Bartec Auto ID TAP100 User manual

[Type here] [Type here] [Type here]

Bartec Auto ID Ltd. SW Version: R.5.3 (English) 2019

TAP100/TAP200

Tread Depth and Pressure Tool

User Guide

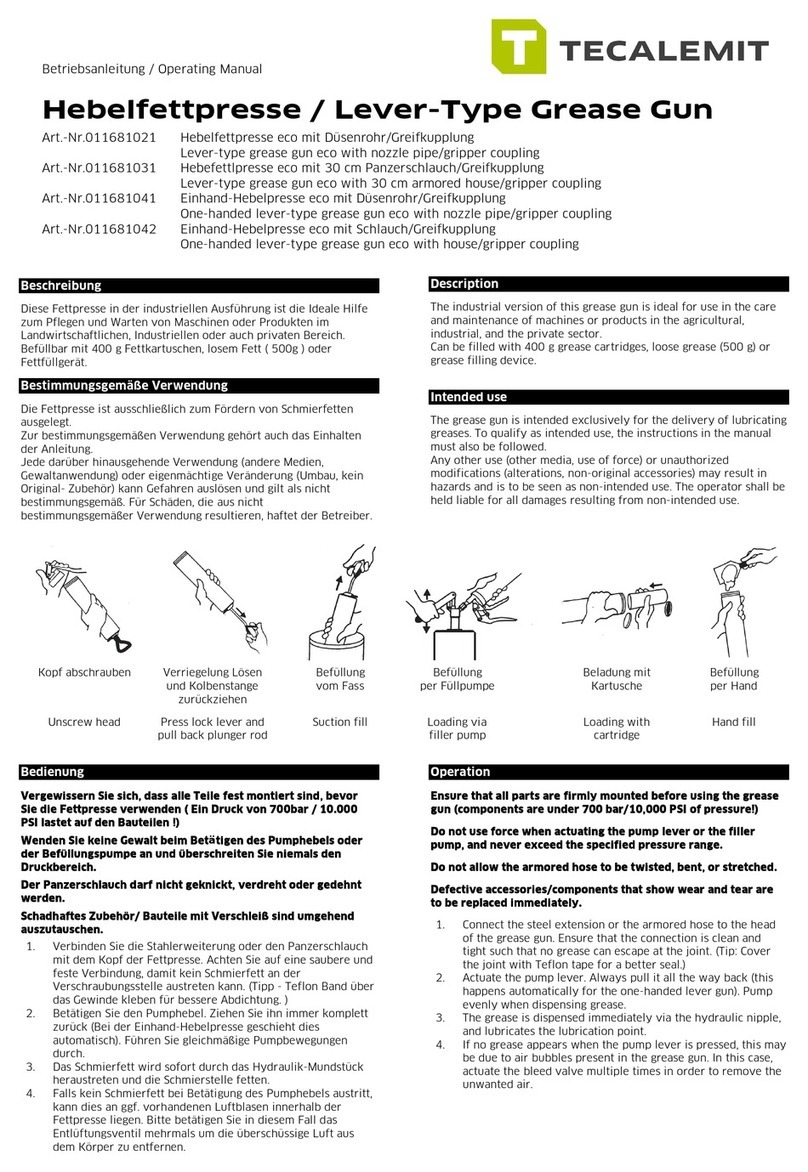

Enter

Display

Rubber

housing

Up/Down

navigation

Wireless

wall

charger

Pressure hose

connection with

protective cap

Hose

Pin cover

Tread

depth pin

Micro USB

port for

updating

On/Back

TAP100/200 User Guide R.5.3 2019

2 |Page

FOREWORD

Dear customer,

Thank you for having chosen one of our tools. We are certain that it will give the utmost satisfaction and be

a great help on the job.

Please become fully familiar with the instructions in this user’s manual. It should be kept ready to hand for

consultation whenever required.

The TAP100 and TAP200 tools are designed to measure a tyres tread depth and pressure in a simple and fast

process and displays the results on a high resolution colour display, making them easily presentable for the

customer.

These tools are acceptable for use during statutory test conducted in accordance with Motor Vehicle (Tests)

Regulations 1981, as amended.

DVSA (MOT-UK) approval numbers are: TAP100 - EINYA19863-0716026

TAP200 - EINYA19863-0117005

CE COMPLIANCE

Type Designation: TAP100, TAP200

Description/Intended Use: Hand Held Tread Depth and Pressure Reader used to read tyre data and presenting the

results.

Hereby, Bartec declares that the product referenced above is in compliance with the essential requirements of Directive

1999/5/EC, on the approximation of the laws of the member states relating to Directive 1999/5/EC.

TAP100/200 User Guide R.5.3 2019

3 |Page

LIST OF CONTENTS

FOREWORD...................................................................................................2

LIST OF CONTENTS ......................................................................................3

IMPORTANT NOTICES ..................................................................................4

SAFETY PRECAUTIONS .................................................................................4

BEFORE GETTING STARTED .........................................................................6

KIT COMPONENTS .......................................................................................7

MENU NAVIGATION.....................................................................................8

TOOL POSITIONING......................................................................................9

TOOL CONNECTIONS ...................................................................................9

CHARGING TOOL....................................................................................... 10

POWER ON/OFF SEQUENCE .................................................................. 11

HOME MENU............................................................................................. 11

START MEASUREMENTS............................................................................ 11

VEHICLE AUDIT SCREEN ........................................................................... 12

TREAD DEPTH AND PRESSURE READ ....................................................... 12

SEND DATA................................................................................................ 13

CLEAR VEHICLE DATA............................................................................... 14

WHEELS ..................................................................................................... 14

SETUP ......................................................................................................... 14

TOOL INFO................................................................................................. 15

REGISTERING YOUR TOOL ........................................................................ 16

TPMS DESKTOP ....................................................................................... 18

UPDATING YOUR TOOL VIA TPMS DESKTOP ........................................ 19

TECHNICAL SPECIFICATION ...................................................................... 23

BARTEC PRODUCT RANGE &ACCESSORIES ............................................ 24

TAP100/200 User Guide R.5.3 2019

4 |Page

IMPORTANT NOTICES

SAFETY DEFINITIONS

All Danger, Warning, Important, and Note messages must be followed for your safety. These safety messages

are in the following form

DANGER: Means you may risk possible loss of life.

WARNING: Means you may risk possible bodily harm.

CAUTION: Means you risk damage to the vehicle or the tool.

These safety messages cover situations Bartec is aware of. Bartec cannot know, evaluate and advise you as

to all the possible hazards. You must be certain that any conditions or service procedures encountered do not

jeopardise your personal safety.

COPYRIGHT

No part of this manual may be reproduced, stored in a retrieval system or transmitted, in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Bartec.

DISCLAIMER

All information, illustrations, and specifications contained in this technical instruction manual are based on the

latest information available at the time of publication. The right is reserved to make changes at any time

without obligation to notify any person or organization of such revisions or changes. Further, Bartec shall not

be liable for errors contained with the furnishing, performance or use of this material.

SAFETY PRECAUTIONS

Read carefully the installation, operating and maintenance instructions in the Operator’s manual.

Do not allow unqualified persons to use this equipment. This will prevent injury to persons and damage to the

equipment.

The work place must be dry, sufficiently lit and well ventilated.

Do not forget that breathing carbon monoxide (odourless) can be very dangerous and even fatal.

When working on the vehicle:

•Wear suitable clothing and act in such a way as to prevent industrial accidents.

•Before starting, check to be certain the gear shift is in neutral (or in PARK (P) if the transmission is

automatic) and put the handbrake on and check to be sure the wheels are completely locked.

•Do not smoke or use naked flames when working on a vehicle.

•Wear safety glasses to protect your eyes from dirt, dust or metal chips.

TAP100/200 User Guide R.5.3 2019

5 |Page

Disposing of equipment

•Do not dispose of this equipment as miscellaneous solid waste but arrange to have collected

separately.

•The re-use or correct recycling of electronic equipment (EEE) is important in order to protect the

environment and human health.

•In accordance with European Directive WEEE 2002/96/EC, special disposal points are available for

waste electrical and electronic equipment.

•Public administrators and producers of electrical and electronic equipment are involved in facilitating

the re-use and recovery of waste electrical and electronic equipment through these collection

activities and use of appropriate planning arrangements.

•Unauthorised disposal of waste electrical and electronic equipment is punishable by law with

appropriate penalties.

Disposing of batteries

•The TAP100 and the TAP200 contain a Lithium Polymer rechargeable battery which is not accessible

to the user.

•Batteries must be recycled or disposed of properly. Do not throw batteries away as part of normal

refuse disposal.

•Do no throw batteries on to an open fire

Correct use of the tool

•Do not expose the tool to excessive moisture.

•Do not use the tool near sources of heat or polluting emissions (stoves, ovens, etc.).

•Do not drop the tool.

•Do not allow the tool to come into contact with water or other liquids.

•Do not open the tool or attempt to perform maintenance or repair operations on any internal parts.

•You are advised to keep the packaging and to re-use it if the tool is moved to another site.

When using the tool remember:

•Do not subject the tool to magnetic or electric interference.

Reception, maintenance and guarantee:

Inspect the tool when delivered. Damage sustained during shipment is not covered by the guarantee. Bartec will

accept no responsibility for material or bodily harm resulting from inappropriate use of the product, failure to

maintain it, or incorrect storage conditions.

Bartec provides training for clients desirous of acquiring the knowledge required for the correct use of its products.

Only personnel authorized by Bartec are permitted to make any repairs that may be necessary. This tool is

guaranteed against any manufacturing fault for 12 months as of date of invoice (parts and labour) only if product

has been correctly used. Serial number must stay readable and proof of purchase must be retained for presentation

upon request.

Bartec Auto ID Ltd

Unit 9

Redbrook Business Park

Wilthorpe Road

Barnsley

S75 1JN

+44 (0) 1226 770581

TAP100/200 User Guide R.5.3 2019

6 |Page

BEFORE GETTING STARTED

Before you get started using your Tyre Tool, there are a few items to be aware of.

Charge your tool

The tool is shipped with a fully charged battery, but due to shelf drain it may require charging. It is

recommended to charge your tool 2+ hours before use.

(See page 10 for charging instructions)

Register your tool

You can register your Bartec tool at www.bartecautoid.com. Follow the on-screen prompts filling in your

information and tool serial number. A valid serial number and supplier is required to process your registration,

which can take up to 24hrs once submitted.

(See page 16 for instructions)

Update your Tool

Once your tool is registered, verify the software level loaded to the level available online and update your tool

if necessary. Refer to section on tool updating for further instruction.

(See page 19 for update instructions)

Calibration depth and pressure

We recommend you carry out a monthly calibration of the depth gauge to ensure your tool functions

accurately. (Please use the setup menu and follow the displayed instructions)

We recommend you arrange for Pressure calibration annually. For further help please contact:

www.bartecautoid.com

TAP100/200 User Guide R.5.3 2019

7 |Page

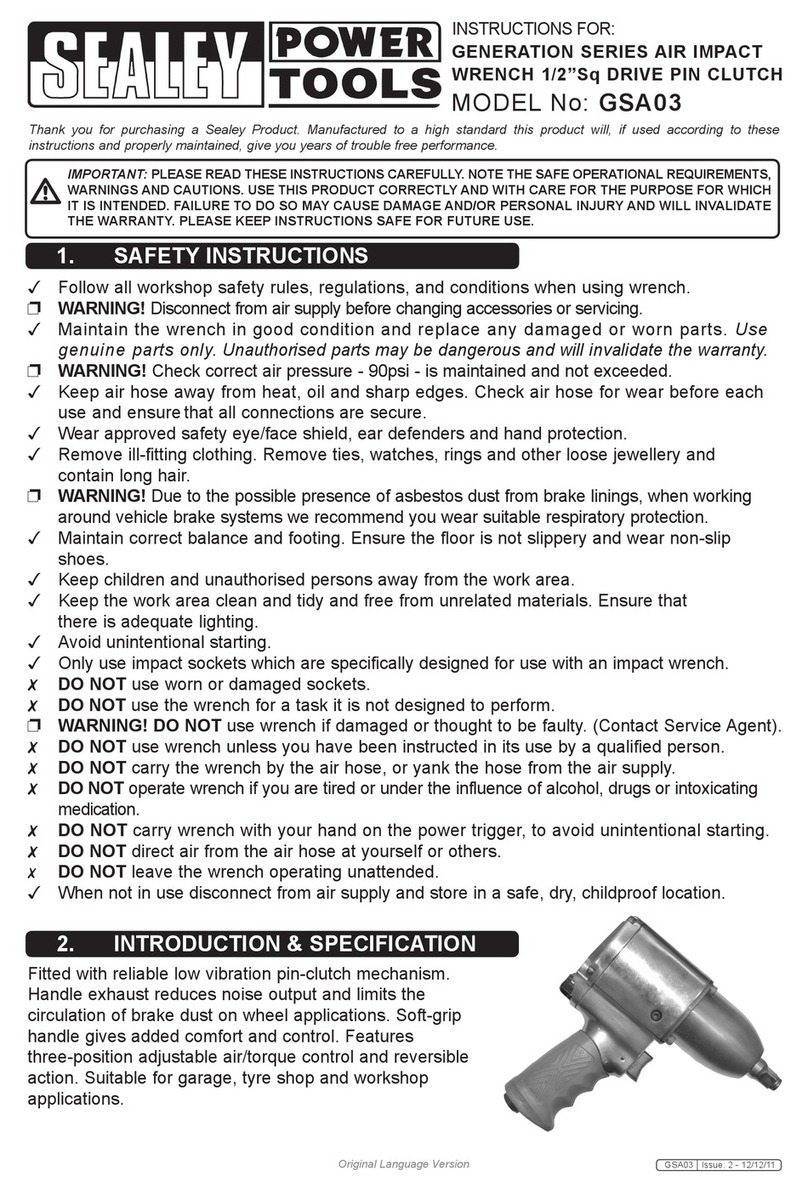

KIT COMPONENTS

The TAP100 or TAP200 kit inside the tool box includes:

•Tread Depth and Pressure Reader

•Rugged Rubber boot

•Pressure hose

•USB cable

•Wireless wall charger

•User Manual

•Carry case

•Pin Cover

Identifying Kit Components and Features

The tool is battery operated and measures tread depth with its steel pin and tyre pressure with the included

hose.

Note:

The major difference between the TAP100 and the TAP200 is the length of the tread depth pin.

The TAP100 has a 15mm pin which is used for passenger vehicle tyres.

The TAP200 has a 25mm pin which is used for vehicles with deeper tread depths.

Wireless

wall charger

and power

supply

Tread Depth

and Pressure

Reader

Pressure

hose

User

manual

TAP100/200 User Guide R.5.3 2019

8 |Page

MENU NAVIGATION

The tool’s menu system provides a hierarchy of instructions and commands. The top line of the display will

always indicate the current menu selected.

The menu system is navigated by the directional keys:

Up Arrow

Key Navigates up within the current menu selection

Down Arrow

Key Navigates down within the current menu selection

ENTER Key Navigates to the next menu or actions

the currently highlighted item

Back/ESC

and ON Key

Press to turn on

Navigates to the previous menu item

All menus wrap around. The enter key will often move to a sub menu.

TAP100/200 User Guide R.5.3 2019

9 |Page

TOOL POSITIONING

Proper tool positioning is important to insure correct measurement of tyre data. Place the tool on the tyre,

use the pin on the back side of the tool for measuring tyre tread depth and connect the hose to the valve in

order to check tyre pressure.

Tread Depth and Pressure Measurement

Tread Depth

To check the tyre’s tread depth, hold the pin on the backside of the tool in each groove, press to the bottom

and wait for the tool’s signal.

Pressure

In order to measure tyre pressure, connect the hose to the valve of the wheel and wait for the tool’s signal.

MOT Testing

When using the tool for UK MOT Testing please follow the testing procedures and pass/fail limits that are

laid out in Section 4 of the relevant DVSA MOT Inspection Manual.

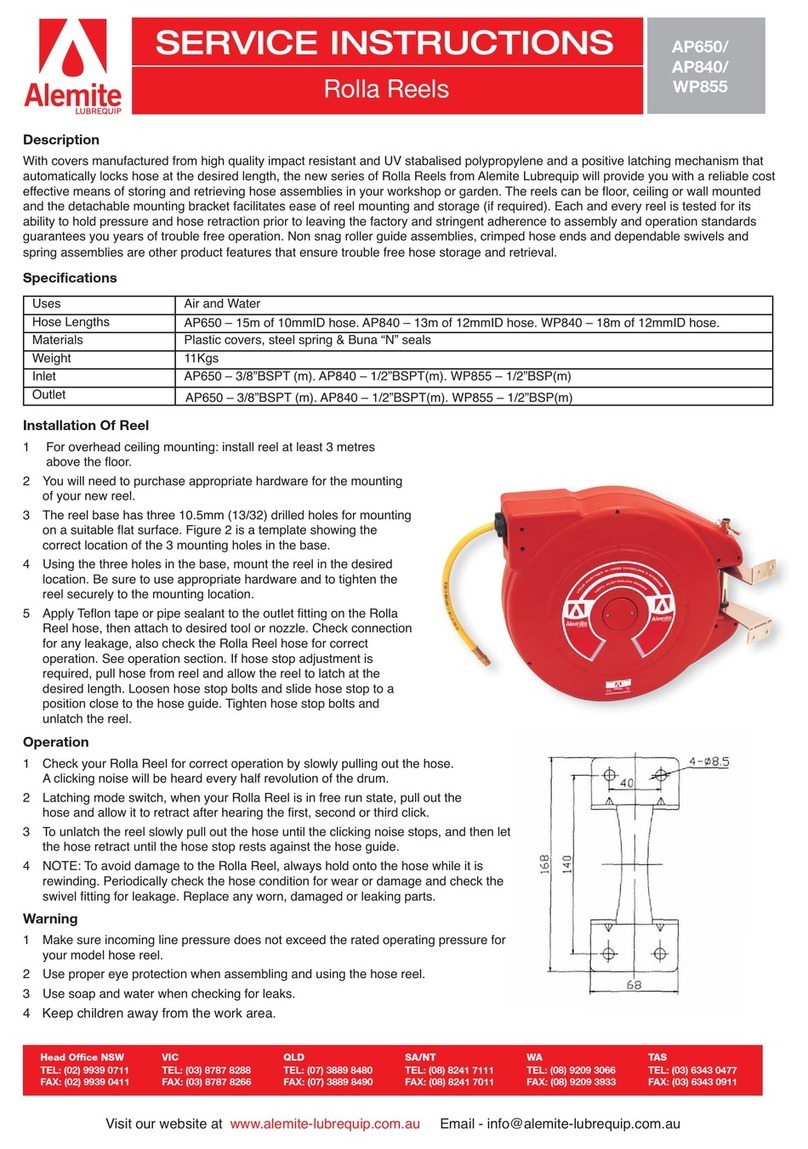

TOOL CONNECTIONS

Hose connection for tyre pressure measurement.

TAP100/200 User Guide R.5.3 2019

10 |Page

CHARGING TOOL

The tool is supplied with a wall-mounted Inductive Charging Cradle with a

wall adapter power supply. For optimal performance, return the tool

securely to the cradle when not in use to ensure that the battery is

charged.

NOTICE: Only use the power supply or USB cable that is included in the

tool kit to charge this tool. The use of un-approved power supplies may

damage your tool and will void the tool warranty.

The tool comes with the rechargeable battery already installed. Battery replacement must be done at the

factory.

Battery Indicator

The battery indicator in the lower right of the tool screen indicates the estimated power status of the tool’s

rechargeable battery:

FULL Charge

Partial Charge - charging shortly is suggested.

Little power in the battery- charging required.

The battery is FLAT, requires charging

When an insufficient amount of power remains, the tool will display a flashing battery icon and power off.

TAP100/200 User Guide R.5.3 2019

11 |Page

POWER ON/OFF SEQUENCE

The TAP100/200 is powered up using the Back/On key.

To power the tool on, press the Back/On key. The display will light, indicating the tool name. The tool will

then display the Main menu.

Power down the tool by selecting “Off” from the Main menu and pressing the Enter key. “Goodbye” is

displayed, and the tool will power off.

Auto Off can be configured under “Setup” from the Main menu.

IMPORTANT NOTE: The tool does not store data after being powered off. Be sure to send any existing

measurements to TPMS Desktop before the tool turns off for any reason.

HOME MENU

The home screen, which provides access to the main functional items of the tool, is shown after power up.

From the Main menu, highlighting a selection and pressing the Enter key provides access to the following

features:

START MEASUREMENTS

Pressing the Enter Key, the vehicle audit screen appears, where tread depth

and air pressure is measured.

TAP100/200 User Guide R.5.3 2019

12 |Page

VEHICLE AUDIT SCREEN

On entry to the audit screen, the Left Front wheel will be flashing, prompting the operator to start at this

wheel position. Pressing the Enter button will open the tyre audit screen with the arrow pointing on the left

groove of the tyre.

The flashlight is now illuminated. Hold/press the pin into the marked groove of the tyre,

the tool will then beep and take the depth reading. Its depth is measured and saved for

this position. The arrow will then automatically move on to the next groove and

respectively to the next tyre (Right Front, Right Rear, Left Rear and then Spare Wheel).

Three readings should be taken for each tyre.

Tread Depth can be measured and displayed in Millimetres or Inch Fractions (these can

be changed in the setup menu).

To take the tyre pressure, simply connect the hose to the tool and then the valve of the

tyre. Complete the process by selecting Tyre Condition and Manufacturer in the menu. Once all data is entered

click accept for saving the data and returning to the vehicle audit screen. Continue with the remaining tyres.

Pressure can be measured and displayed in PSI, Bar or kPa (these can be changed in the setup menu).

TREAD DEPTH AND PRESSURE READ

The reading is shown by a colour coding system. Green for okay (over 2.3mm tread available), amber for

recommended tyre change in the near future (between 1.6-2.2mm tread available) and red for immediate tyre

change (below 1.5mm). These values can all be changed/updated in the settings menu, tyre tread bands.

A flat surface display shows that the tyre is wearing evenly. The image shows even

tyre wear with a tread depth still within a safe (green) range.

A display where the tyre surface curves inward indicates that the tyre’s surface is

wearing faster in the centre than on the sides. This is a common side effect of

over-inflated tyres.

A display where the tyre surface curves outward indicates that the tyre’s tread is

wearing faster on the sides than in the centre. This is a common side effect of

under-inflated tyres.

TAP100/200 User Guide R.5.3 2019

13 |Page

A display where the tyre surface is slanted outward or inward

indicates that the tyre’s tread is wearing faster on one side in

comparison to the opposite side. This is a common side effect

of a tyre or tyres being out of alignment.

SEND DATA

When paired to your PC or tablet, the tool will send existing audit data to your device for use within the

TPMS Desktop application (see Page 18 for information on TPMS Desktop and for details on pairing via

Bluetooth on Page 21).

TAP100/200 User Guide R.5.3 2019

14 |Page

CLEAR VEHICLE DATA

Deletes all tire data stored on the tool. After pressing the Enter key on Clear Vehicle Data from the Main

menu, you will be prompted to confirm whether you wish to delete all data. Use the Arrow keys to highlight

Yes or No and press Enter to confirm.

WHEELS

Allows selecting the correct number of tires for a vehicle. The Main menu will display the current setting. To

change this setting, press the Enter key and use the Arrow keys to highlight your selection. Press Enter to

save.

SETUP

Setup is a sub-menu in which you will find all the options to adapt the tool to your needs and preferences.

Calibration: The user can carry out calibration of the tread depth. It is recommended this is carried out every

month.

Bluetooth Pair: The tool searches Bluetooth-capable devices in its reach and displays all of them, so the user

can select one.

Brightness: Change the brightness of the display using the up and down keys.

Depth Units: Select the unit for the display of the tread depth, Millimetres or Inch Fractions.

Pressure Units: Choose between PSI, Bar or kPa.

Tyre Selection: Select Seasonal or none. The option Seasonal enables the selection of Summer, Winter or All

Season Tyres before the measurement.

Tyre Tread Bands: Choose between Standard, Summer, Winter or All Season Tyres. Change the respective

tread depth limits for the tyre types to your needs and your local regulations.

Auto Off: Select the time the tool switches off automatically when not in use.

TAP100/200 User Guide R.5.3 2019

15 |Page

Language: Select Language for the tool.

Update Tool: Receive the latest software on your tool by choosing ‘Update Mode’ from the menu.

TOOL INFO

Sub-menu containing important information about the tool itself.

Tool Info

Displays the following information:

- Software version currently installed

- Build date of the installed Software

- Serial number of the tool

- Total number of tread measurements taken (Tread Meas.)

- Total number of pressure measurements taken (Pressure Meas.)

Note that the number of tread/pressure measurements is a running total, and is not cleared when the tool is

recalibrated or data is sent to a device via Bluetooth.

TAP100/200 User Guide R.5.3 2019

16 |Page

REGISTERING YOUR TOOL

It is of great importance to register your tool. The registration enables:

#1 Access to Software Updates

#2 Access to new Manuals

#3 Access to Technical Service Bulletins

#4 Answers to FAQs

#5 Activation of your product warranty

#6 Protection of your investment

#7 Information on new promotion

#8 Receipt of our TPMS Newsletter

To register your tool, navigate to the Bartec TPMS website at www.tools.bartecautoid.com.

The first page you will see is the TPMS Tool Support Center page, showing the latest software release versions

of the respective Bartec tools.

Select ‘Register’ to create a new account. It is important to fill in all fields completely and accurately. This

information will help Bartec remain in contact with you regarding updates and other important TPMS

information. Choose a username (without a space) and password.

If your details are accepted, you get the following message.

The following email should arrive within a few minutes:

TAP100/200 User Guide R.5.3 2019

17 |Page

Following the ‘Confirm account’ link will take you back to the website.

This page is showing that you are now a registered user. Click on ‘this page’ to log in.

From now on you only need to log in as a registered user:

After Login, you are shown your personal settings, which can be changed or not, as required.

Selecting Tools gives you the option to register a new tool. The serial number is in the ‘Tool Info’ menu.

Note that this Serial Number is validated by the website and it must be correct, including the first zero.

If the number is accepted you will see the tool listed, along with a “TPMS Desktop required” button which will

lead to the Bartec website, where the free Software can be downloaded:

TAP100/200 User Guide R.5.3 2019

18 |Page

TPMS DESKTOP

“TPMS Desktop is free PC software that is the easiest way to update all of your Bartec tools

without logging in to this website, and it also has many other benefits. TPMS Desktop is required

to update the TAP100, TAP200 and the TPMS PAD, and is the best way to update the Tech300,

Tech400 and Tech500.”

Go to https://tools.bartecautoid.com/tpmsdesktop/ to download your free copy now!

TPMS Desktop features:

Update: Automatically retrieve update files from your current

registered account

Reports:Complete job reports recorded and stored for when

you need them

Vehicle List: Lookup TPMS information for a vehicle quickly

and easily

Settings: Configure your settings for Bluetooth and

Wi-Fi configuration

PAD: Launches the software to run your TPMS PAD

Display:Software available to display vehicle details, tyre pressure and tread depth

readings on a TV or Monitor for Tyre shop garages or waiting rooms

Training Videos:Learn about TPMS

TAP100/200 User Guide R.5.3 2019

19 |Page

UPDATING YOUR TOOL VIA TPMS DESKTOP

Click on Update, the software will be automatically be downloaded to your tool, and it will be ready to use.”

Updating the TAP only works with the TPMS Desktop installed on your computer.

Power on your tool. Go to the Main Menu, select Setup and Update Tool.

The tool will prompt user to “Please Connect USB”.

Insert the USB cable to the tool and connect it to the PC with TPMS Desktop installed.

Click the Update button on the TPMS Desktop and it will show the picture below:

This will be shown under Connected Tools if you connect a tool and click Refresh.

If you already had a tool connected when you clicked on the Update tab, you see this picture straight away:

Update:will only be available to click if a newer version is available to install

Recover Software: this will reinstall the current version, if you think that you have any problems

with your tool

Register:you need to register your tool once in order to use the updates service

TAP100/200 User Guide R.5.3 2019

20 |Page

The Register button takes you to the website:

Reports

Search, view and print job reports. This preformatted and detailed record

contains the necessary job information that you and your customers

need. Sort or filter reports by date, make, model and year. Simply print a

report and attach it to the invoice as proof of work completed. Use

reports to create customer receipts and limit liability.

Vehicle Lookup

Browse our extensive vehicle and sensor database. Search by make, model and year to quickly find the data

you need: OBD location, TPMS relearn, sensor information – it’s all there with TPMS Desktop. Plus, the

database is regularly updated.

TPMS PAD

Program sensors using the dedicated, easy to use TPMS PAD. Simply

connect your TPMS PAD to your PC using a USB cable to program and test

sensors with ease. Copy and create a universal sensor with Copy Sensor and

Create Sensor – features only available with TPMS Desktop.

This manual suits for next models

3

Table of contents

Other Bartec Auto ID Tools manuals

Popular Tools manuals by other brands

Chicago Pneumatic

Chicago Pneumatic S-type Product instructions

Bostitch

Bostitch BT1855SP-A Safety and operating instructions manual

One Stop Gardens

One Stop Gardens 66437 Instructions and precautions

Sealey

Sealey VS8625 Instructions for use

SMC Networks

SMC Networks Vector User instructions

Clearbox

Clearbox nControl user manual

VonHaus

VonHaus 3500046 ASSEMBLY & USE

Panduit

Panduit BlackFin CT-2600 Series instruction manual

Sealey

Sealey GSA03 instructions

Alemite

Alemite Rolla AP650 Service instructions

SCHUNK

SCHUNK VERO-S NSL mikro 50-13 Translation of the original operating manual

Alpha Professional Tools

Alpha Professional Tools Alpha BAB3GRD instruction manual