Bartlett 3K User manual

Operation manual for Model 3K with Cone fire

RAMPCONEA 9-18-08

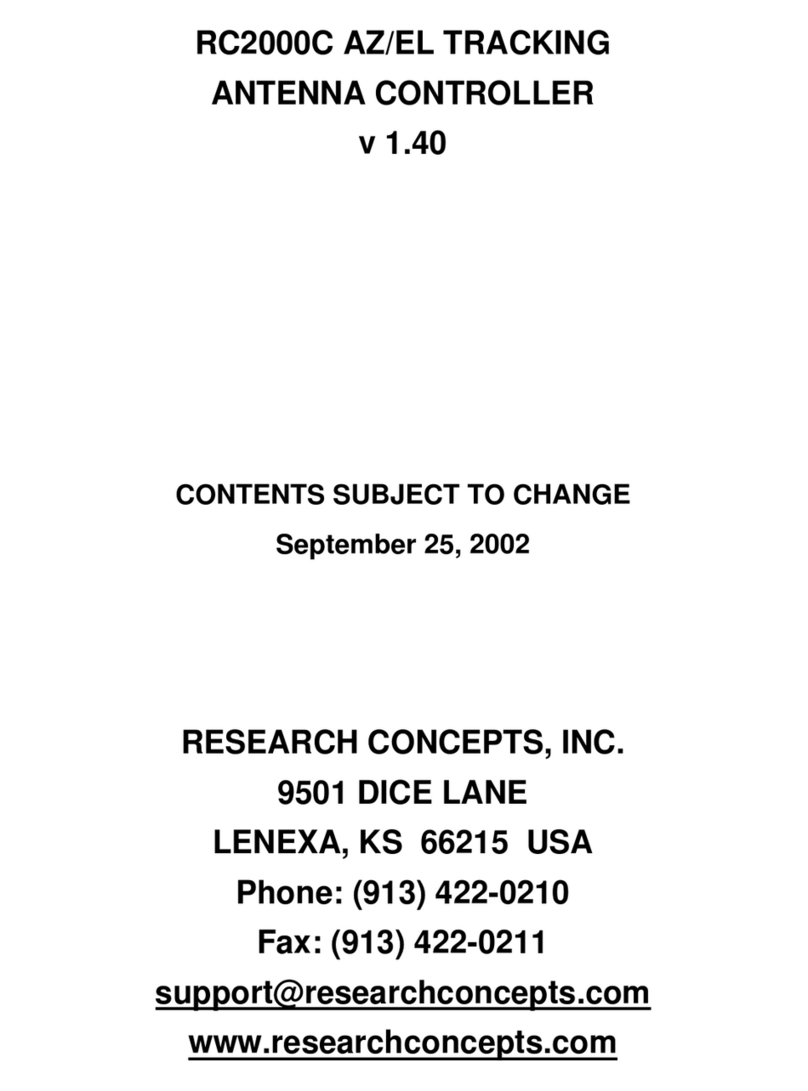

KEY PAD OPERATION

Function of Each Key at Different Controller Stages

CONTROLLER

STAGE

START/STOP/ENTER

KEY

UP ARROW

DOWN ARROW

IDLE

Initiates programming

No function

Press once to review

and refire last

program.

Press twice to go

directly to “redi”

PROGRAMMING

Stores displayed value

Increases displayed

value. Hold for

rapid scrolling

Decreases displayed

value. Hold for rapid

scrolling

At Ready (redi)

Starts firing

No function

No function

During firing

STOPs

the firing

Shows current

segment and target

temperature.

Provides access to

skip step and add

time or temperature

Reviews current

program

At complete or

error code

Back to idle

No function

No function

Operation manual for Model 3K with Cone fire

RAMPCONEA 9-18-08

From idle,

Press enter

Use arrow keys to select

ConeFire or rampHold;

Press enter

r-Hd selected

C-Fr selected

Enter user #

Enter # of segments

Enter first

rate

Enter first

temperature

Enter first

hold time

Enter 2nd

rate

Enter 2nd

temperature

Enter 2nd

hold time

Enter last rate

Enter last

temperature

Enter last

hold time

“REDi”

Press enter to start

firing

Enter preheat time at

200 degrees F.

Enter cone #

Enter Hold time at

Top temperature

……….

Enter speed

PROGRAMMING FLOW CHART

Enter delay

start

Enter delay

start

Note –“enter delay

start” is an option that

can be disabled and may

not show up.

Operation manual for Model 3K with Cone fire

RAMPCONEA 9-18-08

GETTING TO IDLE

When power is applied, the display will show the controller’s firmware version

and then ErrP, an error code, or IdLE or StOP, flashing with the current temperature.

If ErrP is displayed press any key to clear this error message.

If StOP or IdLE is alternating with the current temperature, you are ready to begin

programming.

CONE FIRE PROGRAMMING

STEP DESCRIPTION

1. Start with the display reading IdLE, Press “enter”.

2. Select cone fire. If “C-Fr” is displayed, press “enter”, else press an arrow key

to display “C-Fr” and then press “enter”.

3. Set delay start –The beginning of the firing can be delayed from the time

you press “start”. This allows the firing to start later and end when you can

supervise the end. Use the arrow keys to adjust the amount of delay and press

enter. ** Caution should be taken to make sure that no one can place

anything around or on the kiln during the delay start. Treat the kiln as

firing during the delay start. **

4. Enter the preheat time. The first segment of a cone fire program ramps to

200 F. The preheat time is the length of time you will hold at 200 F. Thin, dry

clay may not need any preheat time and thick hand-built items may require

several hours of preheat. Use the arrow key to adjust the preheat time and

then press “enter” to store the value. REMEMBER the time is displayed in

the form HH.mm. H= hours, m=minutes

5. Enter Cone #. Use the arrow keys to display the desired cone number. The

up arrow moves toward a hotter cone number. Press “enter” to store the

displayed cone #.

6. Enter Heating rate. Use the arrow keys to display Slow, Medium or Fast.

7. Enter hold time. A hold at the top temperature adds heat work and can help

produce a more even firing from top to bottom. Typical hold times are in the

10-15 minute range (00.15). Use the arrow keys to display the desired hold

time and then press “enter” to store the value.

8. READY “rEdi” You are now at ready. Press “enter” to start the firing.

The cone fire profiles are listed at the end of the manual

Operation manual for Model 3K with Cone fire

RAMPCONEA 9-18-08

RAMP-HOLD PROGRAMMING

STEP DESCRIPTION

1Start with the display reading IdLE, Press “enter”.

2Select ramp-hold. If “r-Hd” is displayed, press “enter”, else press an

arrow key to display “r-Hd” and then press “enter”.

3Set delay start –The beginning of the firing can be delayed from the time

you press “start”. This allows the firing to start later and end when you

can supervise the end. Use the arrow keys to adjust the amount of delay

and press enter. ** Caution should be taken to make sure that no one

can place anything around or on the kiln during the delay start. Treat

the kiln as firing during the delay start. **

4Enter user #. The controller holds 4 user programs. This step chooses

which of the 4 programs you are going to use. Use the arrow keys to

display the correct user number and then press “enter”. To reuse a

previously entered program simply press “enter” for each value. To

change a program, just adjust the displayed value.

5Choose number of segments. All programs consist of 1 or more

segments as shown in the sample profile at the end of the manual. Each

segment has 3 parts –ramp rate (speed of temperature rise in degrees per

hour), soak temperature, and hold time at soak temperature. It is helpful to

draw your profile to see how many segments you need. Then use the

arrow keys to display the desired number of segments and press “enter” to

store the value.

6ENTER RAMP RATE. The rate is displayed in degrees per hour. Slow

rates range from 1-50 degrees per hour and are used for thick glass

projects. Medium rates range from 60 to 200 degrees per hour and are

used for thick, hand-built ceramics. Fast rates range from 250 –1000

degrees per hour and are used for glazes, thin ceramics and small glass

projects. A rate of 9999 sets the kiln to ramp as fast as possible. Use the

arrow keys to adjust the rate and press “enter” to store the value.

7ENTER SOAK TEMPERATURE. For a single segment program, this

is the top temperature of the firing. For multi-segment programs, this can

be a temperature where you want to hold to dry the ware or for carbon

burn-out, or equalize the temperature across the item or it can be where

you just want to switch ramp rates without a hold. Adjust the temperature

with the arrow keys and press enter to store the displayed value.

8ENTER HOLD TIME. Use the arrow keys to adjust the hold time at the

soak temperature. Hours are displayed to the left of the decimal point and

minutes to the right (HH.mm). Use a zero (00.00) hold time to move to

the next segment without holding. Drying ware can take several hours

Operation manual for Model 3K with Cone fire

RAMPCONEA 9-18-08

while holds at peak temperature usually range 10 –15 minutes to even out

the kiln temperature.

9REPEAT STEPS 5-7 for each segment.

10 DISPLAY WILL SHOW “REDI” (ready) when all segments have been

entered. Press “enter” to start the firing.

To re-fire the last used program, press the DOWN key when StOP or IdLE is displayed.

The program will be quickly reviewed and rEdi will be displayed. Press START to begin

the firing. Note –pressing the down arrow twice will go directly to redi.

KILN OPERATION DURING A FIRING

At the start of a firing, the controller sets its traveling set point to the current

temperature in the kiln. The traveling set point is where the controller wants the kiln

temperature to be. The controller will then move the traveling set point up at the

programmed rate and cycle power to the elements to make the temperature follow the

traveling set point. You will hear the relays clicking to regulate the kiln temperature. The

elements will receive power when the temperature is below the traveling set point. The

relays will click off when the temperature is above the traveling set point. The current

segment and traveling set point can be viewed by pressing the up arrow during a firing.

Options During Firing

Displaying the current set-point and accessing the following options. During a firing you may

advance from the current segment to the next ramp rate by using Skip Step or if you are in a hold

period you may add time and temperature to the hold period. When the UP key is pressed during

a firing the current ramp or hold is displayed followed by the current or traveling set-point, then

"SStP" is displayed. If you do not press a key within several seconds the display will return to

showing the current temperature in the kiln.

Skip Step. This option allows you to skip from the present segment to the next ramp rate. Press the

UP key, the display will show the current segment, then the set-point, then "SStP". When "SStP"

is displayed press ENTER to skip to the next ramp rate.

Add Time to Hold Period Available only during a hold period This option allows you to add time

in 5 minute increments to a hold (soak) period. When in a hold period (during a hold or soak, the

temperature in the kiln will be alternating in the display with the remaining hold time), press the

UP key. When "SStP" is displayed press the UP key again and "tME" will be displayed. Press

ENTER and 5 minutes will be added to the hold time. You may use this procedure as many

times as necessary to get the hold time that you want.

Operation manual for Model 3K with Cone fire

RAMPCONEA 9-18-08

Add Temperature to Hold Period Available only during a hold period This option allows you to

add temperature in 5 degree increments to a hold (soak) period. When in a hold period (during a

hold or soak, the temperature in the kiln will be alternating in the display with the remaining hold

time), press the UP key. When "SStP" is displayed press the UP key twice more and "tMP" will

be displayed. Press ENTER and 5 degrees will be added to the hold temperature. You may use

the add temperature procedure as many times as necessary to get the hold temperature that you

want.

Error Codes

tC FAIL tC alternating with FAIL indicates the thermocouple has failed. Replace the defective thermocouple. To clear the error, press

any key.

ErrP ErrP is displayed whenever there is a power interruption that is long enough to stop the firing. If the power interruption is brief the

kiln will continue to fire when power is restored; in this case there will no indication of a power failure. To clear the error, press

any key.

tC- - The red and yellow thermocouple wires are reversed.

Messages

CPLt Firing Cycle Complete (firing time is alternately displayed).

dELA Delay. Displays when entering the delay time (hour:minutes) until the start of the firing.

DLy Delay. Alternates with the remaining delay time until the start of the kiln.

F # Segment temperature in F –Set temperature for a user program.

C # Segment temperature in C –Set temperature for a user program. A decimal point will display in lower right corner.

EdIt Edit the default options (beeping at complete, temperature scale, cone fire, delay, maximum programmable temperature)

ErrP There has been a power interruption that has stopped the firing. Press any key to clear.

FULL Beeps continuously at end of firing until a key is pressed.

HLd# Soak time in hours:minutes at a hold temperature.

OFF No beeping when firing is complete.

On Beeps for 15 seconds at end of firing.

rA # Ramp Number (rate per hour of temperature increase or decrease).

rEdl Ready to fire current program. Press START to begin firing.

SEG Short for Segments. You can enter up to 8 segments in a program.

SStP Skip Step (used to advance to the next ramp)

StOP The kiln is at idle and ready to be programmed. Stop alternates with the current kiln temperature.

USr # User program number displayed

Operation manual for Model 3K with Cone fire

RAMPCONEA 9-18-08

CONE FIRE PROFILES

FAST

SEGMENT

RAMP RATE °/HR

TEMPERATURE

HOLD

1

570

200

PREHEAT

2

570

1050

0

3

570

CT -256

0

4

200

CT

HOLD

NOTE

CT= CONE

TEMPERATURE

MEDIUM

SEGMENT

RAMP RATE °/HR

TEMPERATURE

HOLD

1

120

200

PREHEAT

2

400

1050

00.10

3

300

CT -256

0

4

120

CT

HOLD

NOTE

CT= CONE

TEMPERATURE

SLOW

SEGMENT

RAMP RATE °/HR

TEMPERATURE

HOLD

1

80

200

PREHEAT

2

200

1050

00.30

3

200

CT -256

0

4

108

CT

HOLD

NOTE

CT= CONE

TEMPERATURE

TIME

Segment 1

Seg 2

Segment 4

°F 1

Rate 1

Hold 1

Segment 3

Sample glass profile

Table of contents

Other Bartlett Controllers manuals

Popular Controllers manuals by other brands

Mitsubishi Electric

Mitsubishi Electric MELSEC-F FX3U-232ADP-MB installation manual

Siemens

Siemens OpenAir GCA Series Technical instructions

Leviton

Leviton Decora Smart DW15P Getting started guide

Circor

Circor RTK REact 30 Series Installation and operating instructions

Klereo

Klereo Kompact Installation guides

Firetrol

Firetrol FTA570F-AG003E Installation and maintenance manual