Adtech ADT-CNC4220 User manual

A

AD

DT

T-

-C

CN

NC

C4

42

22

20

0

CNC Lathe Control System

User Manual

Operation&Test

Adtech (Shenzhen) CNC Technology Co., LTD

Address: 5th floor ,27-29th Bulding,Tianxia IC Industrial Park,MaJiaLong,Yiyuan Road,

Nanshan District, Shenzhen City, China P.C: 518052

TEL:+86-755-26099116 FAX:+86-755-2672 2718

Website://www.adtechen.com

C NC42 20 M a chi ne Tool Op era t ion an d Test

1

Copyright Warning

The property right in work regarding all the contents of this manual is owned by Adtech

(Shenzhen) CNC Technology Co., LTD (hereinafter referred to as Adtech), without the permission of

Adtech, any company or individual is not allowed to imitate, copy, reproduce or translate this manual.

Our company makes no warranty, express representation or other imply regarding the contents of this

manual. Adtech and its employees assume no responsibility for any direct or indirect information

disclosure, benefit loss or business termination due to this manual or the products information

described in it. In addition, the products and their information described in this manual are only for

the purpose of reference, we reserve the right to amend the manual without prior notice.

All Rights Reserved, Reprint Not Allowed .

Adtech (Shenzhen) CNC Technology Co., LTD

C NC 42 20 M achine Too l Op era t ion an d Test

2

Version Upgrading Instruction

Program No.

Version

Number

Modification

Date Instruction

XT20061225 9.0 2010/2/23 The Ninth Version

Remarks: the meanings of the three numbers in the version number are as follows:

Bank Main Version Number/ Bank Secondary Version Number/ Reservation

Notes:

1. This user manual is strictly emended and checked by ADTECH (SHENZHEN) CNC TECHNOLOGY CO., LTD,

however, it is not guaranteed that the user manual has no any mistake or error.

2. ADTECH (SHENZHEN) CNC TECHNOLOGY CO., LTD commits itself to improve the product functions and

the service quality consistently. Therefore, the company reserves the right of changing any products as described,

any software program, and the content of the user manual, without prior notice.

C NC 42 20 M achine Too l Op era t ion an d Test

3

Contents

1. OPERATION MODES AND DISPLAY INTERFACES ..................................................................7

1.1. DESCRIPTION OF EDITING KEYPAD.............................................................................................8

1.2. DISPLAY MENUS.........................................................................................................................9

1.3. CNC PANEL ...............................................................................................................................9

1.4. OPERATION MODES ..................................................................................................................10

1.5. DISPLAY INTERFACE................................................................................................................. 11

1.5.1 Position interface ..................................................................................................................12

1.5.2 Program display....................................................................................................................14

1.5.3 MDI......................................................................................................................................14

1.5.4 Program directory .................................................................................................................15

1.5.5 KNIFE COMPENSATION INTERFACE .............................................................................15

1.5.6 aLARM INTERFACE........................................................................................................... 16

1.5.7 sETTINGS INTERFACE......................................................................................................16

1.5.8 gRAPH INTERFACE ...........................................................................................................17

1.5.9 GRAPH PARAMETERS ......................................................................................................17

1.5.10 gRAPH DISPLAY ..............................................................................................................17

1.5.11 pARAMETER INTERFACE...............................................................................................18

1.5.12 Diagnosis INTERFACE ...................................................................................................... 18

2. SAFE OPERATION ......................................................................................................................20

2.1 HARDWARE OVERTRAVEL PROTECTION .....................................................................................20

2.2 SOFTWARE OVERTRAVEL PROTECTION.......................................................................................20

2.3 EMERGENCY OPERATION .......................................................................................................... 21

2.4 RESET .....................................................................................................................................21

2.5 EMERGENCY STOP....................................................................................................................21

2.6 FEEDING MAINTAINING ............................................................................................................21

2.7 CUTTING OFF POWER SUPPLY....................................................................................................21

2.8 TURNING OFF...........................................................................................................................22

3. MANUAL OPERATION...............................................................................................................22

3.1 MANUAL FEEDING ...................................................................................................................22

3.2 QUICK MOVING........................................................................................................................ 22

3.3 MANUAL MAGNIFICATION SELECTION ....................................................................................... 22

3.4 QUICK MAGNIFICATION SELECTION...........................................................................................22

3.5 COORDINATES RESET ...............................................................................................................23

3.5.1 Relative position reset...........................................................................................................23

3.5.2 CNC coordinates reset ..........................................................................................................23

3.6 OTHER MANUAL OPERATIONS ...................................................................................................23

3.6.1 Main axis control ..................................................................................................................23

3.6.2 Cooling liquid control........................................................................................................... 24

3.6.3 Chuck control .......................................................................................................................24

3.6.4 Manually replacing knife ......................................................................................................24

3.6.5 Regulation of main axis magnification..................................................................................24

4. SINGLE STEP/HANDWHEEL OPERATION...............................................................................24

C NC 42 20 M achine Too l Op era t ion an d Test

4

4.1. SINGLE STEP FEEDING ..............................................................................................................24

4.2. INCREMENT SELECTION ............................................................................................................ 25

4.3. MOTION DIRECTION SELECTION................................................................................................25

4.4. HANDWHEEL FEEDING..............................................................................................................25

4.5. INCREMENT SELECTION ............................................................................................................ 26

4.6. MOTION AXIS AND DIRECTION SELECTION .................................................................................26

4.7. OTHER AVAILABLE OPERATIONS IN HANDWHEEL/SINGLE STEP MODE ..........................................26

4.8. DESCRIPTION...........................................................................................................................27

5. MDI OPERATION ........................................................................................................................27

5.1. INPUT AND EXECUTION OF MDI INSTRUCTION WORDS ...............................................................27

5.2. PARAMETER EDITING AND SETTING ...........................................................................................28

6. PROGRAM EDITING AND MANAGEMENT.............................................................................28

6.1. CREATING PROGRAM................................................................................................................28

6.1.1 program content Input........................................................................................................... 28

6.1.2 Searching instructions words.................................................................................................29

6.1.3 Inserting instruction word .....................................................................................................32

6.1.4 Deleting instruction word...................................................................................................... 32

6.2. DELETING PROGRAM................................................................................................................33

6.2.1 Deleting single program........................................................................................................33

6.2.2 Deleting lines from the program............................................................................................33

6.2.3 Deleting all programs............................................................................................................34

6.3. PROGRAM SELECTION ..............................................................................................................34

6.3.1 Searching.............................................................................................................................. 35

6.3.2 Scanning...............................................................................................................................35

6.3.3 Cursor confirmation..............................................................................................................35

6.4. PROGRAM MANAGEMENT.........................................................................................................35

6.4.1 Program directory .................................................................................................................35

6.4.2 locking Program.................................................................................................................... 35

7. KNIFE BIAS AND ALIGNMENT ................................................................................................36

7.1. FIXED KNIFE ALIGNMENT .........................................................................................................36

7.2. TEST CUTTING KNIFE ALIGNMENT .............................................................................................37

7.3. KNIFE ALIGNMENT IN MECHANICAL ORIGIN...............................................................................38

7.4. EDITING THE BIAS VALUE ......................................................................................................... 40

7.4.1 Absolute value input of knife compensation .......................................................................... 41

7.4.2 Increment input of knife compensation .................................................................................41

8. AUTOMATIC OPERATION ......................................................................................................... 41

8.1 AUTOMATIC RUNNING...................................................................................................................41

8.1.1 Automatic running start.........................................................................................................42

8.1.2 Automatic running stop......................................................................................................... 42

8.1.3 Automatic running in any section..........................................................................................43

8.1.4 Feeding magnification regulation.......................................................................................... 43

8.1.5 Main axis speed regulation....................................................................................................44

8.1.6 Single section running...........................................................................................................44

8.1.7 Program section skip.............................................................................................................45

8.1.8 Other operations....................................................................................................................45

C NC 42 20 M achine Too l Op era t ion an d Test

5

9. ORIGIN OPERATION ..................................................................................................................45

9.1. PROGRAM ORIGIN ....................................................................................................................45

9.1.1 Program origin......................................................................................................................45

9.1.2 Procedures of program origin................................................................................................45

9.2. MECHANICAL ORIGIN...............................................................................................................46

9.2.1 Procedures of mechanical origin ...........................................................................................46

9.2.2 Other operations in origin mode............................................................................................47

10. DATA SETTING AND SAVING................................................................................................47

10.1. DATA SETTING ...................................................................................................................... 47

10.1.1 Options in setting interface..................................................................................................47

10.1.2 Settings in graph interface...................................................................................................48

10.1.3 System/diagnosis parameters setting ...................................................................................48

11. FILE MANAGER ......................................................................................................................49

11.1. CONNECTING USB DISK TO PC .............................................................................................49

12. PROCESSING EXAMPLES......................................................................................................52

12.1. CREATING NEW PROGRAMS ................................................................................................... 53

12.2. PROGRAM VERIFICATION.......................................................................................................55

12.2.1 Graph parameter setting ...................................................................................................... 55

12.2.2 Program running .................................................................................................................56

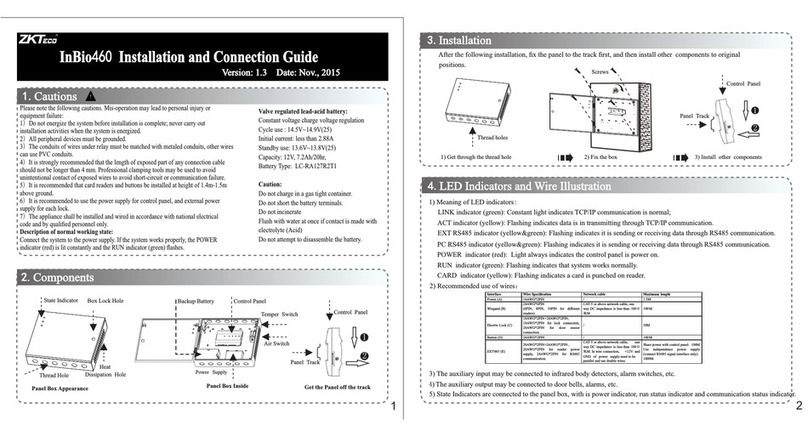

13. CONNECTION TEST................................................................................................................ 58

13.1. MOTOR DRIVE CONNECTION TEST..........................................................................................60

13.1.1 Connection of motor, drive and controller ...........................................................................61

13.1.2 Setting and calculation of eletronic gear ratio......................................................................63

13.1.3 Acceleration/deceleration features adjustment ..................................................................... 64

13.1.4 Troubleshooting for motor drive..........................................................................................64

13.2. HARD LIMIT FUNCTION .........................................................................................................65

13.2.1 Enabling hard limit function................................................................................................ 65

13.2.2 Troubleshooting for hard limit............................................................................................. 66

13.3. MECHANICAL ORIGIN ADJUSTMENT....................................................................................... 66

13.3.1 Origin parameter setting......................................................................................................66

13.3.2 Troubleshooting for mechanical origin ................................................................................68

13.4. REVERSE CLEARANCE COMPENSATION ..................................................................................68

13.5. DRIVE PROTECTION SETTINGS AND CHECKING .......................................................................69

13.6. MAIN AXIS ENCODER ............................................................................................................70

13.6.1 Troubleshooting for main axis encoder................................................................................70

13.7. MAIN AXIS CONTROL ............................................................................................................71

13.7.1 Wiring diagram ................................................................................................................... 71

13.7.2 Main axis parameter setting.................................................................................................73

13.7.3 Calibration of analog voltage .............................................................................................. 73

13.7.4 Time sequence and V/S characteristic diagram....................................................................74

13.7.5 table of Multi-section speed regulation states ......................................................................74

13.7.6 Troubleshooting for main axis control................................................................................. 75

13.8. CHUCK CONTROL..................................................................................................................75

13.8.1 Wiring diagram ................................................................................................................... 75

13.8.2 Chuck parameter setting......................................................................................................75

C NC 42 20 M achine Too l Op era t ion an d Test

6

13.8.3 Troubleshooting for chuck control.......................................................................................76

13.9. TAILSTOCK CONTROL ...........................................................................................................77

13.9.1 Tailstock wiring diagram.....................................................................................................77

13.9.2 Parameter settings ............................................................................................................... 78

13.10. KNIFE REPLACING CONTROL .................................................................................................78

13.10.1 Wiring diagram of electric knife rack ................................................................................78

13.10.2 Knife replacing parameter setting...................................................................................... 80

13.10.3 Troubleshooting for knife replacing...................................................................................80

13.11. HANDHELD BOX AND ADDITIONAL PANEL INTERFACE XS7......................................................80

13.11.1 Internal wiring diagram of the handheld box .....................................................................80

13.11.2 Pin function of handheld box interfaces.............................................................................80

13.11.3 Wiring diagram of additional panel....................................................................................82

13.11.4 Precautions and parameter setting for handheld box ..........................................................82

13.11.5 Troubleshooting for handheld box .....................................................................................82

13.12. WIRING DIAGRAM OF COOLING AND LUBRICATION CONTROL..................................................83

13.13. WIRING DIAGRAM OF WORKING INDICATORS..........................................................................83

13.14. PROGRAMMABLE I/O PORT ...................................................................................................84

13.14.1 Wiring diagram of programable i/o port ............................................................................84

13.14.2 Wiring diagram of programable input and certain control ports ......................................... 84

13.15. WIRING DIAGRAM OF MAIN POWER SUPPLY............................................................................85

13.16. SYSTEM PARAMETERS TABLE.................................................................................................86

13.17. ALARM INFO REFERENCE TABLE ............................................................................................89

13.18. MAIN FUNCTIONS AND PARAMETERS REFERENCE TABLE ......................................................... 92

13.19. SYSTEM WIRING DIAGRAMS ..................................................................................................94

13.19.1 Servo drive wiring diagram...............................................................................................94

13.19.2 Step drive wiring diagram .................................................................................................95

13.19.3 Main axis encoder wiring diagram ....................................................................................95

13.19.4 Hard limit wiring diagram................................................................................................. 96

13.19.5 Mechanical origin wiring diagram.....................................................................................96

13.19.6 Main axis control wiring diagram......................................................................................97

13.19.7 Chuck control wiring diagram........................................................................................... 98

13.19.8 Tailstock control wiring diagram.......................................................................................98

13.19.9 Electric knife rack wiring diagram ....................................................................................99

13.19.10 Additional panel wiring diagram ................................................................................... 101

13.19.11 Cooling and lubrication wiring diagram.........................................................................101

13.19.12 Power supply wiring diagram........................................................................................ 102

13.19.13 Indicator wiring diagram............................................................................................... 103

13.19.14 Installation dimensions.................................................................................................. 103

C NC 42 20 M achine Too l Op era t ion an d Test

7

1. Operation modes and display interfaces

Product appearance

The appearance and deployment of the operation panel are shown below:

State indicators

Edit To indicate the edit mode Manual To indicate the manual

mode

Auto To indicate the auto mode Single

step

To indicate the single

step mode

Parameter settings 00004 N0000

1. Multiplying ratio of

instructions in X axis

2. Frequency division coefficient

of instructions in X axis

3. Multiplying ratio of

instructions in Z axis

4. Frequency division coefficient

of instructions in Z axis

5. Feeding speed 4000 (mm/min)

6. Start speed of feeding 300 (mm/min)

7. Feeding acceleration time 200 (ms/min)

System parameters Page 1

Multiplying ratio of instructions in X axis

S0000 T0100

Manual mode

1

1

1

1

Edit

Auto

Manual

MDI

Reset

Single

step

Single

segment

Main

axis/negative

Main

axis/stop

Main

axis/

positive

Cooling

Chuck

Knife

replacing

Pause

Start

Insert

Knife

compensation

Delete

Cancel

Magnification

Reset

Position

Program

Settings

Parameters

Diagnosis

Skip

C NC 42 20 M achine Too l Op era t ion an d Test

8

Single

segment

To indicate the single

segment mode Reset To indicate the reset

mode

1.1. Description of editing keypad

Keys Name Function description

Reset Reset key

System reset, feeding, output stop, etc.

Address

keys Input address

Double

address

key

Press the keys repeatedly to switch between

the letters

Number

keys

Input numbers

The number keys 8, 2, 6 and 4 are X-, X+, Z-

and Z+ in manual mode and single step

mode respectively; the direction key 5 is the

quick switch in manual mode

Minus

sign key Input the minus sign

Radix

point Input radix point

Cancel Cancel

key Clear the contents in input line

Insert/Delete Editing

keys

Insert or delete programs or fields while

editing

C NC 42 20 M achine Too l Op era t ion an d Test

9

EOB key Input the end symbol of program segment, or

edit the option

Cursor

moving

keys

Control the moving of cursor in program

editing mode and parameter interface

Adjust the feeding and magnification quickly

in auto mode

Single step mode: Adjust the increment in

single step

Page

turning

keys

Turn pages in same display mode

1.2. Display menus

Menu keys Remark

Position

Enter the position interface, which consists of relative

coordinate, absolute coordinate, comprehensive coordinate,

and position/program.

Program Enter the program interface, which consists of program, MDI

and program directory.

Knife

compensation

Enter knife bias interface, which includes knife compensation

data and macro variable

Settings

Enter the setting interface and graph interface (press

repeatedly to switch); the setting interface includes code

setting and switch setting; the graph interface includes graph

parameters and graph display

Parameters Enter the parameter interface, display the system parameters

Diagnosis

View alarm info when there is alarm

Enter the diagnosis interface and machine tool panel (press

repeatedly to switch); the diagnosis interface and diagnosis

parameters; the soft keypad operation can be performed on the

machine tool panel

1.3. Machine tool panel

The keys are described in the table below:

Keys Name Function description

Pause Feeding

maintaining key

Pause program, MDI instruction

running

Start Loop start key Start program, MDI instruction

running

C NC 42 20 M achine Too l Op era t ion an d Test

10

Magnification

Feeding rate /

Rapid

magnification /

Main axis

magnification

switch key

Automatic or manual feeding speed /

fast-moving magnification / Main

axis speed regulation

Knife replacing Manual knife

replacing key Replace the knife manually

Chuck Switch key of

lubricant Lubricant on/off of the machine tool

Cooling Switch key of

cooling liquid Cooling liquid on/off

Main axis/positive

Main axis/stop

Main axis/negative

Main axis control

key

Forward rotating of main axis

Main axis stops

Reverse rotating of main axis

Manual feeding

key

X axis and Z axis move in

positive/negative direction in manual

and single step operation modes

Quick switch Switch quick/manual feeding speed

Single section Single section

switch

Switch running state between single

section and continuous for the

program; if single section is valid,

the single section indicator is on.

Edit Editing mode

selection key Enter editing mode

Auto Auto mode

selection key Enter auto mode

MDI Data input mode

selection key

Enter MDI operation mode, enter

program reset operation mode

Reset

Mechanical reset

mode selection key

Enter mechanical reset mode

Single step

Single step/

handwheel mode

selection key

Switch single step/ handwheel mode

Manual Manual mode

selection key Enter manual operation mode

1.4. Operation modes

This system allows seven operation modes, which are edit, auto, MDI, mechanical reset, single

step/handwheel, manual and program reset.

Editing operation mod

In editing mode, you can create, delete and modify the processing program.

Auto operation mode

C NC 42 20 M achine Too l Op era t ion an d Test

11

In auto mode, the program runs automatically

MDI operation mode

In MDI mode, input the parameters, and insert and execute instruction segment.

Mechanical reset operation mode

In mechanical reset mode, perform the mechanical reset operation for X axis and Z axis

respectively

Handwheel/single step operation mode

In single step/handwheel feeding mode, the system moves in selected increment

Manual operation mode

In manual mode, perform the operations such as manual feeding, manual speed, feeding

rate regulation, quick rate regulation, main axis start/stop, cooling liquid switch, lubricant

switch and manual knife switch.

Program reset operation mode

In program reset mode, perform the program reset operation for X axis and Z axis

respectively.

1.5. Display interface

This system contains six interfaces, including position and program. Each interface contains several

pages. Press the display menu key to switch interfaces, and press the Up/Down key to turn pages.

The interfaces (pages) are independent to the operation modes.

C NC 42 20 M achine Too l Op era t ion an d Test

12

1.5.1 POSITION INTERFACE

Press the position key to enter the position interface, which consists of absolute, relative,

comprehensive and position/program pages. You can press the Up/Down key to

view.

Absolute coordinates

The X coordinate and Z coordinate are the absolute position of the knife in current work piece

coordinates system, which is specified by G50.

Fig. 1-3-1

Programming speed: the speed specified by F code in the program (unit: mm/min).

Actual speed: the actual processing speed (unit: mm/min) after the magnification has been adjusted

in the actual processing.

Feeding magnification: the current feeding magnification

Quick magnification: the current quick magnification

G function code: current valid G code processing pieces in Group 01 and 03: when the program has

executed M30, the processing pieces are increased by 1.

Cutting time: the cumulative time when the program and MDI are running; the time format is: Hour:

Minute: Second. The cutting time is 0 when the system is electrified.

T: current tool number

S: current main axis rotation speed

Note: The main axis encoder is necessary to display the actual rotation of the main axis.

Relative coordinates

The U coordinate and W coordinate, which are 0 when the system is electrified, are the

relative coordinates of current position relative to the reference point. In manual mode, press the

letter key or , and the U or W flashes in the page; press the Cancel key to

reset the U or W coordinate.

Setting

s

Settings

interface

Parameter switch

Graph

interface

Graph parameters

File manager

Graph display

Program

Program

interface

MDI

Program display

Program directory

Position

Position

interface

Comprehensive coordinates

Position/program

Relative position

Absolute position

Knife

compe

nsation

Knife bias

interface

Knife alignment value

interface

Knife bias interface

Macro variable display

Diagnosis

Diagnosis

interface

Output point state

Handh

eld box and main axis

encoder test

Keypad test

Input point state

Alarm info display

Current position (absolute coordinates)

Manual rate: G code:

Actual rate: Processing pieces:

Manual magnification: Cutting time:

Main axis magnification:

Manual mode

C NC 42 20 M achine Too l Op era t ion an d Test

13

Fig. 1-3-2

Comprehensive coordinates

In comprehensive position page, relative coordinates, absolute coordinates, machine tool

coordinates and remaining movement are displayed at the same time. The value of machine tool

coordinates is the coordinates of current position in machine tool coordinates, which is created

through mechanical reset. The remaining movement is the difference between the target

coordinates of program section or MDI instruction and the current absolute coordinates.

The page follows:

Fig. 1-3-3

Position/program

In position/program page, the absolute coordinates and relative coordinates of current

position and program line of current program are displayed at the same time. When the

program is running, the displayed program line refreshes dynamically.

Current position (relative coordinates)

Manual rate: G code:

Actual rate: Processing pieces:

Manual magnification: Cutting time:

Main axis magnification:

Manual mode

Current position

(machine tool coordinates) (Absolute coordinates)

(Relative coordinates) (Remaining movement)

Manual mode

Current position

(machine tool coordinates) (Absolute coordinates)

Manual mode

Fig.

1

-

3

-

4

C NC 42 20 M achine Too l Op era t ion an d Test

14

Program interface

Press the Program key to enter the interface, which consists of program, MDI and program

directory pages in non-editing operation mode. Press the Up/Down key to view.

1.5.2 PROGRAM DISPLAY

In the program page, display the contents of the program, including current program section. In

editing mode, press the Up/Down key to view the contents of the program.

Fig. 1-3-5

1.5.3 MDI

In MDI page, display the current instruction states of G, M, S, T and F, and display the contents

of current program section in auto and MDI modes.

Fig. 1-3-6

Program

Data

Manual mode

Program section value Mode state value

Data

Manual mode

C NC 42 20 M achine Too l Op era t ion an d Test

15

1.5.4 PROGRAM DIRECTORY

The contents in program directory page:

(a) System version number: display the current version number of the system

(b) Saved programs: the saved programs number (including sub-programs); remaining: the

programs number that still can be saved

(c) Occupied memory: the memory occupied by the saved programs; Remaining: available

memory

(d) Program directory: display the numbers saved programs in sequence

Fig. 1-3-7

1.5.5 KNIFE COMPENSATION INTERFACE

Press the Knife compensation key to enter the bias interface, and press the Up/Down key

to display knife bias and macro variable.

Knife bias display

Fig. 1-3-8

Program directory

Version: Hardware version:

Current work area: Library version:

Saved programs: Remaining:

Used storage: Remaining:

Manual mode

Measurement value Fixed knife alignment

S/N

Data =

Position:

C NC 42 20 M achine Too l Op era t ion an d Test

16

1.5.6 ALARM INTERFACE

When the system alarms, press the Diagnosis key to enter the alarm interface and view the

alarm information.

Fig. 1-3-10

Settings interface

The Setting key is composite, and you can press it repeatedly to switch the setting/graph interface.

1.5.7 SETTINGS INTERFACE

The settings interface contains two pages, and you can press the Up/Down key to

view.

Fig. 1-3-12

Parameter switch: when the parameter switch is on, you can edit the parameters; when it is off,

you can’t edit; press the key to switch the state in MDI mode

Program switch: when the program switch is on, you can edit the program; when it is off, you

can’t edit; press the key to switch the state in MDI mode

Alarm info

41-Main axis control logical error

Alarm

Manual mode

Settings

Parameter switch (W): OFF ON

Program switch (H): OFF ON

Manual mode

C NC 42 20 M achine Too l Op era t ion an d Test

17

1.5.8 GRAPH INTERFACE

The graph interface contains graph parameters and graph display pages, and you can press

the Up/Down key to view.

1.5.9 GRAPH PARAMETERS

In graph parameters page, you can select coordinates system of graph, scaling and range.

Graph parameters

Coordinates selection(0:XZ,1:ZX)

Scaling +

Graph center X (work piece coordinates) (mm)

Graph center Z (work piece coordinates) (mm)

Maximum X (mm)

Minimum X (mm)

Maximum Z (mm)

Minimum Z (mm)

X origin bias of graph (mm)

Z origin bias of graph (mm)

Data =

Manual mode

Fig. 1-3-13

1.5.10 GRAPH DISPLAY

In graph display page, the motion track (referring to absolute coordinates) of the processing

program is displayed. Press the S key in this page to start drawing, press the T key

to stop and press the R key to clear.

Fig. 1-3-14

Graph

Start drawing S * End drawing T

Manual mode

C NC 42 20 M achine Too l Op era t ion an d Test

18

1.5.11 PARAMETER INTERFACE

Press the Parameter key to enter the interface, which consists of system parameters and

data parameters. You can press the Up/Down key to view. In parameters display page,

the prompt line of parameter contents displays the contents of the parameter that the cursor points

to. The parameters can be edited in MDI mode. Input the target parameter number and press the

EOB key to go to the specified parameters.

Parameter settings

1. Axis X instruction magnification

2. Axis X instruction frequency conversion coefficient

3. Axis Z instruction magnification

4. Axis Z instruction frequency conversion coefficient

5. Feeding speed

6. Start feeding speed

7. Feeding acceleration time

System parameters Page 1

1. Axis X instruction magnification

Manual mode

Fig. 1-3-15

1.5.12 DIAGNOSIS INTERFACE

The Diagnosis key is composite, and you can press it repeatedly to switch between

diagnosis interface and machine tool panel interface.

Diagnosis interface display

Press the Up/Down key to view the I/O signal state and system state of the

diagnosis display system and machine tool

Input point status interface

Input point state

(mm/min)

(mm/min)

(mm/min)

C NC 42 20 M achine Too l Op era t ion an d Test

19

Main axis encoder and handheld box interface

Output point status interface

Output point state

Keypad test interface

Main axis encoder test

Main axis encoder

Handheld box test

Handwheel

Keypad test

Press Cancel to return

Table of contents

Other Adtech Control System manuals

Adtech

Adtech Q2BYG806DK User manual

Adtech

Adtech CNC9 Series User manual

Adtech

Adtech ADT-DK300A User manual

Adtech

Adtech ADTECH4 CNC Series User manual

Adtech

Adtech 4 Series Mounting instructions

Adtech

Adtech ZM430A-A01 User manual

Adtech

Adtech ADT-09 Series User manual

Adtech

Adtech 4 Series User manual

Adtech

Adtech NCT-04 User manual

Adtech

Adtech TV5600-B01 Series User manual