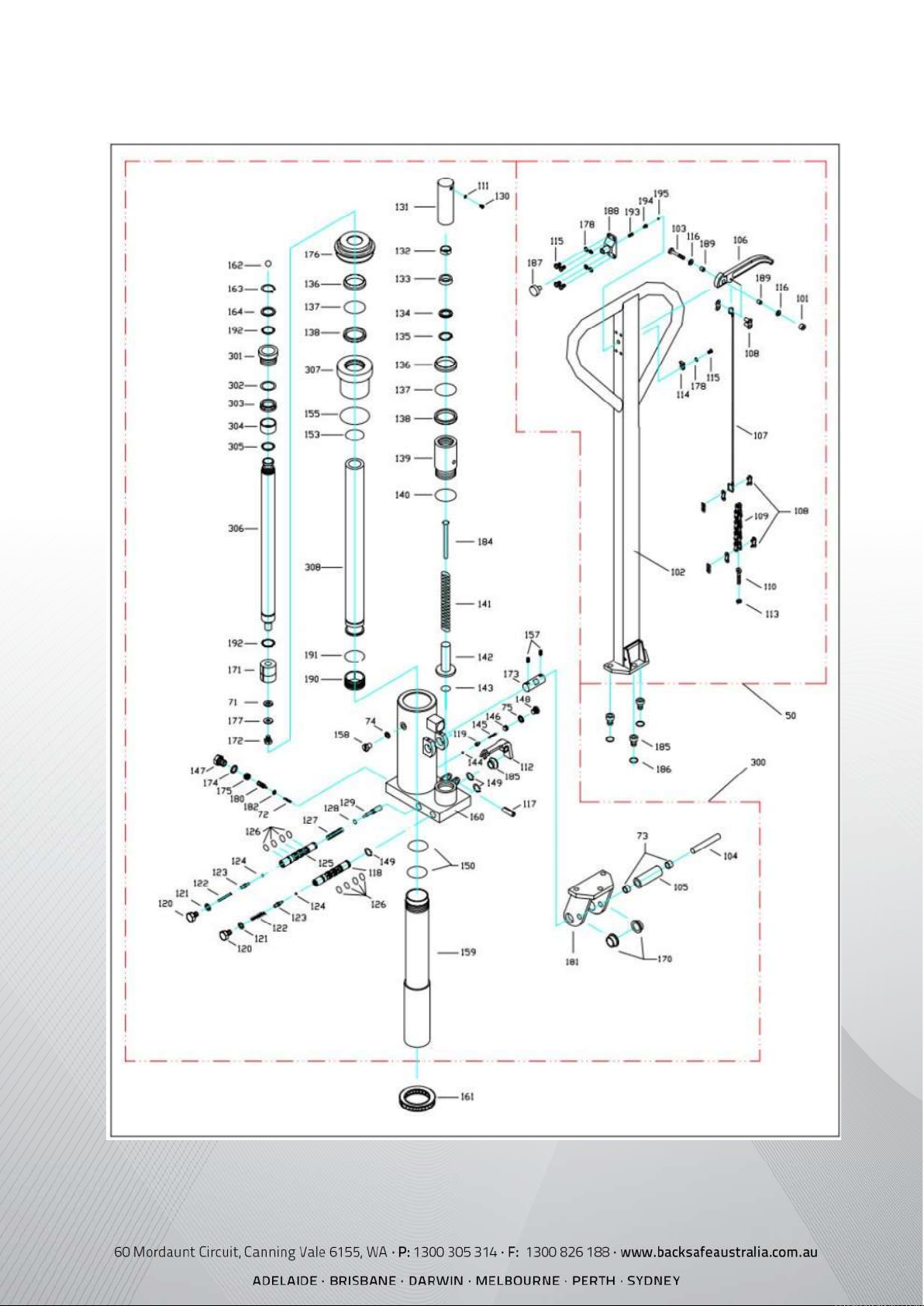

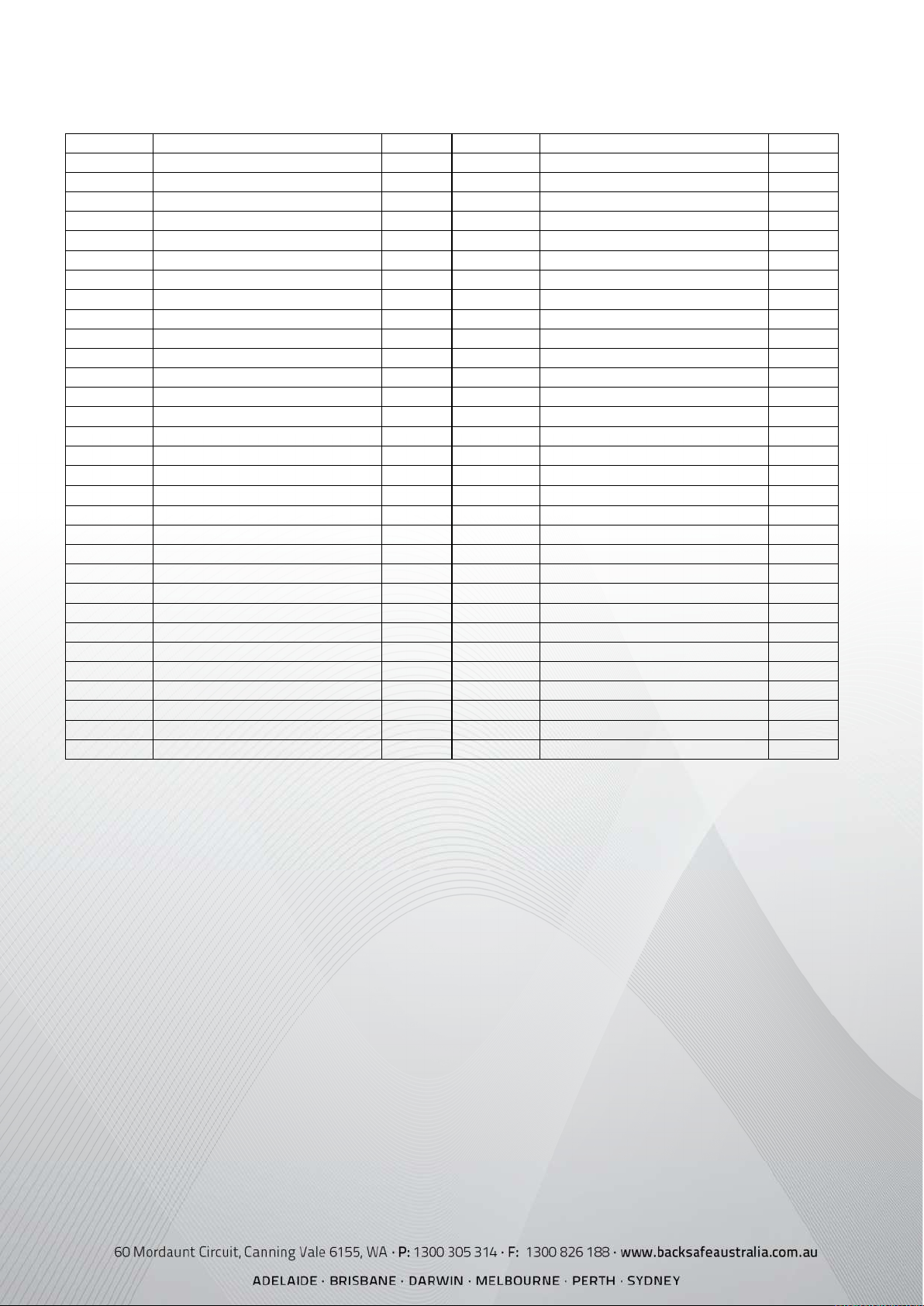

Parts List (2) continued

Part No. Description Qty Part No. Description Qty

162

Ball 1

163

Snap Ring 1

164

Washer 1

170

Bush 2

171

Piston 1

172

Screw 1

173

Axle 1

174

Gasket 1

175

Lock Screw 1

176

Rubber Sleeve 1

177

Washer 1

178

Washer 5

180

Adjusting Screw 1

181

Handle Base 1

182

Adjusting Washer 1

183

Rubber Sleeve 1

184

Spring Guide 1

185

Screw 3

186

Spring Washer 3

187

Lock Screw for Release

Lever 1

188

Spring Socket 1

189

Spacer 2

190

Copper Piston 1

191

Snap Ring 1

192

Snap Ring 2

193

Spring 1

194

Pin 1

195

Ball 1

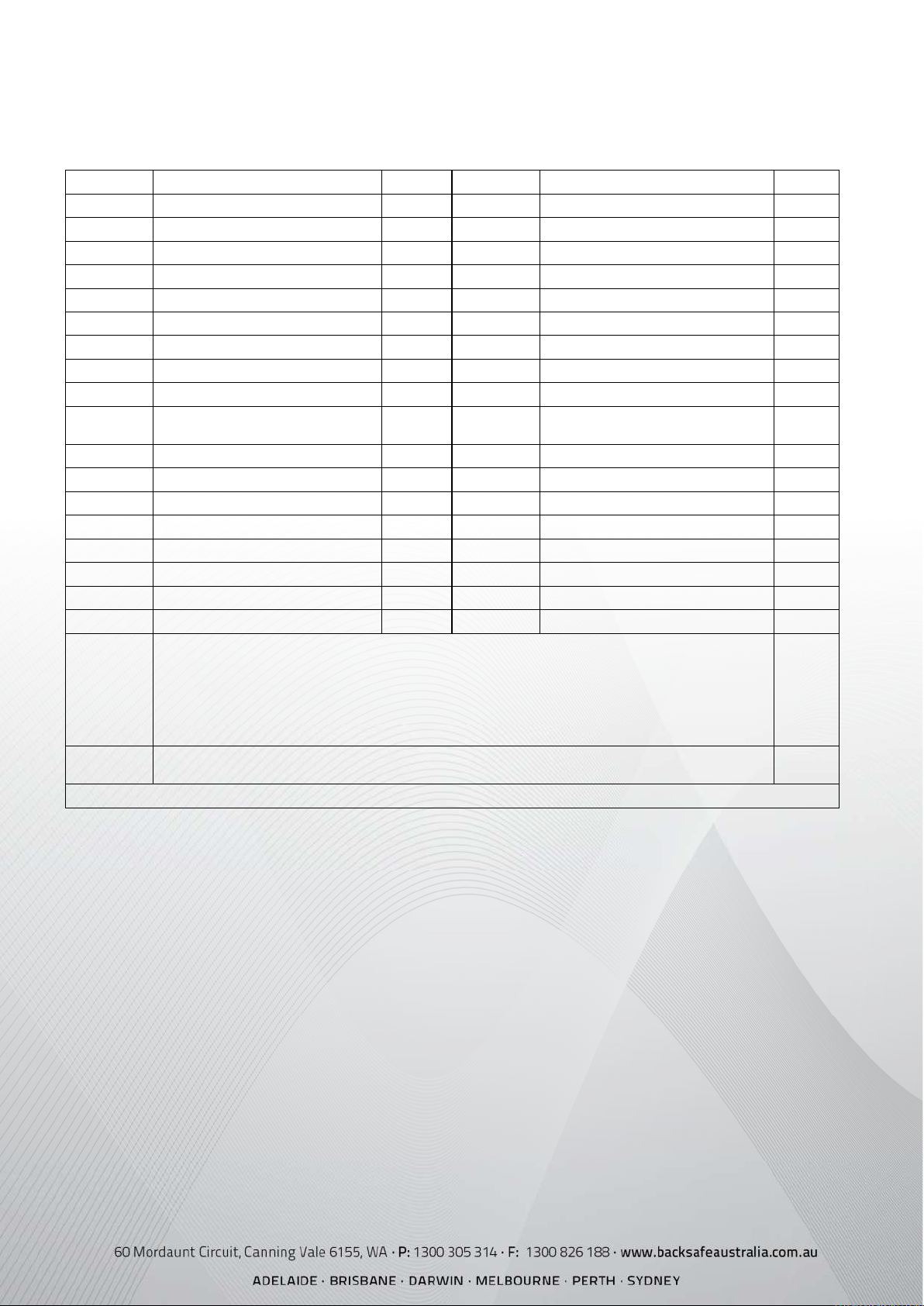

301

Bush 1

302

Back-Up Ring 1

303

Y-Ring 1

304

Bush 1

305

Snap Ring 1

306

Piston Rod 1

307

Cylinder Head 1

308

Lifting Ram 1

300

Pump Unit (includes Part No’s

71,72,73,74,75,104,105,111,112,117,118,119,120,121,122,123,124,125,126,127,

128,129,130,131,132,133,134,135,136,137,138,139,140,141,142,143,144,145,146

147,148,149,150,153,155,157,158,159,160,163,164,170,171,172,173,174,175,

176,177,180,181,182,183,184,185,186,190,191,192,301,302,303,304,305,306,

307,308)

1

50

Handle Assembly (includes Part No’s

101,102,103,106,107,108,109,110,113,114,115,116,178,187,188,189,193,194,195)

1

Parts with “※” mark are supplied together with the High Lifter and packed in the poly bags.