2

General Safety

Because this pump can be

incorporated into a pressurized

systems, the following safety

precautions should be observed.

Check equipment regularly and repair or

replace worn and damaged parts.

Never alter or modify any parts of this pump,

doing so may cause damage to pump and/or

personal injury.

Under no circumstances should the dispensing

valve be aimed at any person at any time.

Personal injury may result.

Release pressures built up in the system

before any service or repair is begun. See the

pressure relief procedure below.

Do not operate this pump above 150 PSI

(10.3 BAR) air inlet pressure or 200 cycles per

minute.

Always read and follow the uid manufacturer’s

recommendations regarding the use of

protective eyewear, clothing and respirators.

IMPORTANT

!

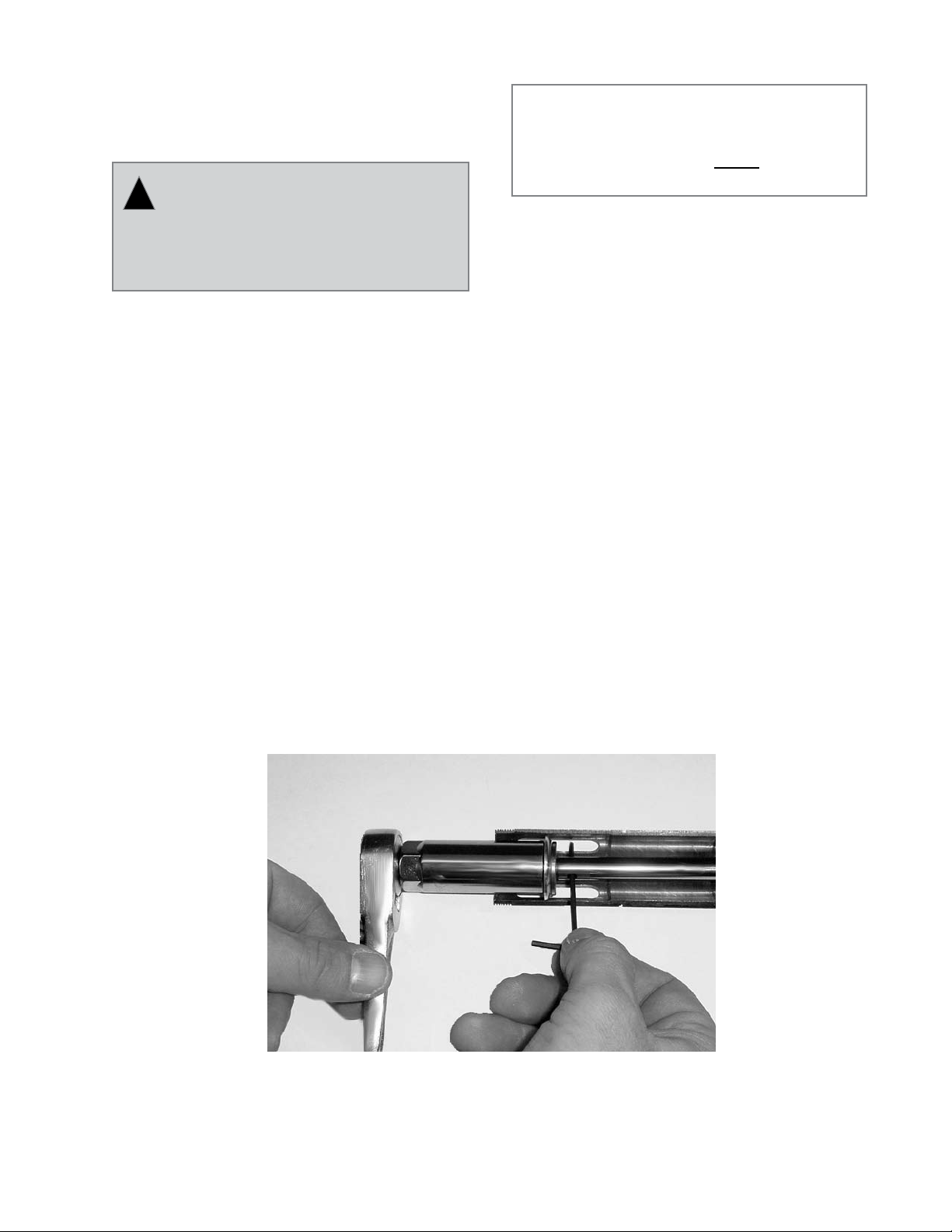

Pressure Relief Procedure:

Follow this procedure whenever you shut off

the pump, when checking or servicing any part

of the system and when installing, cleaning or

changing any part of the system.

1) Disconnect the air to the pump.

2) Point dispensing valve away from

yourself and others.

3) Open dispensing valve until

pressure is relieved.

WARNING

!

WARNING

!

THIS PUMP CONTAINS

ALUMINUM AND ZINC

PARTS. DO NOT use 1-1-1

Trichloroethane, methylene chloride or other

halogenated hydrocarbon solvents or uids

containing such solvents in this pump. Use

of these solvents/uids may result in a

violent chemical reaction, causing serious

bodily injury, property damage or death. All

uids used in this pump must be chemically

compatible with the wetted parts materials

shown on page two (2) of this manual.

Consult your chemical supplier to ensure

compatibility.

WARNING

!

WARNING: The Panther®50:1

grease pump develops up to 7500 psi (517

Bar) maximum working pressure at 150 psi

(10.3 Bar) maximum inlet air pressure and

stall conditions. Be sure that any components

or accessories used in the system are rated

to withstand this pressure. To determine uid

output pressure at stall conditions, multiply

the ratio of the pump by the air pressure

being used.

EXAMPLE: 50:1 Pump Ratio x 100 psi air

pressure = 5000 psi uid pressure at stall.

WARNING

!

DANGER: Not for use with

fluids that have a flash point

below 100°F (38°C). Examples:

gasoline, alcohol. Sparking could

result in an explosion which could result in

death.

In the presence of explosive

vapors, take action to prevent

static sparking. Failure to

ground the pump, piping, valves, containers, or

other miscellaneous equipment can result in re or

explosion. A green grounding lug is provided on the

pump.

WARNING

!

WARNING

!

Use 3241-002 Pump Over-Run

control valve on pump air inlet for remotely

operated pumps. Failure to use this valve can

cause pump to cycle quickly when barrel is

empty of grease. THIS WILL DAMAGE THE

PUMP and may void factory warranty.

Thoroughly read and understand this manual

before installing, operating or servicing the

described products.