Self-regulating trace heating systems

05-6066-7D0001/A

05/2021-EHT-405838

Notice Technical data subject to change without notice.

No claims for damage arising from alternations, errors or misprints shall be allowed.

Overview

This manual covers the installation and operation of BARTEC Self-

regulating trace heating systems for roof and gutter de-icing using the

following self-regulating trace heaters:

BARTEC BACAB FT “black”;

Typen FT115-1410P (120 V) und FT215-1410P (240 V)

The self-regulating trace heater features a temperature-dependent

resistive heating element between two parallel copper conductors, that

regulates and limits the heat output of the trace heater according to the

ambient temperature. If the ambient temperature rises, the power out-

put of the trace heater is reduced. This self-regulating property prevents

overheating which would cause damage to the trace heater. Even

crossing or overlapping with other trace heaters (or other portions of the

same trace heater) are possible.

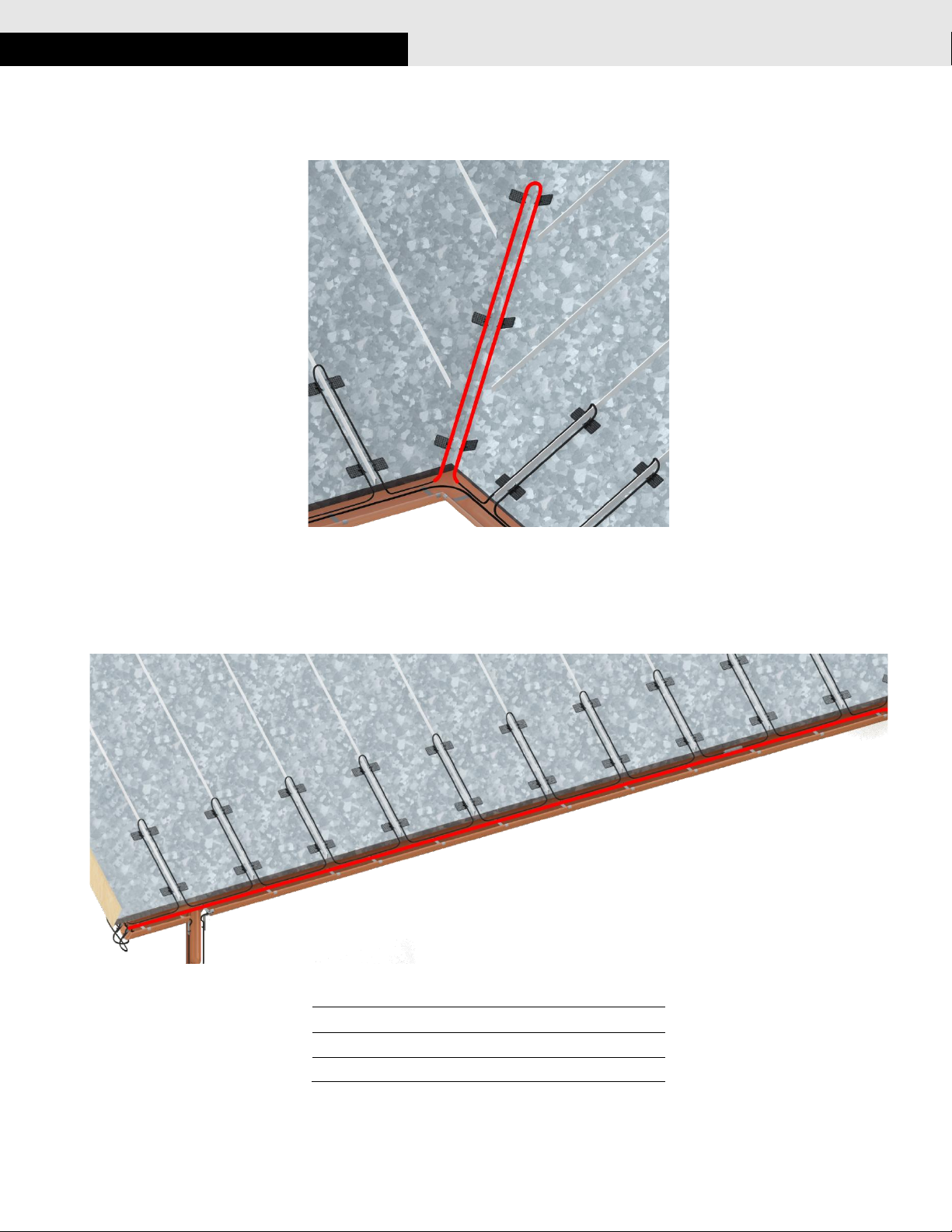

The trace heaters are fixed equipment heating systems for roof and

gutter de-icing in ordinary locations. Thanks to the parallel design the

trace heater can be cut and installed to any required length (up to the

maximum heating circuit length as shown on page 10).

Multiple options for connection, splicing and end termination of the

heating circuit are available to meet the individual requirements on site.

A large variety of accessories allows for easy customization and exten-

sibility.

Technical data

-67 to 185 °F / -55 to 85 °C

(temporary: up to 185 °F / 85 °C)

-40 to 150 °F /-40 to 65 °C

5 W/ft (15 W/m) @ 50 °F (10 °C)

Resistance of the

grounding braid

0.46” x 0.23” (11.8 x 5.8 mm)

1” (25 mm)

Do not bend on the narrow axis.

Certifications / Approvals

Self-regulating trace heater

BARTEC BACAB FT “black” trace heater for roof and gutter de-icing

Safety

For safe installation and operation of BARTEC Self-regulating trace

heating systems the technical requirements and instructions given in

this manual must be followed.

Risk of fire or electrical shock. Follow these guidelines to avoid per-

sonal injury or material damage.

All electrical systems and installations must comply with BARTEC

GmbH requirements and be installed in accordance with the relevant

electrical codes and any other applicable national and local codes.

BARTEC GmbH, the US and Canadian electrical codes require

ground fault protection to be provided for all trace heating circuits.

Install the trace heater circuit carefully.

Use the trace heater in accordance with the intended purpose and

strictly comply with the operational data specified in section Tech-

nical Data.

The bending radius of the trace heater must be at least 1” (25 mm).

Do not bend on the narrow axis.

To avoid short circuits, do not connect the trace heater bus wires

together.

Keep all components and the trace heaters dry before and during

installation.

Each heating circuit must be marked with electrical warning labels

(see Section Accessories on page 6).

Keep these instructions for future reference. If applicable, leave them

with the end user.

De-energize before installation or servicing.

Use only original BARTEC accessories.

Personnel requirements

The personnel executing installation and maintenance tasks must have

acquired the skills and specialized knowledge relating to the types of

protection and types of devices concerned. At least, the personnel must

have:

a general understanding of the relevant electrical engineering

a working knowledge and understanding of the relevant standards for

electrical installations in general and trace heating in particular

a basic knowledge of quality assurance, including the principles of

auditing documentation, traceability of measurements and calibration

of measurement instruments.