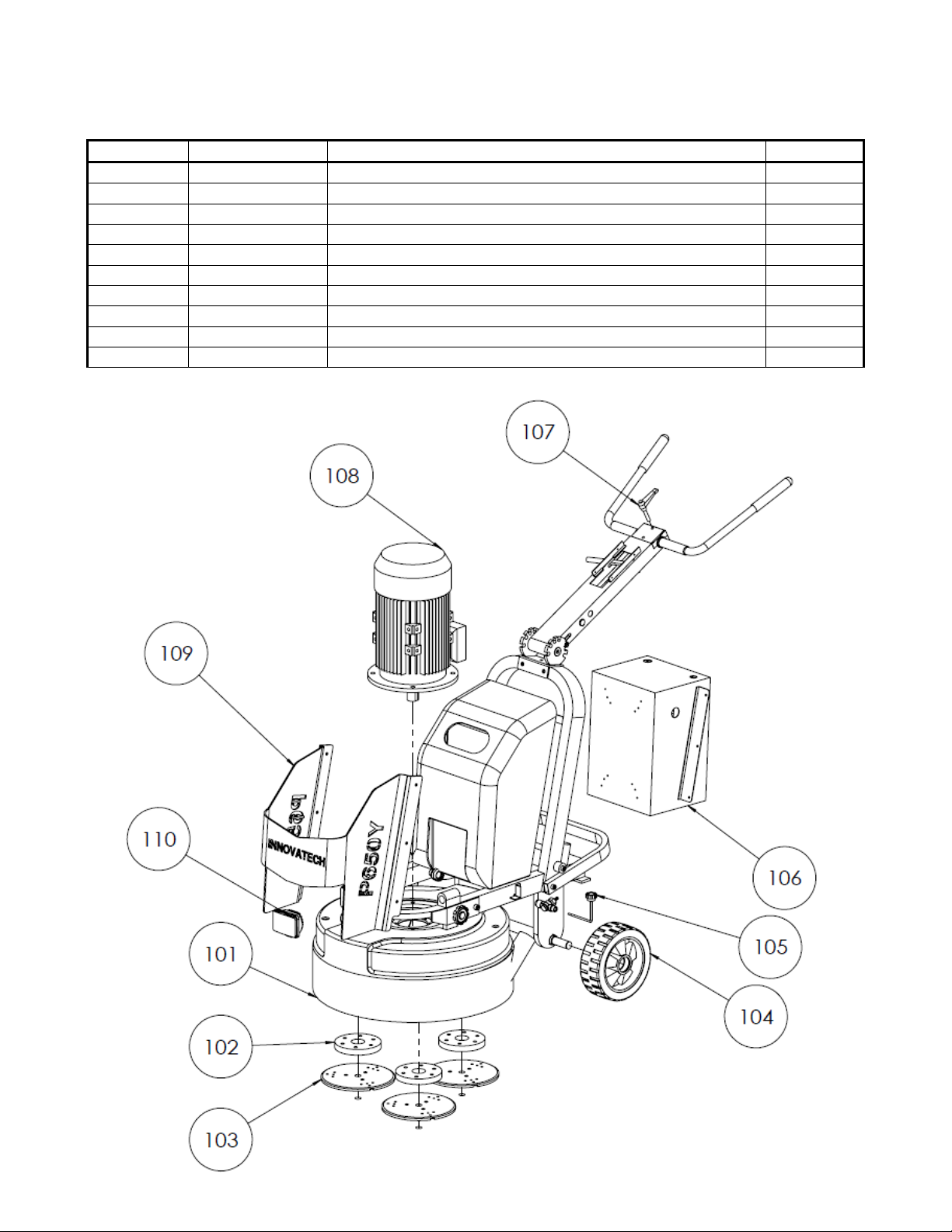

Y Grinder

Owner’s Manual

0IPB-I02003-YGRINDERS_V0.0 5 12/21/18

1. About This Manual

This Manual contains the information and procedures to assist you to operate and maintain

the P550Y, P650Y and P750Y floor grinder safely and correctly. Read this Manual before

you operate or service the equipment. If you need additional information or assistance,

please get in touch with our Customer Service Department:

Innovatech Products & Equipment Co.

4701 Allmond Ave

Louisville, KY 40209

(425) 402-1881 or 800-267-6682

Fax (425) 402-8547

2. Important Safety Instructions

Safety Guide

•The operator must wear waterproof and insulating work shoes and gloves.

•The external power cable must be 6-gauge wire (for the P750Y) or 8-gauge wire

(P650Y & P550Y) and connected with the earth wire for electrical shock prevention.

•Make sure the power cables are not damaged or showing significant signs of wear.

•When wet grinding, waterproof protection should be installed for the water tank,

inverter and control panel for preventing equipment failure and personal injury.

•Make sure not to run over the power cables while operating the machine. Doing so

could result in equipment failure and personal injury.

•In all instances, make sure to have dry hands before inserting plugs to prevent

injuries and/or death from electric shock.

Precautions

•After dry or wet grinding, completely clean the tooling and grinding plates to increase

the service life of your machine.

•Only dry grind while connected to a vacuum cleaner, so as to ensure dust-free

operation. This will also decrease the load on the inverter.

•In the process of replacing consumables and transporting, please be sure to put

down the equipment gently to prevent damage and oil leakage from the gearbox.

Lifting handles are provided if one person can’t easily carry the equipment alone.

•In a certain range of output frequency, the frequency inverter may produce a

resonance which will cause the equipment to stop working. If such an event

happens, avoid that resonant frequency.

•When grinding on a floor with large differences in floor height, be sure to grind from

high to low to prevent damaging the grinding plates and gearbox.