Barnant Company 877-9605 User manual

OPERATING MANUAL

LIQUID-SENSOR CONTROLLERS

MODEL NO. 877-9600

MODEL NO. 877-9605

AND

LIQUID-PAD DETECTORS

MODEL NO. 877-9500

MODEL NO. 877-9501

Barnant Company

28W092 Commercial Ave.

Barrington, Illinois U.S.A. 60010-2392

(847) 381-7050

(847) 381-7053 (Fax)

800-637-3739

www.barnant.com

A-1299-0578

Edition 03

SAFETY PRECAUTIONS

WARNINGS:If the equipmentisusedinamannerotherthanasspeci-

fied, protection provided by the equipment may be

impaired.

No user serviceable parts are inside of this Controller.

Refer servicing to your dealer.

WARNING:The LIQUID SENSOR Controller must be positioned so

leaking liquid will not enter the rear power connectors.

Use of a power line with a Ground Fault Interrupt (GFI) is

recommended.

CAUTION:Use with caustic liquids not compatible with detector

materials voids warranty.

i

EU Declaration of Conformity

Name of Apparatus:Liquid-Sensor Controller

Model Number:877-9605

Description of Apparatus:Fluid Monitor System

Barnant Company declares that the above model is in conformity to the following

harmonized standards and directives:

Applicable

DirectivesApplicable

SpecificationsManufacturer’s

Report Number

73/23/EEC

93/68/EECEN61010-1/A2: 1995TR9516

89/336/EEC

92/31/EEC

93/68/EEC

EN61326-1/A1: 1998TR9519

The last two digits of the year in which the current configuration of the above models

was assessed per the Low Voltage Directive is: 00.

Manufacturer:

Barnant Company Division

Cole-Parmer Instrument Company

28W092 Commercial Avenue

Barrington, IL 60010

USA

Tel.: 847-381-7050

Manufacturer’s Signature:

22 August, 2000

________________________________________________

James W. DollDate

Vice President, Engineering

TABLE OF CONTENTS

TitlePage

SAFETY PRECAUTIONS.....................................i

INTRODUCTION...........................................2

APPLICATIONS............................................3

DESCRIPTION.............................................6

INSTALLATION AND SETUP..................................9

OPERATION.............................................13

Operator Control and Indicators.............................13

Startup Procedure.......................................15

Operational Checks......................................15

SENSITIVITY ADJUSTMENT................................16

MAINTENANCE AND TROUBLESHOOTING....................17

Fuse Replacement.......................................17

Cleaning ...............................................17

Troubleshooting.........................................18

ACCESSORIES...........................................19

SPECIFICATIONS.........................................20

WARRANTY..............................................21

PRODUCT RETURN.......................................21

TECHNICAL ASSISTANCE..................................21

APPENDIX A: AUXILIARY CABLE CONNECTIONS.............22

Only the Model 877-9600 Liquid-Sensor Controller is UL and cUL listed.

1

Trademarks bearing the ® symbol in this publication are registered in the U.S. and in other countries.

INTRODUCTION

The LIQUID-SENSOR Controller is a two-channel alarm system used to

sense liquid leaks using a specially designed detector or used with other

liquid detectors such as high or low liquid level detectors. The Model

877-9600 LIQUID-SENSOR Controller operates from 115V ACand the

Model877-9605operatesfrom230VAC.Whenanalarmconditionissensed

oneitherchannel,theLIQUID-SENSORControllercanperformthefollowing

actions:

•Disconnect power to a pump drive.

•Activate an auxiliary pump drive to resume pumping through a second

pump drive.

•Activate the front panel red ALARM ON indicator.

•Sound an audible alarm if the audible alarm is enabled.

•Provide a contact closure output that can be used to activate an

Environment Monitor for automatically telephoning the user of the failure,

or to activate any other device that operates from a contact closure

input. The contact closure may also be used to operate shut-off or

switchable valves to redirect flow.

The LIQUID-PAD Detector Model 877-9500 (detector with cable) or Model

877-9501 (detector without cable) is used to sense leaks in pump heads

resultingfromrupturesofthetubing.Thisdetectorisnotsuppliedwiththeunit

and must be ordered separately. (See ACCESSORIES.)

2

APPLICATIONS

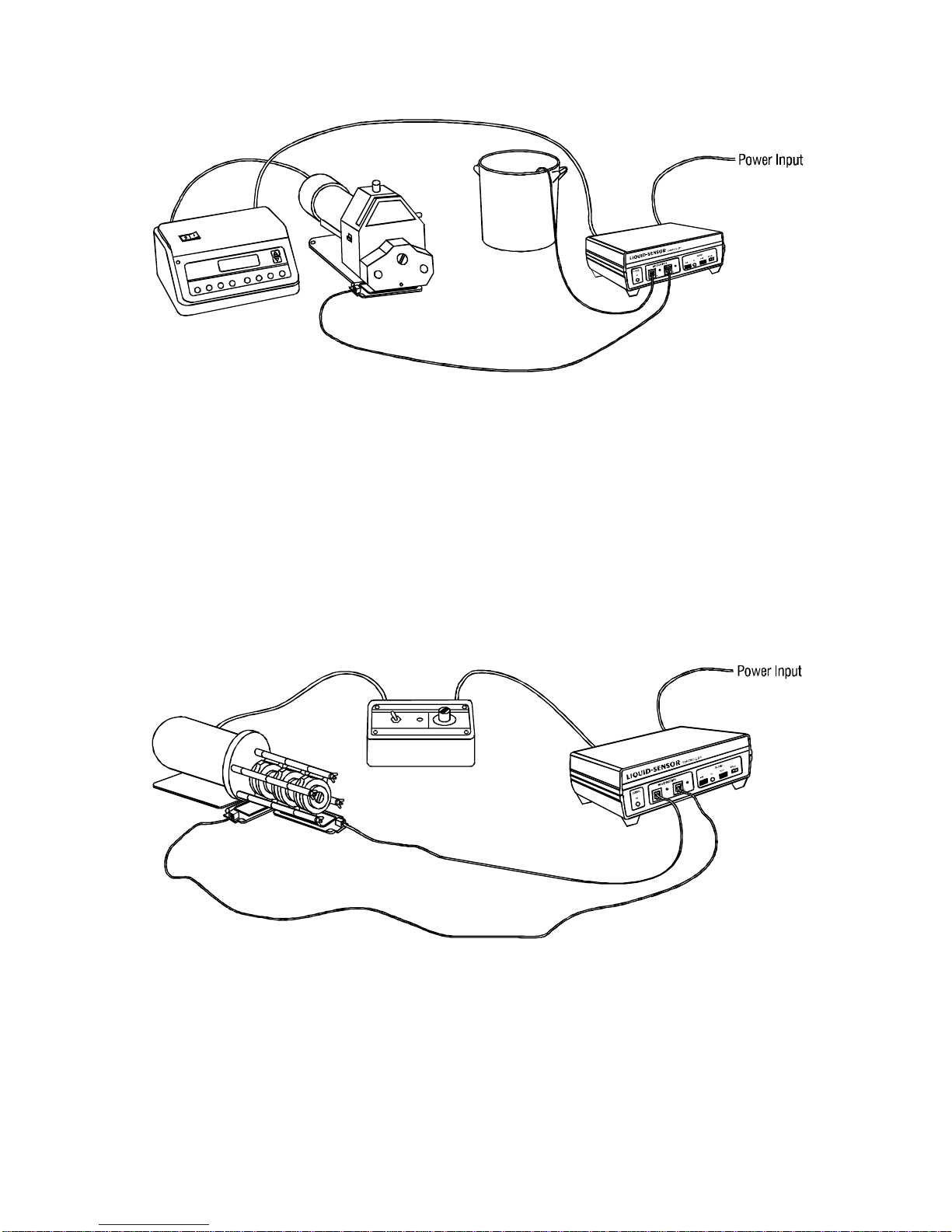

The LIQUID-SENSOR Controller and LIQUID-PAD Detector can be used

with a wide variety of different pump systems for leak detection. The alarm

controller has two inputs. These can both be used with LIQUID-PAD

Detectors, or one input can be used with a LIQUID-PAD Detector and the

secondinputusedwithothertypedetectorssuchasaliquidleveldetectorfor

determining high or low levels in a container. Figures 1 through 5 show

varioussuggested detectorarrangements indifferent pumpsystems. Tubing

is omitted for clarity.

3

Figure 1. Typical B/T ®RAPID-LOAD ®Pump with LIQUID-PAD Detector

positioned under open side of pump

4

Figure 2. Typical L/S ®Cartridge Pump with two LIQUID-PAD Detectors

centered under the group of cartridges

Figure 3. Typical L/S EASY-LOAD ®Pump with LIQUID-PAD Detector

positioned under main pump, auxiliary pump mounted on top

of main pump and both pumps connected to Alarm Controller

for automatic switch over when a leak is detected

5

Figure 4. Typical I/P ®EASY-LOAD Pump with LIQUID-PAD Detector

centered under the pump and a level detector connected to the

second input of the Alarm Controller

Figure 5. Standard Stacked Pump System with two LIQUID-PAD

Detectors positioned for optimum leak detection

DESCRIPTION

The LIQUID-SENSOR Controller, shown in Figure 6, is used to monitor

various liquid detector devices. When an alarm condition is detected, the

controller deactivates the rear panel MAIN OUTPUT power connector and

suppliespowertotheAUXILIARYOUTPUTpowerconnector.Also,whenthe

alarm condition is detected, a contact closure output is provided at the rear

panel CONTACT CLOSURE OUTPUT connector (a 1/8-inch phone-type

connector) for activating remote devices such as an Environment Monitor or

a second pump drive. The fault condition is indicated by a red ALARM ON

indicator on the front panel and by an audible alarm (unless the ALARM

AUDIBLE switch has been set to OFF).

TheMAINandAUXILIARYconnectors,showninFigures7and8,areusedto

connect to external devices such as pumps. The pump connected to the

MAINOUTPUTconnectorwilloperatewhennoalarmconditionexists.When

an alarm condition is detected, power to the MAIN OUTPUT connector is

turnedoffandpowerisappliedtotheAUXILIARYOUTPUTconnector.Thus,

ifnopumpisconnectedtotheAUXILIARYOUTPUTconnector,pumpingwill

cease. If a pump is connected to the AUXILIARY OUTPUT connector, that

pump will be turned on. The switch over occurs within one second after

detection of an alarm condition.

6

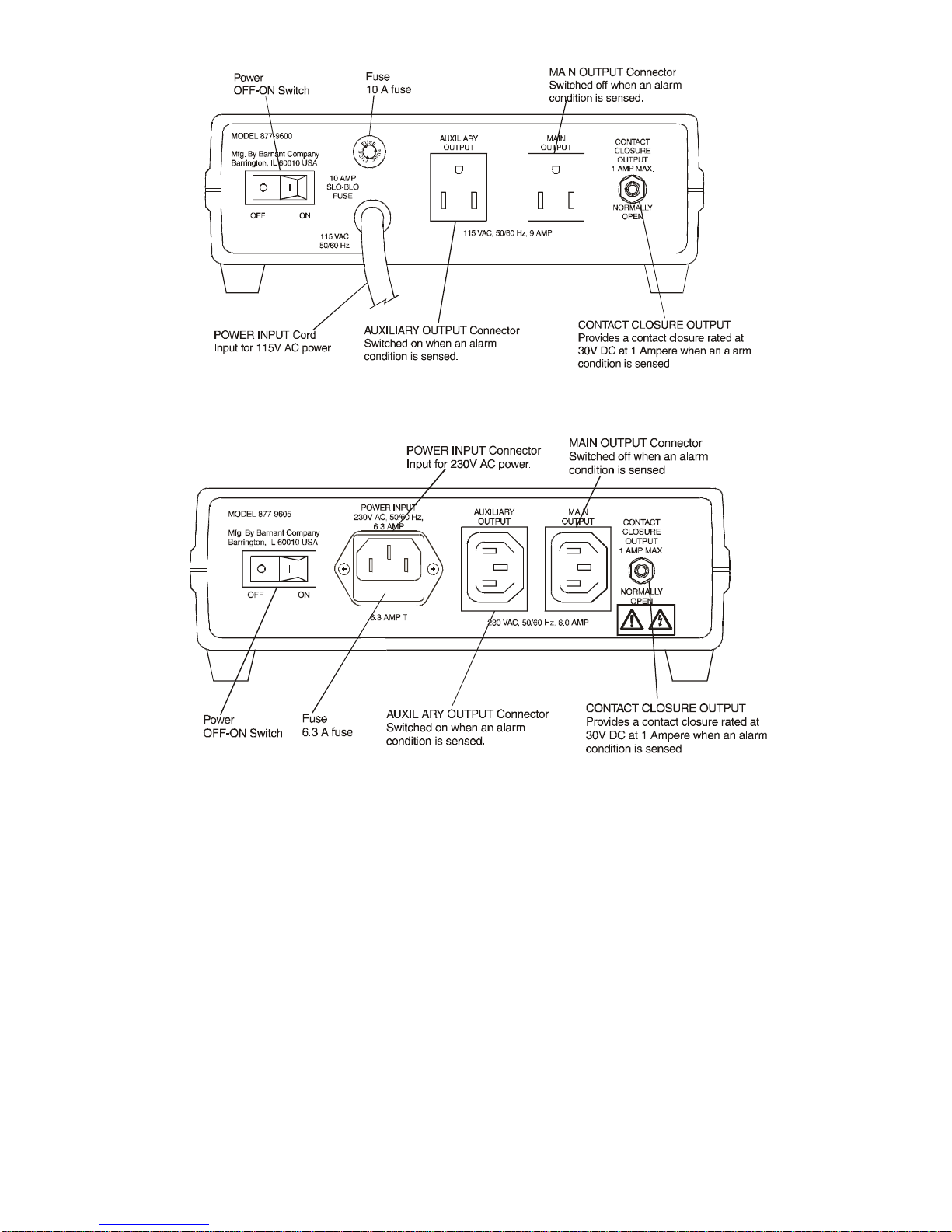

Figure 6. LIQUID-SENSOR Controller (Alarm Module)

Power is applied to the unit through a permanently attached line cord on the

115V AC model and through an IEC 320/CEE 22 connector coupler (female

line cord/male socket) on the 230V AC units. A number of accessory input

and output power cords are available. (See ACCESSORIES.) The power is

controlled by the rear panel OFF-ON switch. Power-on is indicated by a front

panel green POWER ON indicator.

The CONTACT CLOSURE OUTPUT connector (rear panel) provides a

latched contact closure output, rated 30V DC at 1 ampere max., when an

alarmconditionisdetected.ThisoutputcanbeconnectedtoanEnvironment

Monitor,whichthencantelephonetheusertosignalthealarmcondition.This

output can also be connected to any device that operates from a contact

closure condition, such as a warning system. An accessory cable is listed in

the ACCESSORIES Section.

7

Figure 7. Rear Panel Model 877-9600 (115V AC)

Figure 8. Rear Panel Model 877-9605 (230V AC)

The locking modular INPUT connectors (front panel) connect to external

detectors. Each input has a SENSITIVITY adjustment that is used only with

the LIQUID-PAD Detectors. The sensitivity is factory set so that when the

detector is placed within one inch of the pump, less than one mL of

water-based liquid will trigger the detector. For other types of liquids, or to

change the sensitivity level, refer to the SENSITIVITY ADJUSTMENT

Section. Sensitivity adjustment may be required when operating with cables

longer than 3-1/2 feet or in a high-temperature, high-humidity environment.

The LIQUID-SENSOR Controller is housed in a slate gray ABS plastic

enclosure, with aluminum front and rear panels. The unit can be placed on a

flat surface, on a support platform or on the top surface of some

MASTERFLEX ®or other type pumps.

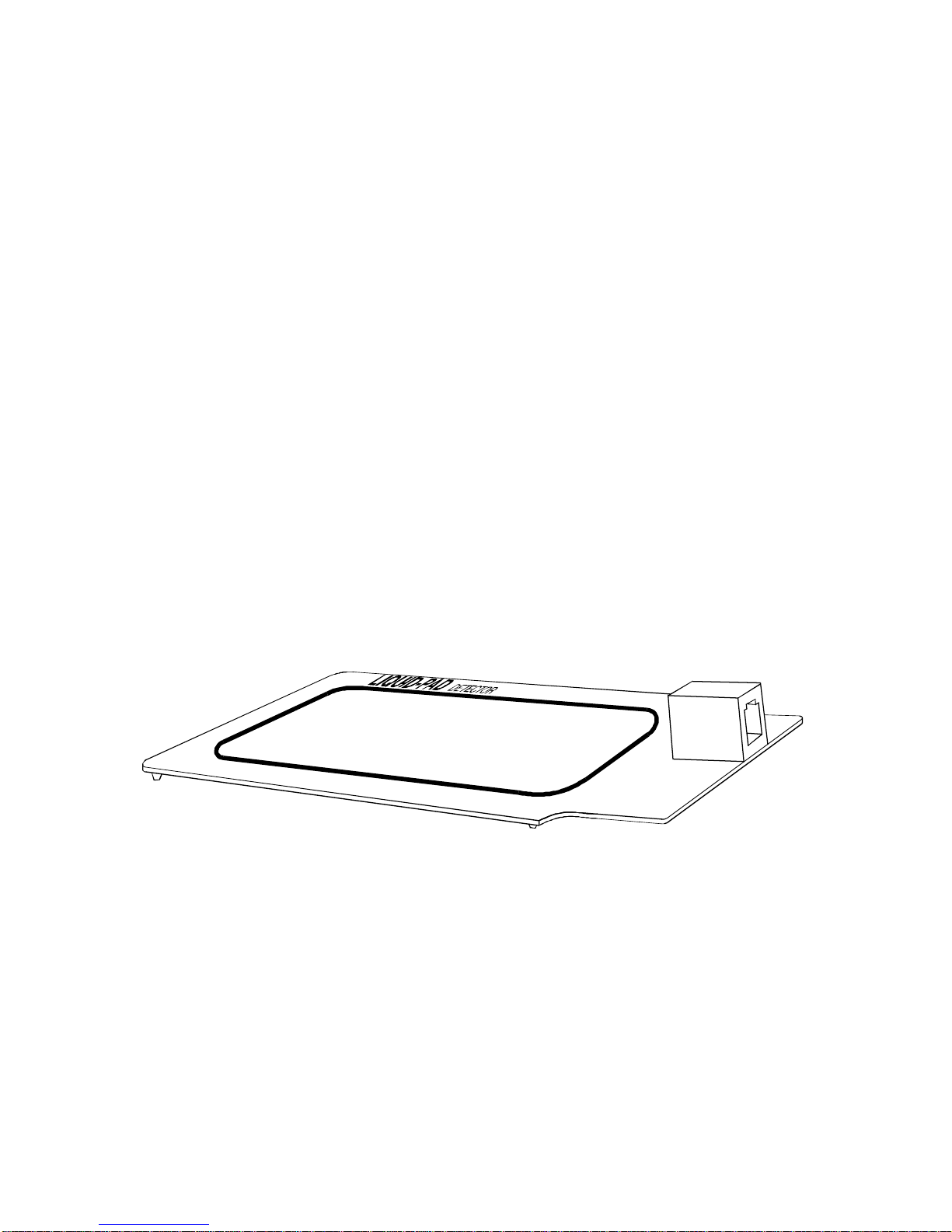

The LIQUID-PAD Detector Model 877-9500 (with cable) or Model 877-9501

(without cable), Figure 9, operates on a capacitance change principle. The

detector is designed to be placed under the pump. If a leak occurs in the

pump tubing, the liquid will fall on the top surface of the detector. When

sufficient surface area is moistened (less than 1 mL of water-based liquid

when using the factory sensitivity setting), the change in capacitance is

sufficient to activate the alarm circuits. The detector has a locking modular

type connector. The cable between the detector and the controller is 3-1/2

feet long with modular locking connectors on both ends. Ten-foot and

fifteen-foot accessory cables are available. Refer to APPENDIX A for pin

configuration for the cables when connecting other detector types.

A four-inch hook-and-loop fabric fastener strip allows for attachment of the

detector pad to a flat surface to prevent the detector pad from moving. The

detector pad can also be permanently mounted by attaching it to a flat

surfacewithtwo#4screws.Thescrewlocationsatthecornersofthedetector

padare indicated bytwocircular markers.Thedetector structurewillneedto

be punctured by the screw for permanent attachment.

8

Figure 9. LIQUID-PAD Detector Model 877-9501

INSTALLATION AND SETUP

NOTE:Retainallpackingmaterialsuntilproperoperationhasbeenverified.

WARNING:The LIQUID-SENSOR Controller must be positioned so

leakingliquidwillnot enter the rear power connectors.Use

ofapowerlinewithaGroundFaultInterrupt(GFI)isrecom-

mended.

Proceed as follows to setup the LIQUID-SENSOR Controller:

1. Place the rear panel power OFF-ON switch in the OFF position.

NOTE:For 115V AC pump models, the pump power cord will plug directly

into the MAIN OUTPUT or AUXILIARY OUTPUT connectors on the

rearpanel of theLIQUID-SENSORController. For230VACmodels,

use pump cable 77096-50 for pumps with European connectors or

pump cable 77096-55 for pumps with other style connectors.

2. Connect pumps as follows:

a.If a main pump and a standby (auxiliary) pump are to be used,

connectthemainpumptotheMAINOUTPUTconnector on therear

panel and connect the standby (auxiliary pump) to the AUXILIARY

OUTPUT connector.

b.Ifonly themainpump istobe usedwithno standby,andthe pumpis

to shut down when an alarm condition exists, connect the main

pump to the MAIN OUTPUT connector. The AUXILIARY OUTPUT

connectorcanbeusedtopowerotherdevicessuchaslights,remote

alarms or other equipment.

c.Ifonly themainpump istobe usedwithno standby,andthe pumpis

not to shut down when an alarm condition exists, connect the main

pump to a separate power source. The MAIN OUTPUT connector

andtheAUXILIARYOUTPUTconnectorcanbeusedtopowerother

devices such as lights, remote alarms or other equipment.

3. Connect one end of the detector cable(s) to the front panel INPUT

connector(s) and the other end to the desired detector(s). Only one

detectorcanbeconnectedtoeachINPUTconnector.Detectorsmustbe

connected using a cable configured as shown in APPENDIX A. Make

sure cable connections are secure or unit will not function

properly .

4. The LIQUID-PAD Detector must be positioned under the pump so that

any leakage will drip onto the detector pad target area (area outlined

with the black lines). The detector can be secured in place using

hook-and-loop fabric fasteners or can be permanently fastened with #4

screws.Twocircularmarksarelocatedontheouteredgeofthe detector

9

for position of screws. Do not insert screws in any other location on the

detectorpads.Thelocationofthedetectorforvarioustypicalpumpsare

as follows:

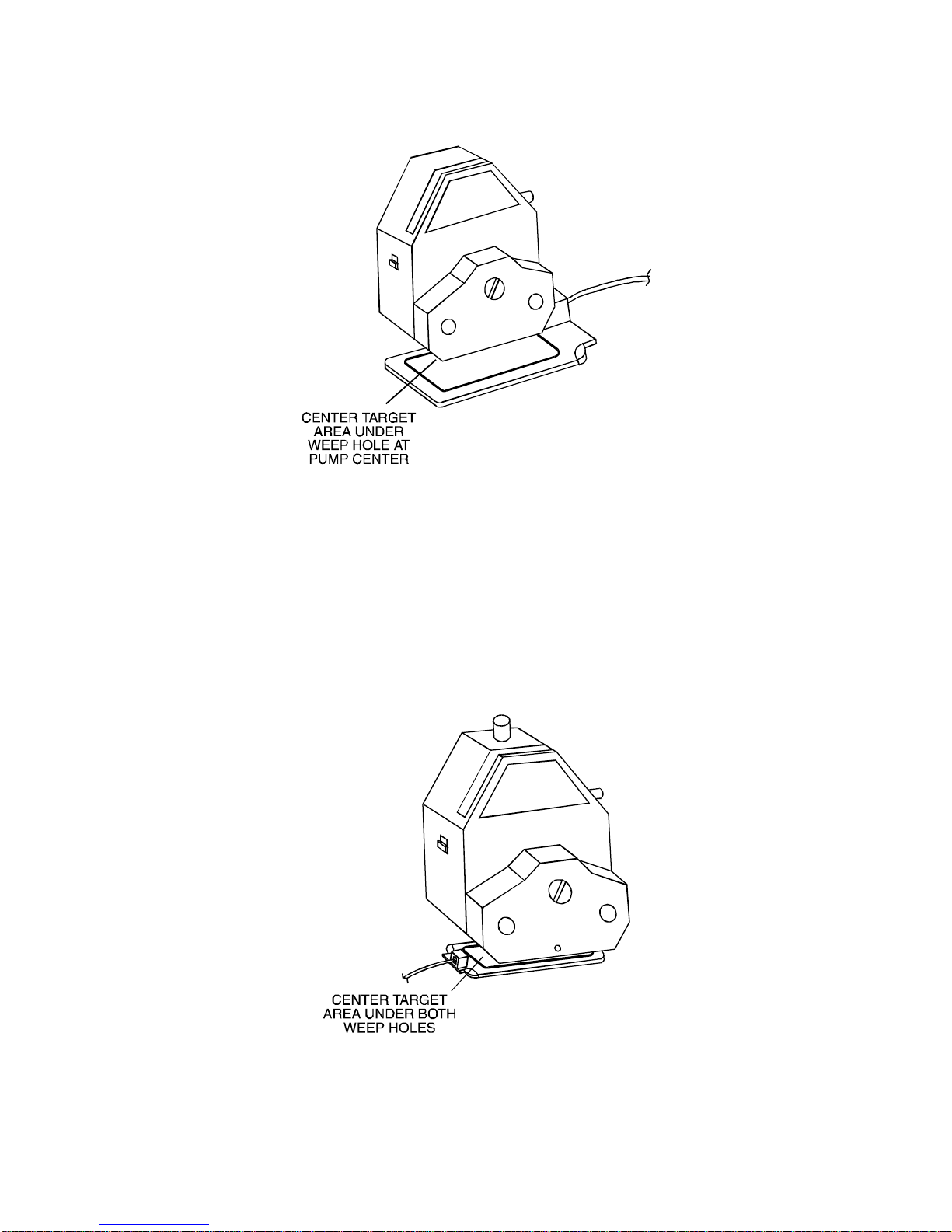

a.For a typical B/T RAPID-FLOW pump, the detector should be

located directly under the opening at the right side of the pump as

shown in Figure 10.

b.For typical L/S Cartridge pumps, the detector should be centered

under the group of cartridges. For large numbers of cartridges, use

two detectors as shown in Figure 11.

10

Figure 11. Positioning LIQUID-PAD Detectors

under an L/S Cartridge Pump

Figure 10. Positioning a LIQUID-PAD Detector

under a B/T RAPID-FLOW Pump

c.FortypicalL/SEASY-LOADpumps,thedetectorshouldbecentered

directly under the weep hole as shown in Figure 12.

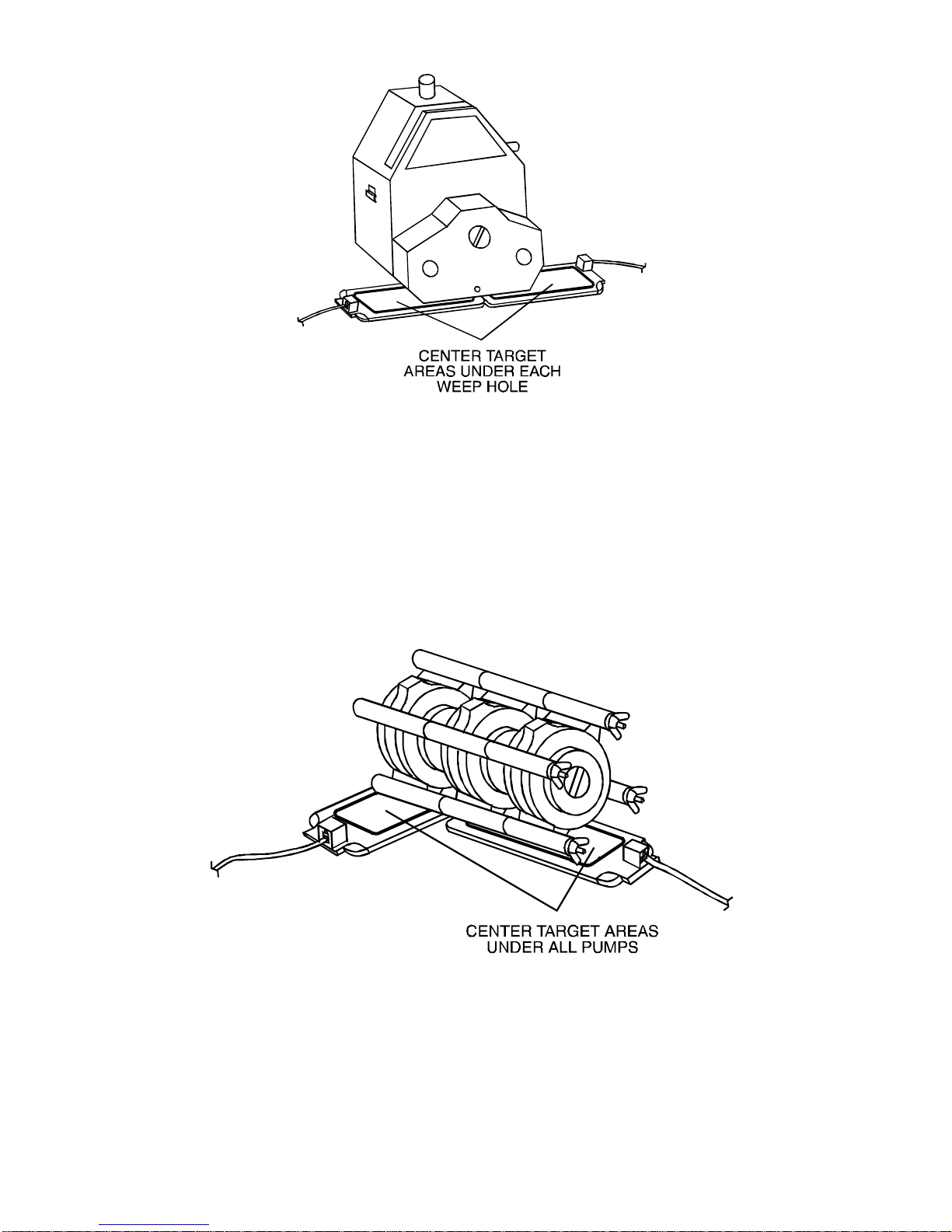

d.For typical I/P EASY-LOAD pumps, two weep holes are located

under the pump. A single detector can be centered under the weep

holes as shown in Figure 13. For better reliability, two separate

detectors can be used with one centered under each weep hole as

shown in Figure 14.

11

Figure 12. Positioning a LIQUID-PAD Detector under an

L/S EASY-LOAD Pump

Figure 13. Positioning a single LIQUID-PAD Detector under an

I/P EASY-LOAD Pump

e.For typical standard stacked pumps where only one or two pumps

are used, a single detector can be centered under the stack of

pumps. When a larger number of pumps are used, two detectors

should be positioned to assure optimum leak detection as shown in

Figure 15.

12

Figure 14. Positioning two LIQUID-PAD Detectors under an

I/P EASY-LOAD Pump

Figure 15. Positioning two LIQUID-PAD Detectors under a

stack of Standard Pumps

5. If an Environment Monitor (such as a COLE-PARMER Model 08330) is

to be used or if another external device requiring a contact closure to

activate it is to be used, connect the 1/8-inch phone cable connector

from the rear panel CONTACT CLOSURE OUTPUT connector to the

external device.

6. Connect the LIQUID-SENSOR Controller POWER INPUT cord as

follows:

a.For 115V AC unit, connect line cord to 115V AC 50/60 Hz power

source.

b.For230VACunit,connectpowercablebetweenrearpanelPOWER

INPUT connector and 230V AC 50/60 Hz power source.

This completes the electrical connectors. Proceed with the OPERATION

Section.

OPERATION

Operator Controls and Indicators

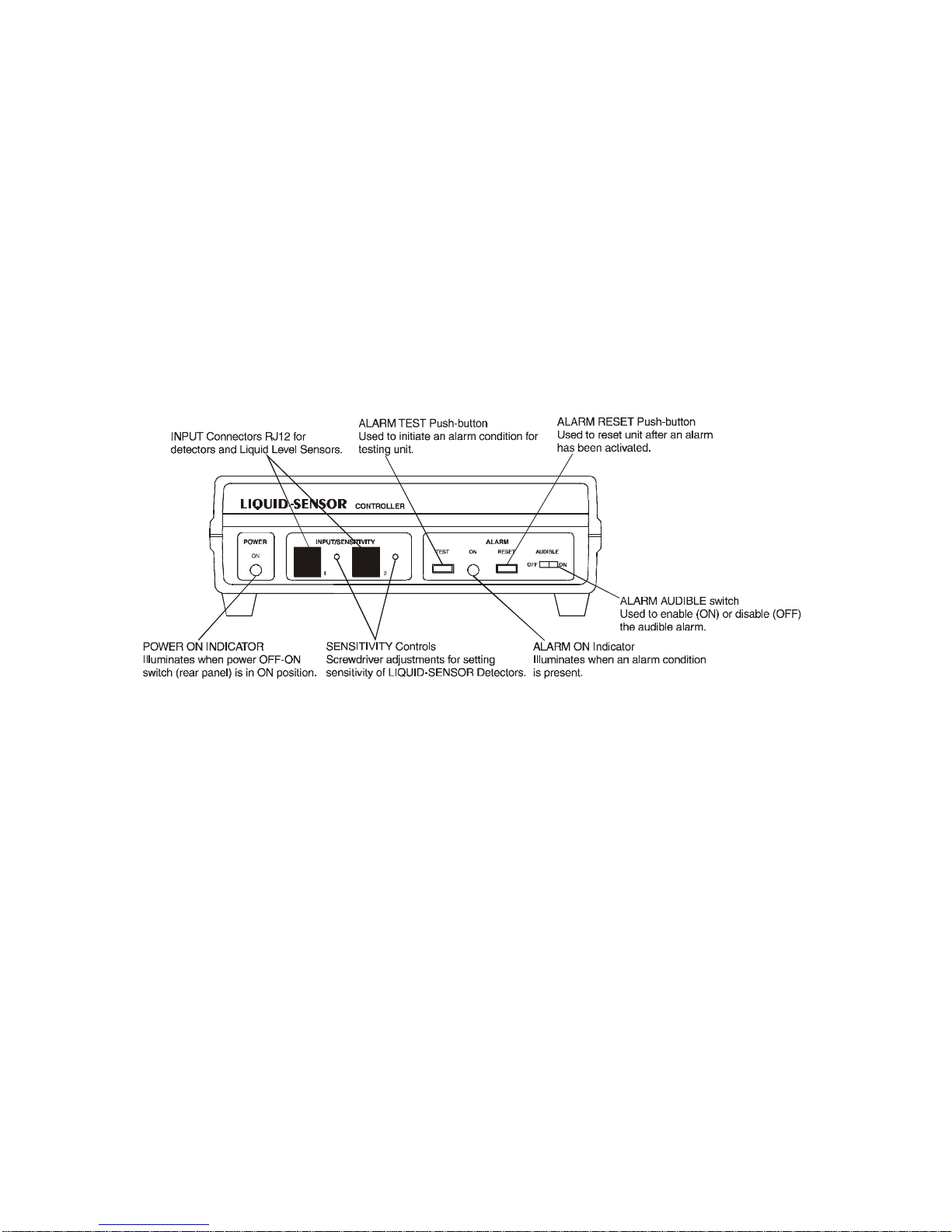

All operator controls except the power OFF-ON switch are located on the

front panel as shown in Figure 16. These controls and indicators are as

follows:

POWER ON IndicatorGreen LED illuminates when power

OFF-ON switch is in the ON position and

input power is present.

SENSITIVITY ControlsAdjusts the sensitivity of the circuit for use

with the LIQUID-PAD Detectors. (Pre-set at

factory for typical applications.)

ALARM TEST Momentary push-button. Tests the audible

alarm, the visual alarm, the switching of AC

power from the rear panel MAIN OUTPUT

to the AUXILIARY OUTPUT connectors and

the contact closure at the rear panel

CONTACT CLOSURE OUTPUT connector.

These are activated while the button is

pushed and reset automatically upon

release.

ALARM ON IndicatorRed LED illuminates when an alarm

condition is present.

13

ALARM RESET Momentary push-button. Resets alarm

circuits after alarm condition is removed

(detector pad wiped clean, tank filled, etc.).

While push-button is held in, the system

reverts to the non-alarm condition. If the

alarm condition is not cleared when the

ALARM RESET switch is released, the unit

will go back into the alarm condition. It may

be convenient to hold in the ALARM

RESET button while priming or purging the

system when a level detector is used.

ALARM AUDIBLE

OFF-ON SwitchIn the OFF position, the audible alarm will

not sound during an alarm condition. In the

ON position, the audible alarm will sound

during an alarm condition.

Power OFF-ON Rocker type switch located on rear panel.

Disconnects all AC power from unit and

from equipment connected to the MAIN

OUTPUT or AUXILIARY OUTPUT

connectors.

14

Figure 16. LIQUID-SENSOR Controller Front Panel

Startup Procedure

1. Check that all connections have been made as described in the

INSTALLATION Section.

2. Check that detectors are connected and properly positioned. Only one

detector can be connected to each channel. Use hook-and-loop fabric

fasteners to secure detector in position or, if permanent mounting is

desired, detector can be attached with #4 screws as described in the

INSTALLATION Section.

NOTE:Tubing may break at locations other than expected. Using a second

detector can provide for better detection.

3. Iftheaudible alarmistooperate,set ALARMAUDIBLEswitchtothe ON

position.Ifnoaudiblealarmisdesired,placeALARMAUDIBLEswitchin

the OFF position.

4. Set rear panel power OFF-ON switch to the ON position and check that

the front panel green POWER ON indicator is lit. The equipment should

now be operating normally.

5. If an alarm condition exists, proceed to the SENSITIVITY

ADJUSTMENTSection.Ifleveldetectorsareused,theymayneedtobe

inverted or rotated 180 °for proper operation. The audible alarm can be

turnedoffbyplacingtheALARMAUDIBLEswitchintheOFFposition.

6. Perform the LIQUID-PAD Detector Sensitivity Check using drops of the

same liquid used in your application.

Operational Checks

LIQUID-SENSOR CONTROLLER

An operational check of the LIQUID-SENSOR Controller can be performed

using the ALARM TEST switch. This test should be performed only when

temporary transfer of power from the MAIN OUTPUT connector to the

AUXILIARY OUTPUT connector will not be disruptive.

Proceed as follows:

1. Set the ALARM AUDIBLE switch to ON for the audible alarm to be

activated or to OFF to deactivate the audible alarm.

2. Set power OFF-ON switch to ON position and check that POWER ON

indicator is illuminated.

3. Press and hold the ALARM TEST SWITCH. Check that the audible

alarm sounds (if activated), the ALARM ON indicator is illuminated, that

power shifts from the MAIN OUTPUT connector to the AUXILIARY

OUTPUT connector and that the CONTACT CLOSURE OUTPUT

activates any equipment connected to the output.

15

LIQUID-PAD DETECTOR SENSITIVITY CHECK

The LIQUID-PAD Detector sensitivity may be checked as follows:

1. Connect detector to one of the front panel INPUT connectors, if not

already connected.

2. Place water one drop at a time on the detector pad. Do not drop water

from more than one inch.

3. Check number of drops required to activate alarm. Pre-set factory

setting should activate alarm with less than 1 mL of liquid. If activation

level is not as desired, refer to SENSITIVITY ADJUSTMENT Section.

4. After activating alarm, momentarily press then release the RESET

button. Alarm condition should still be present.

5. Wipe detector surface clean with a dry cloth and momentarily press,

then release, the RESET button. Alarm condition should terminate,

ALARM ON indicator should extinguish and, if activated, audible alarm

should turn off.

SENSITIVITY ADJUSTMENT

Generally, no sensitivity adjustment of the LIQUID-SENSOR Controller is

required. However, various liquids or environmental conditions such as

temperature and humidity may require adjustment of the SENSITIVITY

controls for use with the LIQUID-PAD Detectors. The SENSITIVITY

adjustment is accessed through the small hole adjacent to each INPUT

connector. Contact closure or logic level detectors do not require adjustment

of the SENSITIVITY control.

If the factory default setting for sensitivity is not activating the alarm, or is

falsely activating the alarm for the liquid being sensed, adjust the input

sensitivity with one channel connected at a time. Turn the SENSITIVITY

control clockwise to increase sensitivity (fewer drops will activate) or

counterclockwise to decrease sensitivity.

NOTE:If the sensitivity is increased so much that the red ALARM ON

indicator illuminates, the RESET button must be depressed each

time sensitivity is decreased until the indicator extinguishes.

Normal sensitivity adjustment is between one-quarter and two turns

counterclockwise from the activation point. The activation point is defined as

that sensitivity set when ALARM ON indicator just illuminates. Refer to Table

1 for typical sensitivity settings for various liquids. The middle column

indicatesthe number of turns counterclockwisefrom theactivation pointthat

16

the sensitivity control should be set for proper operation. The last column

indicates the quantity of fluid required in the target area of the detector to

activate the detector.

Sensitivity will change with detector position or when used near metallic

objects (e.g., table). Also, sensitivity changes when using longer (optional)

cables.

CAUTION:Use with caustic liquids not compatible with detector

materials voids warranty.

MAINTENANCE AND TROUBLESHOOTING

WARNING:No user serviceable parts are inside of this Controller.

Refer servicing to your dealer.

Fuse Replacement

The 115V AC LIQUID-SENSOR Controller uses a 10-A Slo-Blo fuse (3AG,

part number B-1115-0052), which is located in the fuse holder on the rear

panel. The 230V AC LIQUID-SENSOR Controller uses a 6.3-A fuse (5 x 20

mm, part number B-1115-0054), which is located in the drawer in the

POWER INPUT connector on the rear panel. Replace only with the correct

fuse.

Cleaning

Cleanthetopsurfaceofthedetectorpadwithasoft,drycloth.Ifliquidcleaner

is used, rinse and dry thoroughly before resuming operation. Keep the

LIQUID-SENSOR Controller enclosure clean by using a mild detergent.

Never immerse or use excess fluid.

17

Fluid TypeSetting (Turns ccw

from activation point)Nominal Volume

Distilled Water112< 1 mL

Tap Water112< 1 mL

Acetic Acid (10% max.)112< 0.5 mL

Alcohols112< 0.5 mL

Glycerin112< 2.0 mL

10W Motor Oil12< 2.0 mL

Table 1. Typical Sensitivity Settings

Troubleshooting

The following chart will help identify most problems that can be corrected by

the operator. If the fault cannot be located, return unit for servicing.

Troubleshooting Chart

SYMPTOMCAUSEREMEDY

POWER ON indicator

does not illuminate

with Power OFF-ON

switch in ON position

Fuse blownReplace fuse

Power cord not

plugged into active

power source

Plug in power cord

ALARM LIGHT

illuminates but audible

alarm does not sound

ALARM AUDIBLE

switch not set to ON

position

Set switch to ON

position

Alarm does not

activate for a fault

condition

Detector not connectedConnect detector

Sensitivity set too lowIncrease sensitivity

(LIQUID-PADDetector

only)

Detector cable

defectiveReplace cable

Detector inoperativeReplace detector

RESET button does

not reset unit when

depressed

Fault not clearedClear fault

Sensitivity set too

highLower sensitivity

(LIQUID-PAD Detector

only)

RESET button failureReturn unit for servicing

Alarm activated but

pump continues to

operate

Pump not connected

to MAIN OUTPUT

but directly to a

power source

Connect pump to MAIN

OUTPUT for shutdown

when an alarm

condition is sensed.

Alarm activated but

auxiliary pump does

not turn on

Auxiliary Pump not

connected to

AUXILIARY OUTPUT

Connect auxiliary pump

to AUXILIARY OUTPUT

18

This manual suits for next models

3

Table of contents

Popular Controllers manuals by other brands

MicroSet

MicroSet MS pH 97 instruction manual

Siemens

Siemens K60 4I/1O operating instructions

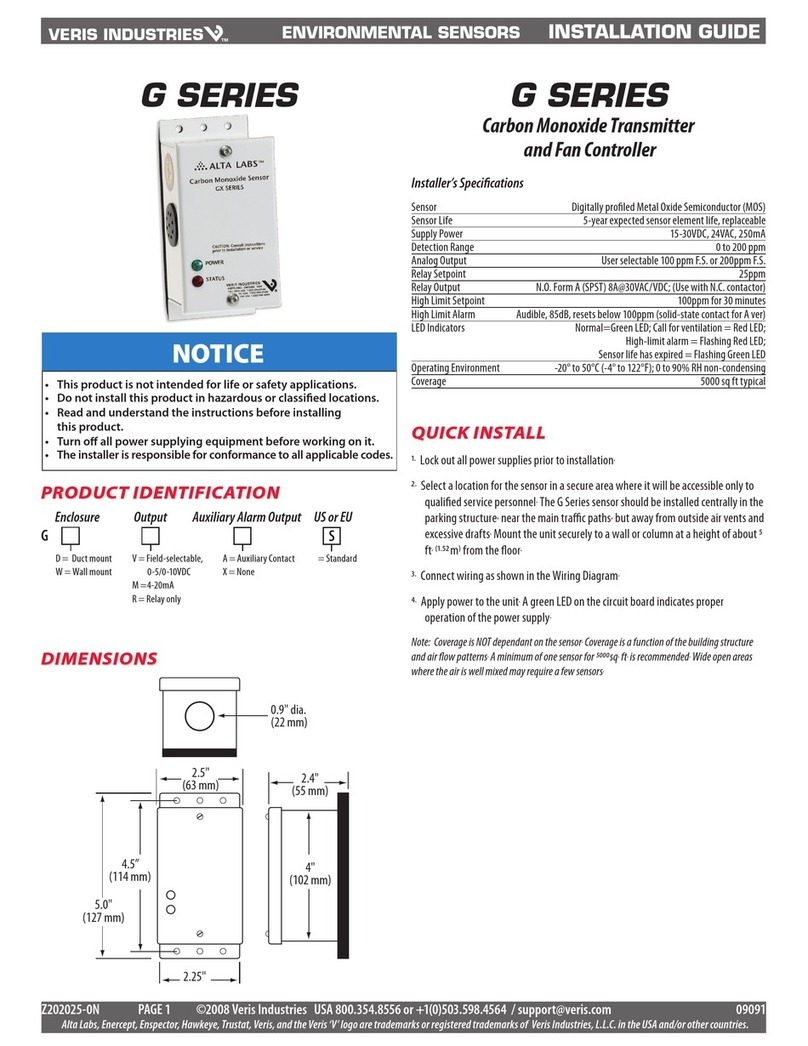

Veris Industries

Veris Industries G Series installation guide

Viessmann

Viessmann 4100 H0 Operation manual

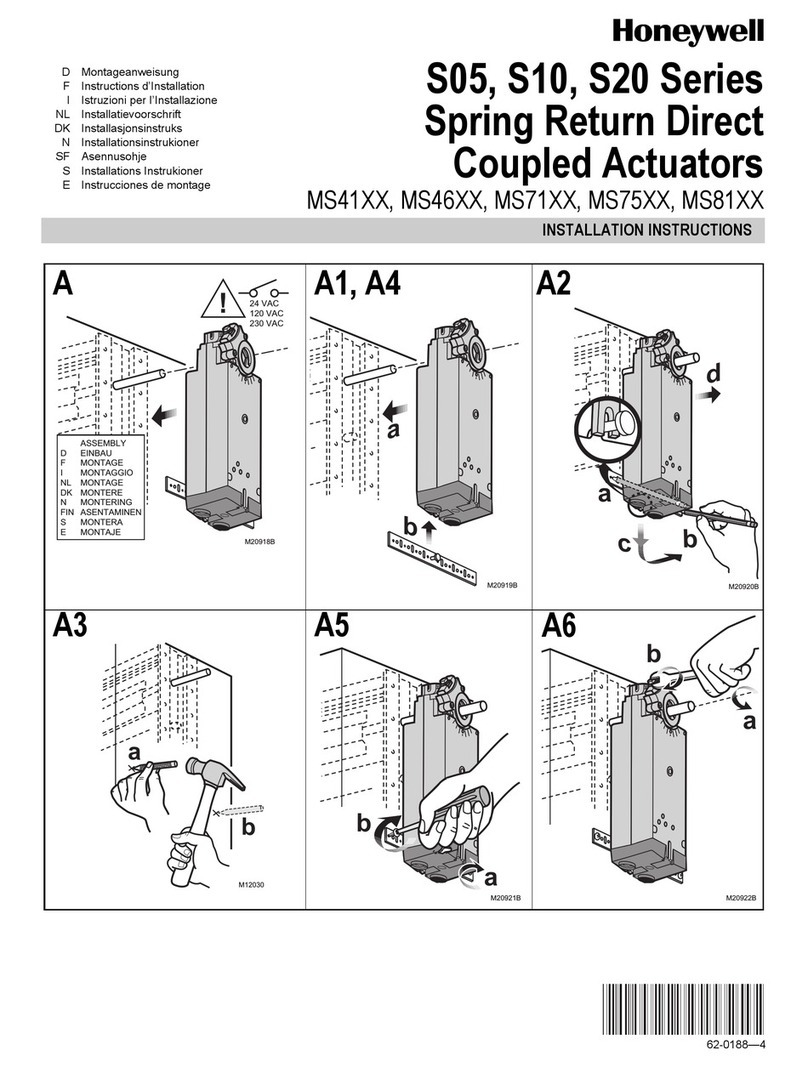

Honeywell

Honeywell S05 Series installation instructions

omal automation

omal automation AE 10 instruction manual

ILX Lightwave

ILX Lightwave LDC-3900 user guide

Kolin

Kolin KAG-75WCINV user manual

MSR ELECTRONIC

MSR ELECTRONIC PolyGard SPC3-11 Series user manual

Rockwell Automation

Rockwell Automation Allen-Bradley 1756-L72EROMS installation instructions

ETAP

ETAP Easydim2 installation manual

Chromalox

Chromalox CTF-025 Quick start manual