Created: 07/04

Revised: 08/14

BARTELL MORRISON INC. BARTELL MORRISON (USA) LLC

375 ANNAGEM BLVD, MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

200 COMMERCE DRIVE, FREEHOLD, NEW JERSEY, USA, 07728 732-566-5400 FAX 732 -566-5444

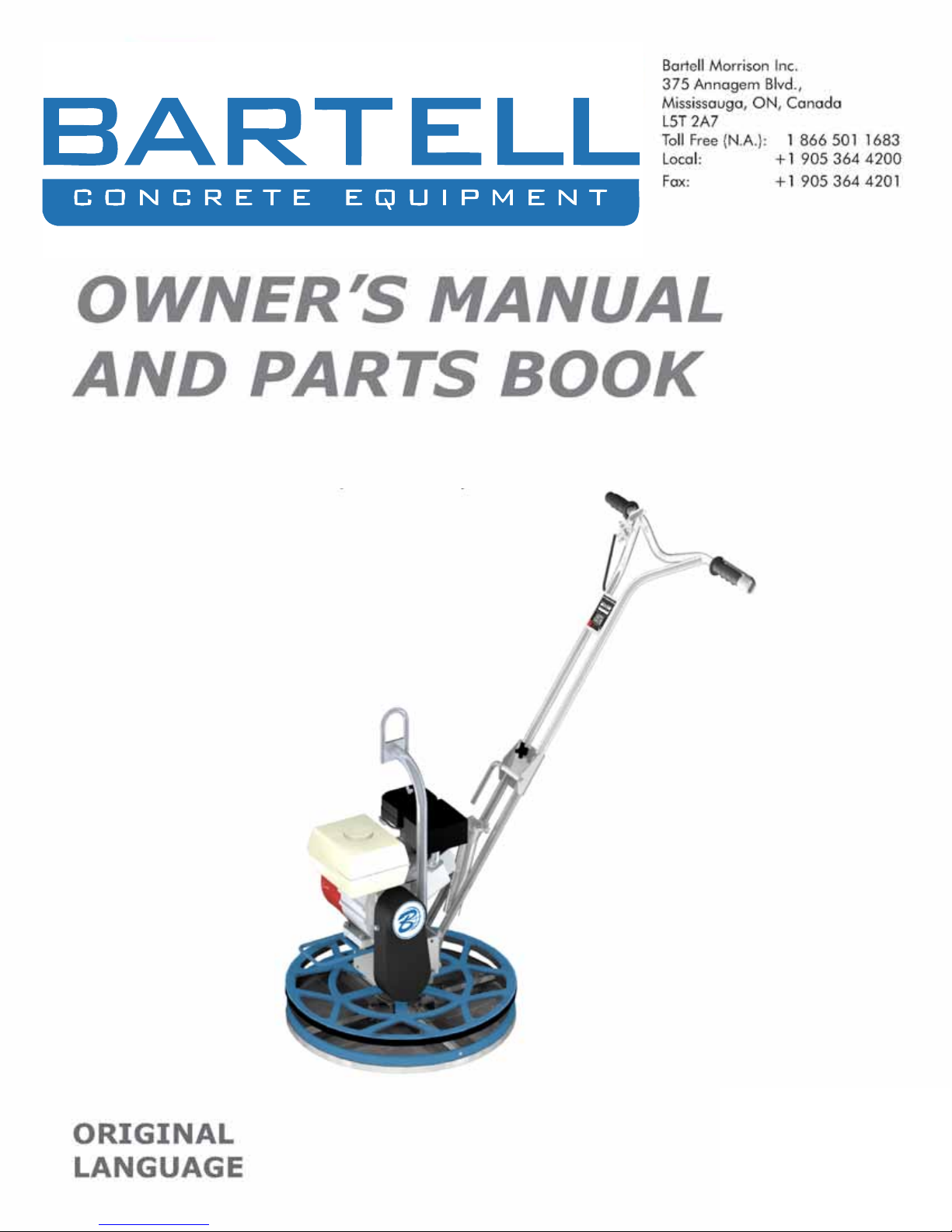

EDGER TROWEL INSTRUCTION MANUAL

BARTELL MORRISON INC. BARTELL MORRISON (USA) LLC

375 ANNAGEM BLVD, MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

25 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-5400 FAX 732-566-5444

Created:07/04

Revised: 06/12

TABLE OF CONTENTS

QUALITY ASSURANCE/MACHINE BREAK-IN...............................................................................4

EDGER POWER TROWEL WARRANTY......................................................................................... 5

MAINTENANCE RECORD ............................................................................................................... 6

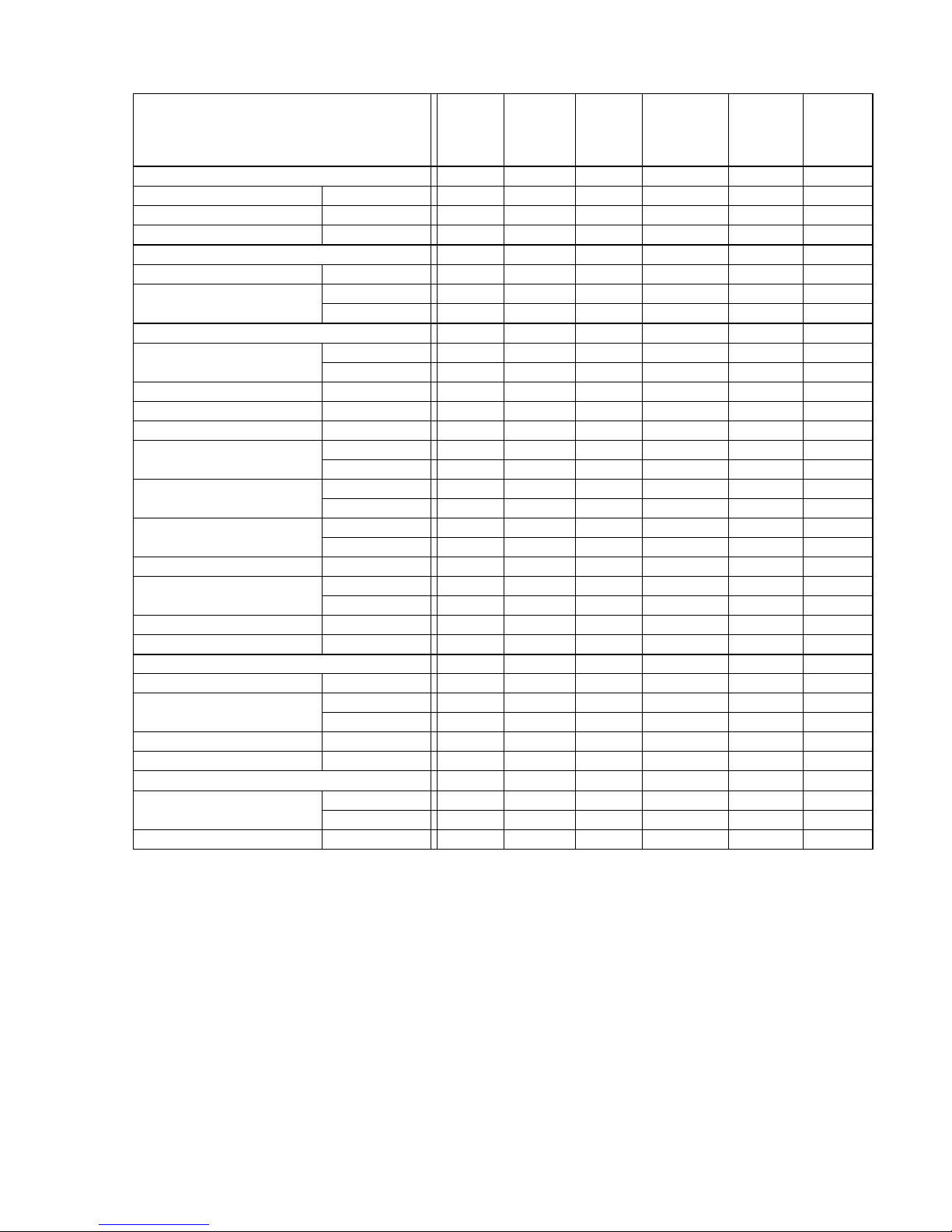

ROUTINE SERVICE INTERVALS .................................................................................................... 7

FOREWORD ..................................................................................................................................... 9

SAFETY PRECAUTIONS ................................................................................................................. 9

ASSEMBLY INSTRUCTIONS...........................................................................................................9

OPERATION (FLOATING) ...............................................................................................................9

OPERATION (FINSHING)................................................................................................................. 9

1. STARTING PROCEDURES -WARM TEMPERATURES........................................................... 10

2. STARTING PROCEDURES -COLD TEMPERATURES ............................................................ 10

3. STOPPING PROCEDURES........................................................................................................ 10

MAINTENANCE ..............................................................................................................................10

1. AIR CLEANER............................................................................................................................. 10

2. LUBRICATION ............................................................................................................................ 10

3. SPARK PLUG.............................................................................................................................. 10

4. BELT TENSION........................................................................................................................... 10

TRANSPORTING ............................................................................................................................ 10

LUBRICATION................................................................................................................................ 10

1. ENGINE OIL ................................................................................................................................ 10

2. SPIDER PLATE........................................................................................................................... 10

3. GEARBOX................................................................................................................................... 10

ENGINE OIL SPECIFICATIONS..................................................................................................... 10

STORAGE ....................................................................................................................................... 10

ASSEMBLY DRAWINGS AND PARTS LIST................................................................................. 11

1. EDGER TROWEL ASSEMBLY (FIGURE 1) ...............................................................................12

EDGER TROWEL PARTS LIST -B424 ...................................................................................... 14

2. SPIDER PLATE ASSEMBLY (FIGURE 2) ..................................................................................16

SPIDER PLATE ASSEMBLY PARTS LIST................................................................................. 17

3. GEARBOX ASSEMBLY (FIGURE 3) .......................................................................................... 18

4. FOLDING HANDLE ASSEMBLY (FIGURE 4)............................................................................. 19

FOLDING HANDLE ASSEMBLY PARTS LIST........................................................................... 20

TROUBLESHOOTING ....................................................................................................................21

SPECIFICATIONS ..........................................................................................................................22

COMPANY INFORMATION............................................................................................................ 23

NOTES ............................................................................................................................................ 25

- 3 -

QUALITY ASSURANCE/MACHINE BREAK-IN ......................................................................................................

WARRANTY INFORMATION ...................................................................................................................................

MAINTENANCE RECORD .......................................................................................................................................

ROUTINE SERVICE INTERVALS ............................................................................................................................

FOREWORD .............................................................................................................................................................

SAFETY PRECAUTIONS .........................................................................................................................................

ASSEMBLY INSTRUCTIONS ..................................................................................................................................

OPERATION (FLOATING) .......................................................................................................................................

OPERATION (FINISHING) .......................................................................................................................................

STARTING PROCEDURE - WARM CLIMATE ........................................................................................................

STARTING PROCEDURE - COLD CLIMATE ..........................................................................................................

STOPPING PROCEDURE .......................................................................................................................................

MAINTENANCE .......................................................................................................................................................

1. AIR CLEANER ......................................................................................................................................................

2. LUBRICATION ......................................................................................................................................................

3. SPARK PLUG .......................................................................................................................................................

4. BELT TENSION ....................................................................................................................................................

TRANSPORTING .....................................................................................................................................................

LUBRICATION .........................................................................................................................................................

1. ENGINE OIL .........................................................................................................................................................

2. SPIDER PLATE ....................................................................................................................................................

3. GEARBOX ............................................................................................................................................................

STORAGE ................................................................................................................................................................

EXTENSION CORD CHART ...................................................................................................................................

ELECTRIC EDGER OPERATION ............................................................................................................................

ELECTRIC EDGER SETUP .....................................................................................................................................

ELECTRIC EDGER START-UP ...............................................................................................................................

ELECTRIC EDGER WIRING DIAGRAM ..................................................................................................................

ASSEMBLY DRAWINGS AND PARTS LIST ...........................................................................................................

1. EDGER POWER TROWEL FULL ASSEMBLY TOP (DRAWING) .......................................................................

2. EDGER POWER TROWEL FULL ASSEMBLY TOP (PARTS LIST) .....................................................................

3. EDGER POWER TROWEL FULL ASSEMBLY BOTTOM (DRAWING).................................................................

4. EDGER POWER TROWEL FULL ASSEMBLY BOTTOM (PARTS LIST) .............................................................

5. SPIDER PLATE ASSEMBLY (DRAWING AND PARTS LIST) ..............................................................................

6. FOLDING HANDLE ASSEMBLY (DRAWING) ......................................................................................................

7. FOLDING HANDLE ASSEMBLY (PARTS LIST) ...................................................................................................

TROUBLESHOOTING .............................................................................................................................................

SPECIFICATIONS.....................................................................................................................................................

TECHNICAL INFORMATION ...................................................................................................................................

COMPANY INFORMATION ......................................................................................................................................

NOTES ......................................................................................................................................................................

4

5

6

7

9

9

9

9

9

10

10

10

10

10

10

10

10

10

10

10

10

11

11

11

12

13

13

15

17

18

19

20

21

22

23

24

25

26

27

28

29