WARNING: NEVER USE YOUR HAND TO PRESS FOOD THROUGH THE MACHINE, BUT PRESS THE

VEGETABLE WITH THE PESTLE SUPPLIED.

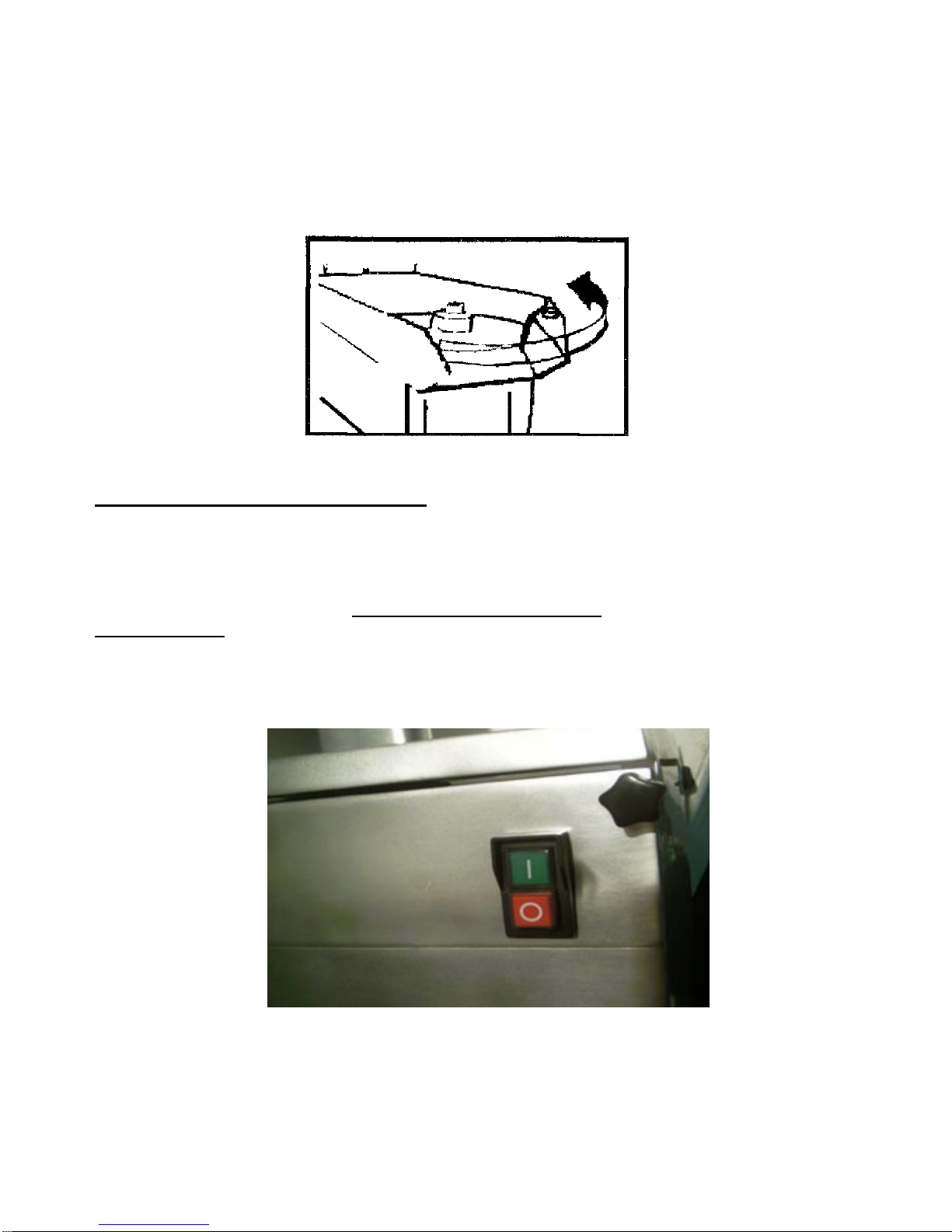

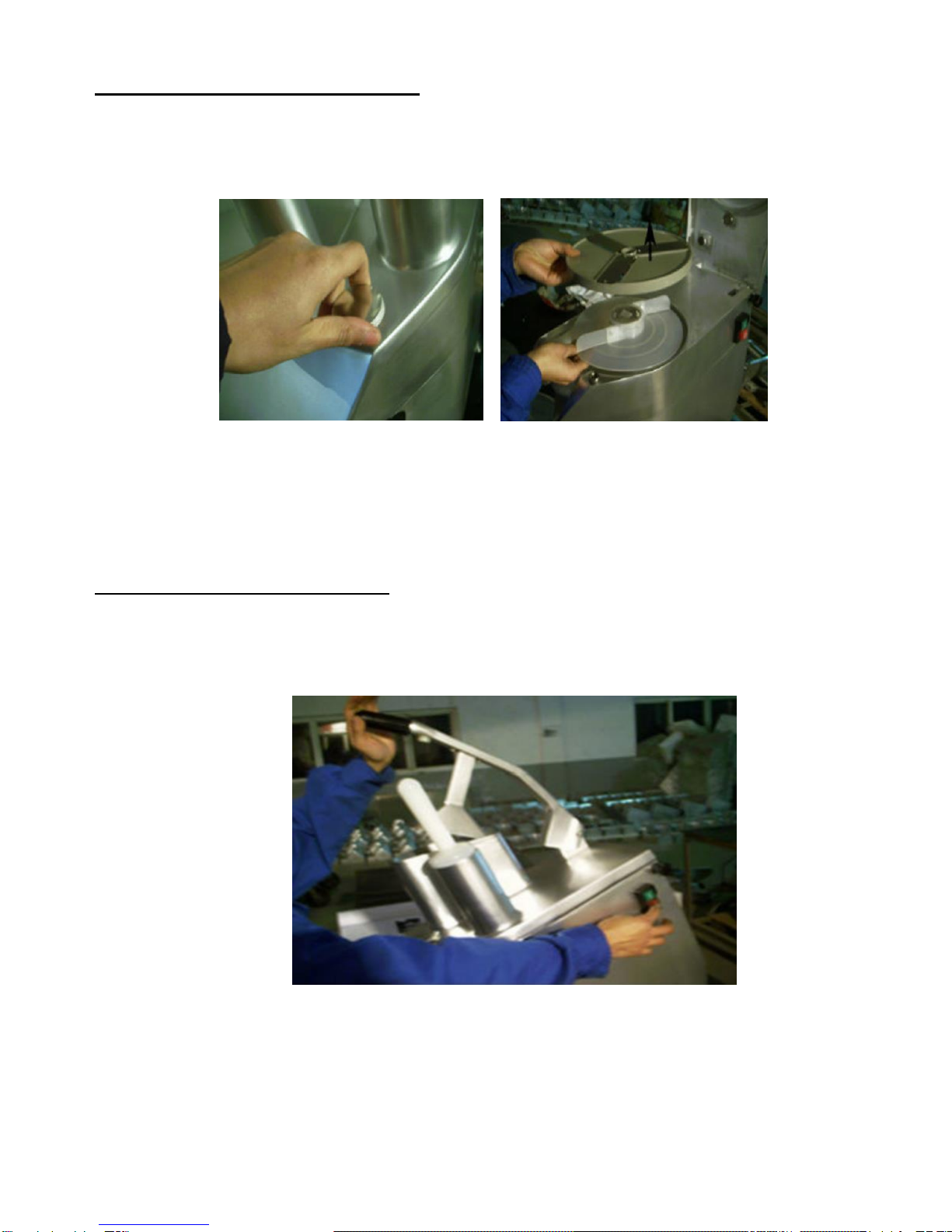

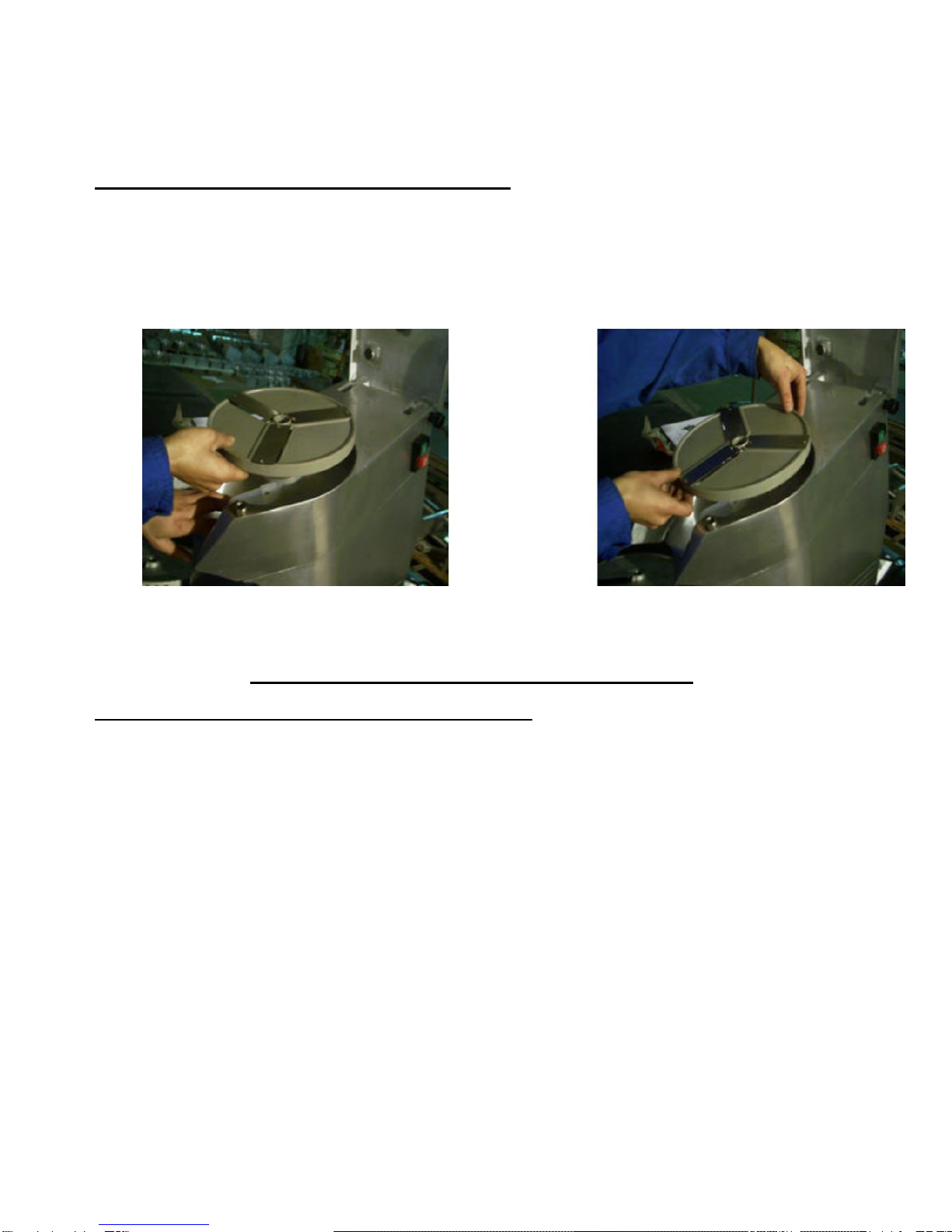

4.4. RELEASE AND REPLACEMENT OF THE DISCS

•TURN THE KNURLED HANDLE AND LIFT THE COVER. FIGURE (1)

•TURN THE DISC COUNTER CLOCKWISE AND COVER THE CUTTING EDGE WITH

APPROPRIATE MATERIAL (RUBBER, FABRIC, ETC), THEN LIFT IT BY SETTING YOUR HAND

UNDER THE DISC.

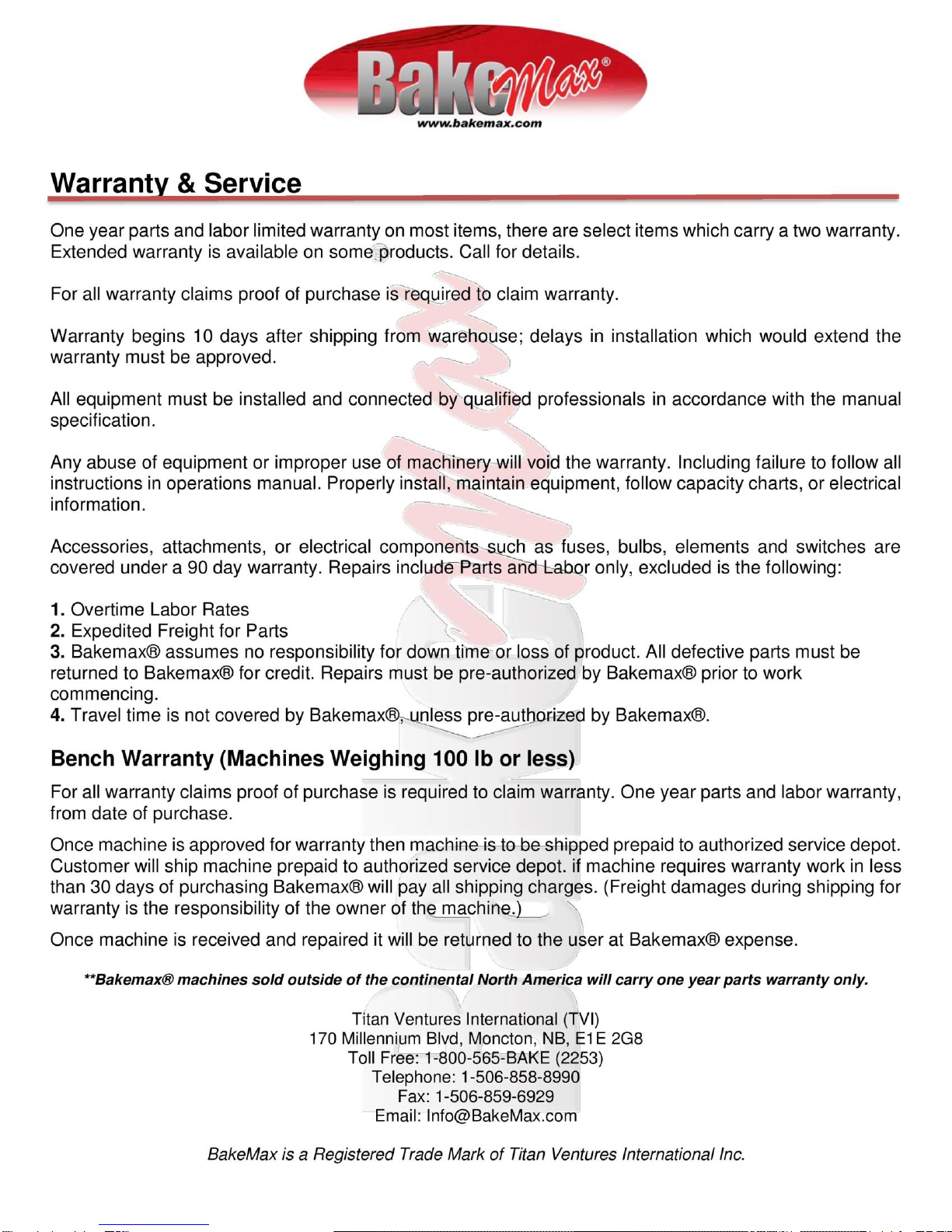

•SIMPLY LIFT THE DISCS TO REMOVE THE GRID DISC FOR DICE CUTTING, OR THE DISC FOR

STICK CUTTING WITH THE PLASTIC DISC. FIGURE (4-5)

5. CLEANING AND MAINTENANCE OPERATIONS

5.1. GENERALITIES AND PRODUCTS FOR CLEANING

•BEFORE CARRYING OUT ANY CLEANING OR MAINTENANCE OPERATIONS, CHECK TO MAKE

SURE THAT THE MAINS SWITCH IS OFF AND THE SUPPLY PLUG DISCONNECTED FROM THE

MAIN POWER SUPPLY.

•PROPERLY CLEAN THE EQUIPMENT AND THE DISCS EVERY DAY TO ENSURE CORRECT

OPERATION AND LONG LIFE FOR THE EQUIPMENT.

•THE DISCS, THE GRID FOR CUTTING DICES, AND THE PLASTIC EJECTOR, CAN BE REMOVED

FOR WASHING UNDER A WARM WATER.

•CAREFULLY REMOVE ALL WASTE TO PREVENT THE DISCS FROM CHANGING THEIR

POSITION.

•OPEN THE COVER AND LOOSEN THE 2 PINS AS SHOWN IN FIG6. REMOVE THE COVER AND

WASH UNDER WARM WATER.

•CAREFULLY CLEAN THE MACHINE, PARTICULAIRLY WHERE THE DISCS REST WITH A CLOTH

OR A WET SPONGE

•CLEAN THE SURFACES WITH WATER AND SOAP, ALCOHOL, DETERGENTS WITHOUT

ABRASIVES OR SUBSTANCES BASED ON CHLORINE OR SODA (CHLORINE WATER, MURIATIC

ACID).

•NEVER USE ABRASIVES, STEEL WOOL, OR SIMILAR PRODUCTS AS THEY MAY DAMAGE THE

FINISH, COAT, ON THE MACHINE BODY FOR CLEANING. USE NON-TOXIC PRODUCTS AND

ONES THAT GUARANTEE THE BEST HYGIENE.