BART-TECH 3D BT1.2 User manual

FDM 3D printer - BT1.2 model

Operating Manual

Operating Manual for 3D Printer BT1.2

2

CONTENT

1. Introduction

2. Technical specifications

2.1 Device description

2.2 Technical specifications

2.3 Description of individual parts

2.4 Package Contents

3. Safety instruction

3.1 Operator's obligations

3.2 Electrical equipment operation

3.3 Personnel without professional electrical qualification

3.4 Electrical equipment

3.5 Disposal of the product and its parts

3.6 Operator safety instructions

4. Printer assembly and connection instructions

4.1 Equipment construction assembly (mechanical part)

4.2 Connection (electrical part)

4.3 Commissioning

5. Printer

5.1 Starting printing - programme (* .gcode)

5.2 Pad calibration

5.3 Introduction of a new printing string - filament replacement

5.4 Restarting the printer - RESET

5.5 Turning the printer off

6. Maintenance

6.1 Moving parts

6.2 Printing pad

6.3 Print head (extruder)

Operating Manual for 3D Printer BT1.2

3

1. Introduction

This operating manual contains device technical data, data and instructions for its

assembly, as well as information concerning device operation and commissioning.

However, the manual could not fulfil its aim if its contents are not familiar to those

who operate and maintain the device.

It is the user and operator's responsibility to familiarise themselves properly with

these operating instructions before commencing work. It contains important

information on work safety and maintenance, and therefore must be considered

as part of the equipment. The device's fault-free, safe operation and also its service

life largely depends on its correct use and maintenance.

Any arbitrary changes made to this device without the manufacturer's permission

void the manufacturer from liability in relation to consequential damage or injury!

If you find it difficult to understand any information in this manual, contact the

device manufacturer. We recommend that you keep the original instructions safe.

When working, follow the safety instructions to avoid the risk of injury either to

yourself, or others around you.

These instructions are marked with the following safety warning symbols in

the operating instructions:

▪CAUTION RISK TO HEALTH OR DAMAGE TO PROPERTY

▪CRUCIAL INFORMATION FOR THE OPERATOR

▪GENERAL INFORMATION FOR THE OPERATOR

▪RISK OF HAND INJURY

▪CAUTION HOT SURFACE

Operating Manual for 3D Printer BT1.2

4

2. Technical Specifications

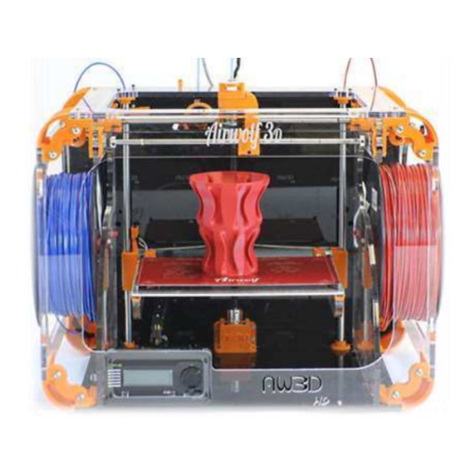

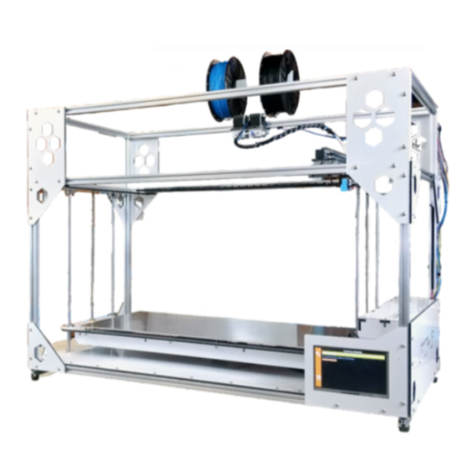

2.1 Device description

The device is delivered in kit-form, it is already partially assembled

and unconnected. Instructions for installation and correct connection

are part of this manual. Stepper motor drivers are already set to

optimal values, there is no need to set anything. The extruder nozzle

is tightened by heat.

The BT1.2 3D printer is designed as a single-purpose device for melting

and controlled plastic lamination - a process also called FDM (Fused

Deposition Modelling or FFF-Fused Filament Fabrication), and is a

common 3D printing technology.

This device is basically a computer-controlled machine.

2.2 Technical Data

Description

Value

Version

BT1.2

Producer

BART-TECH 3D s.r.o.

Height

639 mm

Width

459 mm

Length

559 mm

Weight

9.3kg (without printing string-filament)

Voltage source

180-264 V AC 47-63 Hz/ 12 V DC / 250W

Operating voltage

12 V DC

Operating temperature

range

18 to 38° C

Maximum humidity

85%

Nozzle temperature

max. 255° (recommended 210° -230° C)

Pad temperature

max. 110° (recommended 70° -90° C)

Print space (w x d x h)

220 x 220 x 240 mm

For materials

thermoplastic filaments Ø1.75 mm with a melting point up

to 250°

(PLA, PETG, HIPS, ABS, WOOD, NYLON, HIPS, ASA, ..)

Printing pad

magnetic + steel plate with PEI surface

Extruder

Dual drive

Control board

Makerbase MKS GEN L V1.0

Resolution of stepper

motors

400 steps / revolution (0.9° step angle)

The identification plate with a serial number is located on the rear of the aluminium profile.

Charged voltage: 230V / 50Hz, Max. current: 2.8 A

Operating Manual for 3D Printer BT1.2

5

2.3 Description of individual parts

Filament spool holder

Control unit MKS GEN L V1.0

Y-axis motor

Y

Extruder

Y

DC 12V power supply

230V mains

cable

connector

with 10A

fuse

Touch control panel

Z2 axis motor

Z1 axis motor

X-axis motor

nuts for

adjusting

the pad

height

Trapezoidal

movement

screws

Z-axis guide

rods

2x End switch

of Z1 axe on

the left, Z2 on

the right

X-axis limit

switch

Heated

magnetic

printing pad

with a PEI

surface

Y-axis belt

tensioner

X-axis belt

tensioner

Y-axis

guide rods

Aluminum frame

X-axis

guide rods

Anti-vibration

pads

main

switch

USB connector

(PC connection)

Operating Manual for 3D Printer BT1.2

6

Printhead - EXTRUDER

motor E

filament feed

wheel

filament pressure

wheel

compression spring

adjustment screw for

the pressure force on

the pressure wheel

heatblock

nozzle

blowing nozzles

ventilator FAN2

heatbreak

cooler

ventilator FAN1

pressure door

extruder body 1

extruder body 2

heater hole

temperature sensor

hole

Operating Manual for 3D Printer BT1.2

7

2.4 Package contents

•instructions for use and installation

•completely assembled lower frame including cables… 1 piece

•display including cover, brackets and connecting material… 1 piece

•completely assembled X axis including extruder and cables… 1 piece

•aluminium profile 20x40x400….. 2 pieces

•plastic holder for power supply 12V….. 1 piece

•aluminium corner connector…. 2 pieces

•upper part of the frame

•hardened guide bar 8h6 x 400…. 2 pieces

•movement screw with trapezoidal thread TR8x2… 2 pieces

•voltage source 230V / 12V incl. cables…. 1 piece

•mains (PC) cable with plug 230 V… 1 piece

•cabinet with control board and fan… 1 piece

•Allen key 2.5… 1 piece

•flat screwdriver 3mm… 1 piece

•Allen key 3… 1 piece

•Allen key 2… 1 piece

•flat nozzle wrench size 7… 1 piece

•flat nozzle wrench size 20… 1 piece

•side splitting pliers

•connecting material (part of each component)

•electrical cable ties… 6 pieces

•SD card

Operating Manual for 3D Printer BT1.2

8

3. Safety Instructions

Using this device in any way other than that specified by the manufacturer is contrary to its purpose!

Any arbitrary changes made to this device without the manufacturer's permission void the

manufacturer from any liability for consequential damage or injury! When working, follow the

safety instructions to avoid risk of injury to either yourself or others around you. Use extreme

caution when handling the printer, as this is an electrical device with moving and high-temperature

components.

The printer is designed for indoor use. Place the printer in a stable, clean place at a suitable

distance from other objects. There must be no flammables or explosives within reach.

Before connecting the printer with the power cable to a 230V, 50Hz power outlet, make sure that

the cable is not mechanically damaged. Replace a damaged cable immediately.

Do not touch the nozzle or heated pad when the printer is running. The surface temperature can

be up to 100 °C depending on the type of printing and the nozzle temperature up to 250 °C.

Never disassemble the printer's power supply. In the event of a malfunction, always hand the

printer over to a qualified service technician or contact the manufacturer. Use extreme caution

when operating the printer.

The device has a number of moving and rotating parts, which could result in injury if handled

incorrectly. Touching these parts during operation is forbidden.

The printer must not be left unattended when running.

The printer produces fumes and odours due to melting plastic, so place the printer in a well-

ventilated area without drafts. Drafts have a negative effect on the print quality.

3.1 Operator's obligations

(Operator's obligations related to equipment maintenance in accordance with applicable regulations

and standards)

➢maintain electrical equipment in a permanently safe and reliable condition in accordance with the

applicable electrical regulations

➢make sure that electrical equipment is not tampered with by people without electrotechnical

qualifications (lay people) and that they do not carry out work in accordance with applicable standards

and regulations

➢demonstrably acquaint all personnel who operate the electrical equipment in question with the

operator and safety regulations, and also with the possible risk of electric shock

3.2 Electric Equipment Operation

(equipment operation requirements in terms of electrical equipment qualification)

➢only personnel with the required qualifications may operate electrical equipment

➢people without professional electrical qualification (laymen) can operate small and low voltage

electrical equipment which are designed so that they cannot come into contact with exposed live parts

of electrical equipment during their operation

➢if local or other safety and work regulations or instructions are drawn-up, they must be accessible in a

suitable place, and staff must be demonstrably acquainted with them

➢people operating the equipment must be familiar with the equipment being operated and its function

➢the operator can only touch parts that are intended for the operator

➢there must always be free access to serviced parts

➢in the event of damage to electrical equipment or a failure that could endanger an employee's

health and safety, the employee who detects such a condition and who is unable to eliminate the

Operating Manual for 3D Printer BT1.2

9

cause of the danger themselves must take measures to prevent or reduce the risk of injury, fire or

other hazards.

➢electrical appliances must be safely disconnected from the power supply before moving

3.3 People without professional electrical

qualifications

(requirements for operating equipment in terms of electrical equipment qualifications)

➢before moving electrical equipment connected to the mains by flexible cable and a plug, safe

disconnection from the mains must be done by taking the plug out of the socket.

➢when operating electrical equipment, the operator must observe the relevant instructions as well as

local operating regulations for its use, and also make sure that the equipment is not excessively

overloaded or otherwise damaged.

➢maintain electrical equipment in accordance with the manufacturer's instructions

➢only replace remelted inserts of threaded and instrument fuses with new inserts of the same value

(remelted inserts must not be repaired)

➢when the electrical device is switched off, they can move and extend the movable leads with

connecting cables provided with appropriate connecting parts

➢switch simple electrical devices on and off

➢if the operator notices a fault in the equipment, e.g., damage to insulation, burning odour, smoke,

unusually noisy or shock operation of electrical equipment, strong humming, jerky start, some

electrical equipment part overheating, sparks, armour from electric current, THE ELECTRICAL

EQUIPMENT MUST BE SWITCHED OFF IMMEDIATELY!

3.4 Electrical equipment

(equipment operation requirements)

➢DAMAGED ELECTRICAL EQUIPMENT MUST NOT BE USED!

3.5 Disposal of the product and its parts

(equipment disposal ecology)

OBSERVE APPLICABLE ECOLOGICAL REGULATIONS!

When the equipment is eventually decommissioned (at the end of its service life), bear in

mind the environmental protection and recycling options (in general):

➢dispose of toxic waste (e.g., batteries, electronics), separate plastic materials in accordance

with regulations and offer them for recycling

➢separate metal parts for scrapping in accordance with the type

➢it is necessary for the facility owner to comply with the Waste Act when disposing of waste in

terms of care for healthy living conditions and environmental protection

➢it is necessary for generated waste to be offered to waste disposal facility operators,

particularly metals, oils, lubricants, plastics, etc.

Operating Manual for 3D Printer BT1.2

10

3.6 Operator Safety Instructions

(the device operator must follow these instructions)

THE EQUIPMENT'S ELECTRICAL PARTS MUST NOT BE RINSED WITH WATER!

➢Safety elements must always be kept in perfect condition

➢Keep the device safety markings legible

➢Be sure to follow this manual's safety instructions

➢Read these operating instructions, including other instructions for any sub-equipment, carefully before

using the device in any way.

➢If the device begins to shake strongly, shows increased noise or other abnormalities during operation,

turn it off and have it checked immediately.

➢Do not start the device without covers

➢damaged equipment must never be used

➢the equipment must only be used for the purposes for which it was designed

➢only work in good lighting conditions

➢Before starting work, the operator must perform a visual inspection on the equipment's moving parts

for signs of excessive wear or damage.

➢This device cannot be used with excessively worn or damaged parts

➢Only carry out device maintenance and cleaning when the power supply is disconnected

➢This device may only be operated by people over 18 years of age, who are mentally and physically fit,

well acquainted with its properties and familiar with the relevant regulations for its operation.

Younger people may only operate the device under the supervision.

➢It is forbidden to operate the device under the influence of alcohol, drugs or other narcotics

➢All device maintenance and repairs must only be carried out with the device stopped and properly

secured

➢The device is intended for indoor use only (premises)

Operating Manual for 3D Printer BT1.2

11

4. Printer assembly and connection instructions

4.1 Equipment construction assembly (mechanical

part)

1

2

3

4

5

6

6

7

8

Overview of the main assembly steps:

1. fasten both aluminium profiles

2. slide both guide rods into the

brackets

3. install the x-axis

4. tighten both movement bolts

5. fit the frame's upper part

6. attach the power supply

7. attach the control board unit

8. attach the coil

9. attach the control panel

(See details in the manual's other pages)

9

Operating Manual for 3D Printer BT1.2

12

Slide the profile in until it is in contact with the opposite profile. Hold down and gradually tighten all the bolts in the order

numbered in the picture above. The same applies for both sides.

Tighten the M4 bolt with T-nut (applies to all connections of plastic parts to the aluminium profile)

Insert the rod to the bottom of the hole. Tighten both bolts. The same on both sides

1

T-nut's initial

position when

assembling the

parts together

loosen the bolt so that the T-nut rests on the bottom of

the profile groove

tighten the bolt (T-nut rotates itself in the

profile groove)

Incorrect

Correct

2

after tightening

after tightening

1

2

3

Operating Manual for 3D Printer BT1.2

13

Place the assembled X-axis with sliding bearings on the mounted guide rods. Hold the axis, do not let it fall down by itself!

Hold the X axis raised and turn the movement bolt into the brass nut. Carefully lower the bolt to the motor coupling, where

it reaches the motor shaft. Tighten both bolts on the coupling. Repeat in the manner on the other side.

3

4

Operating Manual for 3D Printer BT1.2

14

Put the upper part of the frame on, put on the profile and check that the entire surface is seated correctly on both sides.

Tighten the 2 M4 bolts with T-nuts (both sides). Tighten the M3 bolts in the rod holder twice (both sides). Attach the corner

connector and tighten both M4 bolts with T-nuts

The cover with the power supply put on the vertical stand and the lower black console. Tighten the M4 bolt. Adjust the

upper power supply bracket height to the threaded hole and tighten the M3 bolt.

5

Loosen

these bolts

before

installing

the bracket.

6

corner connectors location

bracket height adjustment

Operating Manual for 3D Printer BT1.2

15

7

8

Operating Manual for 3D Printer BT1.2

16

9

tighten 4 M4 bolts with T-nuts

Operating Manual for 3D Printer BT1.2

17

4.2 Connection (electrical part)

Control board description

Overview of the main steps with concern to the control board connection:

1. 12V voltage source

2. heated pad (heating, temperature sensor TB)

3. extruder (motor E, heating, temperature sensor TH, ventilators FAN1 and FAN2)

4. stepper motors X, Y, Z1, Z2

5. limit switches X, Y, Z1, Z2

6. LCD - LCD12864 display

7. fix the cable outlets from the cabinet with cable ties

8. connect the FAN0 ventilator in the cabinet cover

(For details, see the photo instructions on the following pages)

input voltage 12V

(for power supply)

- +

+ -

output voltage 12V

heated pad

+ -

+ -

output voltage 12V

extruder heater

output voltage 12V

fan FAN1-hotend

output voltage 12V

fan FAN2-blower nozzle

X-axis motor connection

Y-axis motor connection

Z1 axis motor connection

motor connection E (extruder)

Z2 axis motor connection

USB connector

computer connection

cable hole (extruder

and heated pad)

cable hole (other cabling)

RESET button

LCD TFT28/32 port for

BT1.2 model

limit switch X

End switch Z2

limit switch Y

limit switch Z1

pad temperature sensor

nozzle temperature sensor

tunnel for cable routing

ventilator FAN0 - active

cooling the control

board

Operating Manual for 3D Printer BT1.2

18

Power supply connection to the control board

Connect both contacts to the terminal block, carefully tighten with a flat-blade screwdriver and check the tightness by

pulling. Check the polarity carefully! Front view of the board = left BLACK (-) and right RED (+)

When tightening, hold the terminal block against movement with two fingers. Place the cables in a tunnel around the

board.

!!! CAUTION the control board may get damage in case of incorrect connection or reversing the

polarity!!!

1

gradually insert the supply

cable from the source into the

lower cable holders (plastic

lugs).

Operating Manual for 3D Printer BT1.2

19

Heated pad connection

The printing pad wiring harness has heated contacts (red + black) and a temperature sensor connector on the black wires.

There is a reinforced brace in the cable harness.

Connect both contacts to the "HBED" terminal block, carefully tighten with a flat-blade screwdriver and check the

tightness by pulling.

Front view of the board = left Red (+) / right Black (-).

When tightening, hold the terminal block against movement with two fingers.

Place the red and black thick cables in the cable tunnel again on the left along the board

Connect the temperature sensor connector (white socket "TB" on the bottom left of the board). Compare all the cables to

the tunnel. Before fixing the cable with a cable tie, turn the cable clockwise and pre-tension the cable so that it does not

touch the frame when moving the pad. Cut off the cable tie excess.

2

TB

Operating Manual for 3D Printer BT1.2

20

Extruder connection

3

end of extruder

harness

FAN1 connector

–longer cable

FAN2 connector

–shorter cable

extruder heating contacts

(heater)

motor

connector E

temperature sensor connector

trysky

Connect both contacts to the "HE0"

terminal block, carefully tighten with a

flat-blade screwdriver and check the

tightness by pulling. Polarity does not

matter.

Connect the motor connector

(marked "E") to the socket on the

board marked "E0"

Connect the temperature sensor

connector to the socket on the

board marked "TH1"

Connect the FAN1 connector to the

cable splitter socket (this is already

connected to the "HE1" terminal

block). FAN1 connector is on a longer

cable.

Connect the FAN2 connector to the

"FAN" socket on the board. FAN1

connector is on a longer cable.

After connecting all the contacts,

hide the cables in the side tunnel.

Secure the cable harness with cable

tie over the cable from the heated

pad. Before tightening, pre-tension

the cable again (turn it clockwise).

Cut off the cable tie excess.

Optimal cable formation from the

control unit. They are not in contact

with the frame or pad when moving

E

TH

Note: There is a reinforcing brace in the cable

harness.

Table of contents