page 10

EXTENDED PARAMETER SET

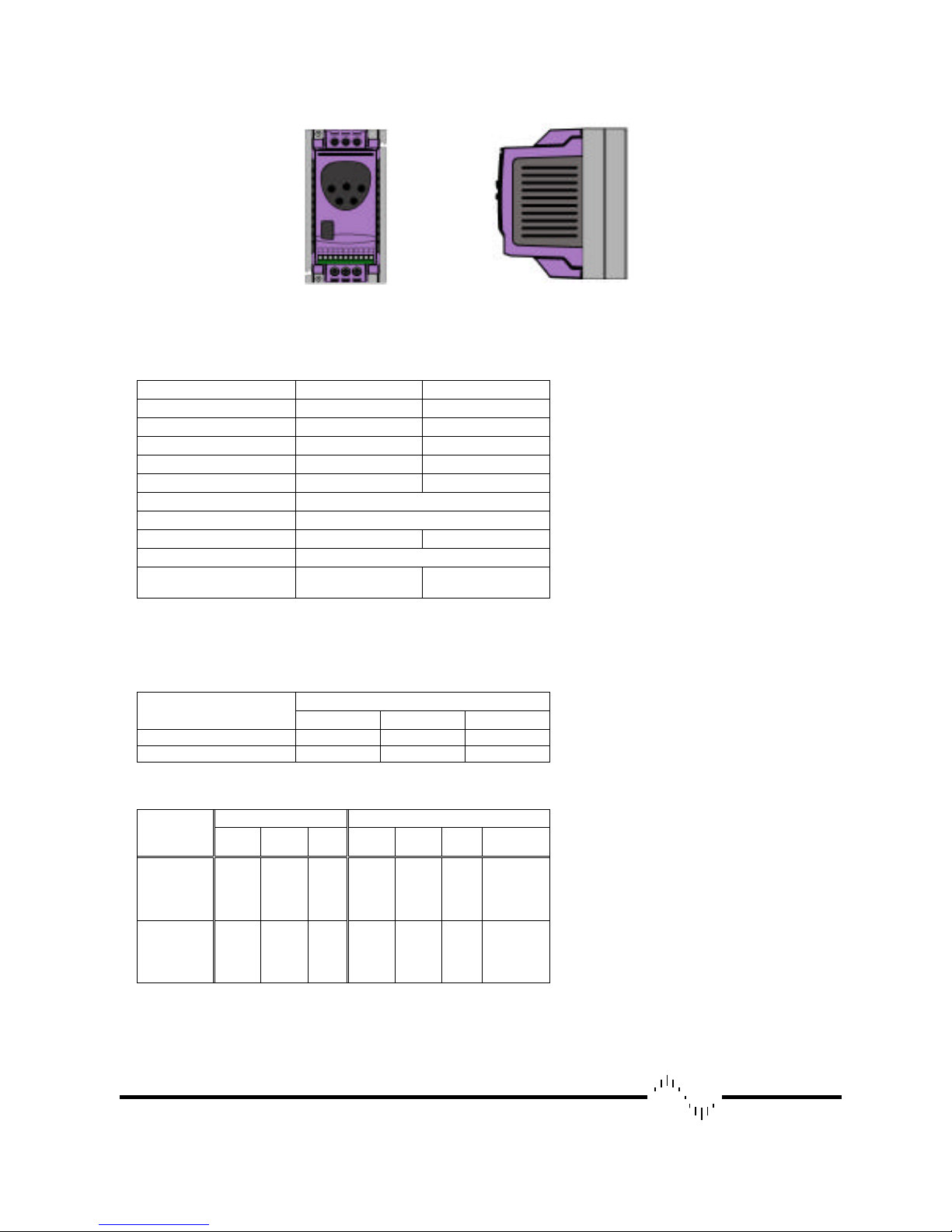

Par. Description Range Default Explanations Set to

P-15 Motor rated voltage 115V product: 40V to 150V

230V product: 40V to 250V 115V for 115V

230V for 230V When P-15 is non-zero, the applied motor voltage is controlled and scaled so that

the specified voltage is achieved at rated freq (P-09)

P-16 Analog input format (V / mA) Voltage: 0-10V, 10-0V

Current: 4-20mA, 0-20mA, 20-4mA 0-10V Analog input format (on terminal 6).

P-17 Switching frequency 8, 16, 32 kHz 16 kHz Effective power stage switching frequency. Improvements in acoustic noise and

output current waveform occur with increasing switching frequency at the expense

of increased losses within the drive

P-18 Relay output function

0: Drive enabled

1: Drive healthy (not tripped)

2: Motor at set speed

3: Motor speed > zero

4: Motor at max speed (P-01)

5: Motor current overload

1

Relay output function. Contacts closed if selected condition is true.

When P-18= 3, (zero speed), the relay contacts close when the output frequency is

greater than 5% of base frequency.

The drive is in overload when the motor current exceeds P-08

P-19 Digital inputs function select 0 to 5, See digital input table 0 Defines function of digital inputs (see also P-16 and Digital Inputs table)

P-20 Preset speed 1 -P-02 (min) to P-01 (max) 50hz/rpm Defines Speed Preset1

P-21 Preset speed 2 -P-02 (min) to P-01 (max) 0 Hz/rpm Defines Speed Preset 2

P-22 Preset speed 3 -P-02 (min) to P-01 (max) 0 Hz/rpm Defines Speed Preset 3

P-23 Preset speed 4 -P-02 (min) to P-01 (max) 0 Hz/rpm Defines Speed Preset 4

P-24 Reserved

P-25 Analog output function (A) 0:Motor Speed 1:Motor current

(D) 2:Drive enabled 3: Set speed 0Analog output select. When P-25 = 0 then 10V = 100% of P-01, or if P-25 =1 then

10V = 200% of P-08.

P-25 = 2 or 3 gives a 10V digital output.

P-26 Reserved

P-27 Skip freq / speed P-02 (min) to P-01 (max) 0 (inactive) Centre point for skip frequency band. The skip frequency band defined by P-27, P-

28 is mirrored around zero for negative speeds.

P-28 Skip freq / speed band 0 to100% of rated speed/freq. P-09 0 Hz / rpm Width of skip frequency band, the center of which is defined by P-27.

P-29 Reserved

P-30 Drive start mode

Edge-r: Close Digital input 1 after

power up to start drive

Auto-0: drive runs whenever Digital

input 1 closed.

Auto-1..4: as Auto-0, except 1..4

Attempts to restart after a

trip

Auto-0

When set to Edge-r, if drive is powered up with Digital Input 1 closed (enabled),

drive will not run. The switch must be opened & closed after power up or after a

clearing a trip for the drive to run.

When set to Auto-0, drive will run whenever digital input 1 is closed (if not tripped).

Auto-1..4 makes 1..4 attempts to automatically restart after a trip (25s between

attempts). If fault has cleared drive will restart. Drive must be powered down, reset

on the keypad or reset by re-enabling the drive to reset auto-reset counter.

When P-12 is set to 1 or 2, P-30 changes automatically to Edge-r.

P-31 Boost frequency 0 to 250Hz 50Hz Optidrive1ph start up frequency maintained during the startup boost period

P-32 Boost duration 0 to 25s 2s Time for which the startup boost period is maintained

P-33 Boost start voltage 0 to 100% 20% % of operational motor voltage applied at start of startup boost period. The applied

voltage is increased to the operational voltage at end of startup boost period.

P-34 Brake resistor enable 0: Disable

1: Enable with overload monitor

2: Enable without overload monitor 0Activates the internal braking transistor. When P-34 =1 the braking resistor is

protected by the drive against overload. When P-34 = 2, a thermal overload relay

must be used to protect the resistor and drive.

P-35 Analog input scaling factor 25% to 500% 84% Scales the analog input at control terminal 6 up or down, or the digital reference in

keypad (or Slave) mode up or down (see P-12).

P-36 Drive address (s-comms) 0 to 63 (0=disable) 1 Distinct drive address for serial comms. 0 = comms disabled

P-37 Access code definition 0 to 9999 101 Defines Extended Parameter Set access code, P-14

P-38 Parameter access lock

0: Parameters can be changed,

auto-saved on power down

1: Parameter changes not saved

on power down

2: Read-only. No changes allowed.

0 (write

access and

auto-save are

enabled)

Controls user access to parameters. WhenP-38 = 0, all parameters can be

changed and these changes will be stored automatically. When P-38 = 1, changes

may be made but these will not be stored when the Optidrive1ph powers down.

When P-38 = 2, parameters are locked and cannot be changed thus preventing

unauthorised access.

P-39 Hours run meter 0 to 99999 hours Read only Not affected by reset-to-default command

P-40 Software checksum 0000 to FFFF (hex) Read only Drive rating, drive type and software version codes