PRODUCTMAINTENANCE

For optimum tubing life, keep tubing straight where it enters and exits

the pump.

Stop the drive when changing the tubing or its position in the rotor

mechanism (the rotor is partially exposed when the loading lever is in

the open position).

Keep the roller clean and dry in order to extend the using life of the

tube and rotor.

WARRANTY

The warranty period for this product is one year. If repair or adjust-

ment is necessary within the warranty period, the problem will be

corrected at no charge if it is not due to misuse or abuse on your part,

as determined by the manufacturer. Repair costs outside the war-

ranty period, or those resulting from product misuse or abuse, may

be invoiced to you.

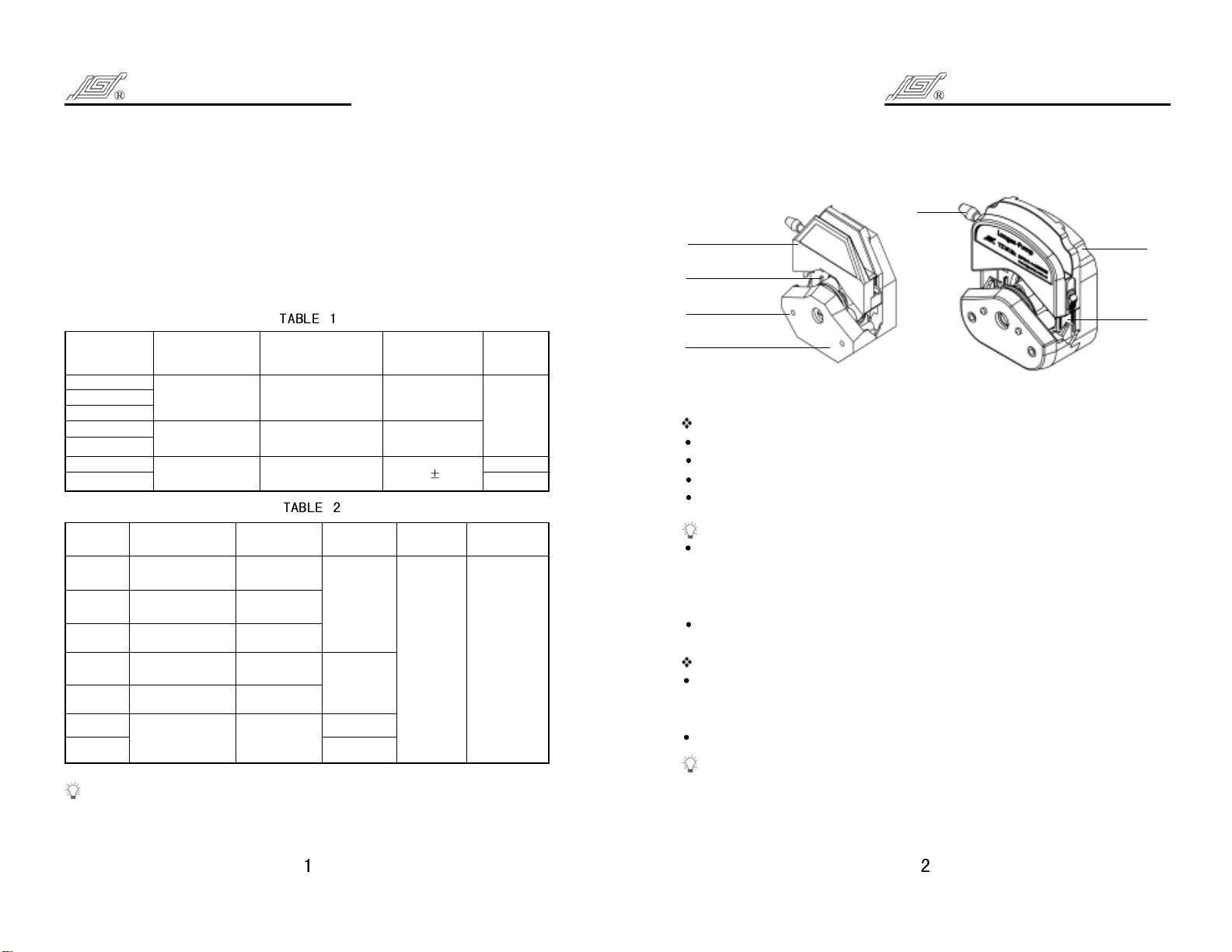

PUMP HEAD INSTALLATION

The pump head is connected to driver unit by three m5 screws. Insert

the three screws into the mounting holes, connect the pump head with

the driver unit end to end, then tighten the screws.

To connect two or more pump heads, longer screws are needed.

PROMPT:

Try your best to tighten the three screws in the same degree. Do not

over-tighten the screws to prevent the support block from deforming

and buzz.

LongerPumpTM YZ Series

OCCLUSION ADJUSTMENT

Usually, the occlusion has been adjusted according to standard wall

thickness tubing.

If the wall thickness of tubing is not standard, you can adjust the

occlusion as follows: first load the tubing, and place the inlet of the

tubing into water. Then loose the locknut of the fine-tune assembly,

and turn the screw with an inner hexagon spanner, till there are ex-

actly no blebs when blowing from the outlet. At last, tighten the locknut.

If there are still blebs after turning the screw to end clockwise, it

suggests that the wall thickness of the tubing is too thin and beyond

the applicable range.

TUBE LOADING

Rotate lever to left to open pump head, load tubing.

Rotate lever to right to close pump head.

Tubing is retained automatically by tubing clamps.

YZ35,YZ35-13 pump head direction for use

Fine-Tune

Assembly

Mounting

Holes

Compression

Block

Lever

Tubing

Clamp

Base

Rotor

Support

Block

PUMP HEAD APPLICABLE TUBING TUBING WALL

THICKNESS

YZ35 73#82#3.5 0.3(mm)

LongerPumpTM YZ Series

Fine-Tune

Assembly