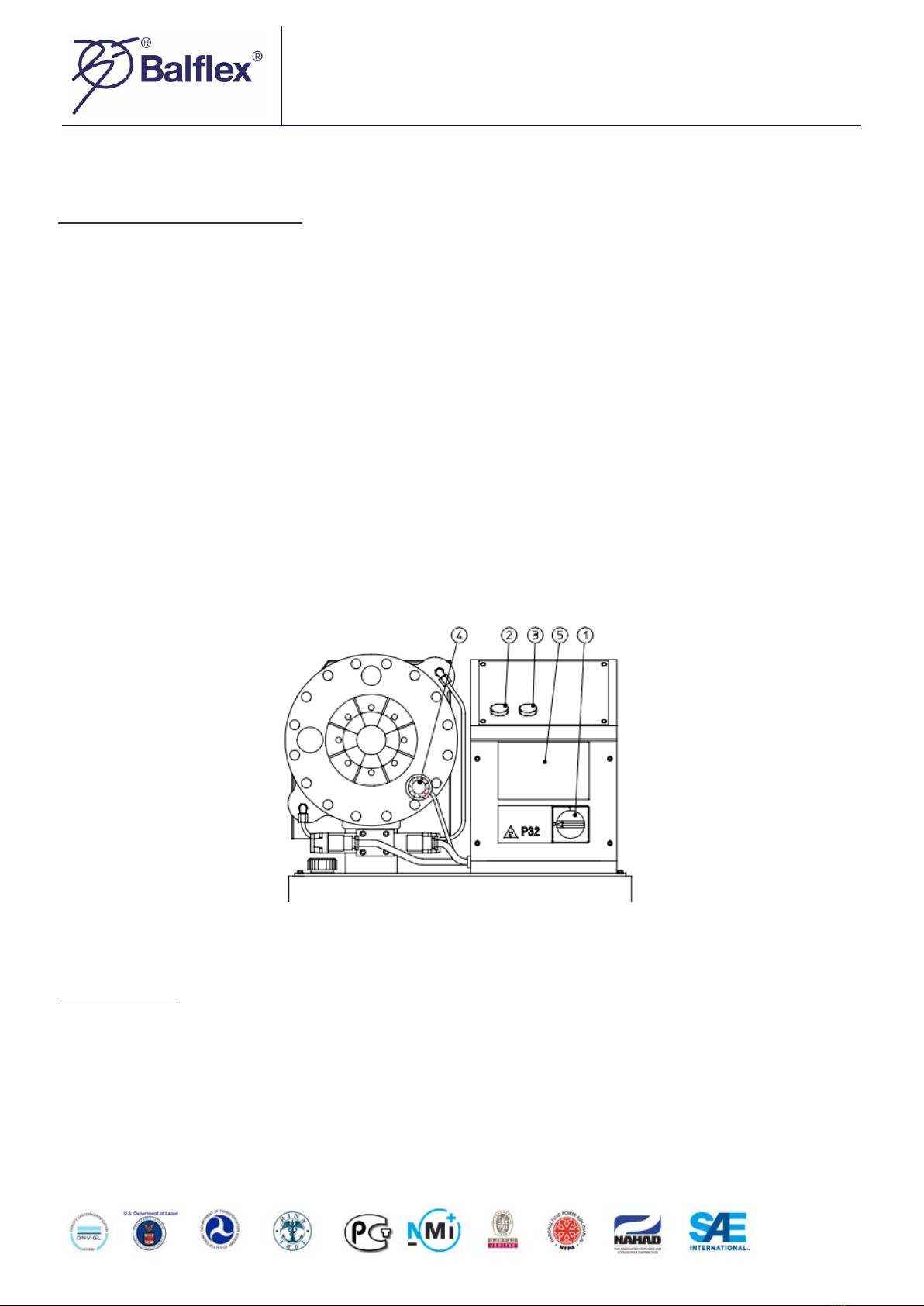

CRIMPING BUTTON

The dies will close when this button is pressed. The dies move until the button is released or the set crimping

diameter has been reached.

When the machine is started with the mode selector in manual mode, crimping cannot be started using the

crimping button before first selecting O-position or opening dies with retraction button 7.Dies will not open if they

are already in the set retraction position.

CRIMPING DIAMETER REACHED

The signal lamp is illuminated when the dies have reached the set crimping diameter

RETRACTION BUTTON

The dies will open when this button is pressed. The dies open until the button is released or the set retraction

diameter has been reached. When using this button, manual mode must be selected.

RETRACTION DIAMETER REACHED

The signal lamp is illuminated when the dies have reached the set retraction diameter, i.e. Retraction position.

Automatic mode cannot get started unless the retraction position has been reached.

DELAY SIGNAL LAMP

The signal lamp is illuminated when the delay function is active

RETRACTION DIAMETER CONTROL

The dial is used to adjust the retraction diameter of master dies after the crimping cycle. Adjust the retraction large

enough so that the fitting to be crimped is easy to insert between the dies but the "extra “movement is as short as

possible. The retraction becomes larger when the dial is turned clockwise.

CRIMPING DIAMETER CONTROL

The crimping diameter is defined by means of this Vernier dial and the die set that is used. The dial covers 0...10

mm. The measuring scale is divided into divisions of either 0.01 mm or 0.1 mm. The crimping diameter increases when

the dial is turned clockwise.