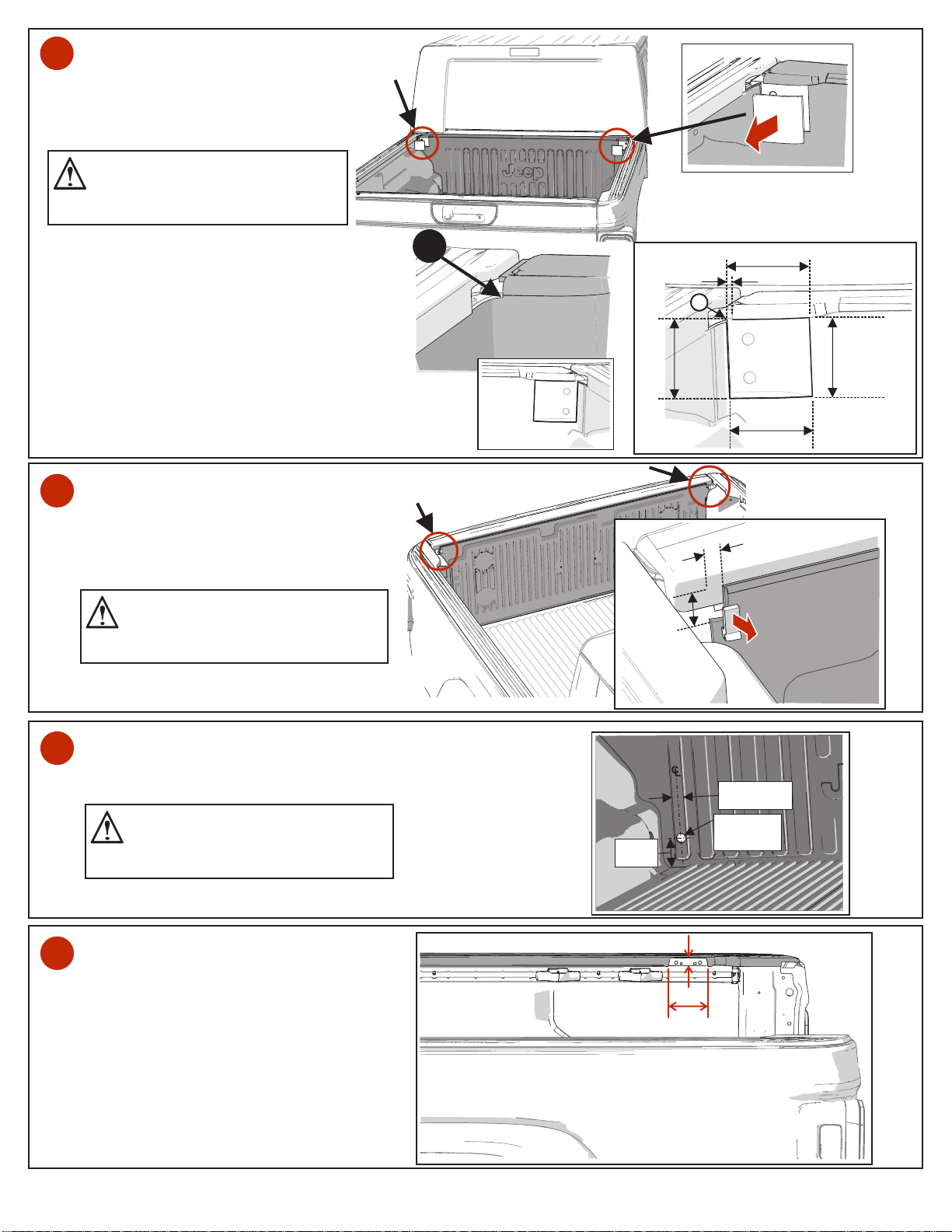

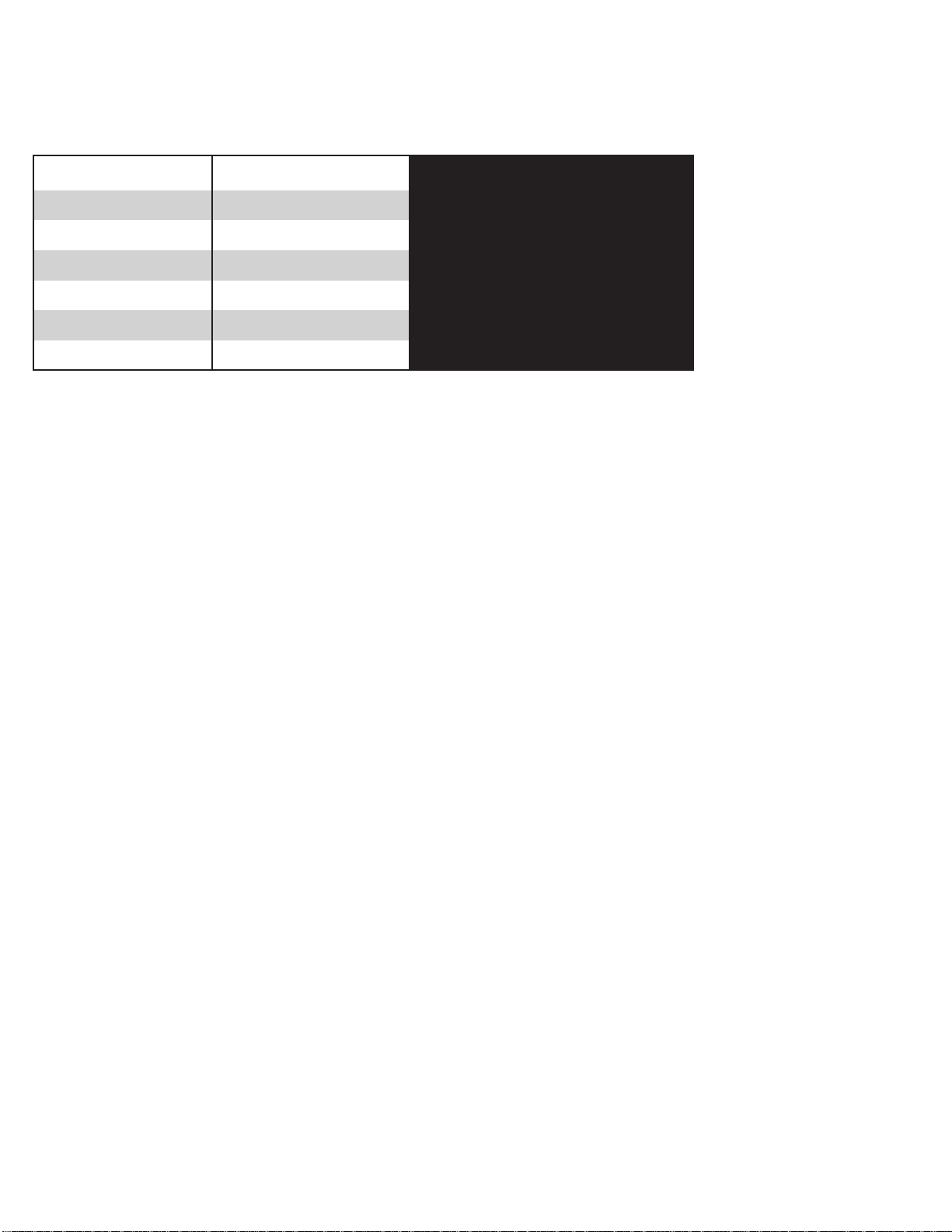

DROP IN LINER TRIMMING

If the truck has a drop in bed liner,

the top corners at the bulkhead,

and the top corners of the tailgate liner

need to be trimmed to allow for the

bed cover rails.

Locate the necessary cuts by starting with

the top left corner edge of the liner (1),

then measure a distance of 0.18”, 4.8mm,

outboard to establish point A.

The first cut is down from A 2.5”,

63.5mm, to point B. The next cut is

from point A, inboard horizontally

2.6”, 66.7mm, to point C.

Cut from point C to D, then finish with a

cut from B to D.

The cut is done on the right hand side as

a mirror image, Figure 5.

Locate the necessary cuts for the tailgate liner

by starting with the outside corner of the liner,

measure a distance of 0.375”, 9.5mm inboard,

then 0.875”, 22.2mm, down.

The cut is done on both sides,

as a mirror image.

10.18”,

4.8mm

2.6”, 66.7mm

2.6”, 66.7mm

2.5”,

63.5mm

2.5”,

63.5mm

BD

C

A

0.375”, 9.5mm

0.875”,

22.2mm

CAUTION: Move the bed liner away

from the truck sheet metal, or remove

the liner from the truck so that the

truck bed is not damaged.

CAUTION: Move the tailgate liner away

from the truck sheet metal, or remove

the liner from the truck so that the

truck bed is not damaged.

CAUTION: Move the tailgate liner away

from the truck sheet metal, or remove

the liner from the truck so that the

truck bed is not damaged.

2

3

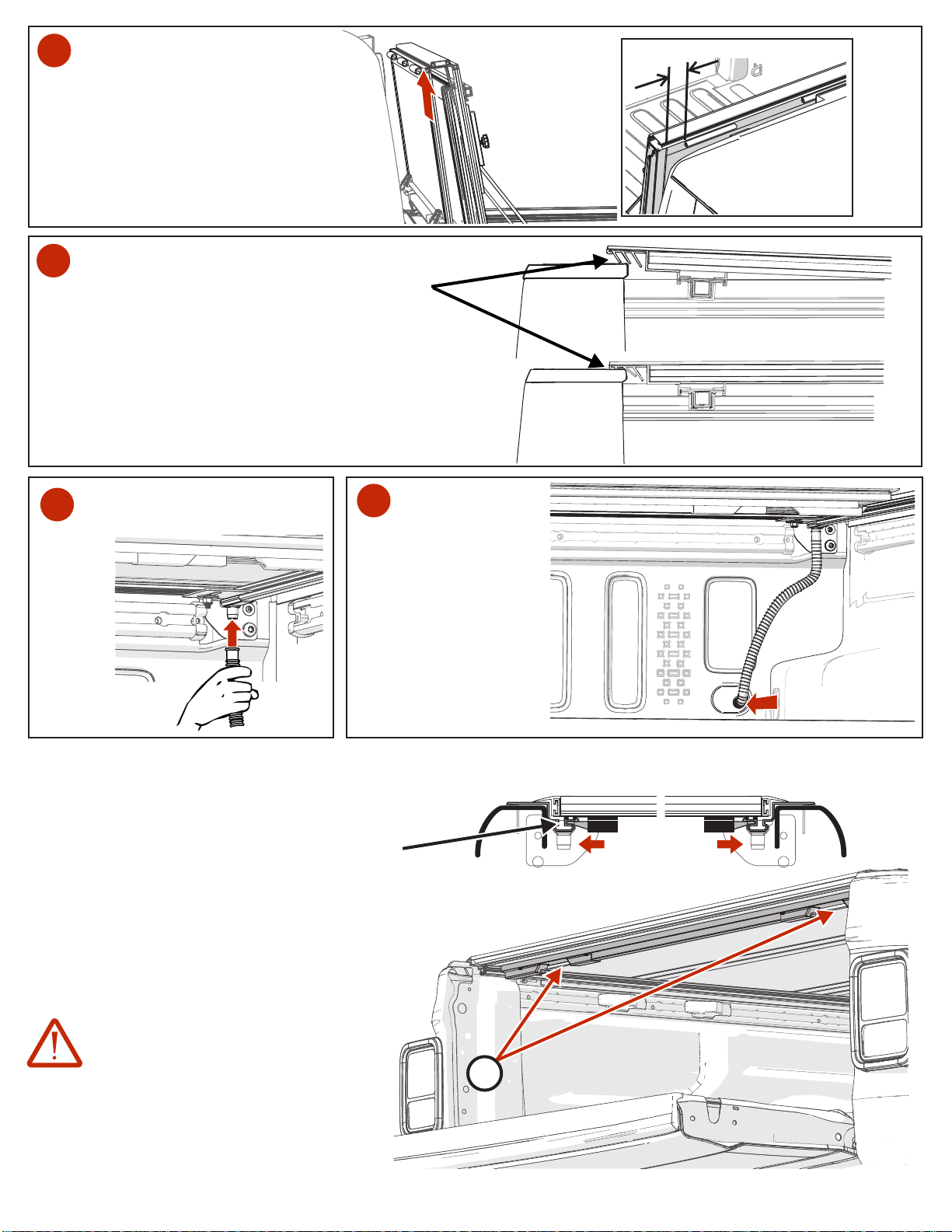

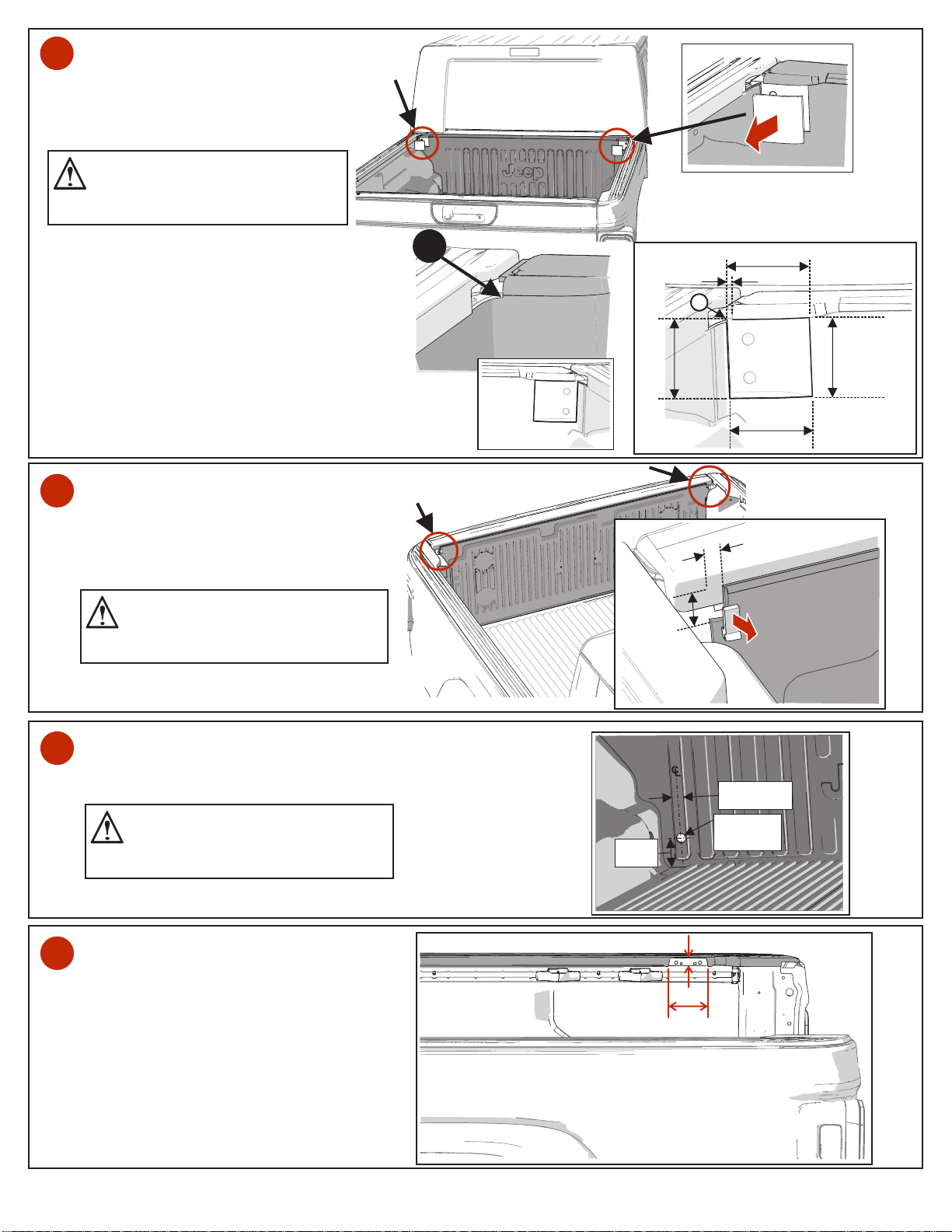

4Holes are necessary in the drop in liner for the bed cover rail drain tubes.

A 7/8”,[0.875”, (22mm)], diameter hole needs to be centered on the first

rib from the edge. The hole will be 2.875”, 73mm, up from the floor.

The hole is cut on both sides, as a mirror image. Centered on

the first rib.

Diameter =

7/8” [0.875”,

22mm]

2.875”,

73mm

Fig. 5

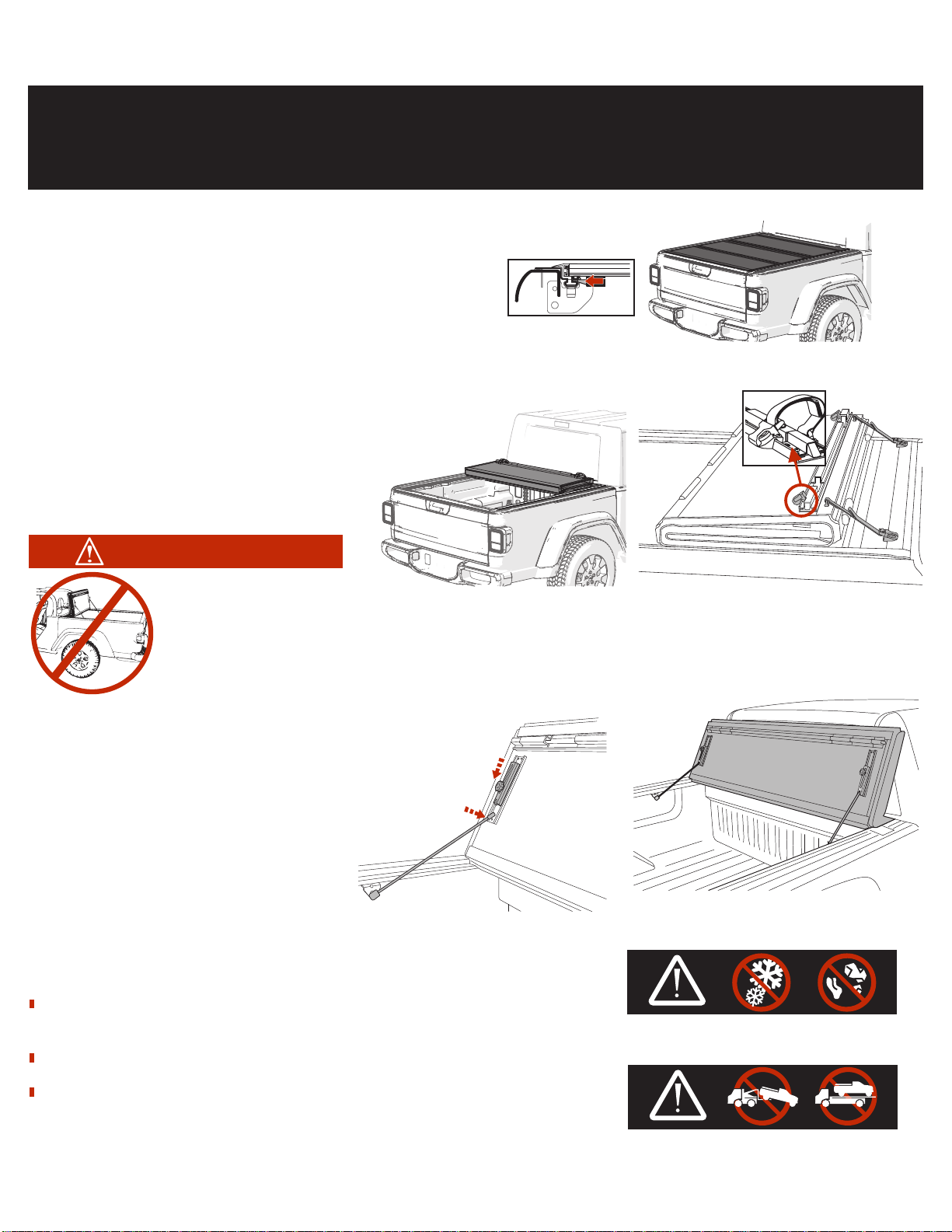

5If the bed rail caps are not trimmed in the rear

/tailgate section, cut using the scribed lines as

a guide to expose the area shown.

Perform this operation on both sides of the

pickup box.

• 1100 N. Glenstone Ave. Suite 140, Springfield, MO 65802 • 818-365-9000 • bakindustries.com BAK Industries Part# 318B0047 Rev. 8.12.2020