page 10page 10

page 10page 10

page 10

640 Mulcher (O)

800-00275

WARNINGWARNING

WARNINGWARNING

WARNING

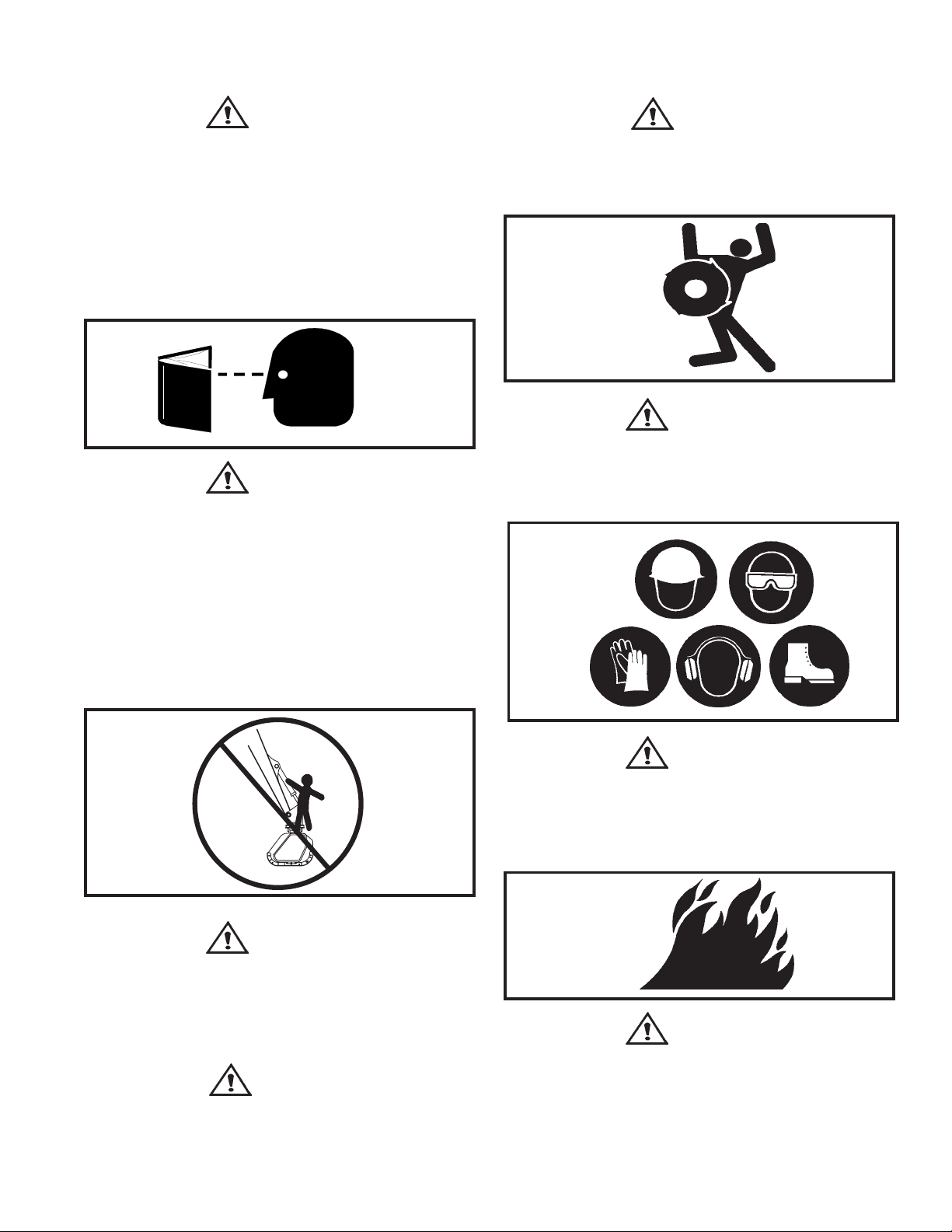

Do not operate or work on machine until you:Do not operate or work on machine until you:

Do not operate or work on machine until you:Do not operate or work on machine until you:

Do not operate or work on machine until you:

--

--

-Read and understand machine manualsRead and understand machine manuals

Read and understand machine manualsRead and understand machine manuals

Read and understand machine manuals

safety decals, employer work rules, andsafety decals, employer work rules, and

safety decals, employer work rules, andsafety decals, employer work rules, and

safety decals, employer work rules, and

applicable government regulations.applicable government regulations.

applicable government regulations.applicable government regulations.

applicable government regulations.

--

--

-Are trained and qualified in safe machineAre trained and qualified in safe machine

Are trained and qualified in safe machineAre trained and qualified in safe machine

Are trained and qualified in safe machine

operation and maintenance.operation and maintenance.

operation and maintenance.operation and maintenance.

operation and maintenance.

--

--

-Consult supervisor to explain any unclearConsult supervisor to explain any unclear

Consult supervisor to explain any unclearConsult supervisor to explain any unclear

Consult supervisor to explain any unclear

instructions and warnings.instructions and warnings.

instructions and warnings.instructions and warnings.

instructions and warnings.

--

--

-Contact Barko to replace lost manuals.Contact Barko to replace lost manuals.

Contact Barko to replace lost manuals.Contact Barko to replace lost manuals.

Contact Barko to replace lost manuals.

DANGERDANGER

DANGERDANGER

DANGER

Rotating mulcher blades will cause death orRotating mulcher blades will cause death or

Rotating mulcher blades will cause death orRotating mulcher blades will cause death or

Rotating mulcher blades will cause death or

severe injury. Do not start up mulcher until allsevere injury. Do not start up mulcher until all

severe injury. Do not start up mulcher until allsevere injury. Do not start up mulcher until all

severe injury. Do not start up mulcher until all

personnel are 300 feet from saw head. Shutpersonnel are 300 feet from saw head. Shut

personnel are 300 feet from saw head. Shutpersonnel are 300 feet from saw head. Shut

personnel are 300 feet from saw head. Shut

down mulcher when not in use.down mulcher when not in use.

down mulcher when not in use.down mulcher when not in use.

down mulcher when not in use.

WARNINGWARNING

WARNINGWARNING

WARNING

Failure to keep the engine shrouding area free ofFailure to keep the engine shrouding area free of

Failure to keep the engine shrouding area free ofFailure to keep the engine shrouding area free of

Failure to keep the engine shrouding area free of

flammable debris such as leaves, twigs, andflammable debris such as leaves, twigs, and

flammable debris such as leaves, twigs, andflammable debris such as leaves, twigs, and

flammable debris such as leaves, twigs, and

wood chips may cause an extreme fire hazard.wood chips may cause an extreme fire hazard.

wood chips may cause an extreme fire hazard.wood chips may cause an extreme fire hazard.

wood chips may cause an extreme fire hazard.

KEEP THIS AREA CLEAN. Keep a fireKEEP THIS AREA CLEAN. Keep a fire

KEEP THIS AREA CLEAN. Keep a fireKEEP THIS AREA CLEAN. Keep a fire

KEEP THIS AREA CLEAN. Keep a fire

extinguisher on machine.extinguisher on machine.

extinguisher on machine.extinguisher on machine.

extinguisher on machine.

WARNINGWARNING

WARNINGWARNING

WARNING

Before transporting:Before transporting:

Before transporting:Before transporting:

Before transporting:

-Lower and secure attachment to trailer bed.-Lower and secure attachment to trailer bed.

-Lower and secure attachment to trailer bed.-Lower and secure attachment to trailer bed.

-Lower and secure attachment to trailer bed.

-Shut down machine and apply parking brake.-Shut down machine and apply parking brake.

-Shut down machine and apply parking brake.-Shut down machine and apply parking brake.

-Shut down machine and apply parking brake.

-Install articulating lock pin to prevent-Install articulating lock pin to prevent

-Install articulating lock pin to prevent-Install articulating lock pin to prevent

-Install articulating lock pin to prevent

articulation.articulation.

articulation.articulation.

articulation.

-Secure machine to trailer bed.-Secure machine to trailer bed.

-Secure machine to trailer bed.-Secure machine to trailer bed.

-Secure machine to trailer bed.

-Cover exhaust pipe.-Cover exhaust pipe.

-Cover exhaust pipe.-Cover exhaust pipe.

-Cover exhaust pipe.

WARNINGWARNING

WARNINGWARNING

WARNING

Allow only operator on machine. Keep riders off.Allow only operator on machine. Keep riders off.

Allow only operator on machine. Keep riders off.Allow only operator on machine. Keep riders off.

Allow only operator on machine. Keep riders off.

Riders on machine are subject to injury such asRiders on machine are subject to injury such as

Riders on machine are subject to injury such asRiders on machine are subject to injury such as

Riders on machine are subject to injury such as

being struck by foreign objects and being thrownbeing struck by foreign objects and being thrown

being struck by foreign objects and being thrownbeing struck by foreign objects and being thrown

being struck by foreign objects and being thrown

off machine. Riders also obstruct operator'soff machine. Riders also obstruct operator's

off machine. Riders also obstruct operator'soff machine. Riders also obstruct operator's

off machine. Riders also obstruct operator's

view, resulting in machine being operated in anview, resulting in machine being operated in an

view, resulting in machine being operated in anview, resulting in machine being operated in an

view, resulting in machine being operated in an

unsafe manner.unsafe manner.

unsafe manner.unsafe manner.

unsafe manner.

Never use the attachment or any other part of theNever use the attachment or any other part of the

Never use the attachment or any other part of theNever use the attachment or any other part of the

Never use the attachment or any other part of the

machine as a work platform or personnel carrier.machine as a work platform or personnel carrier.

machine as a work platform or personnel carrier.machine as a work platform or personnel carrier.

machine as a work platform or personnel carrier.

Death or severe injury may result.Death or severe injury may result.

Death or severe injury may result.Death or severe injury may result.

Death or severe injury may result.

WARNINGWARNING

WARNINGWARNING

WARNING

Know how to put your machine in a zero energyKnow how to put your machine in a zero energy

Know how to put your machine in a zero energyKnow how to put your machine in a zero energy

Know how to put your machine in a zero energy

state for purposes of inspection, maintenance orstate for purposes of inspection, maintenance or

state for purposes of inspection, maintenance orstate for purposes of inspection, maintenance or

state for purposes of inspection, maintenance or

repair.repair.

repair.repair.

repair.

WARNINGWARNING

WARNINGWARNING

WARNING

Be extra careful when traveling on a slope, overBe extra careful when traveling on a slope, over

Be extra careful when traveling on a slope, overBe extra careful when traveling on a slope, over

Be extra careful when traveling on a slope, over

rough ground, near ditches and in congestedrough ground, near ditches and in congested

rough ground, near ditches and in congestedrough ground, near ditches and in congested

rough ground, near ditches and in congested

areas. The danger of tipping is always present.areas. The danger of tipping is always present.

areas. The danger of tipping is always present.areas. The danger of tipping is always present.

areas. The danger of tipping is always present.

Know your machine's capabilities.Know your machine's capabilities.

Know your machine's capabilities.Know your machine's capabilities.

Know your machine's capabilities.

SAFETY SUMMARY CONTINUED...

WARNINGWARNING

WARNINGWARNING

WARNING

Wear required personal protective equipment atWear required personal protective equipment at

Wear required personal protective equipment atWear required personal protective equipment at

Wear required personal protective equipment at

all times to help prevent personal injury. Do notall times to help prevent personal injury. Do not

all times to help prevent personal injury. Do notall times to help prevent personal injury. Do not

all times to help prevent personal injury. Do not

wear loose fitting clothing or personal articles,wear loose fitting clothing or personal articles,

wear loose fitting clothing or personal articles,wear loose fitting clothing or personal articles,

wear loose fitting clothing or personal articles,

loose or uncovered long hair, or jewelry.loose or uncovered long hair, or jewelry.

loose or uncovered long hair, or jewelry.loose or uncovered long hair, or jewelry.

loose or uncovered long hair, or jewelry.