Bandit7

MODEL SG-40 SAFETY PROCEDURES

SAFETY PROCEDURES

YOUR SAFETY IS VERY IMPORTANT TO US!

Before starting the machine, take a minute to

check a few things. The machine should be in an

area restricted from people passing by. This area

around the machine must be free of all objects that

can obstruct your movement when working with the

machine. The machine should be checked for loose

tools or foreign objects. All tools not in use should

be secured in a tool box.

Operators must at all times be located within easy

reachofallcontrolandshut-odeviceswhentheunit

is running. They must be attentive and prepared to

activate the devices.

Torn or loose clothing is more likely to get caught

in moving machinery parts. Keep such items as long

hair, shirt sleeves, and shirt tails properly contained.

Avoid wearing necklaces, rings, watches, and

especially neckties while operating this machinery.

This machine is equipped with safety decals,

guards and designs for your protection.

There must be at least two qualified and

trained operators at the work site. They must be

positioned in safe working locations, following safety

procedures and instructions, and aware of each

others whereabouts. There must, also, be at least

two people on site during maintenance and service

procedures in case an accident should occur.

This equipment is intended for use by adults

who have been properly trained and are physically

capable of operating the machine safely. Never

allow minors to operate this machine. Never operate

anymachinewhileundertheinuenceofdrugsor

alcohol. Never operate equipment that is in need of

repair or adjustment. Keep children, bystanders and

animals clear of working area.

Accidents are typically caused by making

mistakes. The operator does not read the manual,

overlooks safety decals, or fails to use lockouts

provided for their safety. This occurs after the

operator has become familiar with the machine.

The operator is very cautious in the initial start up

and operation because they do not understand the

machine.

Before operating the machine, you must have all

potential operators read and follow manuals and

decals, watch the video and follow the guidelines.

Read and follow all the instructions in this

manual thoroughly. Your safety is dependent on

your knowledge of how to operate and maintain this

machine. You may obtain additional copies of this

manual from your Bandit Dealer.

Always be cautious and careful when operating

your equipment.

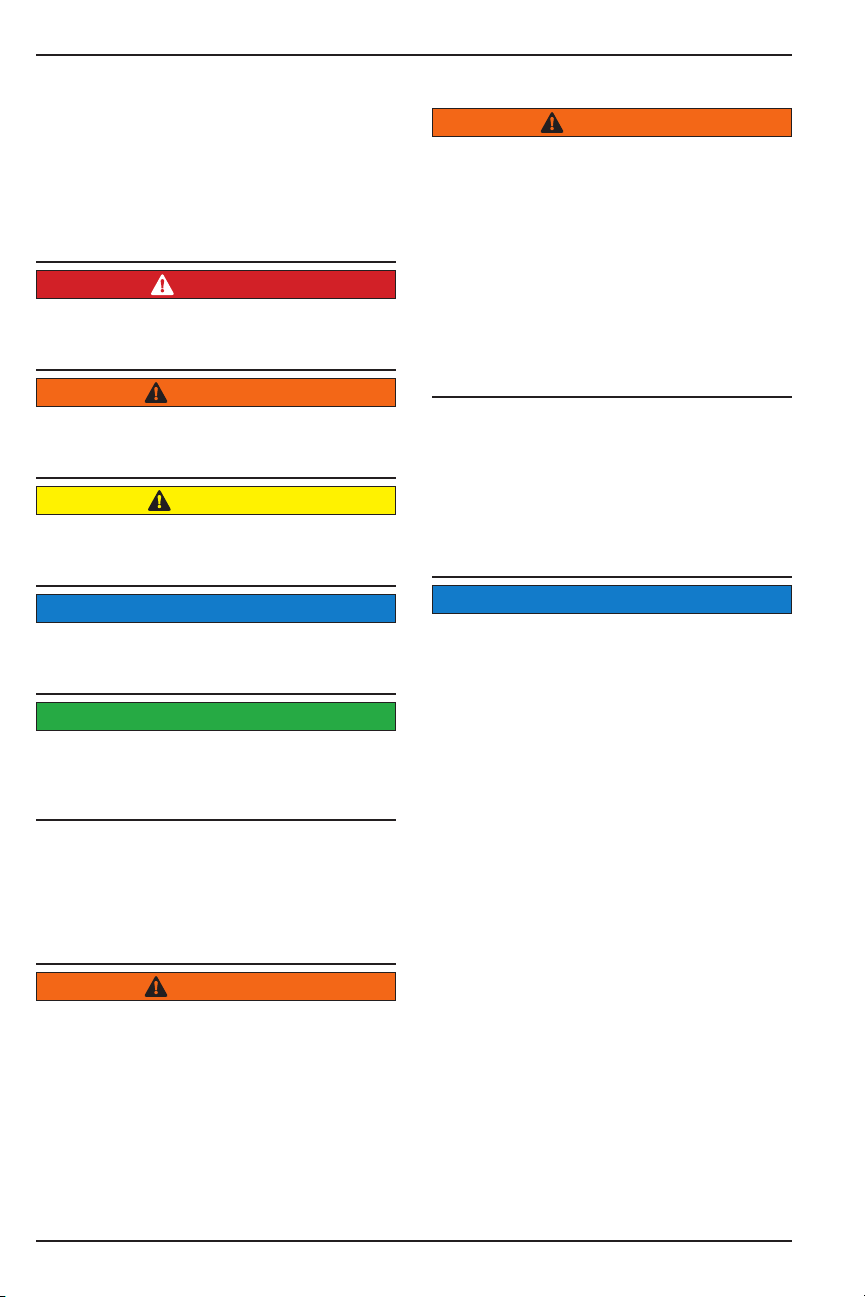

DANGER

NOTICE

Wear all personal protection equipment (PPE)

and follow all safety standards per ANSI and OSHA

instructions. Examples of equipment: hard hat,

face shield, safety glasses, gloves, ear protection,

high visibility vest, and steel toe boots. Do not wear

gauntletorsecuredtgloves.Always keepafully

charged re extinguisher with the machine while

operating or servicing the machine. Failure to do

this will cause severe injury or death.

WARNING

DANGER

Never sit, stand, lay, climb or ride anywhere on this

machine while it is running, operating, or in transit.

You will be injured.

Do not operate this machine indoors. Exhaust

fumes can be fatal.

Never refuel while the machine is running. Never

refuel in the shop or building. Always refuel in a well

ventilatedarea,awayfromsparksoropenames.

Do not smoke while refueling. Extinguish all smoking

materials. Wipe up all spilled fuel before restarting

the engine.

Do not start the engine with the clutch or

cutter wheel engaged. Any debris may become a

dangerous projectile. Contact with the rotating cutter

wheel will result in serious injury or death.

Avoid moving parts. Keep hands, feet, and clothing

away from power driven parts. Keep all guards and

shields in place and properly secured. Contact with

moving parts will result in severe injury or death.

Keep hands clear of all pinch points. Failure to do

this will result in serious injury or death.

Do not go near the rotating cutter wheel for any

reason. Do not go near the cutter wheel while the

engine is running or the cutter wheel is coasting to a

stop. Contact with a rotating cutter wheel will result

in severe injury or death.