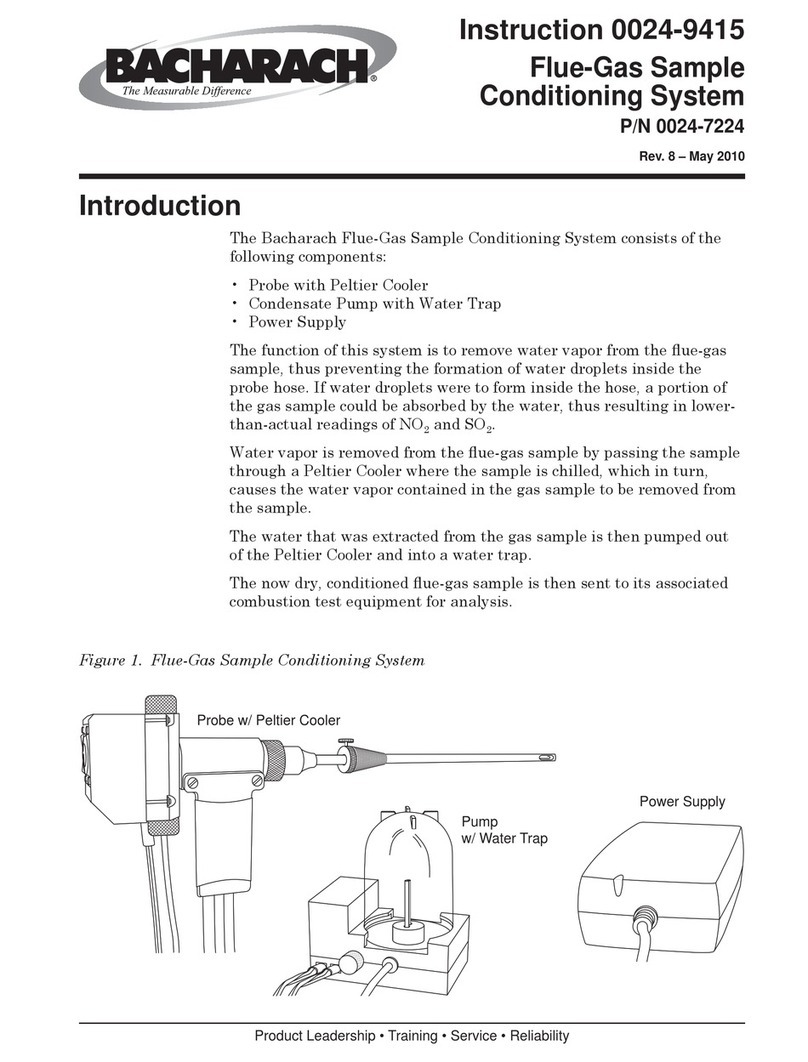

After determining, with instrumentation, that the CO

level has been reduced to a safe level, use your instru-

mentation to find the source of the CO and correct the

conditions which caused the CO formation. (Some local

codes may require that you immediately shut down the

equipment and notify the owner/operator).

CS-6 What are the federal safety standards for

Carbon Monoxide?

The Occupational Safety and Health Administration

(OSHA) has set a maximum limit of 50 ppm for eight

hours exposure in the workplace. In some states this

limit may be lower.

The Environmental Protection Agency (EPA) and the

American Gas Association (AGA) have set a maximum

allowable of 400 ppm (on a CO air free basis) in flue gas.

The American Society of Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE) recommends 9 ppm

as the maximum acceptable level of CO in a residential

setting (ASHRAE Ventilation Standard 62-89).

CS-7 Why is a cracked heat exchanger dangerous?

In a warm air furnace, a cracked heat exchanger can

cause a build-up of toxic gases, including CO, which

would be distributed by the blower into the living or

working area causing sickness or death.

6

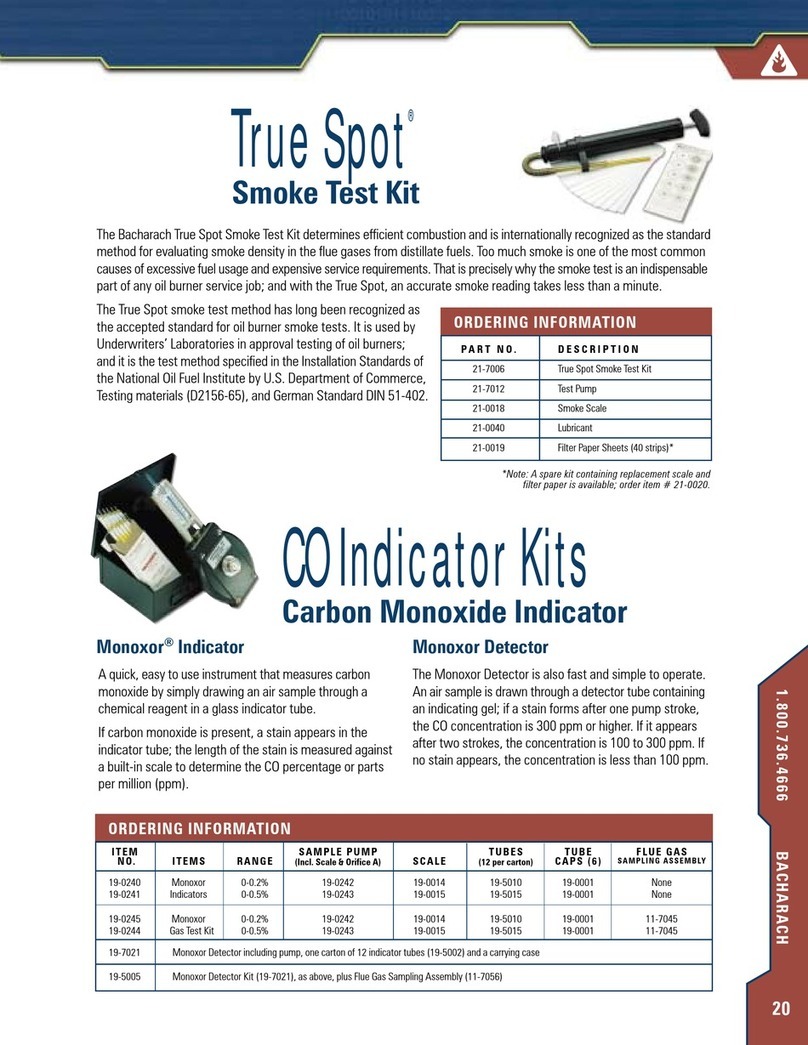

Chart 10

CO CONCENTRATIONS & SYMPTOMS DEVELOPED

Concentrations Inhalation time and

of CO in the air toxic symptoms developed

9 ppm (0.0009%) The maximum allowable concentration for

short term exposure in a living area,

according to ASHRAE.

50 ppm (0.0050%) The maximum allowable concentration for

continuous exposure in any 8-hour period,

according to federal law

200 ppm (0.02%) Slight headache, tiredness, dizziness,

nausea after 2-3 hours

400 ppm (0.04%) Frontal headaches within 1-2 hours, life-

threatening after 3 hours, also maximum

parts per million in flue gas (on an air free

basis), according to EPA and AGA

800 ppm (0.08%) Dizziness, nausea and convulsions within

45 minutes. Unconsciousness within

2 hours. Death within 2-3 hours.

1,600 ppm (0.16%) Headache, dizziness and nausea within

20 minutes. Death within 1 hour.

3,200 ppm (0.32%) Headache, dizziness and nausea within

5-10 minutes. Death within 30 minutes.

6,400 ppm (0.64%) Headache, dizziness and nausea within

1-2 minutes. Death within 10-15 minutes.

12,800 ppm (1.28%) Death within 1-3 minutes.