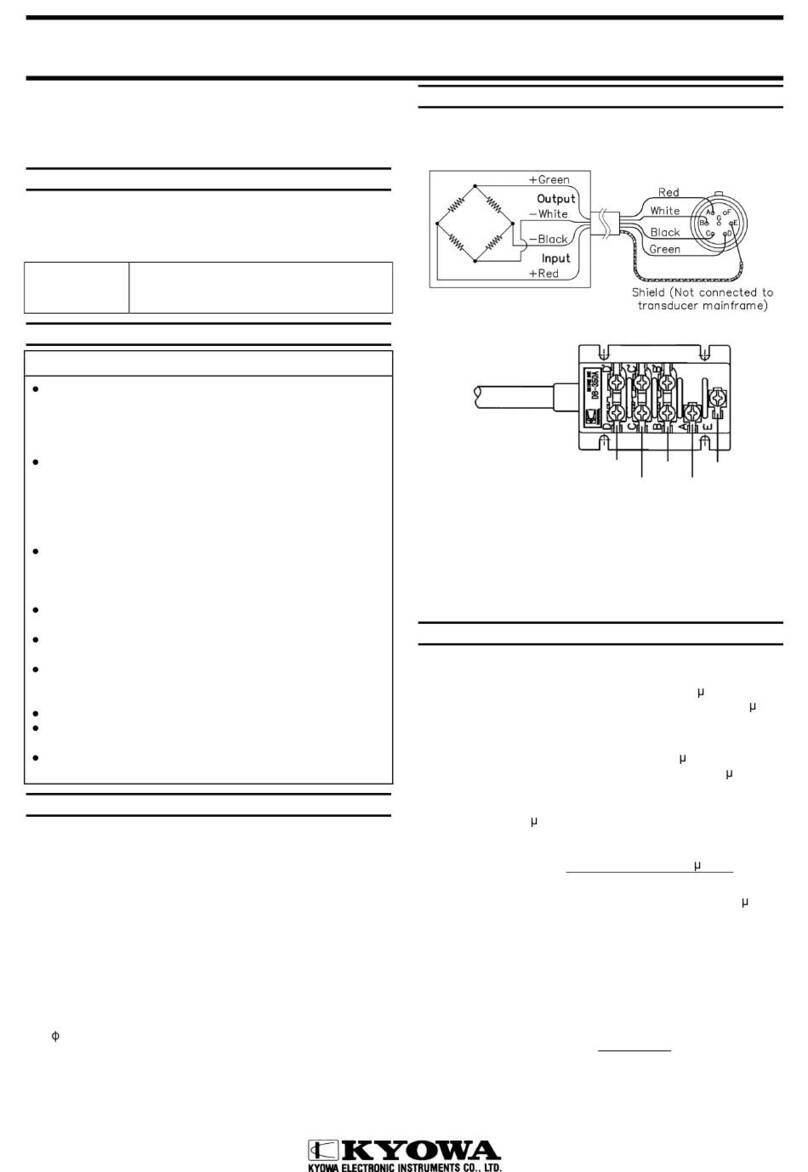

Barksdale UTA 2 User manual

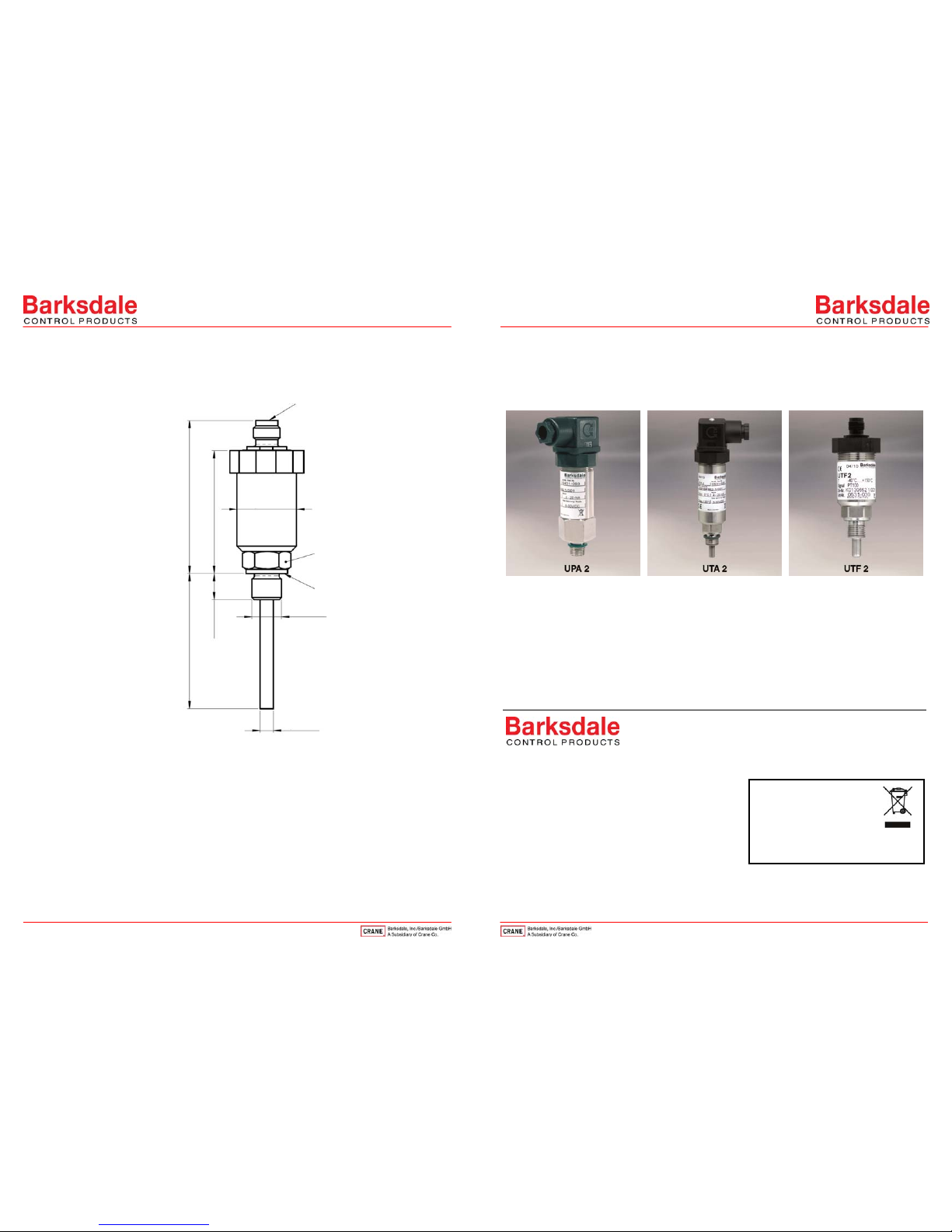

Dimensions in mm (inch) – Electronic temperature sensor UTF 2

Operating Instructions

Electronic Pressure and Temperature Transducers

UPA 2, UTA 2 and UTF 2

1Intended Applications ................................................................................................... 2

2Safety Instructions......................................................................................................... 2

3Standards ....................................................................................................................... 3

4Warranty/Guaranty......................................................................................................... 3

5Installation/Commissioning .......................................................................................... 3

6Maintenance/Cleaning ................................................................................................... 5

7Technical Data................................................................................................................ 5

Barksdale GmbH

Dorn-Assenheimer Straße 27

D-61203 Reichelsheim

Phone: +49 (6035) 949-0

Fax: +49 (6035) 949-111 and 949-113

Internet: www.barksdale.de

1

8

Art. no. 923-1910

Index: C, 15.08.2018

Specifications are subject to changes

without notice!

M12x1

A

B

ØG1/4"

L0

12 (0.47)

Ø6 (0.74)

56 (2.22)

70 (2.76)

Ø27 (1.06)

1 0B0B0B0BIntended Applications

The electronic pressure transducer UPA 2 serves for measuring a system pressure. The electronic

temperature transducer UTA 2 serves for measuring a system temperature. The pressure and

temperature sensors are equipped with analog outputs.

The temperature sensor UTF 2 provides the temperature value as PT100 signal.

DANGER

The electronic measuring devices must not be used for any other applications than those specified

in the instructions.

The temperatures must be within the specified ranges, the pressure values and the electrical rating

must not exceed the values specified.

Observe also the applicable national safety instructions for assembly, commissioning and

operation of the electronic measuring devices.

The electronic measuring devices are not designed to be used as the only safety relevant

elements according to PED 97/23/EC.

2 1B1B1B1BSafety Instructions

The safety instructions are intended to protect the user from dangerous situations and/or material

damage.

In the operating instructions the seriousness of the potential risk is designated by the following

signal words:

DANGER

Refers to imminent danger to men.

Nonobservance may result in fatal injuries.

WARNING

Refers to a recognizable danger.

Nonobservance may result in fatal injuries, and destroy the electronic measuring device or plant

parts.

CAUTION

Refers to a danger.

Nonobservance may result in light injuries and material damage to the electronic measuring device

and/or to the plant.

IMPORTANT

Refers to important information essential to the user.

Disposal

The electronic measuring device must be disposed of correctly in accordance with the

local regulations for electric/electronic equipment.

The electronic measuring devices must not be disposed of with the household garbage!

3 2B2B2B2BStandards

The standards applied during development, manufacture and configuration are listed in the CE

conformity and manufacturer's declaration.

4 3B3B3B3BWarranty/Guaranty

Warranty

Our scope of delivery and services is governed by the legal warranties and warranty periods.

Terms of guaranty

For the electronic pressure transducer UPA 2, the electronic temperature transducer UTA 2 and

the temperature sensor UTF 2 we grant a guarantee according to the legal regulations for

functioning and material in normal operating and maintenance conditions.

Loss of guaranty

The agreed guaranty period will expire in case of:

incorrect use,

incorrect installation or

incorrect handling or operation contrary to the provisions of these operating instructions.

No liability is assumed for any damage resulting therefrom, or any consequential damage.

5 4B4B4B4BInstallation/Commissioning

DANGER

Only install or remove the electronic measuring device when deenergized (electrically and

hydraulically/pneumatically).

Pressure connection and electrical connection must be carried out by trained or instructed

personnel according to state-of-the-art standards.

The electronic measuring devices may only be installed in systems in which the maximum

pressure Pmax or the maximum temperature Tmax is not exceeded (see type label).

CAUTION

Do not insert any objects into the pressure channel of the electronic pressure transducer!

The membrane on front-flush models must never be deformed!

3

2

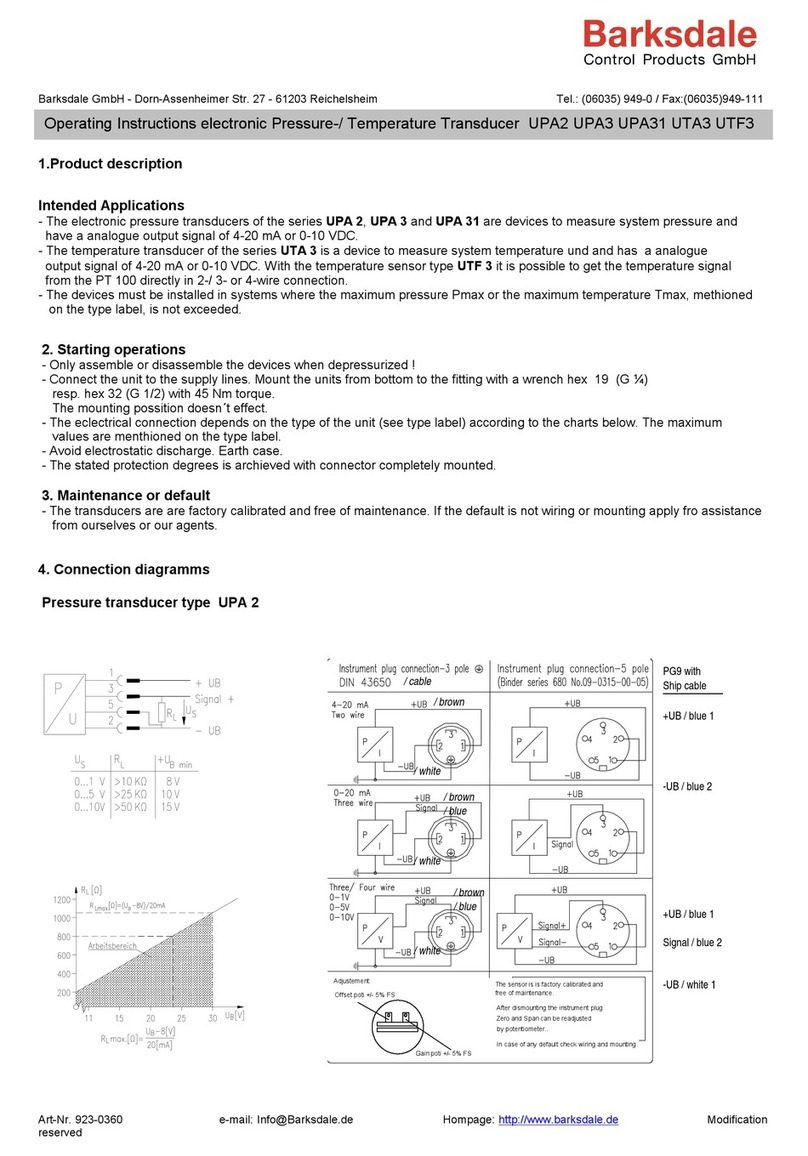

Connecting the electronic measuring devices

CAUTION

The permissible overpressure must not be exceeded, not even in case of pressure peaks!

Install protection elements (e. g. damping screw)

The electronic measuring devices must be mounted at the bottom fitting with a size 19 wrench

(G ¼) or size 32 (G ½) and tightened to a torque of 45 Nm. The installation position is arbitrary.

CAUTION

Avoid electrostatic discharges!

Ground the housing

Electrical connection of the individual models (see type label) must be carried out according to the

chart below. The maximum power supply values are stated on the type label.

UPA 2

UTA 2

Current output

4... 20 mA

(two-wire system)

Voltage output

0... 10 V DC

(three-wire system)

Connection Plug Cable GL cable M12 Plug Cable GL cable M12

Supply (+) 1 brown white 1 1 1 brown blue 1 1

Supply (-) 2 white blue 1 2 2 blue blue 2 3

Signal (+) --- 3 white white 1 2

Signal (-) --- ---

Connection chart for temperature sensor UTF 2

PT100 Plug M12 x 1, 4-pin

6 5B5B5B5BMaintenance/Cleaning

The electronic measuring devices are calibrated in the factory and require not maintenance.

If faults occur which cannot be remedied please contact our local representative closest to you.

7 6B6B6B6BTechnical Data

IMPORTANT

see type label

Dimensions in mm (inch) – Electronic pressure transducer UPA 2 (G1/4")

A Process connection G1/4 acc. to DIN ISO 228-1

B Profile seal acc. to DIN 3869

C Cable gland Pg 11, clamping range Ø 6…8 mm

5

4

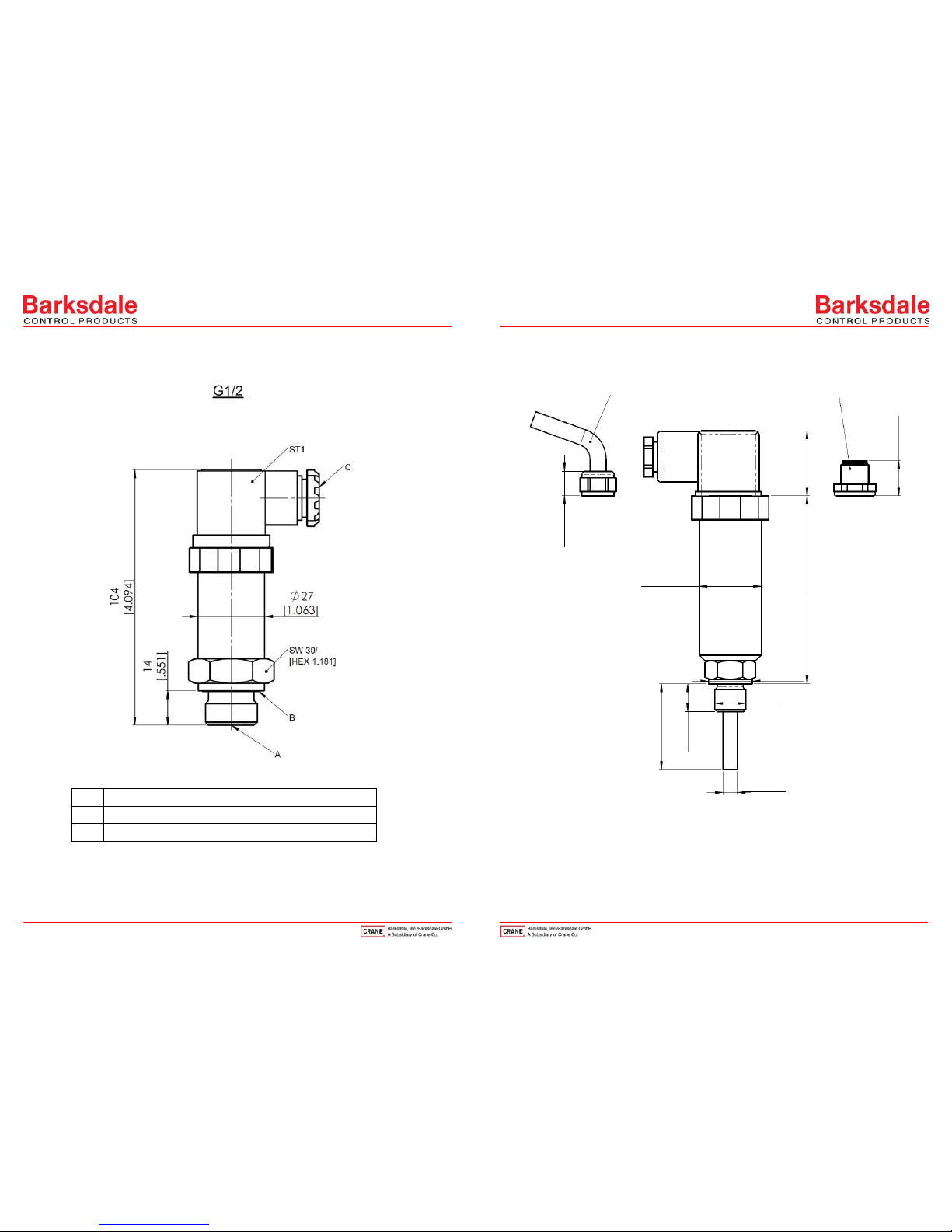

Dimensions in mm (inch) – Electronic pressure transducer UPA 2 (G1/2")

A Process connection G1/2 acc. to DIN ISO 228-1 flush at the front

B Profile seal acc. to DIN 3869

C Cable gland Pg 11, clamping range Ø 6…8 mm

Dimensions in mm (inch) – Electronic temperature transducer UTA 2

7

6

M12x1

~15 (0.59)

A

~28 (1.1)

~81.3 (3.20)

Ø18.9 (0.74)

G1/4"

L0

12 (0.47)

Ø6 (0.74)

11 (0.42)

Ø27 (1.06)

This manual suits for next models

2

Other Barksdale Transducer manuals

Popular Transducer manuals by other brands

Fishman

Fishman SBT-C installation guide

Rockford Fosgate

Rockford Fosgate IBeam IB-200 Installation & operation

GHM

GHM GREISINGER GMUD MP Series Mounting and operating manual

M-system

M-system LECA instruction manual

Novatech

Novatech Bitronics M660 user manual

SIAP+MICROS

SIAP+MICROS t027 TP200 User manual and maintenance