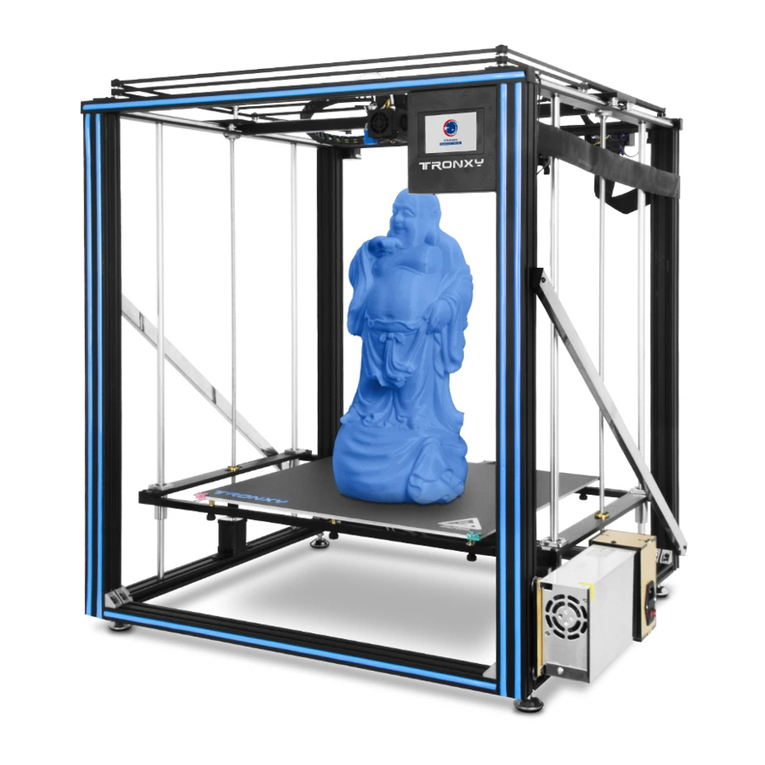

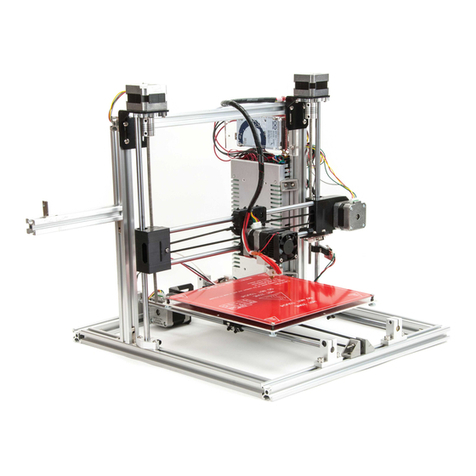

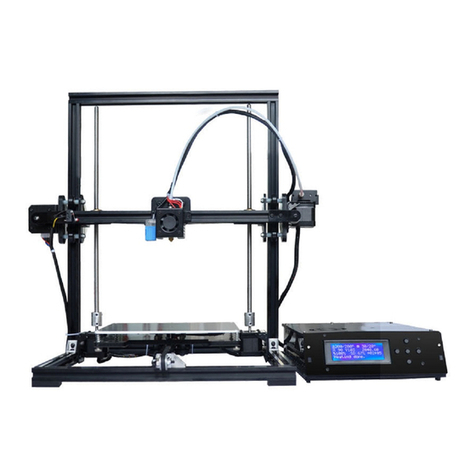

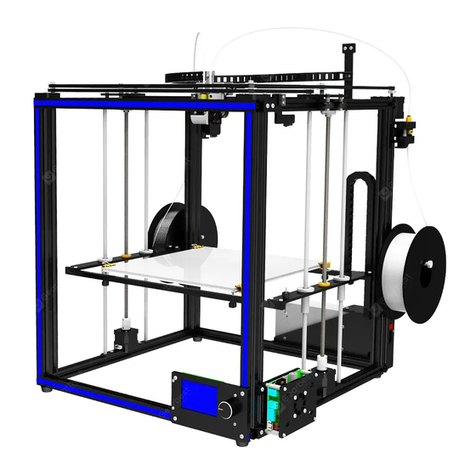

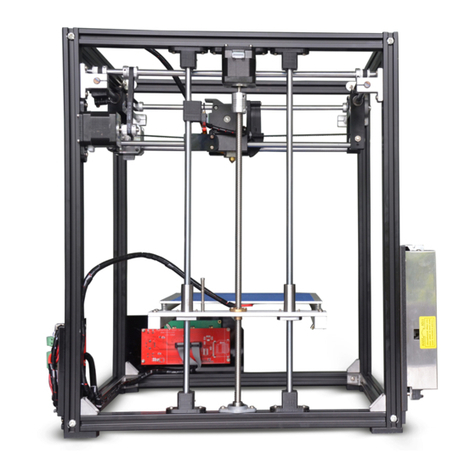

TRONXY X5SA User manual

X5SA

Installation instructions

SHENZHEN TRONXY TECHNOLOG CO.,LTD

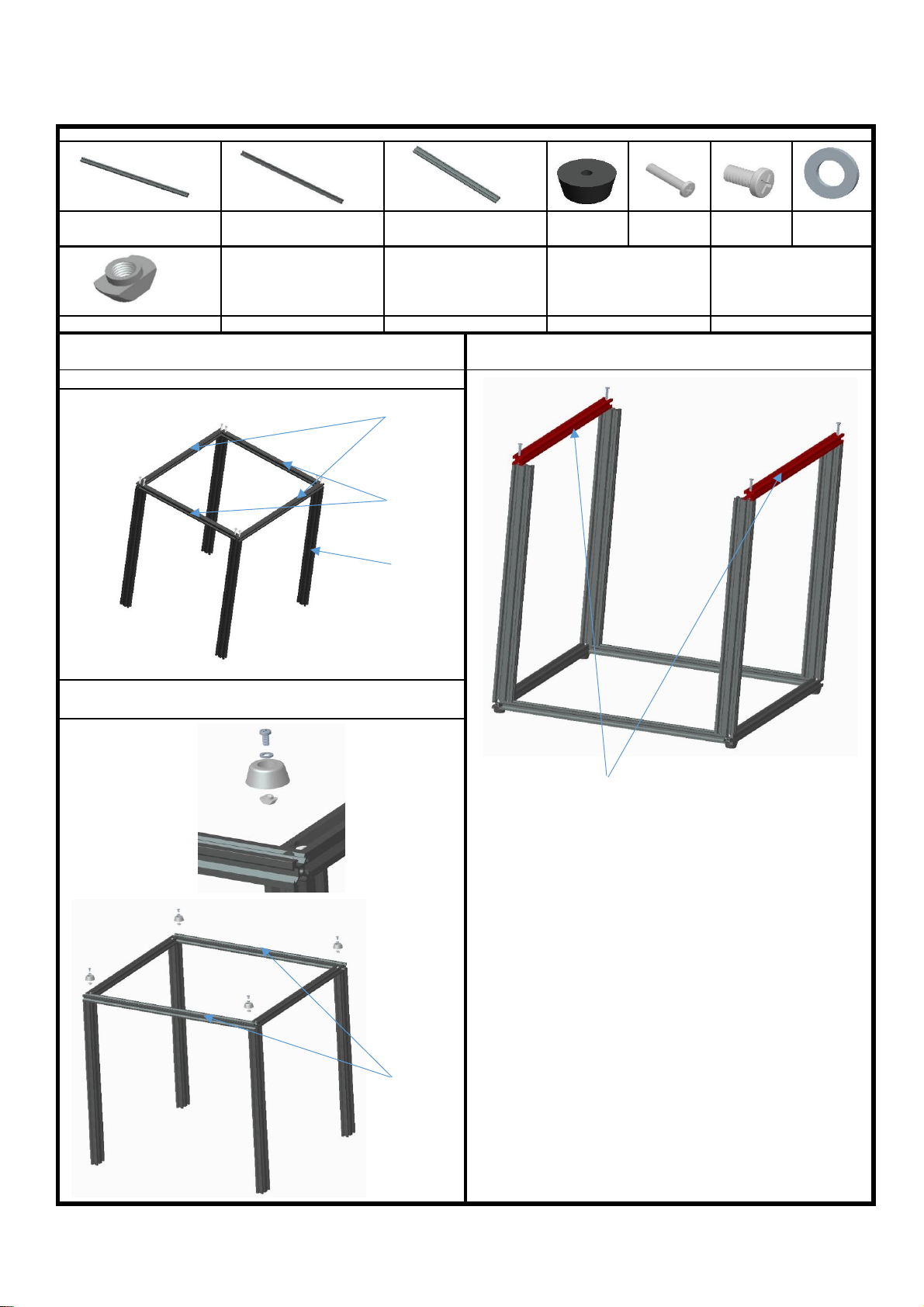

Aluminium profile 1

Aluminium profile 2

Aluminium profile 3

Aluminium profile 1

Aluminium profile 1

2.Assemble the pad, spacer, screw PM4*8, T nut M4 with the aluminium profile 1

together,distance from the end around 20mm, same as the illustration

Aluminium profile 1 20*20*530mm

4pcs

Aluminium profile 2 20*20*460mm

2pcs

Aluminium profile 3 20*40*530mm

4pcs

1.Lock the aluminium profile 1 2pcs, Aluminium profile 2 2pcs, aluminium 3 4pcs

together by 8pcs screw PM5*25, same as the illustration.

Note: Before locking the screws, make sure the aluminum profile are aligned and vertical

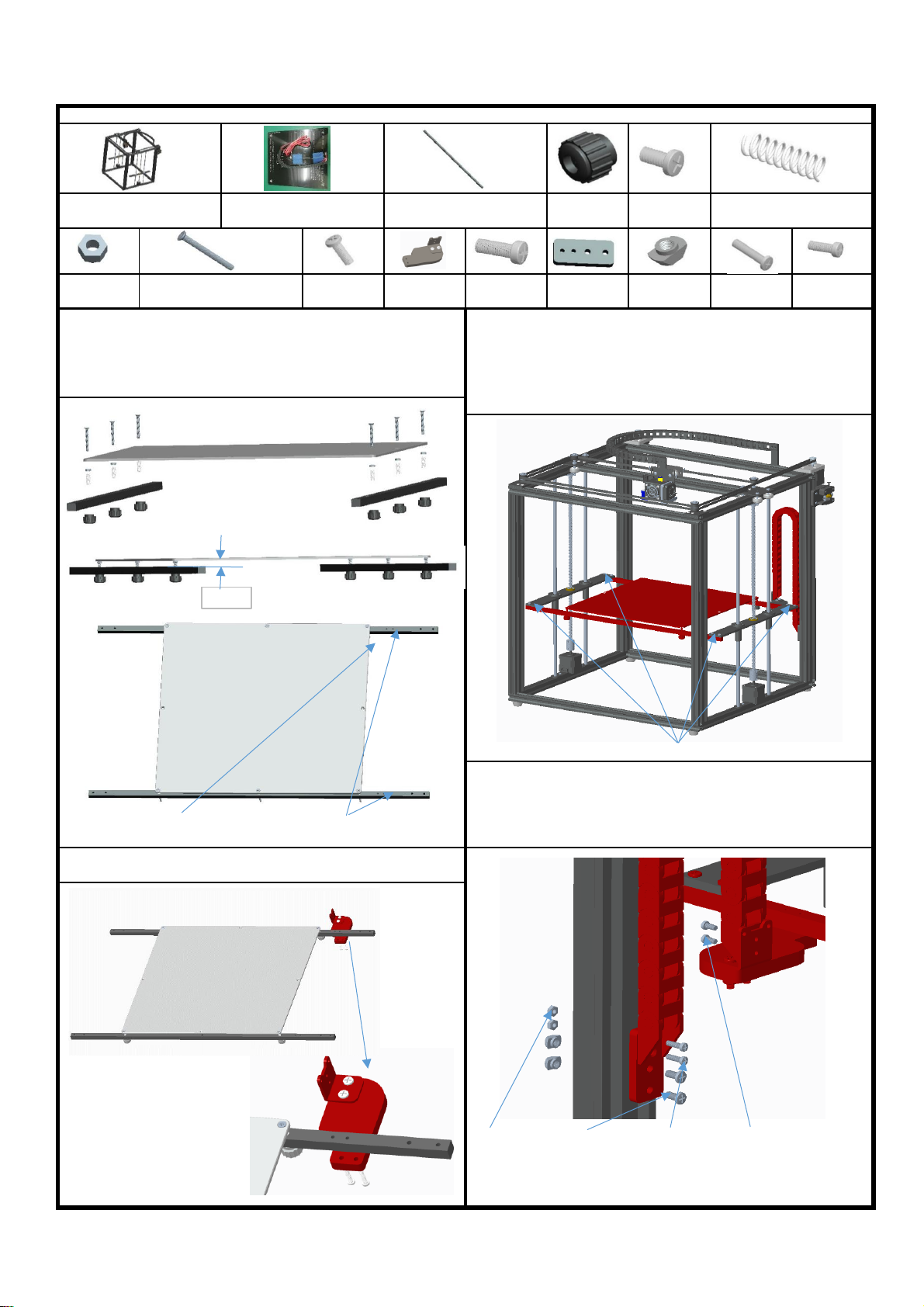

Step 1. Assemble base frame

Assemble parts specifications and quantity:

T nut M4 4pcs

3.Lock the aluminium profile 1 2pcs with 4pcs screw PM5*25

Note: Do not tighten too much, enable they can be adjusted in further step.

Pad 4pcs

Screw PM5*25

12pcs

screw PM4*8

4pcs

Spacer M4

4pcs

1 Product assembly

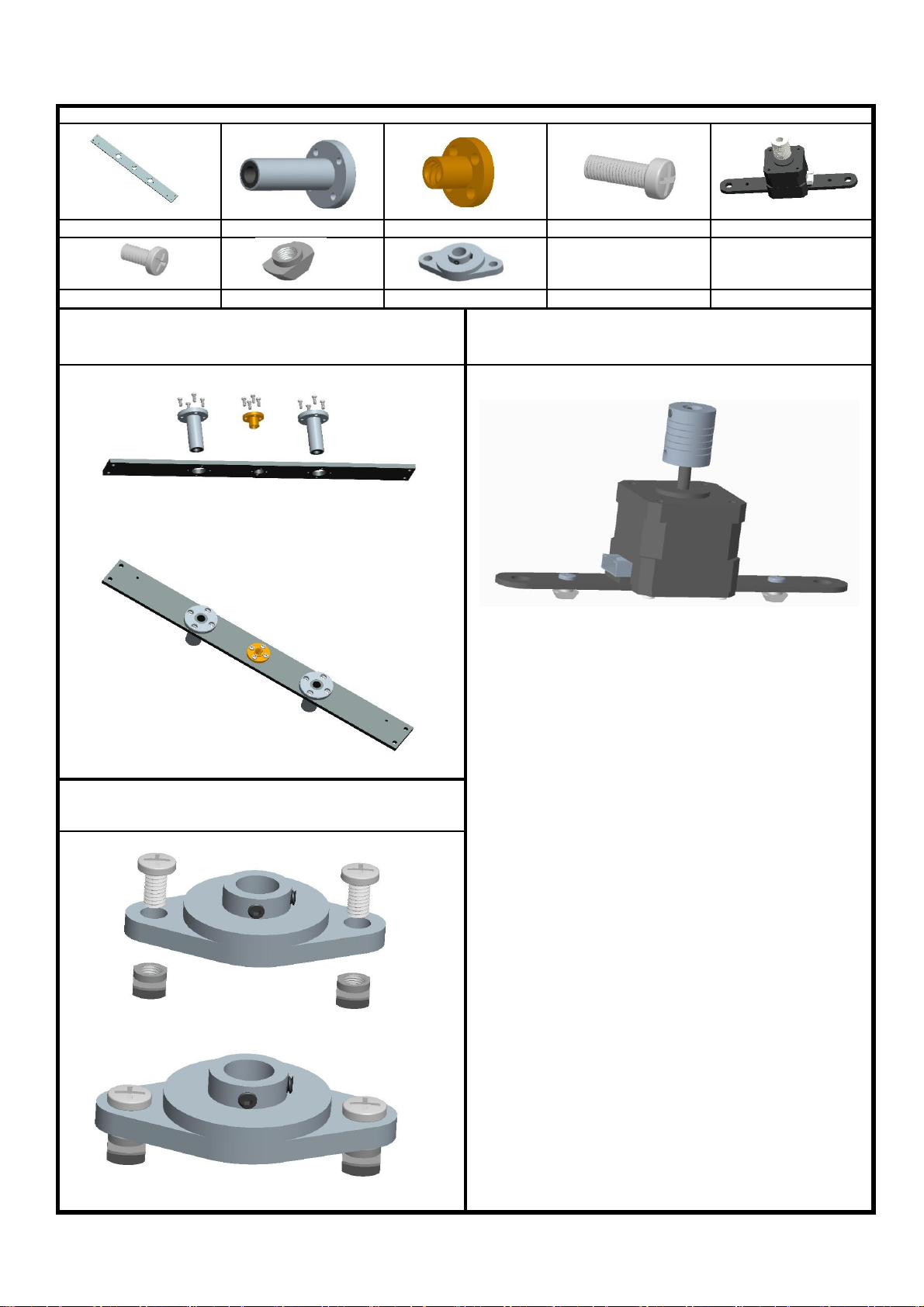

Slider plate(Left) Slider plate(Right)

Step 2:Assemble slider plate

Slider plate (Left) 1pcs

Slider plate (Right) 1pcs

2. Put 2pcs aluminum 2, through Left and Right slider plat

component respecitve, as same as the illustration.

Note: The wheels are on the side without holes, the slide plate is

on the side with the four holes.

Assemble parts specifications and quantity:

Alu. profile 2

20*20*460mm

2pcs

Screws

PM5*25mm

4pcs

PM4*8mm

screws 4pcs

M4 T nut

4pcs

1, Respectively insert 2pcs PM4*8mm screws to Left and Right slider

plate , lock with M4 T nut , as same as the illustration.

3.Put the aluminum 2 components into the end of the aluminum frame 3

of the bottom frame, then secured by 4pcs screw PM5*25, as same as

the illustration.

Aluminium Frame

Pay attention to the sink hole

The eccentric nut

Adjust pulley clearance by rotating eccentric nut

Slider plate(Right) Slider plate(Left)

PM3*16 PM4*12

Aluminium frame

M4 T-Nut

2pcs

Step 3:Assemble printing head

Assemble parts specifications and quantity:

Note:The distance between the aluminum 4 and aluminum 2 is 3mm

M3 Nut

4pcs

Towline holder

1pcs

PM3*16MM

2pcs

PM3*8MM

2pcs

PM4*12mm

2pcs

3, Assemble the Towline and the holder using 2pcs PM3*16mm

screws and M3 Nuts , then place the towline holder to the

aluminium profile as the illustration.

1, Place the towline to the printing heat , secure with 2pcs

PM3*8mm screws and M3 Nut

2.Insert the aluminum profile 4 into the printing head

component,same as the illustration.

The eccentric

nut

Adjust pulley clearance by rotating eccentric nut

4.Put the aluminum 4 component into the T nut of the left and right slide

plate component,screw the screw PM4*8 of the slide plate,same as the

illustration. Move the aluminum profile 4 front and back,make sure it can

move freely,then lock the screw PM4*8, remove the aluminum 4,ensure

it can move freely, lock the screw PM5*25 of the aluminum 2, move the

aluminum 4 again to make sure the movement is flexible. Lock the

screws PM5 * 25 of aluminum profile 2,move the aluminum 4 again to

make sure the movement is flexible, otherwise, please adjust it again,

make sure tthe sliding table is flexible and without gap shaking after

locking the screws

Alu. Profile 4

20*20* 484mm

1pcs

Printing head

component

(with Towline) 1pcs

Step 4:Assemble XY axis motor and wheel

Assemble parts specifications and quantity:

X Motor base

plate 1pcs

M4 T-Nut

10pcs

Screws PM4*12

4pcs

2. Respectively insert 3pcs PM4*8mm screws to Left and Right pulley

component , lock with M4 T nut , as same as the illustration.

1. Assemble X & Y motor and X & Y motor base plate using 4pcs

PM3*10mm screws , Respectively insert 2pcs PM4*12mm screws to the

plates , lock with M4 T nuts , see the illustration

3.Fix the X motor component,Y motor component,left pulley

component,right pulley component and aluminum by PM4*12mm screws

and M4 T nut, as same as the illustrations.

Screws PM3*10

8pcs

Y Motor base

plate 1pcs

Framework

Pulley component

(Right) 1pcs

Pulley component

(Left) 1pcs

Motor 2pcs(With

Synchronous

wheel)

Screws

PM4*8 6pcs

1. Pass the belt through the gear as shown, press the pulley plate

against the motor bottom plate, fasten the lower end of the sheet

metal groove of the print head assembly with the tie belt, as

shown in the figure. After adjusting the spacing between the motor

gear and the belt, lock the 2 meter screws on the gear.Loosen the

motor baseplate screw, pull the motor assembly outward, tighten

the belt (do not force too much), and lock the screw.

2. Pass the belt through the gear as shown, press the pulley plate

against the motor bottom plate, fasten the lower end of the sheet

metal groove of the print head assembly with the tie belt, as

shown in the figure. After adjusting the spacing between the motor

gear and the belt, lock the 2 meter screws on the gear.Loosen the

motor baseplate screw, pull the motor assembly outward, tighten

the belt (do not force too much), and lock the screw.

Step 5:Assemble belt

Assemble parts specifications and quantity:

Main frame 1pc

Belt 2pcs

Tie 4pcs

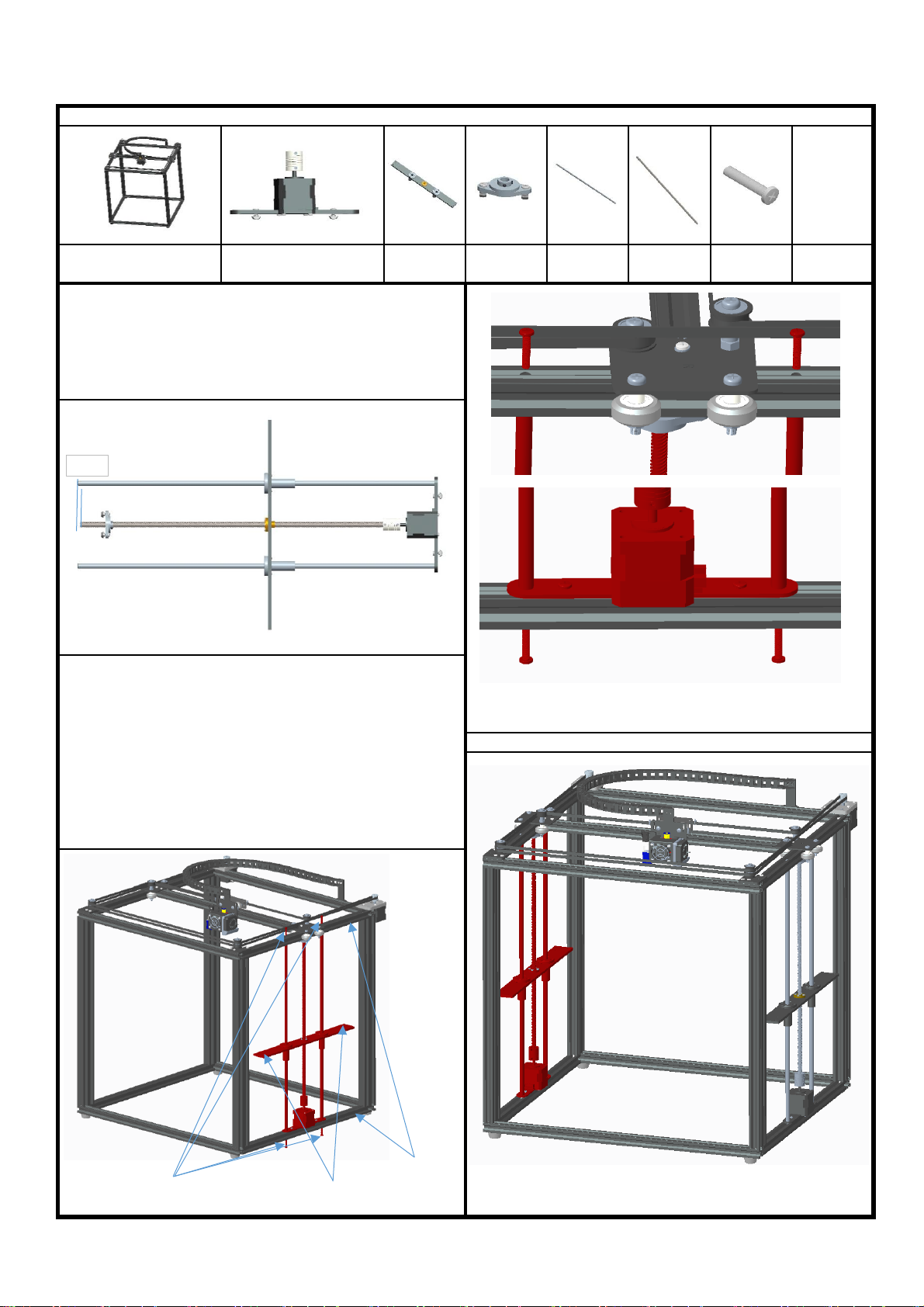

Step 6:Assemble bearings and Z-axis motor

Assemble parts specifications and quantity:

Z fixed plate 2pcs

Flange bearing 4pcs

Copper Nut 2pcs

Screws PM3*8 24pcs

Z motor component 2pcs

Screws PM4*8 8pcs

3.Assemble 1pc Z motor component,2pcs screw PM4*8mm, 2pcs

Elastic gasket and 2pcs T nut M4 together, total need to assemble 2 set.

2.Assemble 1pc bearing seat ,2pcs screw PM4*8mm, 2pcs T nut M4

together,same as the illustration, total need assemble 2set.

M4 T Nut 8pcs

Bearing seat 2pcs

1.Assemble 1pc Z fixed plate , 2pcs bearing seat, 1pc screw nut,12pcs

screw PM3*8 together, as the illustration, total need to assemble 2 set.

Alu. Profile 2

PM4*20

Sliding rod

Φ8*528 4pcs

Z motor component 2pcs

1.Insert the solid end of the Sliding rod to the hole on Z axis motor holder, insert the barrel of the

motor holder into the hole,do not let the pole stand out,same as the illustration.Then, put the Z

fixed plate component with the pole Φ8*528 together. Thread the the lead screws T8*453 through

the copper nut, connect with the coupling hole on the motor,put the bearing seat component on

lead screw T8*453 same as illustration(The T nuts are at the outer end),then the Z axis carriage

is finished. Total need to assemble 2set.

Lead screw

T8*453 2pcs

Step 7:Assemble Z axis component

Assemble parts specifications and quantity:

Bearing seat

component

2pcs

Screw PM4*20

8pcs

Note:When assemble the pole, keep lead screw T8*453 3mm shorter than sliding rod Φ8*528mm

3.Repeat the number 2,assemble other Z aixs carriage, as the illustration.

Z carriage

2pcs

2.Adjust the T nut on the Z motor component, Place the Z motors to the aluminum

profile 2 , the 2 small M3 holes stand outsite as the illustration. Align sliding rod Φ

8*528 with the hole of the aluminum profile, let screw PM4 * 20 through the holes of

the aluminum profile 2, then connect with the M4 hole of the sliding rod Φ

8*528,same as the illustration, rotate the lead screws T8*453,slide the carriage and

the bearing seat to the top, lock the 2pcs screws PM4*20 to the aluminum profile 2

,then lock the M4 T nut and jackscrew of the bearing seat, rotate the lead screws

T8*453, drop the carriage down,make sure it can move freely. Otherwise, please

loosen the jackscrew,adjust it again. then, lock the 4pcs jackscrew in the coupling , T

nut, screw on the Z motor plate, rotate the lead screw T8*453 again,make sure the Z

carriage can slide up and down freely. finally lock the 2pcs PM4*20 screws from the

bottom of the sliding rods .

Base frame component

1pcs

2 small M3 holes stand outside

3mm

Feeding motor component

Step 8:Assemble feeding motor

2.Place the feeding motor component with 2pcs screw PM4*12 and T

nut M4 ,same as the illustration

1.Put 2pcs screw PM4 * 12mm through the board holder,then lock them with the T

nut M4 screw on the boat nut M4

Assemble parts specifications and quantity:

Main framework

Feeding motor component 1pcs

Screws PM4*12 2pcs

M4 T Nut 2pcs

Screws PM4*12

The heatbed wires exit position The holes

M3 Nut PM4*8 screw

PM3*10 screw

PM3*6 screw

2. Place the towline holder to the metal bar by using screw

PM3*16, same as the illustration

4, Assemble the other end of towline and towline base holder by

using PM3*6mm screws , then secure it to right side of

aluminium profile by using 2pcs PM4*8mm screws, same as the

illustration.

1. Put 6pcs KM3 * 30 screws through the heat bed,then lock them with

the nut M3, same as the illustration,put spring through the KM3 * 30

screws,then, extending from the hole of the metal bar,screw into M3

butterfly nuts, adjust and keep 10 mm between the heat bed and the

metal bar.

3.Rotate 2pcs lead screws T8*453,keep 2 Z carriage at the same plane,

secure the heat bed component and metal bar with 8pcs screw PM4*12.

The towline bracket is close to the side of the feed motor component,

rotate the screw in the same direction,let the platform move up and

down, make sure it can move freely, if not freely, please lossen the

screw PM4*12 to adjust it untill it can move freely

KM3*30 screw 6pcs

PM4*12

screw 8pcs

M4 T nut

2pcs

M3 Nut

8pcs

Towline base

holder 1pcs

Towline

holder 1pcs

PM3*16

screw 2pcs

PM3*10

screw 2pcs

Assemble parts specifications and quantity:

Main framework

Heatbed (with towline)

330x330mm 1pcs

M3 Wing

nut 6pcs

Metal bar 2pcs

Step 9:Assemble printer plateform

PM4*8 screw

2pcs

PM3*6

screw 2pcs

Spring 6pcs

10mm

Note: Please assemble it after wiring . Do not touch the

electronic component by hand for avoiding static electricity.

1.Use 3 PM4*6 screws and 3 T nuts to tighten according to the

map position.

3.Take the power supply module, use 3 PM4*8 screws and 3 hull nuts,

and tighten according to the map position.

2.The main board components are loaded into the lower right

corner of the machine, and are fixed in aluminum grooves with T

nuts.

4.Load the power assembly into the lower right corner of the

machine, and use the T nut to fix it in the aluminum slot.

Screw PM4*6 3pcs

Screw PM4*8 3pcs

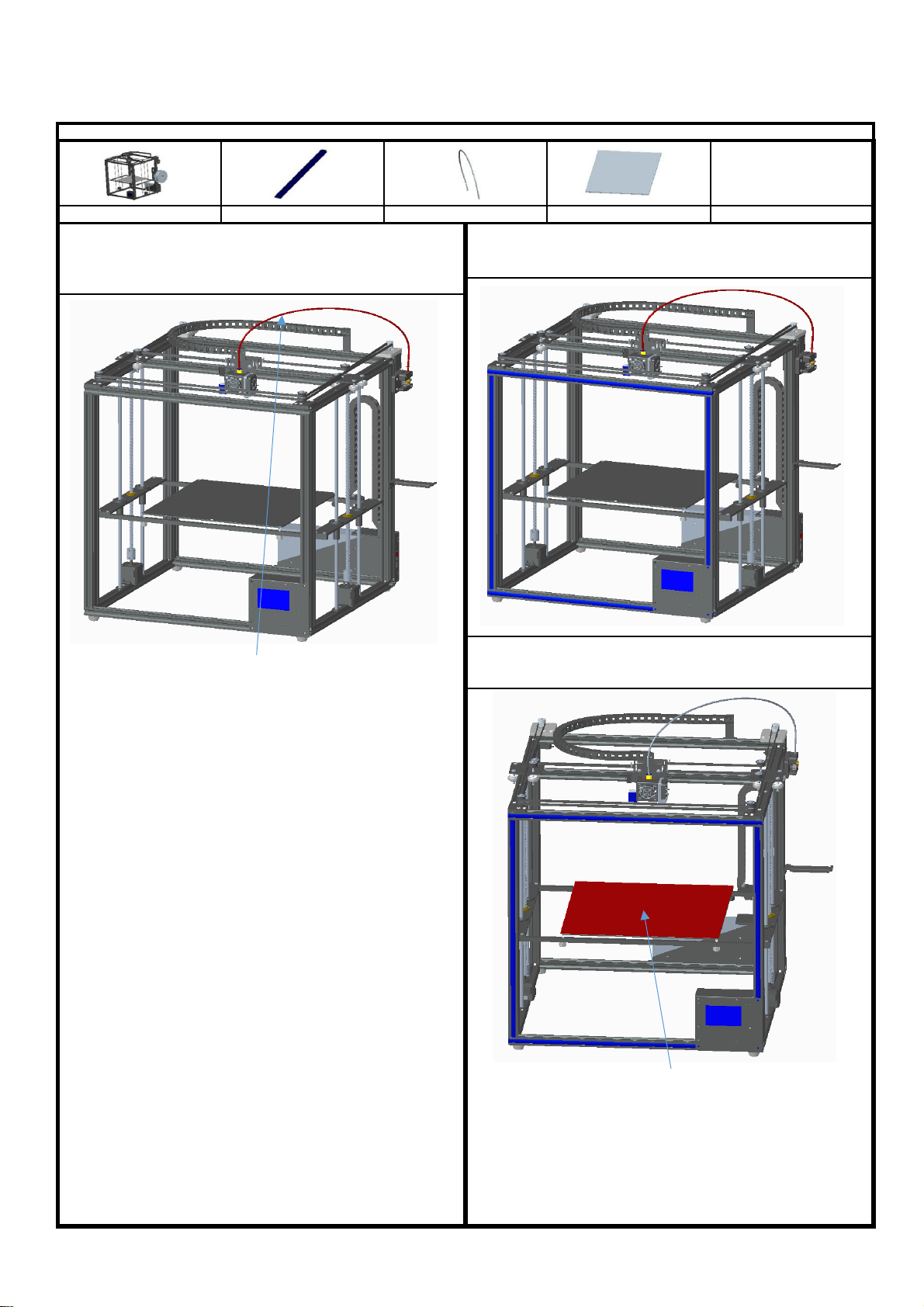

Step 10:Assemble electronic board and power supply

Assemble parts specifications and quantity:

Main frame 1pc

Power supply component 1pc

electronic board and touch-screen component 1pc

T nut M4 6pcs

material rack

material rack 1pcs

T nut M4 2pcs

Screw PM4*6 2pcs

1. Pick 1 piece material rack plate, 2 screwsPM4*6, 2 boat nut M4,

assemble as shown.

2. Fix the material rack assembly into the aluminum profile groove with

boat nut, and lock the 2 screws PM4*6, as shown in the figure.(hang the

material plate on the screw rod)

Main framework

Step 11:Assemble feeding holder

Assemble parts specifications and quantity:

Feeding tube

Print platform sticker

Step 12:Assemble Decorative strip and Feeding tube

Assemble parts specifications and quantity:

1.Put the feeding tube into the hole of the Air cock,insert feeding tube,

press the outer plastic ring of Air cock,loosen the plastic ring,stuck the

feeding tube,same as illustration,move the feeding tube up and down

to make sure it is clenched

2.Align the end seal with the end aluminum profile,then press the seal

into the groove of the aluminum profile,same as illustration.

3, Place the print platform sticker on the heatbed.

Main framework

Aluminium profile seal

Feeding tube 1pcs

Print platform sticker 1pcs

M4 T Nut

2pcs

PM4*8 screws

2pcs

Limit switch (with wires)

1pcs

1. Put 2pcs screw PM4*8 through switch component, then lock

with T nut M4, same as illustration

Step 13:Assemble limit switch

Assemble parts specifications and quantity:

2.Fix switch component in the groove of aluminum profile with

2pcs T nut, then lock 2pcs screw PM4*8,same as the illustration

Main framework

PM4*12

screws 2pcs

M4 T Nut

2pcs

2.Install the filament alarm device in the position shown in the

diagram.To press the end cover into two side aluminum end up and

down.

End cover

1.Put 2pcs screw PM4*12 through cushion plate, then lock with T nut

M4, same as illustration

Main framework

Filament alarm 1pc

End cover 8PCS

Step 14:Assemble Filament alarm

Assemble parts specifications and quantity:

BTEMP

ZSTOP

HOTBED

Power

X-Motor

Y-Motor

Z1-Motor

Z2-Motor

E-Motor

YSTOP

FSTOP

Step 15:Connecting wire

Printing head

Z1-motor

Z2-motor

Y-Motor

X-Motor

E-motor

Heat bed

Printing head The host box

Power

YSTOP

FSTOP

X5SA Physical wiring diagram

F STOP

2. operation instructions

1. Enter the main screen of the startup, display the system and tools, print three main menus, and click on the three sub-menus, as shown in the

figure.Basic functionality for displaying submenus.

2. Click the system menu and enter it into the system submenu, as shown in the figure: click back menu and return to the superior menu.

2.2 click the machine information and display the following figure: display the machine brand, ID, version and other information.Click back menu to

return to the superior menu.

2.3 click the menu to enter Chinese and English.Click back menu to return to the superior menu.

2.1 click the state and display as shown in the figure: display the machine position state parameters.Click back menu to return to the superior menu.

2.4 click factory Settings to ask whether the factory Settings are restored.Click to return to restart and restore the factory Settings.

2.5 click the screen correction icon to enter the screen correction and click the cross position for correction.Adjust the screen when the menu is off, save

it back.

3. Click the tools menu to enter the machine parameter setting and adjustment.

3.1 click the manual menu and enter the manual adjustment mode.Adjust the motor rotation, e. extruder feeding/discharging, XYZ shaft motor moving,

ICONS 0.01mm, 0.1mm, 1mm, 10mm,click on the dark display, such as icon 10mm, each click on the motor stroke moving 10mm.Click the icon and

the machine returns to the origin. icon back to superior menu.

3.2 click the icon of preheating, as shown in the figure, set the heating temperature of the machine extrusion head and the hot bed, heat the icon

hot bed and heat the icon extrusion head, and click the icon in the right and left direction to adjust the setting temperature heating.Use the heating

function when replacing consumables.

3.3 click the icon of loading and unloading consumables to indicate preheating.Remove the consumables to warm up before pulling them out.Set the

heating temperature, the temperature reached, click the icon to return the material.When installing the filaments, make the filaments go straight

out into the hole of the filament run-out detector and press down the feeder's pressing block, as shown in the figure. Pass the filaments through the

feeder to the filaments pipe and then click the icon to send the filaments to the nozzle.Click the icon to stop.

3.4.1 click the leveling icon and enter the leveling menu. There are 3 options: auto leveling, manual leveling and cancel.Click cancel to return.

Other TRONXY 3D Printer manuals

TRONXY

TRONXY X6-2E User manual

TRONXY

TRONXY X3A User manual

TRONXY

TRONXY X5SA-400-2E User manual

TRONXY

TRONXY X5S 2E User manual

TRONXY

TRONXY X5SA-400-PRO User manual

TRONXY

TRONXY X5S User manual

TRONXY

TRONXY P802M User manual

TRONXY

TRONXY XY-3 PRO V2 User manual

TRONXY

TRONXY XY-3 User manual

TRONXY

TRONXY XY-2 PRO User manual

TRONXY

TRONXY X1 User manual

TRONXY

TRONXY VEHO 600-2E User manual

TRONXY

TRONXY D01 User manual

TRONXY

TRONXY VEHO600 User manual

TRONXY

TRONXY X6D User manual

TRONXY

TRONXY XY-2 User manual

TRONXY

TRONXY X5SA-500 User manual

TRONXY

TRONXY Ultrabot User manual

TRONXY

TRONXY X5 User manual

TRONXY

TRONXY XY-2 PRO User manual