0478 216 9907 C - EN

30

2.1General

This instruction manual constitutes

original manufacturer’s instructions in

the sense of EC Directive 2006/42/EC.

STIHL is continually striving to further

develop its range of products; we therefore

reserve the right to make alterations to the

form, technical specifications and

equipment level of our standard

equipment.

For this reason, the information and

illustrations in this manual are subject to

alterations.

This instruction manual may describe

models that are not available in all

countries.

This instruction manual is protected by

copyright. All rights reserved, especially

the right of reproduction, translation and

processing using electronic systems.

2.2 Instructions for reading the

instruction manual

Illustrations and texts describe specific

operating steps.

All symbols which are affixed to the

machine are explained in this instruction

manual.

Viewing direction:

Viewing direction when left and right are

used in the instruction manual:

the user is standing behind the machine

(working position).

Section reference:

References to relevant sections and

subsections for further descriptions are

made using arrows. The following example

shows a reference to a section: (Ö7.1)

Designation of text passages:

The instructions described can be

identified as in the following examples.

Operating steps which require intervention

on the part of the user:

●Release screw (1) using a screwdriver,

operate lever (2)...

General lists:

– Use of the product for sporting or

competitive events

Texts with added significance:

Text passages with added significance are

identified using the symbols described

below in order to especially emphasise

them in the instruction manual:

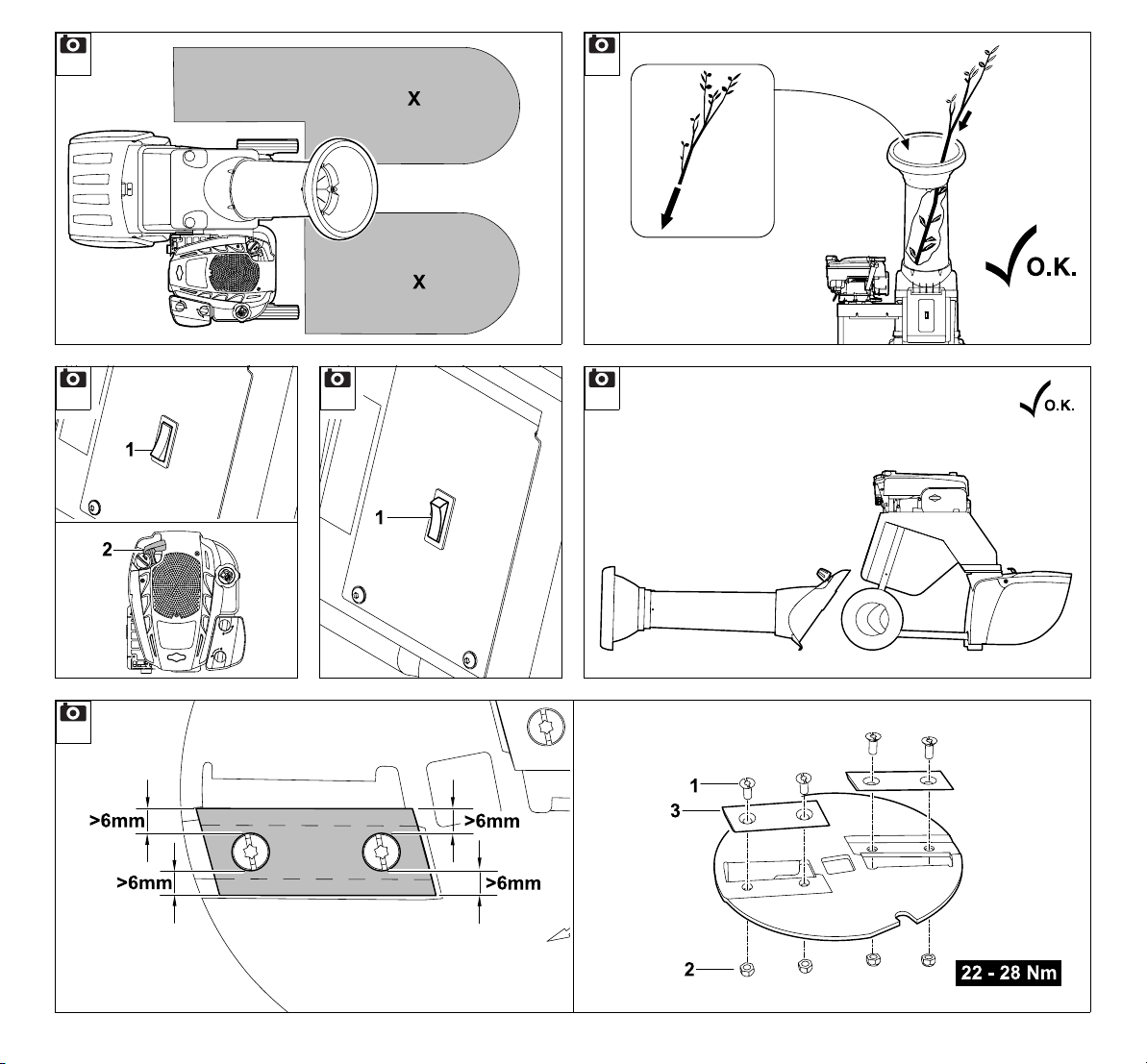

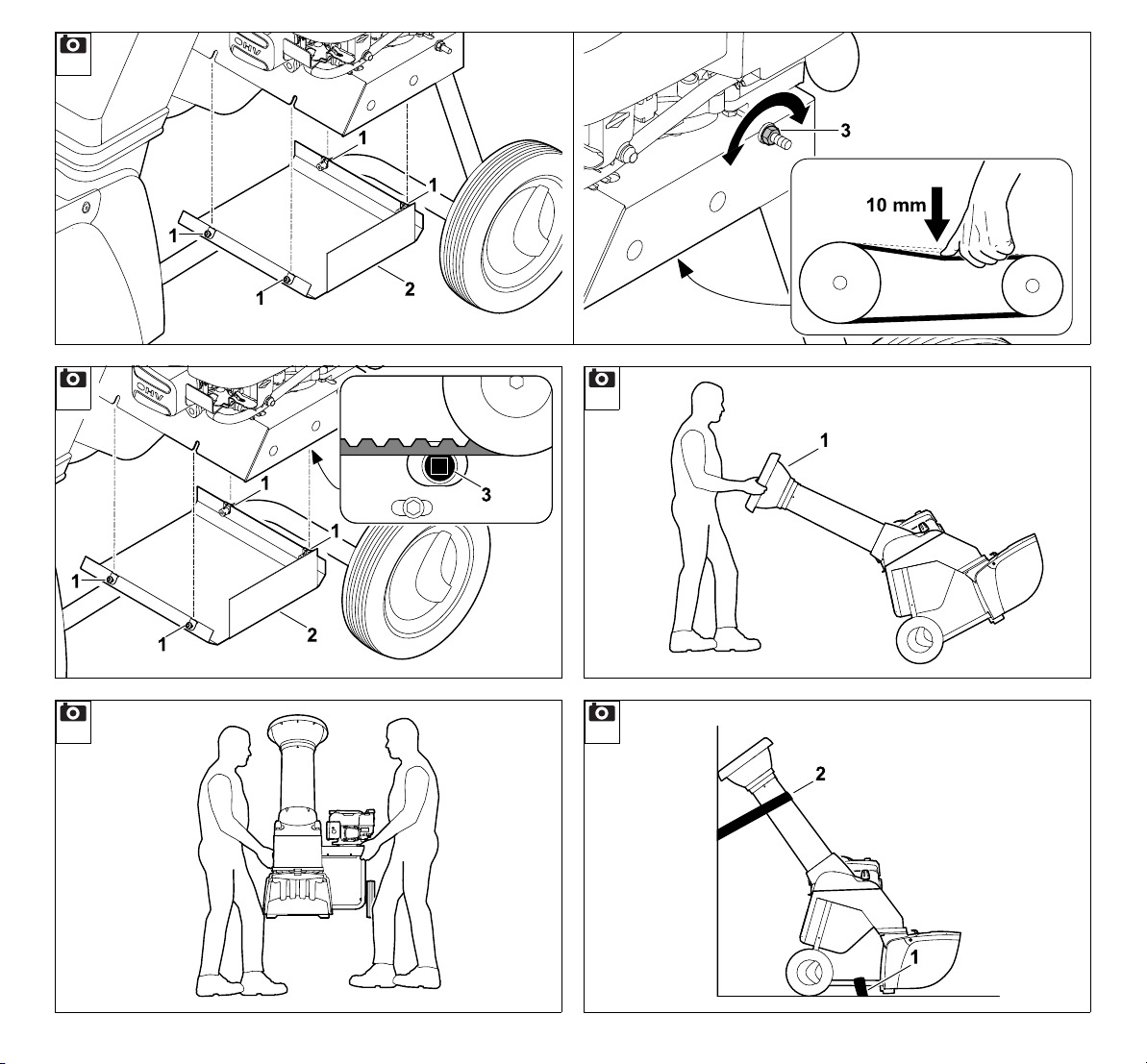

Texts relating to illustrations:

Illustrations relating to use of the machine

can be found in the front of this instruction

manual.

The camera symbol serves to link

the figures on the illustration pages

with the corresponding text

passages in the instruction manual.

4.1General

These safety regulations must

be observed when working with

the machine.

Handover confirmation 44

Service confirmation 44

2. Notes on the instruction

manual

Danger

Risk of accident and severe injury

to persons. A certain type of

behaviour is necessary or must be

avoided.

Warning

Risk of injury to persons. A certain

type of behaviour prevents possible

or probable injuries.

Caution

Minor injuries or material damage

can be prevented by a certain type

of behaviour.

Note

Information for better use of the

machine and in order to avoid

possible operating errors.

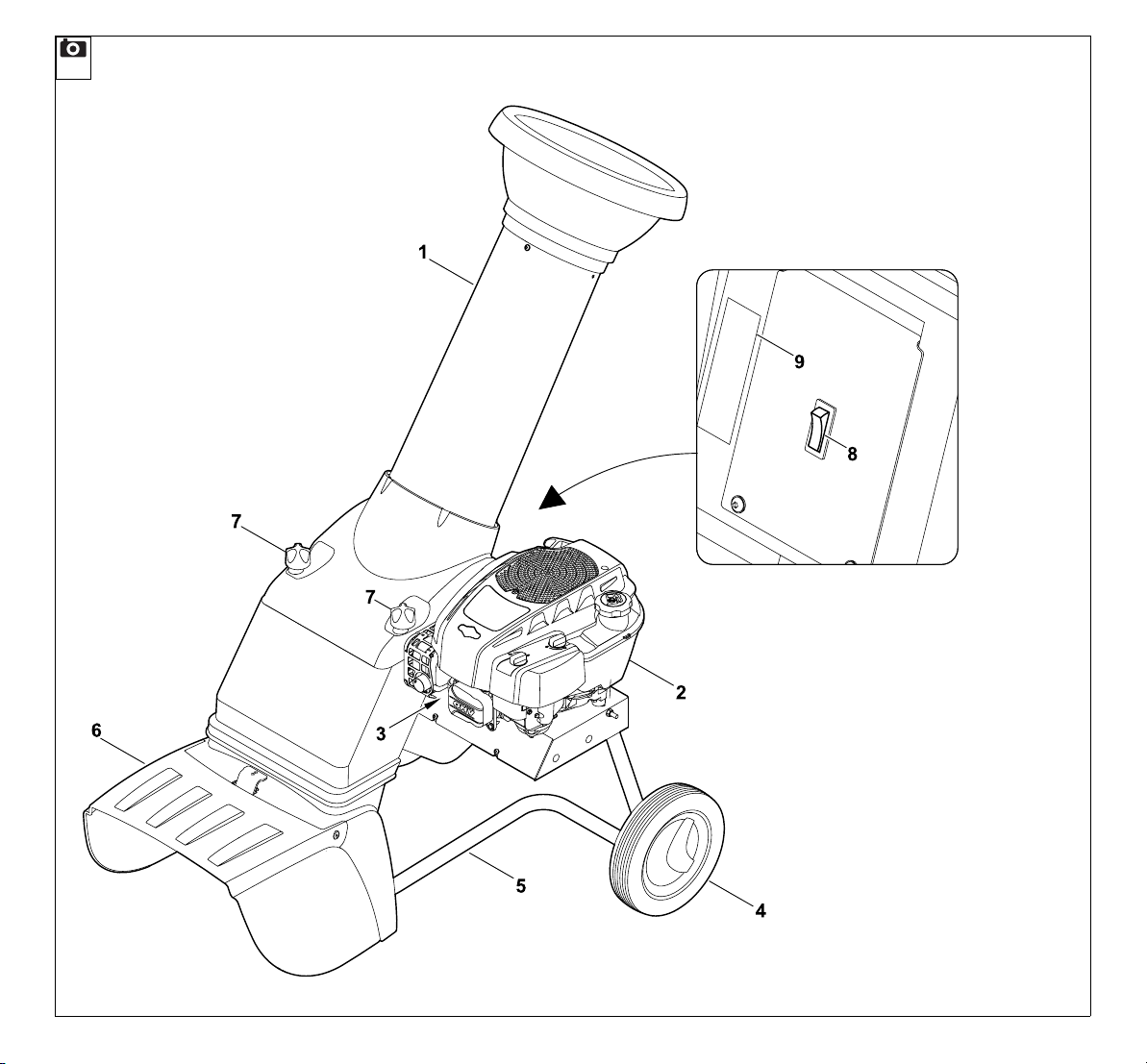

3. Machine overview

1Feed chute

2Engine

3Spark plug socket

4Wheel

5Wheel carrier

6Ejection chute

7Closure screws

8On/Off switch

9Rating plate with machine number

4. For your safety

1

1