Dynamis User Guide

Getting Started

1

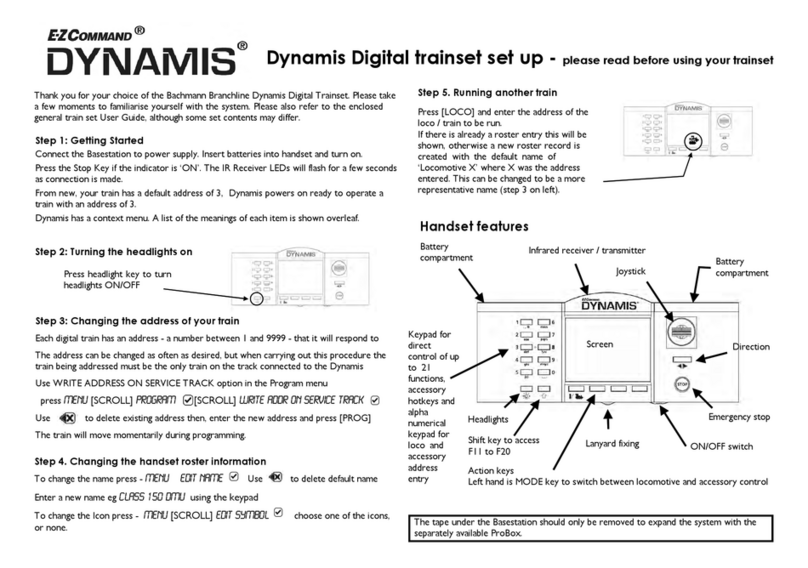

. Attach lanyard to the handset. To avoid

dropping the unit use the lanyard around neck or

wrist.

2

. Insert 4 AAA batteries into handset orientating

as shown on the diagram. The battery covers are

removed by carefully releasing the clips at the rear

of the handset

3

. Connect receiver to terminal on top of the Command Station.

4

. Place Command Station by layout, locating in a position with a good angle of view

to the Command Station infra-red receiver. Remove existing controllers / power

packs and connect the wires to the Command Station.

Use the red lead with ack plug to connect to Bachmann E-Z Track® or the

Bachmann Branchline track powerclip

Other leads with bare wire connectors can be connected to the green

connector block which plugs to the Command Station. This is

recommended for layouts using higher track power.

Please refer to ‘

How to make the best of Dynamis on your layout

section for advice on connecting to existing layouts

5

. Select the appropriate mains pins for the wall transformer: they fit and lock in

place with a twist action. THIS PROCEDURE SHOULD BE CARRIED OUT BY AN

ADULT

6

. Connect the power supply lead to the Command Station. Plug the transformer

into wall socket. The LED on the Command station receiver will be illuminated.

7

. Turn on the Handset with the switch underneath – the Handset always powers up

with the STOP cutout in place (press STOP button to proceed) and ready to run a

locomotive with address 3.

8

. Place a locomotive on the track. New DCC locomotives or decoders are shipped

with an address of 3.

To run a locomotive with a different address, press [LOCO] key and then enter

locomotive address and press [ACCEPT]. This locomotive number shows on the

screen along with a default roster entry that has been created.