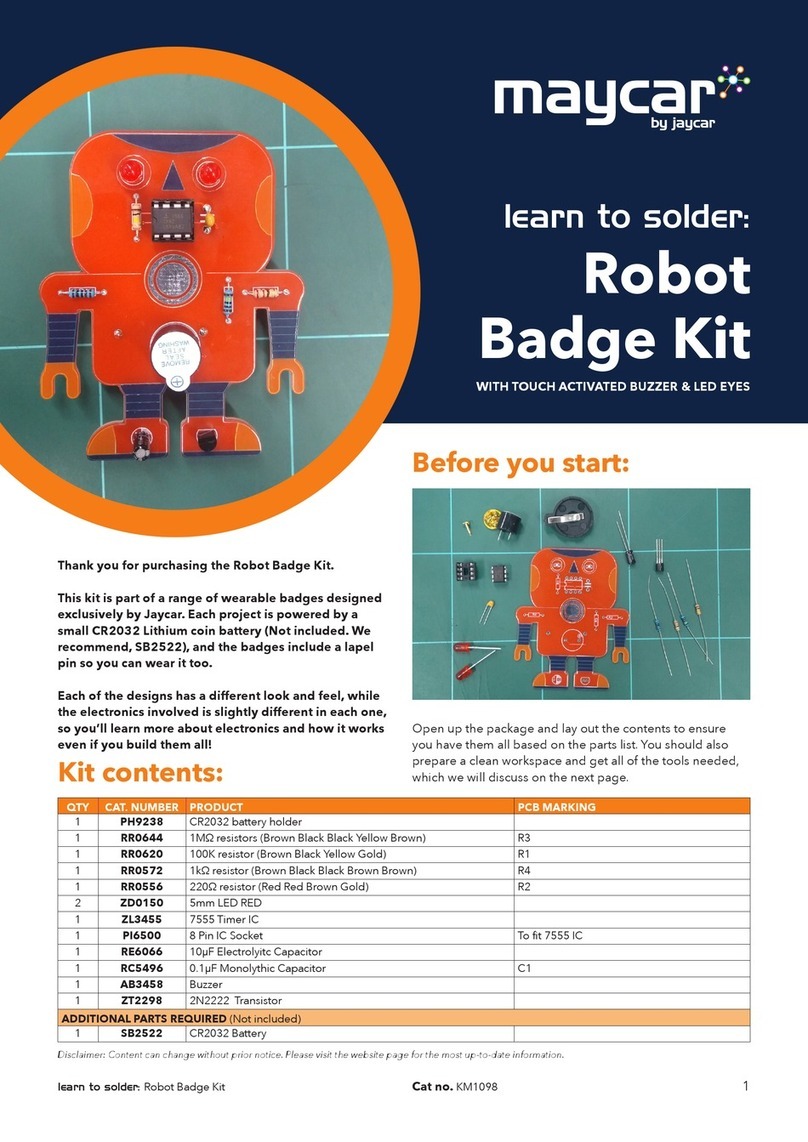

learn to solder: Owl Badge Kit Cat no. KM1092 2

RECOMMENDED

MAKER TOOLS

You will need

the usual Maker

essentials,

including a

soldering iron, solder, and

side cutters. A soldering iron kit is a good place to start if you

are new to electronics, such as the one we show here.

A third-hand PCB holder like the one

shown here is also recommended to

make soldering easier. This product

also includes a soldering iron holder to

securely hold your soldering iron when

you are not using it, a light to make sure

you can see what you are doing, and also a

sponge to clean the soldering iron tip.

Soldering guide:

Before you solder for the rst time, read the following

instructions. We also recommend you watch our Soldering

tutorial video on our YouTube Channel or by visiting:

www.jaycar.com.au/safe-soldering-for-kids

First, a note about safety. A soldering iron

can get very hot and can easily burn

you if you touch the hot end. Make

sure you only have the soldering

iron turned on when you need it

and off when you don’t. Keep it in a

soldering iron stand when not in use

to avoid it falling off your workbench.

Keeping the soldering iron tip clean is

important to create a reliable solder joint.

To prepare your soldering iron tip, turn on the iron and give

it a few minutes to get sufciently hot enough to melt solder.

Touch some solder onto the iron tip so that the solder and ux

(a component of the solder responsible for keeping the joint

clean and “owy”) cleans any rust or dirt off the tip of the iron.

Once you have some solder on the soldering iron tip, you need

to remove it so you are left with a simple clean and shiny

soldering iron tip. You can do this by wiping

the tip onto a damp sponge or rag. (Don’t use

a plastic sponge as it will melt).

If you have a soldering iron tip cleaner that has

a curly brass type cleaner, then stab the tip into

that to clean the tip.

You should now have a clean and shiny soldering iron tip

ready to solder. Use the above tip cleaning process during the

soldering process to keep your soldering iron tip clean.

Jaycar stocks a wide range of solder should you run out. For

example, the NS3013 Hobby Tube.

A GOOD SOLDER JOINT

In simple terms, soldering is joining

two metals together with solder.

In our case, we are soldering each

leg of the components to the

solder pads on the circuit board.

Soldering a component to the

circuit board is a matter of placing the

soldering iron tip against the component’s

leg and the solder pad on the circuit board for a couple of

seconds. This will allow the metals to reach the required

temperature for soldering. You can then quickly add solder by

touching the solder to the pad or lead of the component you’re

soldering (not to the soldering iron tip).

This process needs to be done within a few seconds as you

can damage the component you’re trying to solder if heat is

applied for too long. If the solder joint isn’t great move on to

a different component and let the bad joint cool down before

trying to solder it again.

A bad solder joint may cause your project not to work. If the leg

of the component you are soldering doesn’t reliably join to the

circuit board’s solder pad, the electrical current won’t be able to

ow when you apply power.

The diagram here shows you a good solder joint and two

bad solder joints. A good solder joint is clean and shiny with

a “volcano” shape, which means the component’s leg is fully

soldered to the entire solder pad on the circuit board. If your

solder joint is like the one shown in the middle, it means you

have not applied enough heat to the solder pad on the circuit

board. If your solder joint looks like the one on the right, it

means the component leg was not heated enough by your

soldering iron for the solder to join properly.

TRIMMING THE COMPONENT LEGS

Once you are condent you have a

reliable solder joint, you need to

cut off the leg of the component

that you just soldered. If you don’t

cut away the component legs it

can cause a short circuit when

you apply power to your project.

Using sharp cutters (We recommend

TH1897), trim off the component leg

just above the solder joint.

Note: Make sure you’re holding the lead as you’re cutting as the

cut lead can y off when trimming causing an eye injury.

GOOD

Shiny “Volcano”

type shape

BAD

The solder pad is

too cold

BAD

Component leg

too cold

TS1652 25W

Soldering Iron Starter

Kit with Multimeter

TH1987 PCB Holder

with LED Magnier

TS1510 Soldering

Iron Tip Cleaner