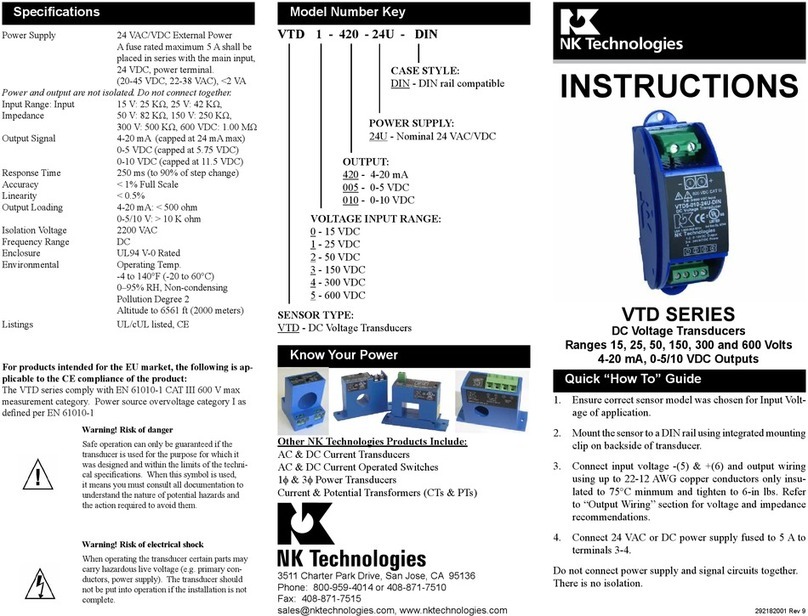

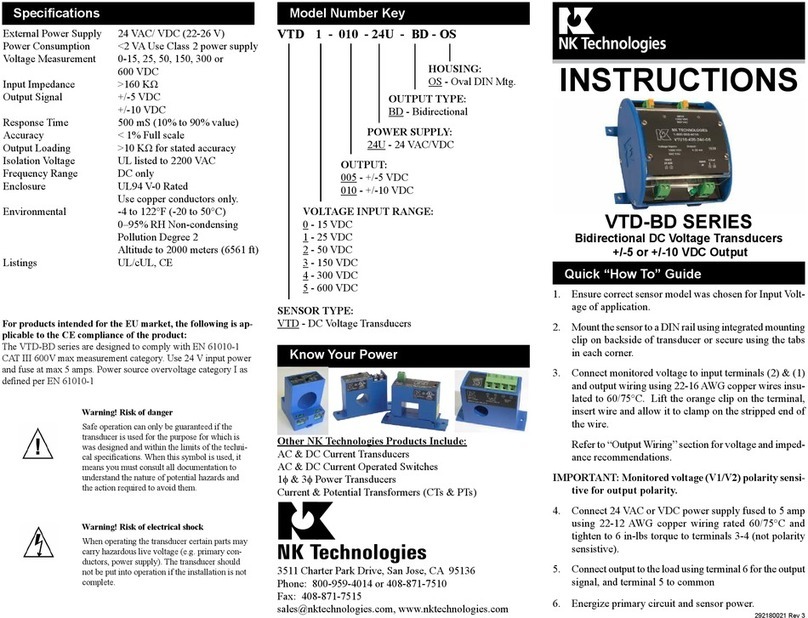

INSTRUCTIONS

1. Ensure correct sensor model was chosen for Moni-

tored Voltage of application.

2. Mount the sensor to a DIN rail using integrated

mounting clip on backside of transducer.

3. Connect monitored voltage (5) & (6) and output

wiring using 24-10AWG copper wires insulated to

75/90°. Refer to Specifications section for voltage

and impedance recommendations.

4. Connect 24VAC or DC power supply fused to 5 amp

to term. 3-4, 24-12 AWG copper. Use twisted pair

for CE compliance. Tighten all conenctions to 5-7

in/lbs torque.

Do not connect power and signal together.

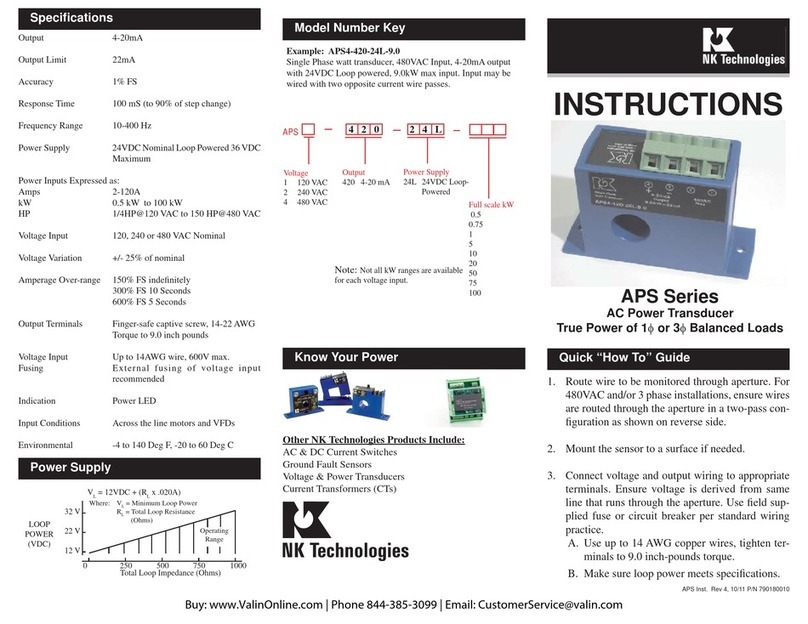

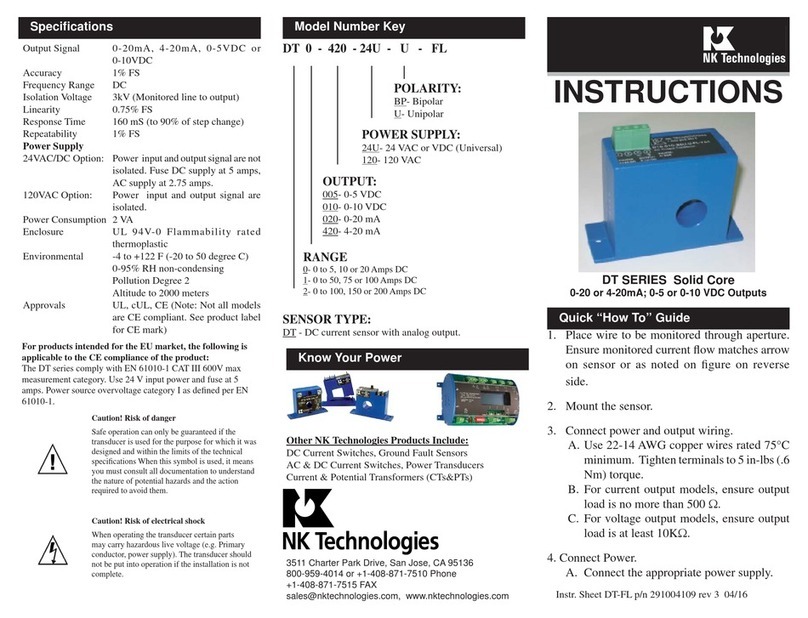

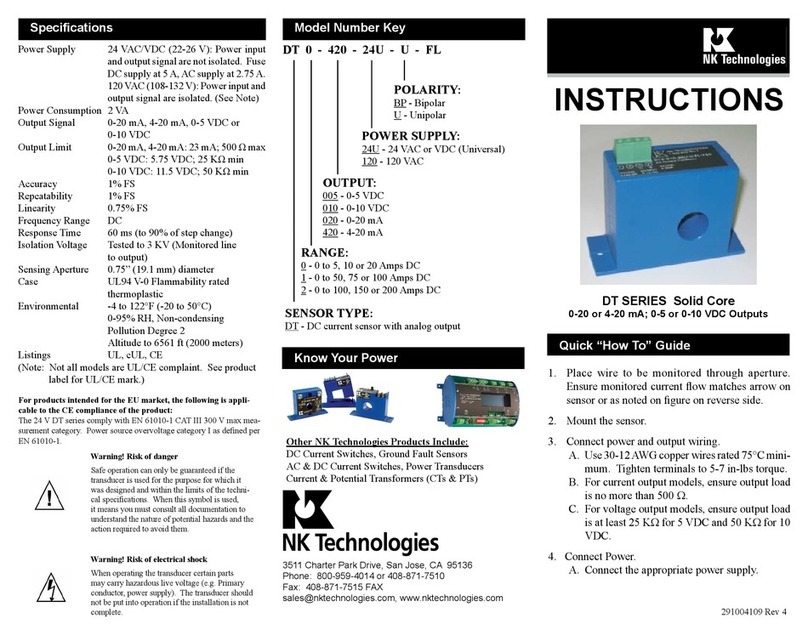

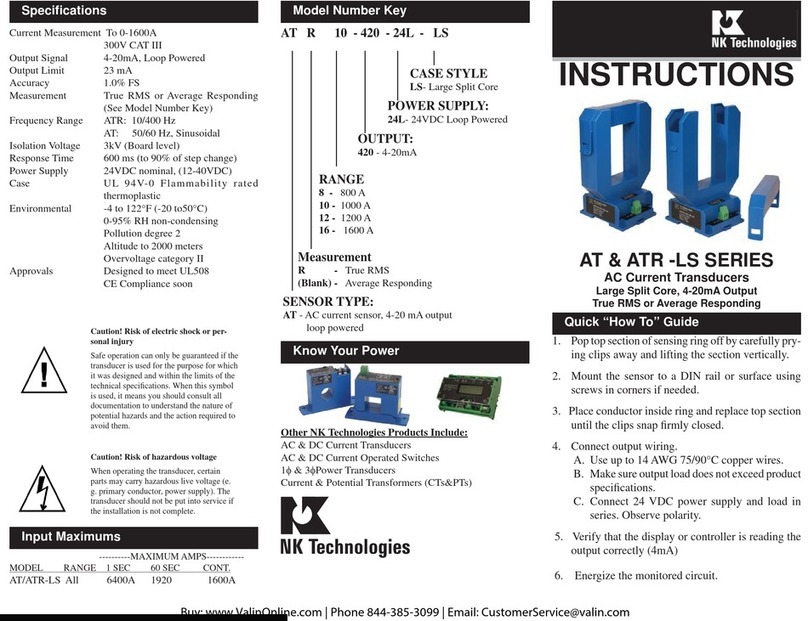

VTU SERIES

AC/DC Voltage Transducers

Ranges 15, 25, 50, 60, 120, 150,

240, 300, 400, 500 and 600 Volts

4-20mA, 0-5/10VDC Outputs

VTU A - 420 - 24U - DIN

OUTPUT:

420 - 4-20mA

005 - 0-5VDC

010 - 0-10VDC

MONITORED VOLTAGE RANGE:

A - 15V

B - 25V

C - 50V

D - 60V

E - 120V

F - 150V

G - 240V

H - 300V

I - 400V

J - 500V

K - 600V

SENSOR TYPE:

VTU - AC/DC Voltage Transducers

Model Number KeySpecifications

Quick “How To” Guide

CASE STYLE:

DIN - DIN rail compatible

POWER SUPPLY:

24U - Nominal 24 VAC/DC

3511 Charter Park Drive, San Jose, CA 95136

800-959-4014 or 408-871-7510 Phone

408-871-7515 FAX

[email protected],

www

.nktechnologies.com

VTU-DIN Instruction Sheet Rev 3 03/19 P/N 292180012 Know Your Power

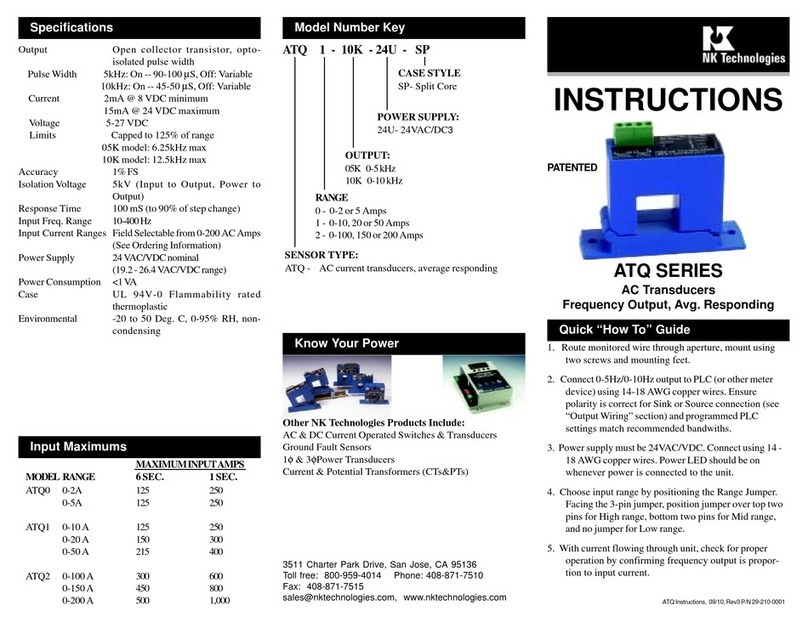

Other NK Technologies Products Include:

AC & DC Current Transducers

AC & DC Current Operated Switches

1φ& 3φ Power Transducers

Current & Potential Transformers (CTs & PTs)

Power Supply 24VAC/DC External Power

(22-26VDC), <2VA

(Note: Output and power supply

negatives are not isolated).

Use class 2 power supply

Voltage Measurement 15, 25, 50, 60, 120, 150, 240, 300,

400, 500 and 600VAC or DC

Frequency Range 0 - 5KHz

Output 4–20mA (capped at 31mAmax)

0-5VDC (capped at 7.75VDC)

0-10VDC (capped at 11.5VDC)

Response Time 500 ms (to 90% value)

Accuracy < 1% Full Scale

Loading 4-20mA: < 400 ohm

0-5/10V: >50K ohm

Isolation Voltage 2500 Volts

Operating Temp. -20°C to 50°C (surrounding sensor)

Enclosure UL94V-0 Rated

Environmental -4 to 122 ° F

(-20 to 50° C),0–95% RH

Pollution Degree 2

Altitude to 2000 meters

Listings Designed to meet UL/cUL, CE

Warning! Risk of danger

Safe operation can only be guaranteed if the

transducer is used for the purpose for which it

was designed and within the limits of the techni-

cal specifications. When this symbol is used, it

means you must consult all documentation to

understand the nature of potential hazards and

the action required to avoid them.

Warning! Risk of electrical shock

When operating the transducer certain parts may

carry hazardous live voltage (e.g. primary con-

ductors, power supply). The transducer should

not be put into operation if the installation is not

complete.

For products intended for the EU market, the following is ap-

plicable to the CE compliance of the product:

The VTU series comply with EN 61010-1 CAT III 600V max

measurement category. Use 24 V input power and fuse at 5 amps.

Power source overvoltage category I as defined per EN 61010-1