3

© 2010 Bakker Hydraulic Products BV

Nijverheidsweg 6

6662 NG Elst (Gld) The Netherlands

Tel : + 31 481 374757 Fax : + 31 481 375280

Site : www.bakker-hydraulic.com E-mail : info@bakker-hydraulic.com

1. INTRODUCTION

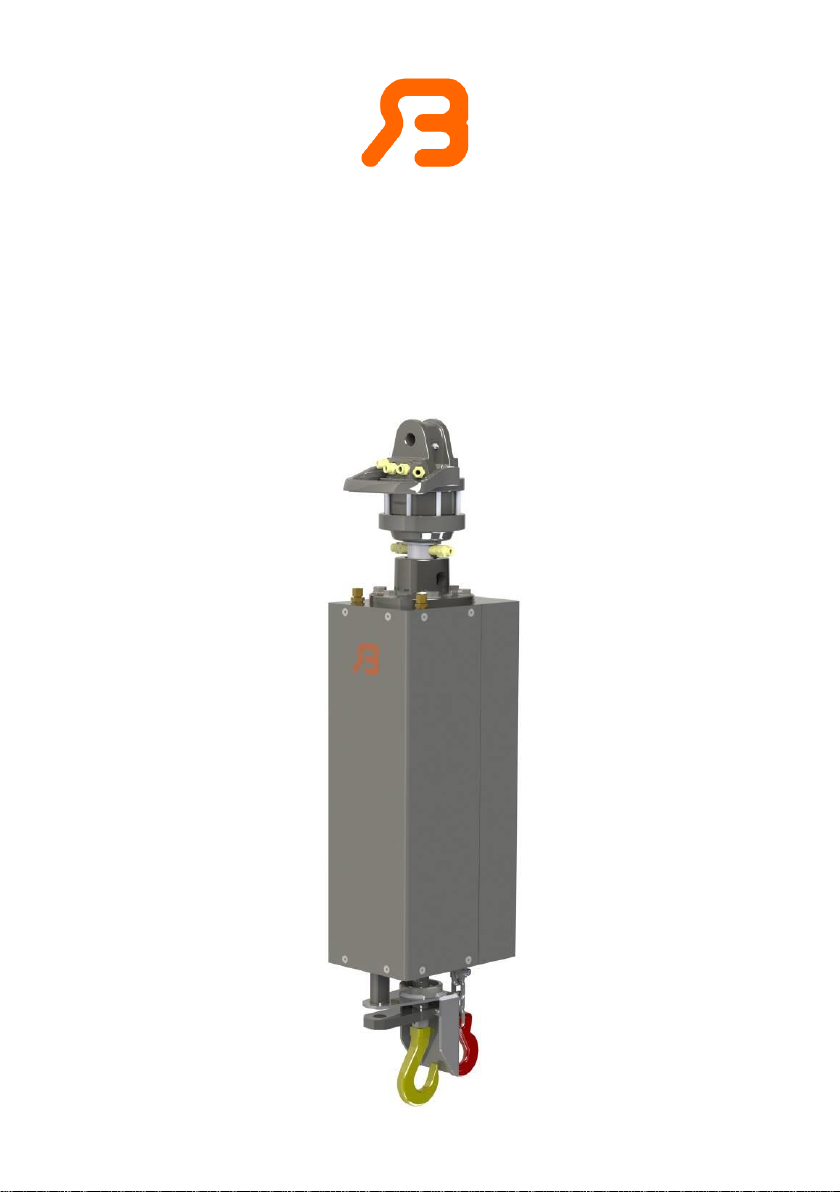

This manual describes the hook grab supplied by Bakker Hydraulic Products

BV and the regulations concerning its connection, operation and

maintenance.

The hook grab is used with a truck-mounted crane for picking up and opening

containers, and is specially adapted to the containers used.

It is essential, before using the hook grab, to read through this manual

carefully to familiarise yourself with its operation, control and maintenance.

Malfunctions are usually caused by incorrect start-up, operation or

maintenance.

Personnel operating the hook grab and those working near it should be aware

of how the hook grab works.

Carefully follow the advice provided here. In case of doubt, Bakker Hydraulic

Products BV is always willing to advise you.

Bakker Hydraulic Products BV holds a large stock of these components and

they can generally be supplied quickly.

If spare parts not supplied by Bakker Hydraulic Products BV are used, the

company accepts no responsibility for the correct functioning of the hook grab.

2. OPERATIONAL CONDITIONS

This hook grab is considered an exchangeable equipment within the scope of

the machinery directive 2006/42/EC. Be sure that the machine, of which this

hook grab will be part of, meets the appropriate requirements and/or

regulations and is well maintained.

Notes

When designing this product, account was taken not only of normal usage but

also of usage that might reasonably be expected.

If the customer modifies the product without the manufacturer's knowledge,

the customer (the user) is liable for the consequences and the guarantee

becomes null and void.

Maintenance is, of course, permitted, providing it is carried out according to

the instructions provided in the manual.

Warning

Ensure that no one is within working range of this product when it is being

used!

Caution

Take note of the maximum headroom!