Neles Jamesbury Series Operating and maintenance manual

Adding live-loaded packing

option to Jamesbury™

Wafer-Sphere™ high

performance buttery valve

Installation, maintenance and

operating instructions

IMO-317 EN Issue 10/2020

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and

operation of the valve.

If you require additional assistance, please contact the

manufacturer or manufacturer’s representative.

SAVE THESE INSTRUCTIONS!

Addresses and phone numbers are printed on the back cover.

Table of contents

GENERAL 3

Scope of the Manual 3

Valve Markings 3

Safety Precautions 3

INTRODUCTION 4

LIVE-LOADING

INSTALLATION 4

MAINTENANCE 5

PRODUCT ORDERING

INFORMATION 5

REPAIR KITS/

SPARE PARTS 5

IMO-317 EN - Issue 10/20202

3IMO-317 EN - Issue 10/2020

1. GENERAL

1.1 SCOPE OF THE MANUAL

This instruction manual contains important information regarding

the installation, operation and maintenance of live loaded packing

to the Jamesbury™ Series 815, F815, 818, F818, 830, F830,

838, F838, 860, F860, 868, and F868 Wafer-Sphere™ High

Performance Buttery Valves. See Table 1 for Valve Model. Please

read these instructions carefully and save them for future reference.

WARNING:

AS THE USE OF THE VALVE IS APPLICATION SPECIFIC,

A NUMBER OF FACTORS SHOULD BE TAKEN INTO

ACCOUNT WHEN SELECTING A VALVE FOR A

GIVEN APPLICATION. THEREFORE, SOME OF THE

SITUATIONS IN WHICH THE VALVES ARE USED ARE

OUTSIDE THE SCOPE OF THIS MANUAL.

IF YOU HAVE ANY QUESTIONS CONCERNING THE

USE, APPLICATION OR COMPATIBILITY OF THE VALVE

WITH THE INTENDED SERVICE, CONTACT NELES FOR

MORE INFORMATION.

WARNING:

SAFETY FIRST! FOR YOUR OWN SAFETY, ASK THE

FOLLOWING QUESTIONS BEFORE REMOVING

THE VALVE FROM THE LINE, AND BEFORE ANY

DISASSEMBLY.

1. WHAT’S IN THE LINE? BE SURE YOU KNOW

WHAT FLUID IS IN THE LINE. IF THERE IS ANY

DOUBT, DOUBLE-CHECK WITH THE PROPER

SUPERVISOR.

2. ARE YOU PROTECTED? WEAR ANY

PROTECTIVE CLOTHING AND EQUIPMENT

NORMALLY REQUIRED TO AVOID INJURY

FROM THE PARTICULAR FLUID IN THE LINE.

3. IS THE LINE DEPRESSURIZED?

DEPRESSURIZE THE LINE AND DRAIN THE

SYSTEM FLUID. THE WAFER-SPHERE™

BUTTERFLY VALVE OFFSET SHAFT CREATES

GREATER DISC AREA ON ONE SIDE OF

THE SHAFT. THIS MEANS THAT A WAFER-

SPHERE™ BUTTERFLY VALVE TENDS TO

OPEN WHEN PRESSURIZED ON THE INSERT

SIDE WITHOUT A HANDLE OR AN ACTUATOR

ON THE VALVE.

4. IS THE VALVE CLOSED? BEFORE YOU

INSTALL A WAFER-SPHERE™ BUTTERFLY

VALVE IN, OR REMOVE IT FROM THE LINE,

FULLY CLOSE THE VALVE. THE WAFER-

SPHERE™ BUTTERFLY VALVE MUST BE

REMOVED FROM THE LINE IN THE CLOSED

POSITION TO PREVENT MECHANICAL

DAMAGE TO THE DISC SEALING EDGE. THE

BLADE DRIVE FLATS ON TOP OF THE SHAFT

WILL INDICATE THE POSITION OF THE DISC

(SEE FIGURES 3 AND 4).

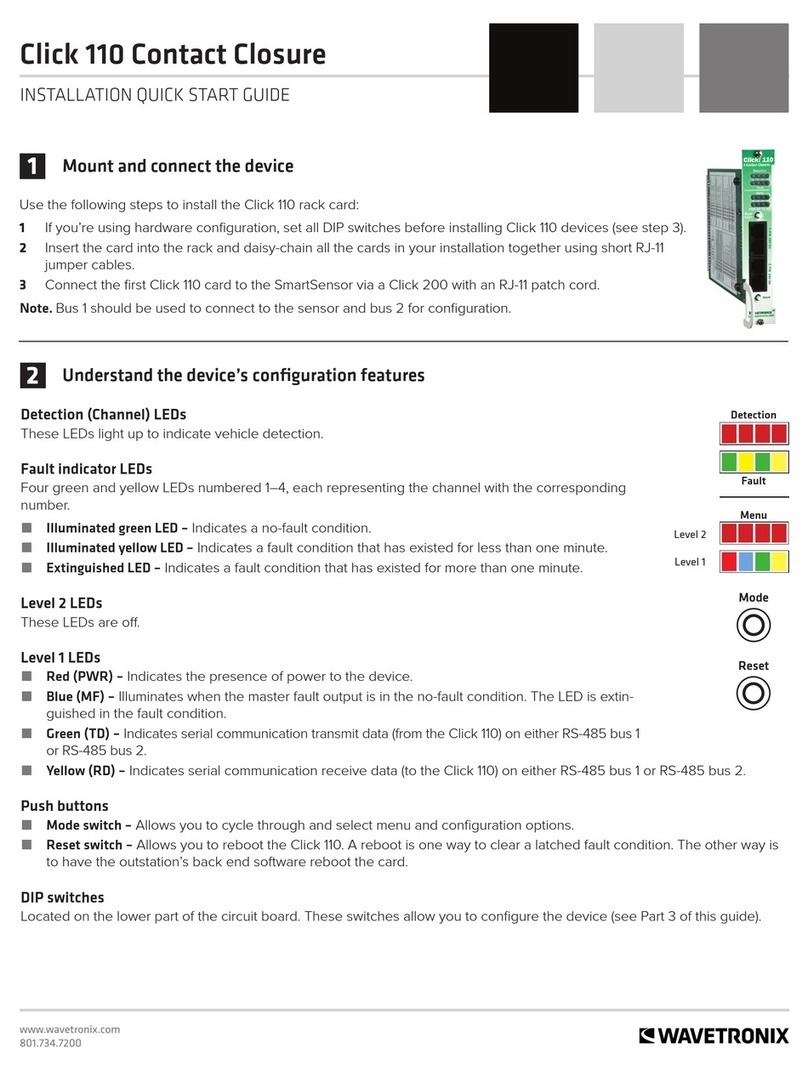

1.2 VALVE MARKINGS

The valve has an identication plate attached to the valve bonnet

(see Figure 1).

Figure 1. IDENTIFICATION PLATE

Identication plate markings:

1. Size

2. Valve catalog code

3. Model

4. Pressure

5. Body Material

6. Seat Material

7. Disc Material

8. Shaft Material

9. Maximum/minimum shut-off pressure/temperature

10. Assembly date

1.3 SAFETY PRECAUTIONS

WARNING:

DO NOT EXCEED THE VALVE PERFORMANCE

LIMITATIONS!

EXCEEDING THE PRESSURE OR TEMPERATURE

LIMITATIONS MARKED ON THE VALVE IDENTIFICATION

PLATE MAY CAUSE DAMAGE AND LEAD TO

UNCONTROLLED PRESSURE RELEASE. DAMAGE OR

PERSONAL INJURY MAY RESULT.

WARNING:

SEAT AND BODY RATINGS!

THE PRACTICAL AND SAFE USE OF THIS PRODUCT

IS DETERMINED BY BOTH THE MAXIMUM/MINIMUM

SHUTOFF RATINGS LISTED ON THE IDENTIFICATION

PLATE. THE RATINGS ARE DEPENDENT ON VALVE

TYPE AND SIZE, MATERIALS, AND TEMPER ATURE. DO

NOT EXCEED THESE RATINGS!

IMO-317 EN - Issue 10/20204

WARNING:

BEWARE OF THE DISC MOVEMENT!

KEEP HANDS, OTHER PARTS OF THE BODY, TOOLS

AND OTHER OBJECTS OUT OF THE OPEN FLOW

PORT. LEAVE NO FOREIGN OBJECTS INSIDE THE

PIPELINE. WHEN THE VALVE IS ACTUATED, THE DISC

FUNCTIONS AS A CUTTING DEVICE. DISCONNECT ANY

PNEUMATIC SUPPLY LINES, ANY ELECTRICAL POWER

SOURCES AND MAKE SURE SPRINGS IN SPRING-

RETURN ACTUATORS ARE IN THE FULL EXTENDED/

RELAXED STATE BEFORE PERFORMING ANY VALVE

MAINTENANCE. FAILURE TO DO THIS MAY RESULT IN

DAMAGE OR PERSONAL INJURY!

WARNING:

WHEN HANDLING THE VALVE OR VALVE/ACTUATOR

ASSEMBLY, TAKE ITS WEIGHT INTO ACCOUNT!

FOLLOW THE LIFTING METHODS SHOWN IN FIGURE 2.

Figure 2. LIFTING THE VALVE

2. INTRODUCTION

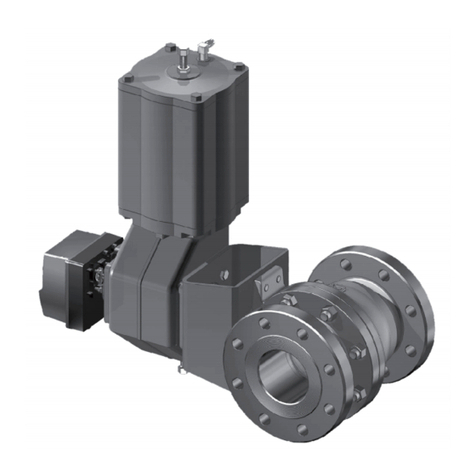

Wafer-Sphere™ High Performance Buttery Valve live-loaded

packing conversion kits are designed to decrease the need for

packing adjustment and to meet evolving emissions standards. Kits

include disc springs, washers, housings, replacement locknuts and

a compression ring or plate. Other soft parts, including packing and

seats are available separately.

Please pay close attention to the following instructions when installing

live-loaded packing conversion kits in your valves.

Valve shown in

Open Position

Figure 3. STANDARD VALVE

Valve shown in

Open Position

Figure 4. VALVE WITH CONVERSION KIT

3. LIVE-LOADING

INSTALL ATION

1. Remove handle or actuator coupling.

2. Remove locknuts (15). Remove the compression plate (10).

(The studs (14) do not have to be removed.)

3. Remove C-shaped retainer ring (47) from the shaft. 14” (DN

350) and larger valves do not have a retaining ring.

4. Remove the compression ring (9). On some valves, the

compression ring is attached to the compression plate.

Retain compression

plate and retaining

ring for reassembly

of conversion kit.

Remove and

discard nuts

and

compression

ring.

47

10

15

14

9

Replace existing hex nuts with

new hex jam nuts supplied in kit.

(See Item 7 in LIVE-LOADING

INSTALLATION Section.)

1

Replace existing

compression ring

with new shorter live

load compression

ring supplied in kit.

5

10

3

4

2

6

Figure 5A. STANDARD VALVE Figure 5B. VALVE WITH CONVERSION KIT

5IMO-317 EN - Issue 10/2020

NOTE: If new packing is required refer to the SHAFT SEAL

REPLACEMENT Section of IMO-302, 303, 308 or 322.

IMO-302 Series 860 (14”-24”) Model A

IMO-303 Series 830 (18”-48”) Model A

IMO-308 Series 815 & 830 (2-1/2” - 24”) Model C

IMO-322 Series 860 (3”-12”) Model C

5. Install new compression ring (5) (shorter than the one

just removed), and replace the retainer ring (47) and the

compression plate (10).

6. Install live-loaded kit as shown in (Figure 6). Note spring

stacking sequence.

NOTE: If the compression plate sits too high to install the live-

loading kit it may be necessary to precompress the shaft seals.

In that case, remove the live-loading kit and install the locknuts

(15). Tighten the locknuts down onto the compression plate to

accomplish the precompression. Remove the locknuts and install

the live-loading kit.

7. Apply thread lubricant to the threads and face of the locknuts

(1). Install and alternately tighten the locknuts (1) in equal

amounts of rotation (1/4 turn max.), until the top of the flat

washer (2) is flush with the top of housing (4) as shown in

(Figure 7).

NOTE: Do not over-tighten or unequally tighten the locknuts, as this

may damage the compression plate, and/or shaft seals, as well as

reduce the cycle life of the shaft seal.

4. MAINTENANCE

Good operating procedure requires periodic observation to ensure

that the valve is functioning well. The frequency will depend on the

application. Routine maintenance consists of adjusting the packing

hex nuts (1) periodically to compensate for shaft seal deection.

When necessary, adjustment of the packing hex nuts shall consist

of alternately tightening in 1/4 turn maximum increments until the at

washer (2) is ush with the top of the housing (4).

NOTE: Do not continue to tighten packing hex nuts (1). If packing

does not immediately react to adjustment, cycle valve to reset and

run-in the packing.

Overhaul maintenance consists of replacing seats and seals. A

standard service kit consisting of these parts may be obtained

through your Neles Distributor or representative.

5. PRODUCT ORDERING

INFORMATION

1. Live-load conversion kits for Wafer-Sphere™ valves can

be obtained through your authorized Neles Distributor or

representative by requesting the appropriate kit from (Table 1).

2. Individual parts from the live-loaded conversion kit parts can

also be ordered through your Neles authorized Distributor or

representative.

6. REPAIR KITS/SPARE

PARTS

For further information on spare parts and service or assistance visit

our website at www.neles.com.

IMO-317 EN - Issue 10/20206

Subsequent Springs to be stacked in

series as shown, quantities vary

depending on kit #.

(See Note 2 under Table 1.)

Install Lower

Spring as shown,

all sizes.

Body Stud

(See Item 7 under

LIVE-LOADED

INSTALLATION

Section.

Figure 6. DISC SPRING STACK ASSEMBLY

To obtain proper load,

tighten down on nut until

top of at washer is even

with top of housing.

4

2

Figure 7. DISC SPRING STACK DETAIL SHOWN INSTALLED

Table 1

Wafer-Sphere Live-Loaded Packing Conversion Kits

Type 815 Model Type 830 Model Type 860 Model Type F815 Model Type F830 Model Type F830 Model Type F860 Model

2-1/2" (DN 65) RKW-510 (C) RKW-510 (C) N/A RKW-742 (C) RKW-742 (C) N/A N/A

3' (DN 80) RKW-510 (C) RKW-510 (C) RKW-510 (C) RKW-742 (C) RKW-742 (C) N/A RKW-742 (C)

4' (DN 100) RKW-510 (C) RKW-510 (C) RKW-512 (C) RKW-742 (C) RKW-742 (C) N/A RKW-744 (C)

5" (DN 125) RKW-510 (C) RKW-510 (C) N/A RKW-742 (C) RKW-742 (C) N/A N/A

6" (DN 150) RKW-511 (C) RKW-512 (C) RKW-513 (C) RKW-743 (C) RKW-744 (C) RKW-793 (A) RKW-745 (C)

8" (DN 200) RKW-512 (C) RKW-513 (C) RKW-515 (C) RKW-744 (C) RKW-745 (C) RKW-794 (A) RKW-747 (C)

10" (DN 250) RKW-513 (C) RKW-514 (C) RKW-680 (C) RKW-745 (C) RKW-746 (C) RKW-795 (A) RKW-748 (C)

12" (DN 300) RKW-514 (C) RKW-515 (C) RKW-681 (C) RKW-746 (C) RKW-747 (C) RKW-796 (A) RKW-749 (C)

14" (DN 350) RKW-515 (C) RKW-753 (C) RKW-747 (C) RKW-754 (C) RKW-850 (A)

16" (DN 400) RKW-680 (C) RKW-681 (C) RKW-748 (C) RKW-749 (C)

18" (DN 450) RKW-753 (C) RKW-682 (C) RKW-754 (C) RKW-750 (C)

20" (DN 500) RKW-681 (C) RKW-683 (C) RKW-749 (C) RKW-751 (C)

24" (DN 600) RKW-682 (C) RKW-684 (C) RKW-750 (C) RKW-752 (C)

30" (DN 750) RKW-683 (C) RKW-774 (C) RKW-751 (C) RKW-776 (C)

36" (DN 900) RKW-684 (C) RKW-752 (C)

Notes:

1. Apply a thread lubricant to studs prior to installing hex jam nuts supplied in kits to prevent galling.

2. Spring stacks in each housing contain an odd number of disc springs. Refer to appropriate kit number for specific quantities. Springs must be stacked as shown in (Figure 6).

PARTS LIST QUANTITY

ITEM PART NAME 2-1/2” -6” 815/F815

2-1/2" -5" 830/F830

3" 860/F860

8" -14" 815/F815

6" -12" 830/F830

4" -8" 860/F860"

16" -24" 815/F815

14" -18" 830/F830

10" -12" 860/F860

30" -36" 815/F815

20" -24" 830/F830"

30" 830/F830

1 Hex Jam Nut 2 2 - - -

2 Flat Washer 2 2 2 2 2

3 *Disc Spring 18 14 6 10 14

4 Spring Housing 2 2 2 2 2

5Comptession Ring 1 1 1 1 1

6Tag 1 1 1 1 1

* The conversion kits used on the Fire-Tite™ valves are supplied with Inconel® disc springs.

7IMO-317 EN - Issue 10/2020

IMO-317 EN - 10/2020

Neles

Vanha Porvoontie 22

9, 01380 Vantaa, Finland.

Te

l. +358 10 417 5000.

neles.co

m

Subject to change without prior notice. Neles, Jamesbury and Easyow by Neles, and certain other

trademarks, are either registered trademarks or trademarks of Neles Corporation or its subsidiaries or

aliates in the United States and/or in other countries. For more information www.neles.com/trademarks

This manual suits for next models

12

Table of contents

Other Neles Control Unit manuals

Neles

Neles R1L Titanium Series Operating and maintenance manual

Neles

Neles PB2 Series Operating and maintenance manual

Neles

Neles XG Series Operating and maintenance manual

Neles

Neles Metso T2 Series Operating and maintenance manual

Neles

Neles JAMESBURY CLINCHER 2000 Series Operating and maintenance manual

Neles

Neles Easyflow J7 Series Operating and maintenance manual