1

Table of Contents

Introduction ..................................................................................................................................................2

Precautions ...................................................................................................................................................2

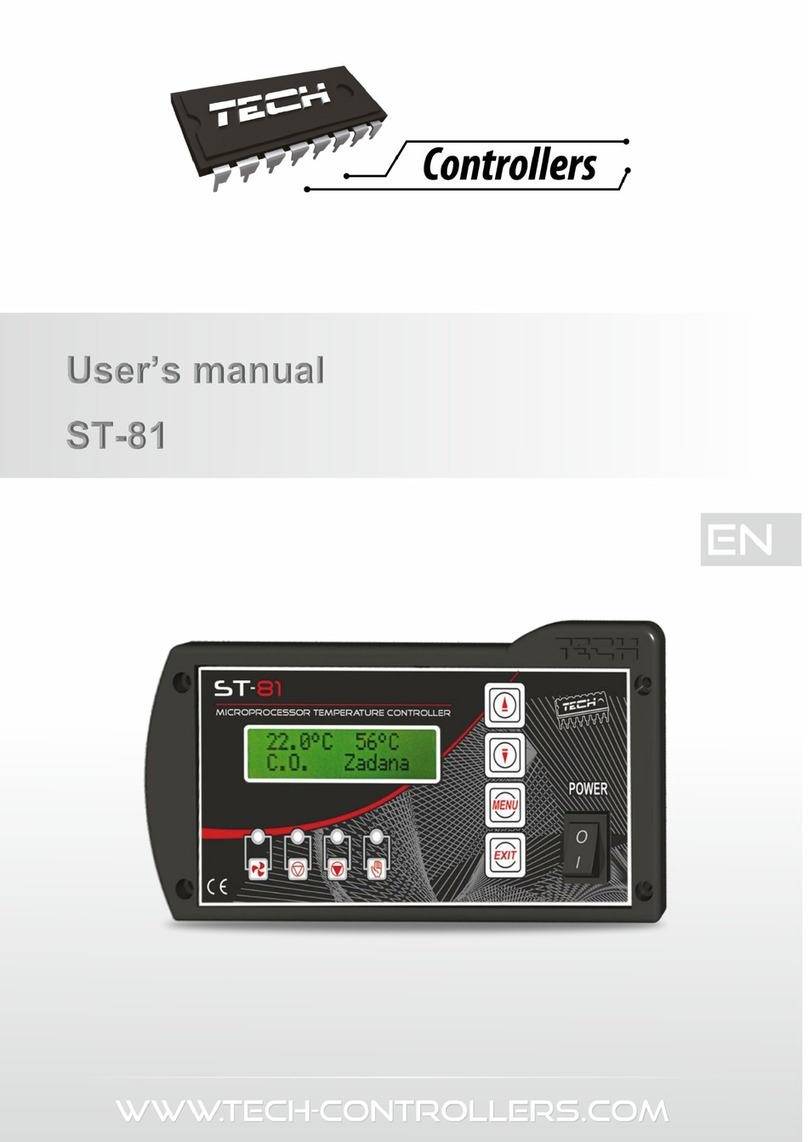

Home Screen Overview.................................................................................................................................3

Quick Start.....................................................................................................................................................4

First Firing of the Kiln....................................................................................................................................5

Program the Controller.............................................................................................................................5

Review Program Before the Firing............................................................................................................5

Start The First Test Firing ..........................................................................................................................6

Review the Results....................................................................................................................................6

Ceramics Programming (Bisc or Glaze).........................................................................................................7

Glass Programming.......................................................................................................................................9

Custom Programming .................................................................................................................................10

Calculating Ramp Rates for Custom Firing..............................................................................................12

Custom Ceramics Program......................................................................................................................13

Start A Firing................................................................................................................................................13

Operation of the Controller During A Firing ...........................................................................................13

Adjustments During a Firing....................................................................................................................15

End of Firing –COMPLETE.......................................................................................................................16

Care of Thermocouple ............................................................................................................................17

Menu Screen...............................................................................................................................................17

Data Menu ..............................................................................................................................................17

Diagnostics..............................................................................................................................................18

Adjustments............................................................................................................................................18

Configuration ..........................................................................................................................................19

Restore Presets .......................................................................................................................................22

Customization .........................................................................................................................................22

Factory Configuration .............................................................................................................................22

Appendix A: Error Codes.............................................................................................................................23

Full Power Test........................................................................................................................................24

Appendix B: Cone Fire Temperature Profiles..............................................................................................25

Appendix C: Custom Firing Default Programs.............................................................................................26

Appendix D: Blank Firing Program ..............................................................................................................29

Appendix E: Common Questions and Situations ........................................................................................30

Appendix F: Zone Control ...........................................................................................................................31

1. Features and Enhancements...........................................................................................................31

2. General Description ........................................................................................................................31

3. Automatic Lag Function ..................................................................................................................31

4. Thermocouple Offsets.....................................................................................................................31

5. Three Thermocouples.....................................................................................................................32

Appendix G: Genesis Connection Diagram .................................................................................................33

Appendix H: Genesis Mini Connection Diagram.........................................................................................34