Contents

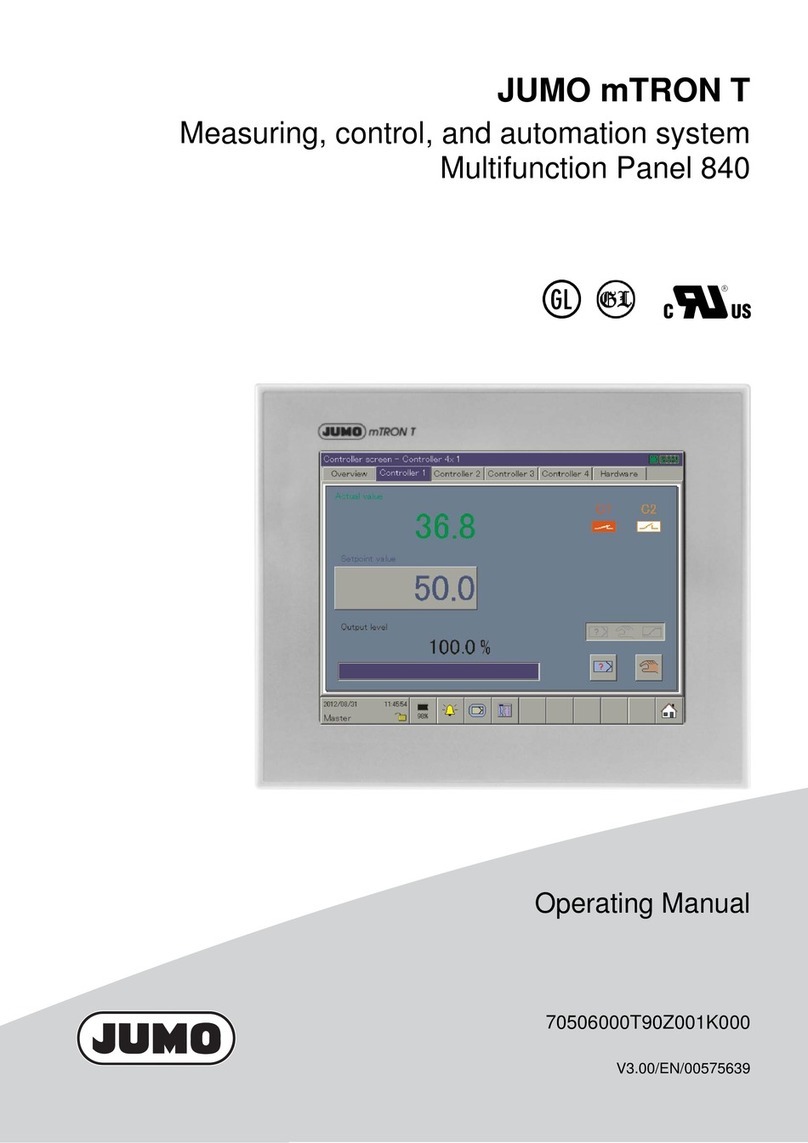

1. Discription ...........................4

2. Safety instructions .......................4

2.1. Explanation of symbols ..................5

3. Mounting ............................5

3.1. Place of operation .....................5

3.2. Panel mounting ......................5

3.2.1. Panel for switch board .................5

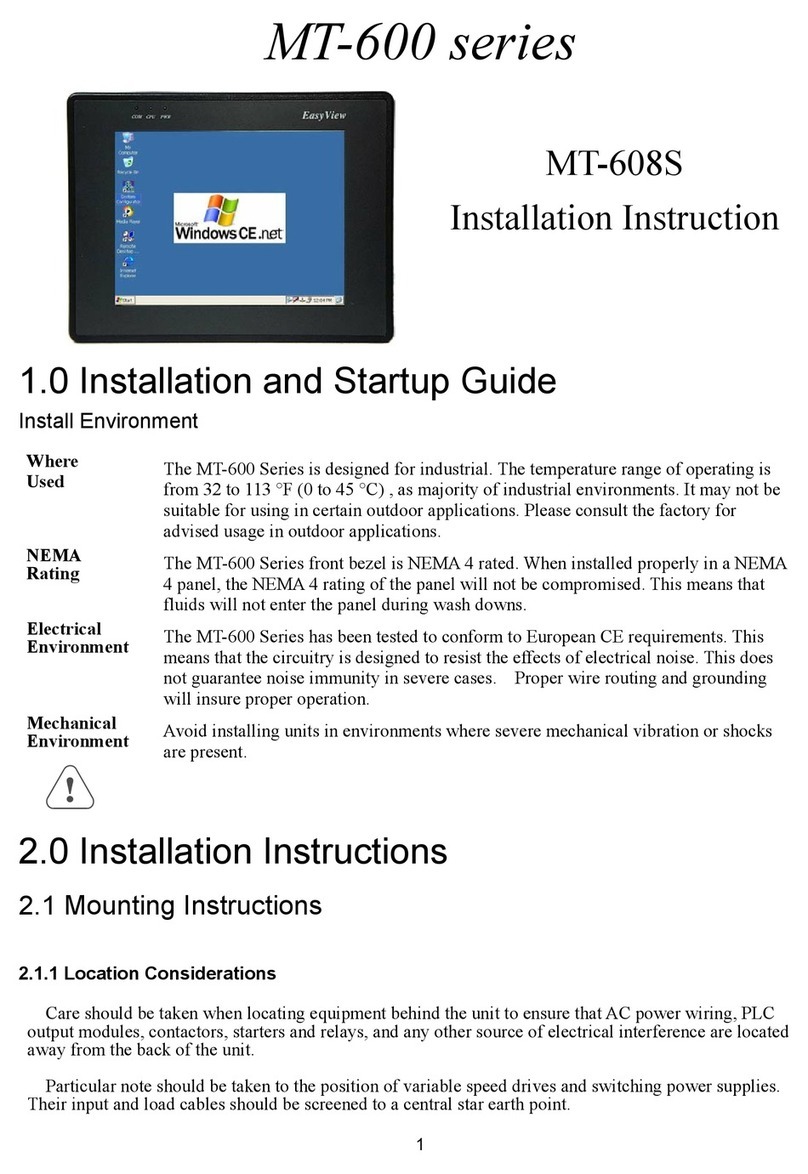

4. Electrical connections .....................6

4.1. General Instructions ....................6

4.2. Hints against noisy enviroment ..............7

4.3. Connection and pin assignment ..............7

4.4. Connection of input signals ................8

4.4.1. Input voltage 0 - 10 V .................8

4.4.2. Input current 0 - 20 mA, 4 - 20 mA ..........8

4.5. Connection of power supply voltage............8

5. Start-Up .............................9

6. Procedure of programming ..................9

6.1. Function of buttons and LEDs ...............9

7. Programming ..........................10

7.1. Programming level for configuration 0-00 .........11

2