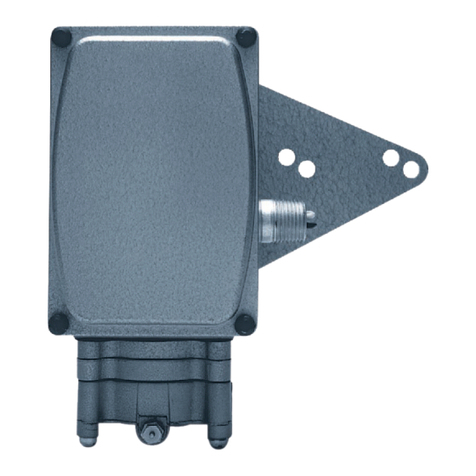

Masoneilan Model 4411 Electropneumatic Transducer Instruction Manual | 4

Copyright 2020 Baker Hughes Company. All rights reserved.

Under no circumstances should PTFE tape be used

for sealing the ttings as this tends to shred small

particles which may nd their way into the instrument

causing malfunctions.

The use of a soft setting anaerobic hydraulic seal is recommended,

(e.g. Loctite Hydraulic Seal 542). Follow the manufacturers

recommendations�

Do not use an excessive amount as this will not set

and could nd its way into the instrument.

If the air supply is not of adequate quality, the device performance

can be affected. Adequate quality can normally be achieved by

the use of air filter regulators.

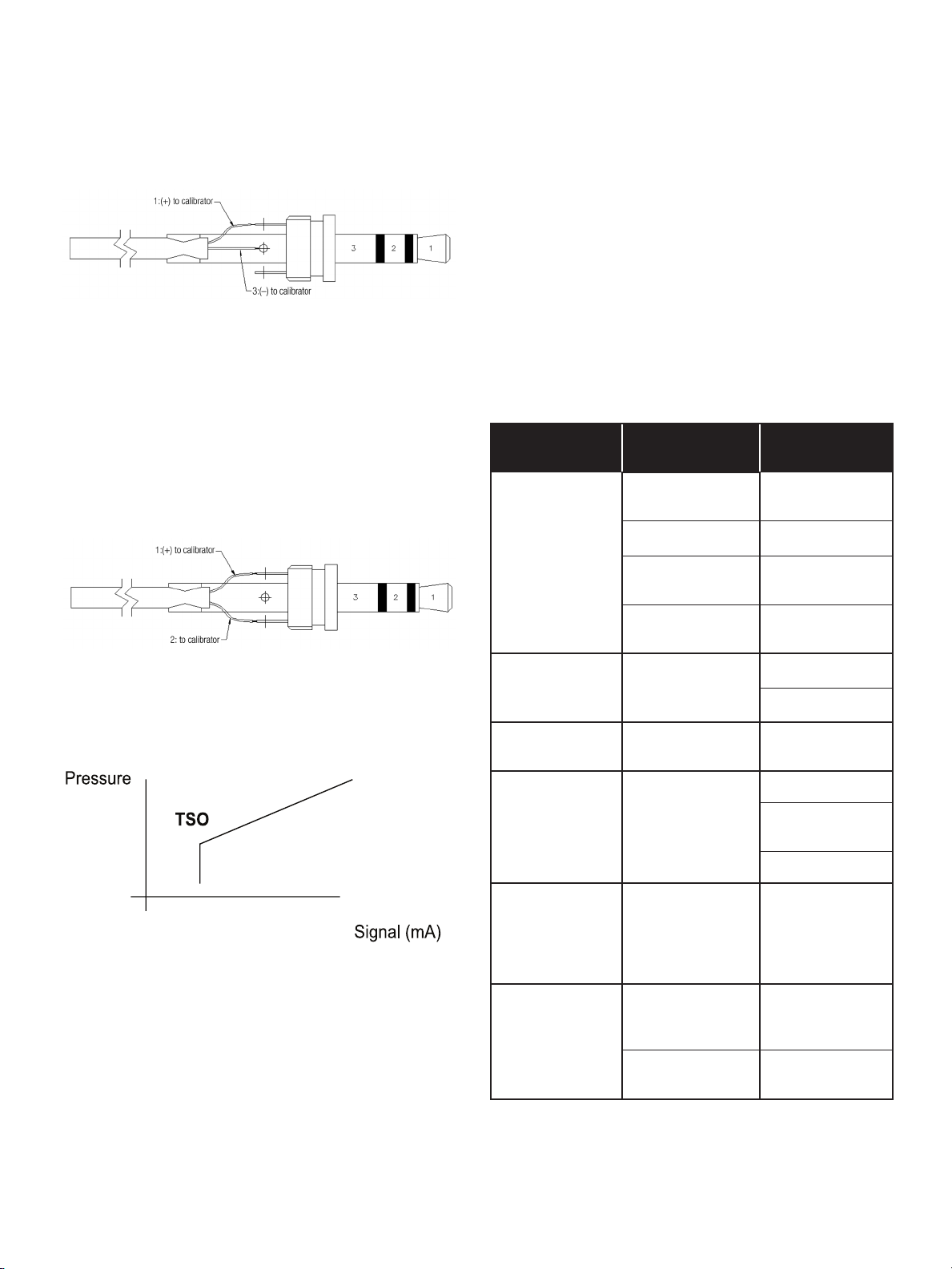

Electrical Installation

The electrical connections should be made as shown in the

dimensional drawing Figure 1. The instrument is protected

against reverse polarity to –100mA, no operation is possible in

this condition�

The Model 4411 approximates a constant voltage load of 6.5

volts across the loop terminals, therefore it is essential that the

loop controller be capable of providing a constant current in the

range 4-20mA with an output voltage of at least 6.5 volts.

Voltage output controllers (e.g. variable voltage power

supplies) are entirely unsuitable for the Model 4411

and could severely damage the electronic circuits.

Important Note

The control electronics of the Model 4411 incorporate

precision electronics. The calibration of the unit may be

affected by very high voltage spikes. Consequently, in

environments where static electricity may be present ESD

precautions should be used.

Wiring And Cable Entry

These instruments must be installed in accordance

with local and national codes of practice, especially for

hazardous area installations. The instruments are fully

isolated from ground and therefore grounding is un-

necessary for functional purposes. However, ground-

ing may be necessary to conform to installation codes.

Note: It is strongly recommended that shielded cable or a

grounded conduit be used to achieve maximum RFI immunity,

if the installation has any risk of electromagnetic interference.

Conduit Entry

The instrument has twin conduit entry threaded 1/2" NPT. For

explosion proof installation, a sealed conduit gland conforming to

explosion-proof specifications must be used. A ground terminal

is provided both internally and externally and should be used if

ground continuity is essential.

The unit is supplied with plastic blanking plugs, which

must be removed before operation/calibration and re-

placed with a blanking plug conforming to the hazard-

ous area certication rating applicable.

Calibration

The instruments are designed for continuous operation without

the necessity for routine overhaul, with continuous monitoring,

adequate precautions and replacement of the filter no longer

than every 5 years.

The most common source of failure for pneumatic instrumentation

has been found to be inadequate air quality, allowing

contaminants to block internal orifices. Air filtering is included

within the instrument but cannot cope with sustained poor air

quality, which may ultimately lead to failure.

The recommendations in the Pneumatic Installation section

should be rigorously observed.

Note: These instruments are factory calibrated at a supply

pressure of 30psig (2 bar).

The instrument cover must be unscrewed to obtain access to

the trimpots�

Do not remove the instrument cover in a potentially

explosive atmosphere when the instrument is powered.

An accurate current source of 4-20mA and pressure gauge are

required. These should be of good quality with an accuracy of

0.1% or better. The current source should be checked to ensure

that it provides at least 6.5V at 20mA output compliance.

• Connect the instrument as described in the installation

section or the test-jack section below.

• Remove the instrument cover to gain access to the trimpots

and jack-socket.

• Set the current to 4.00mA – the instrument outlet should be

3.00+/-0.05psig (0.200+/-0.003 bar). Adjust the Zero trimpot

if necessary.

• For 6-30 psig output, the output pressure should be set to

6.00 ±.05 psig (0.400 ± .003 bar). Adjust trimpot as necessary.

• Set the current source to 20.00mA – the instrument outlet

should be 15.00 +/-0.05psig (1.00+/-0.003 bar). Adjust the

Span trimpot if necessary.

• For 6-30 psig output, the output pressure should be set to

30.00 ±.05 psig (2.00 ± .003 bar). Adjust trimpot as necessary.

If either Span or Zero controls are adjusted it may be necessary

to repeat the above steps until both ends are within the calibration

limits�

Alternatively the Jack Plug can be connected to calibrate and

test the unit. The Jack Plug can be either set-up for Monitoring or

Calibration/Operation set-up.