Operating Instructions

Note: When using the soldering station for the rst time, it is

recommended to set the temperature to 482°F (250°C). When

the iron tip reaches the point where it can melt the solder, apply

a fresh layer of solder containing ux on it and then increase the

temperature to the desired setting.

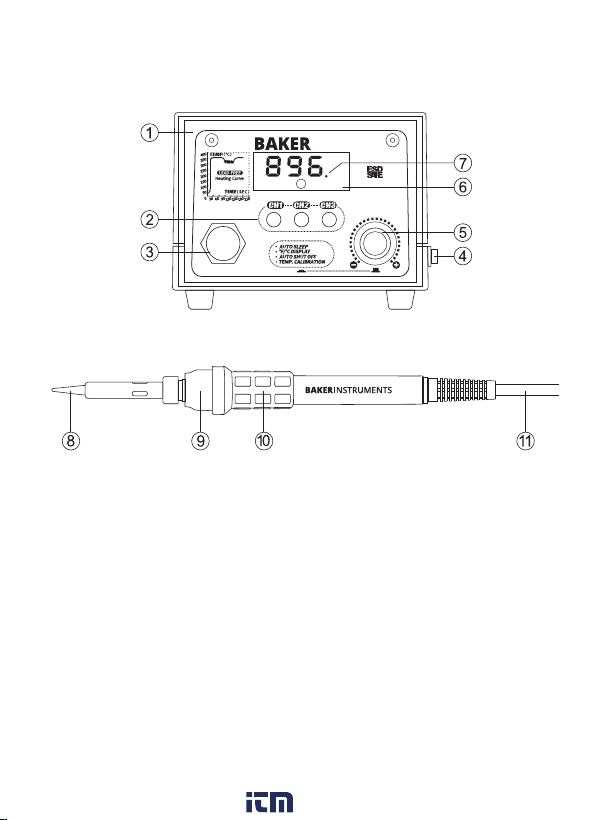

1. Connect the soldering tip cord to the station.

Note: Be sure to turn o the power before connecting or disconnecting

the soldering tip cord to the station to avoid damaging the circuit board.

2. Place the soldering tip into the safety rest.

3. Plug the power cord into an appropriate power source.

Note: Do not operate this unit without a properly grounded, properly

polarized power cord.

4. Turn the power switch to the ON position and the soldering tip will

begin to heat up.

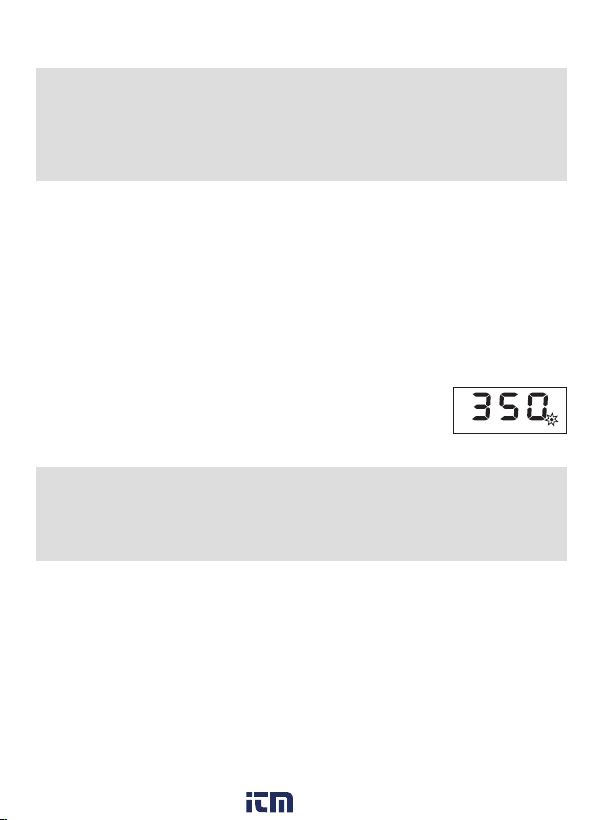

5. Use the temperature control knob to set the desired

temperature. At this time, the soldering station’s LED

heater lamp indicator lights up. (Figure 1)

Note: While the soldering station is heating up to the desired

temperature, the LED indicator will continuously blink. When the

temperature stabilizes, the LED indicator will remain solid. While

cooling down, the LED indicator will remain o.

6. When soldering is complete, set the temperature to 572°F (300°C)

and then clean the soldering tip with a wet sponge or cleaning wire

if any material has not been successfully removed. Recoat the tip

with a fresh layer of solder.

7. Place the soldering iron handle back into the safety rest and turn

o the soldering station.

Note: If the soldering station is not in use for a long period, turn OFF

the power and remove the power plug.

Figure 1

www. .com information@itm.com1.800.561.8187