CONCRETE SAW INSTRUCTION MANUAL

BARTELL MORRISON INC. BARTELL MORRISON (USA) LLC

375 ANNAGEM BLVD, MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

12 INDUSTRIAL DRIVE, KEYPORT, NEW JERSEY, USA, 07735, 732-566-5400 FAX 732-5444

Created: 12/08

Revised: 12/10

Maintain a safe working environment.3. Make sure there is adequate surrounding

workspace.

Avoid unintentional starting.4. Make sure you are prepared to being work before

turning on the Concrete Saw.

People with pacemakers should consult their physician(s) before use. 5.

Electromagnetic elds in close proximity to a heart pacemaker could cause pacemaker

interference or pacemaker failure. Caution is necessary when near the Engine’s

magneto or recoil starter.

Never leave Concrete Saw unattended when it is running.6. Turn off the Engine of the

Concrete Saw before leaving work area.

Always use the Concrete Saw on a at, level, concrete surface. 7. Cut only straight

paths. Do not attempt to cut curved paths.

Make sure to keeps hands, ngers, and feet away from all moving parts of the 8.

Concrete Saw.

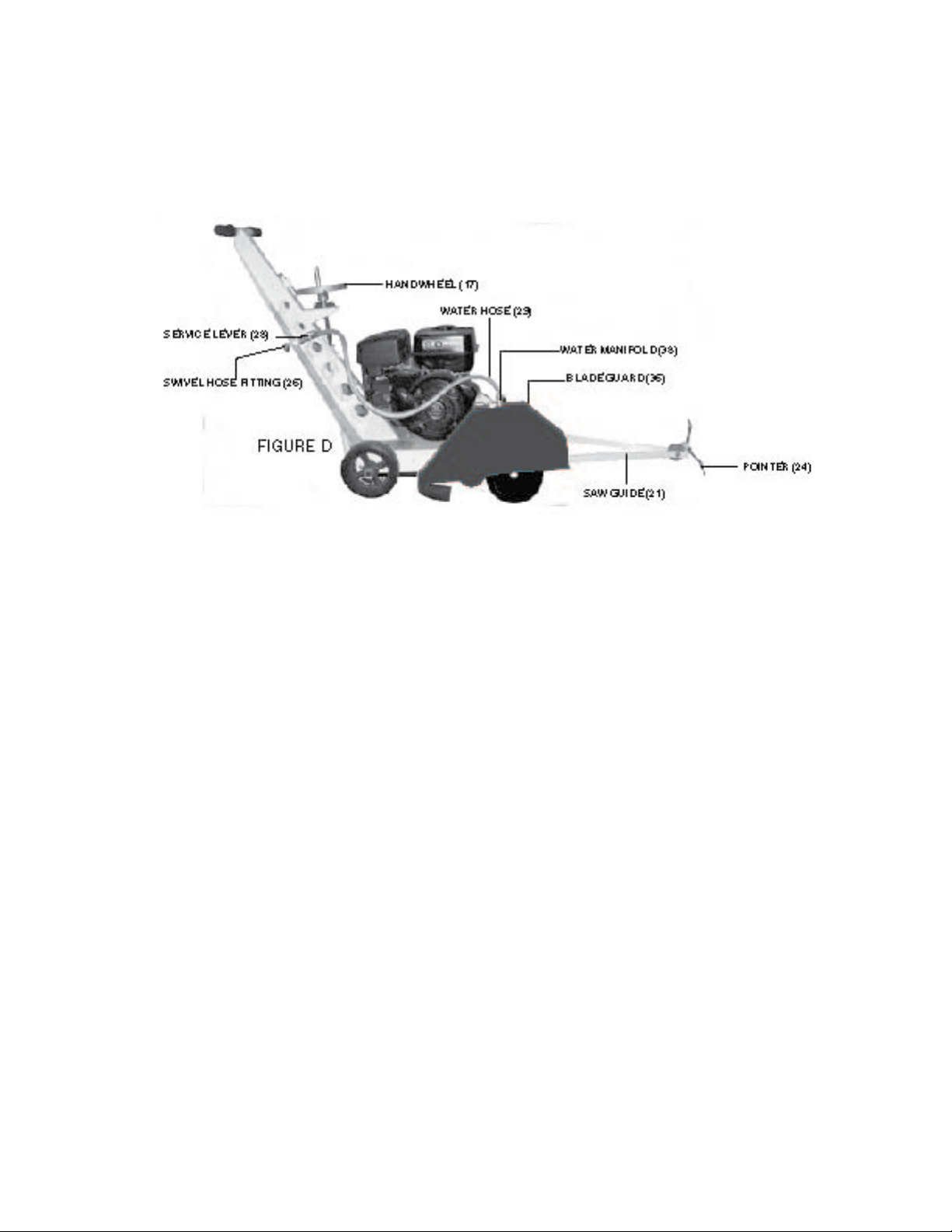

At any time the Concrete Saw is being transported the Saw Guide (21) must be in 9.

its locked (upward) position and the Pointer (24) in its downward position.

Use only 14” diameter, diamond Saw Blades rated at a minimum 4500 RPM with10.

this Concrete Saw.

Prior to using the Concrete Saw, make sure you read and understand this11.

instruction manual and the Engine manufacturer’s instruction manual.

Keep a safe clearance around the Concrete Saw.12. Keep all people (except the

operator) a minimum of six feet from the Saw during operation.

Prior to operating the Concrete Saw, be aware of, and avoid, any hidden 13.

underground electrical cables, gas pipes, water pipes, etc.

WARNING!14. The brass components of this product contain lead, a chemical known to the

State of California to cause birth defects (or other reproductive harm). (California Health

& Safety Code 25249.5, et seq.)

WARNING!15. Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities, contains chemical known (to the State of California) to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals

are: lead from lead-based paints, crystalline silica from bricks and cement or other

masonry products, arsenic and chromium from chemically treated lumber. Your risk

from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to

lter out microscopic particles. (California Health & Safety Code 25249.5, et seq.)

TOXIC FUMES, FIRE, AND EXPLOSION PRECAUTIONS

This Concrete Saw is designed for outdoor use only. Do not operate the Saw in1.

a closed area of poorly ventilated area. When running, the Engine of this unit

produces carbon monoxide, a colorless, odorless, toxic fume that, when inhaled,

can cause serious personal injury or death. Whenever possible, use a carbon

monoxide detector (not included) to detect excessive carbon monoxide fumes in the

work area and in the surrounding area.

Gasoline fuel and fumes are ammable, and potentially explosive. 2. Use proper fuel

storage and handling procedures. Always have multiple ABC class re extinguishers

nearby.