3104CMS OWNER’S MANUAL 9/5/18 Page 2 of 18

TABLE OF CONTENTS

TABLE OF CONTENTS.......................................................................................................................2

WARRANTY OF BARRETO MANUFACTURING EQUIPMENT...................................................2

SAFETY MESSAGES...........................................................................................................................3

CMS ASSEMBLY INSTRUCTIONS ...................................................................................................4

CMS INTENDED USE..........................................................................................................................4

OPERATOR TRAINING.......................................................................................................................5

ROUTINE MAINTENANCE................................................................................................................5

MAINTENANCE PREPARATION......................................................................................................6

LOCKOUT PROCEDURE....................................................................................................................6

HOUR METER......................................................................................................................................7

ENGINE MAINTENANCE...................................................................................................................8

LUBRICATION REQUIREMENTS.....................................................................................................8

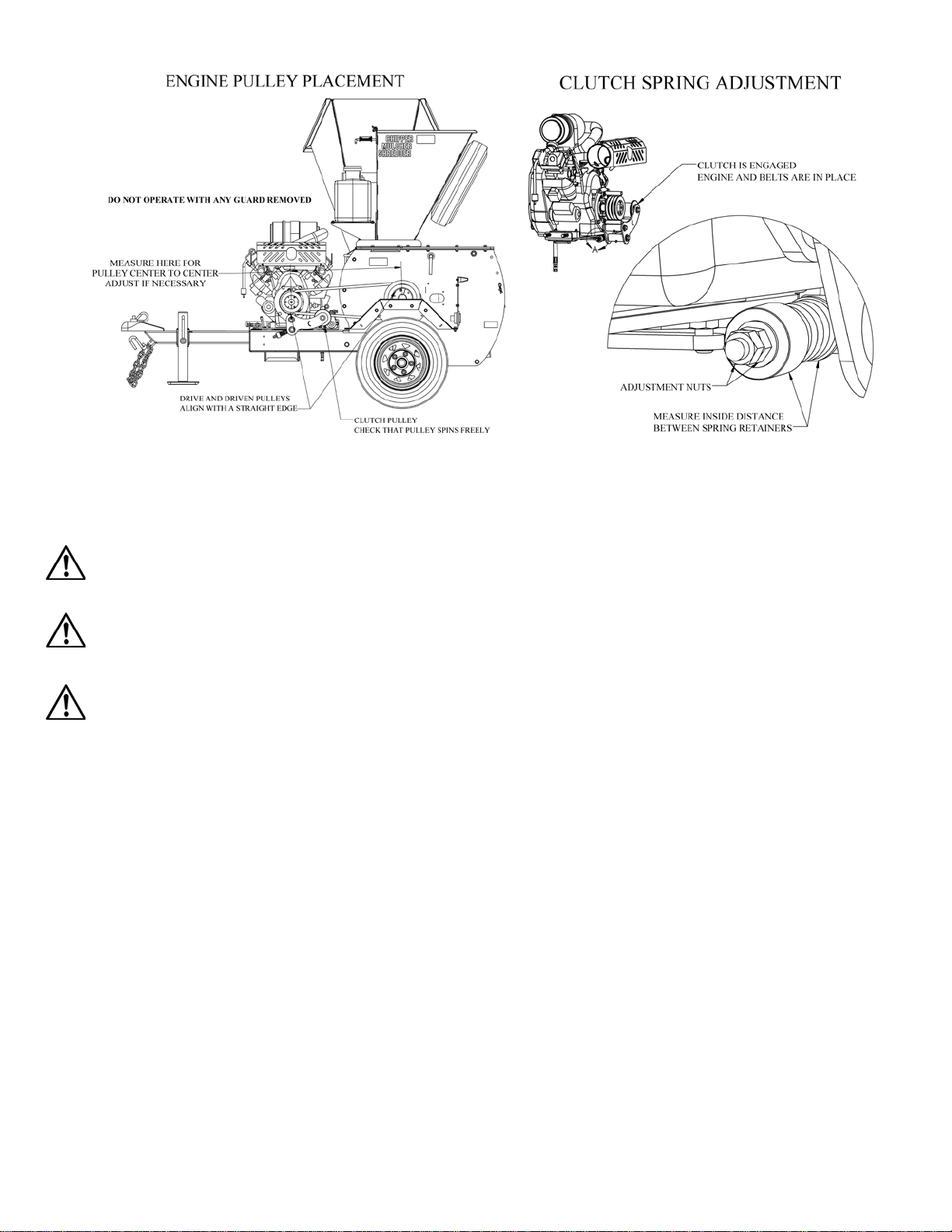

BELT INSTALLATION / REPLACEMENT........................................................................................9

CHIPPER BLADE INSPECTION AND REPLACEMENT...............................................................10

MULCHER HAMMER CHECKING AND REPLACEMENT..........................................................11

ANVIL INSPECTION AND REPLACEMENT .................................................................................13

BATTERY SAFETY INSTRUCTIONS..............................................................................................14

BATTERY MAINTENANCE .............................................................................................................15

CMS TROUBLESHOOTING GUIDE ................................................................................................17

SPECIFICATIONS ..............................................................................................................................18

INDEX..................................................................................................................................................18

WARRANTY OF BARRETO MANUFACTURING EQUIPMENT

Barreto Manufacturing, Inc. warrants all BARRETO equipment to be free of defects in material and

workmanship for a period of one (1) year, dating from the delivery to the original user.

This warranty is in lieu of all other warranties, whether written or implied, and is limited to:

1. Replacement of parts returned to the dealer and/or factory and determined defective upon

inspection. (Replacement for parts to dealers shall be at dealer cost plus shipping charges.)

2. Time for pick-up and/or delivery, transportation of service calls by dealers is excluded.

Manufacturer reserves the right to determine reasonable time required for repair.

Warranty does not apply to damage caused by abuse or neglect. Time and materials required for

normal maintenance and service are also excluded from warranty coverage.

Engines, engine accessories, batteries and tires are warranted by the original manufacturers and

are not covered by the Barreto Equipment Warranty.

Wear parts such as chipper blades, mulching hammers, bearings, belts, pulleys, sheaves, bushings

etc. are also excluded unless it can be determined that a defect has contributed to premature wear.