GRUDGEBOX –BEHIND THE NAME

Grudge racing is street racing, often done illegally, in which real dollars are bet on a single race.

As such, the internal configuration of the engine and drivetrain are a closely guarded secret to

gain an advantage over the competitors. The GrudgeBox was conceived to be a high-

performance transmission with performance inspired gear ratios but no outward appearance to

give away the fact that a thoroughbred torque multiplying machine occupies the inner walls of

the transmission case.

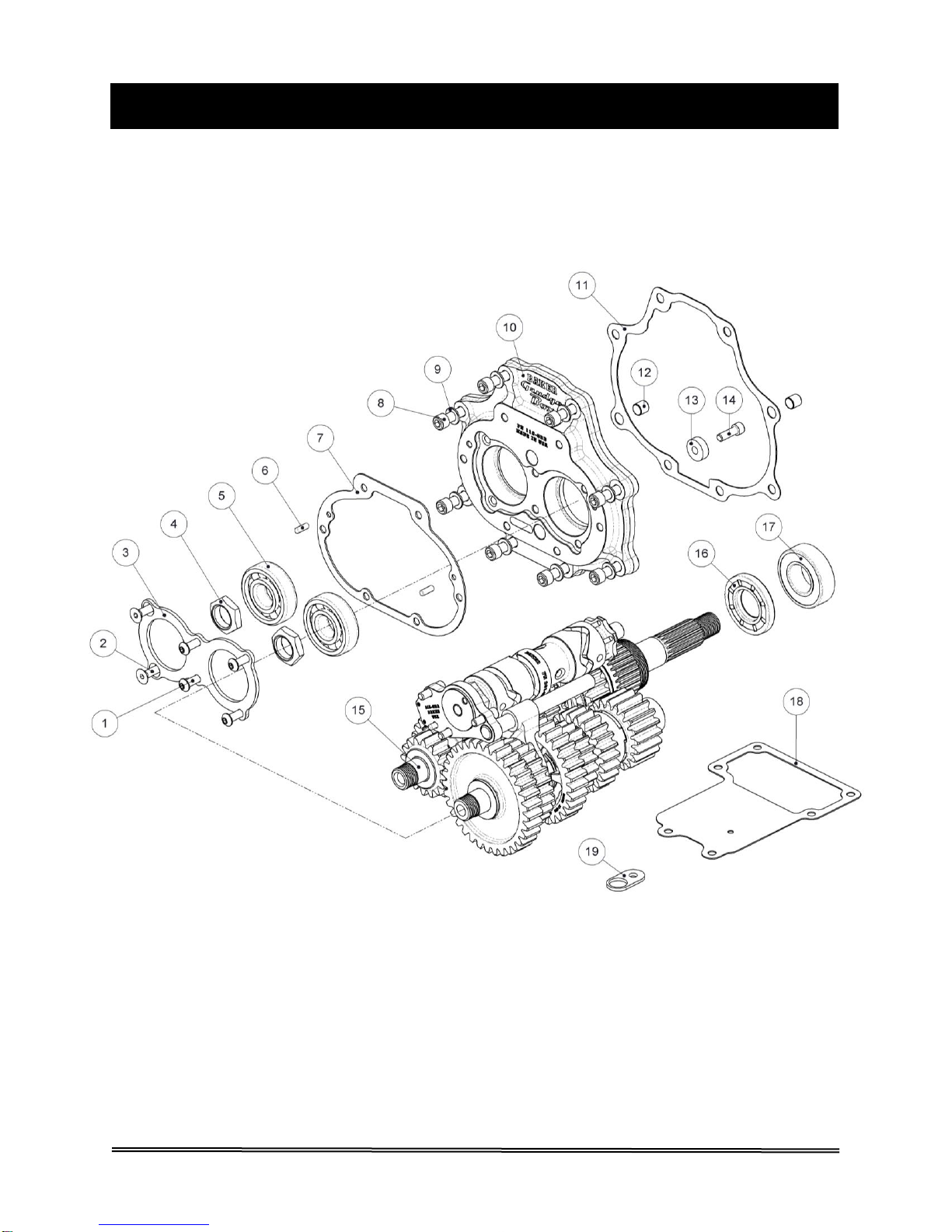

The GrudgeBox is available with different bearing door finishes: machined billet, chrome, polish,

powdercoat with highlights, and Sleeper. The Sleeper door is available to achieve the

aforementioned anonymity. To make the Sleeper door we apply mechanical taxidermy to a

stock factory door by milling out all anatomy and bone structure on the stock door to leave a

.125” thick shell with stock factory powdercoat. The shell then fits over a billet sub-door, like a

3D puzzle, to yield the Sleeper door which fathered the name GrudgeBox (figure 1). Externally,

the GrudgeBox with the Sleeper door gives no indication that a drag racing transmission lives

underneath and that may be the difference between winning and losing.

Three different shift drum configurations are offered; standard pattern (1-N-2-3-4-5-6),

N1 pattern (N-1-2-3-4-5-6), and reverse N1 pattern kill (6-5-4-3-2-1-N).

The N1 drum is similar to the standard pattern drum, but neutral is relocated from the standard

position between 1st and 2nd to the position below 1st gear. The N1 drum makes it

effortless/mindless to find neutral. Racers, those who live in mountainous regions, and people

with restricted foot and leg mobility rely on the N1 pattern to find neutral every time without

having to think about it.

Reverse N1 pattern kill drums are for the advanced disciples of the quarter-mile club. As the

name implies, reverse N1 pattern is just like the aforementioned N1 pattern but reversed. To

upshift, you stomp down on the lever. The “kill”part relates to repurposing the neutral switch to

allow for clutchless upshifts and downshifts. See page 26 for wiring diagram.