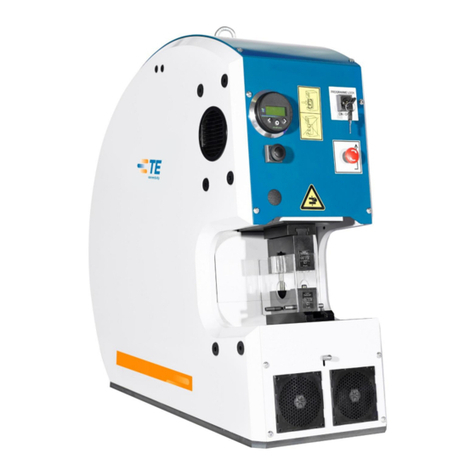

BARTON TOOLS HHYD-300 User manual

HHYD-300 G/H Battery crimping

tool

Manuals

For your safety, please read manual carefully before using

Please keep t is manual properly. If t e user of t e product c anges, please give t is manual to

t e new user

www.barton-tools.com

T anks for your kind appreciation for c oosing our products

Please read t is instruction carefully before use, and wit full understanding. Please contact t e dealer or manufacturer

w en you encounter difficulties or faults. Do not disassemble t e tool by yourself to avoid losing small parts or contaminating

t e ydraulic system losing its function

Main safety notice

Warning:In order to avoid an accident such as fire,electric shock ect,

All must follow below attentions.

Work place

1. Keep work place clean and bright,disorder and dark will be easy to cause accident.

2. Operate t e tool after c ildren and bystander leaving. Distractions can cause you to relax control.

3. T is tool is not electrically insulated. Do not use it w en t e wires or terminals are live 。

4. Do not use or store tools in ig temperature environment wit strong acid, strong alkali or ot er

corrosive liquids, gases. Prevent tools from corrosion and components from aging.

5. Do not c arge or use t e product in t e presence of flammable, explosive liquids, gases and dust

Electric safety

1. T e power plug of t e c arger must matc t e socket and must not be altered in any way.

www.barton-tools.com

2. Do not expose c argers, batteries to rain or damp. ot erwise water entering t e electrical system will

increase t e risk of electric s ock. Do not abuse t e wire, never use t e wire to carry, pull or unplug t e

c arger. Damaged or tangled wires increase t e risk of electric s ock

3. Do not use or disassemble t e c arger if it is badly it, dropped, or damaged.Hand it over to a qualified

maintenance person. Using a damaged c arger may be in danger of electric s ock or fire.

4. Do not c arge t e battery w en t e temperature is lower t an 10 ° C or ig er t an 40 ° C, and do not

cover or block t e c arger and battery eat dissipation ole during c arging

5. Unplug t e c arging power supply w en encountering t understorms and lig tning

6. Do not s ort-circuit or burn t e battery to avoid explosion

Personal safety

1. Keep alarm w en operate.Do not operate t is tool wit fatigue, drug, alco ol, or treatment. Distraction during t e

operation may result in serious life injury.

2. Use and wear safety equipment. Wearing safety elmets, non-skid gloves, insulating s oes, goggles, and safety

belts (working at eig t) can reduce personal injury.

3. Do not operate brutally w en using. Do not start or stop unconsciously , It may cause t e microprocessor and

electronic protection system failure or damage

4. Do not put your fingers or any part of your body into t e jaw of t e working pliers to avoid being clipped 5.

Store unused tools out of reac of c ildren and do not allow people w o are not familiar wit t e tools to

operate it.

Realize your tool

T anks for using battery crimping tool HHYD-300. HHYD-300 wit Hig performance lit ium battery

power, motor driven, microcomputer (MCU )control ,Ultra- ig pressure ydraulic system and ot er

mec atronic integration tec nology, wit ergonomic design, wit beautiful appearance, simple operation, large

output force, super safety, ig efficiency, is one of t e best tools to use in power, lig ting and ot er electric power

construction wire and copper/aluminum terminal crimping

Technical parameter

Max output:6 KN

Crimping range:Cu3 mm2/Al240 2

Working stroke:18

Hydraulic oil: 15#low condensation anti-wear ydraulic oil about 160ml

Enviroment temprature:-1 ℃~4 ℃

Battery:DC 18V 4Ahlion

Cri ping period:3~6s/t(depend on the size of lugs)

Crimping times per saturated battery:about 320ti es(Cu150 2)

Charge power:AC 100V~240V 50~60Hz

Charge ti e:about 2hours

www.barton-tools.com

Product instruction

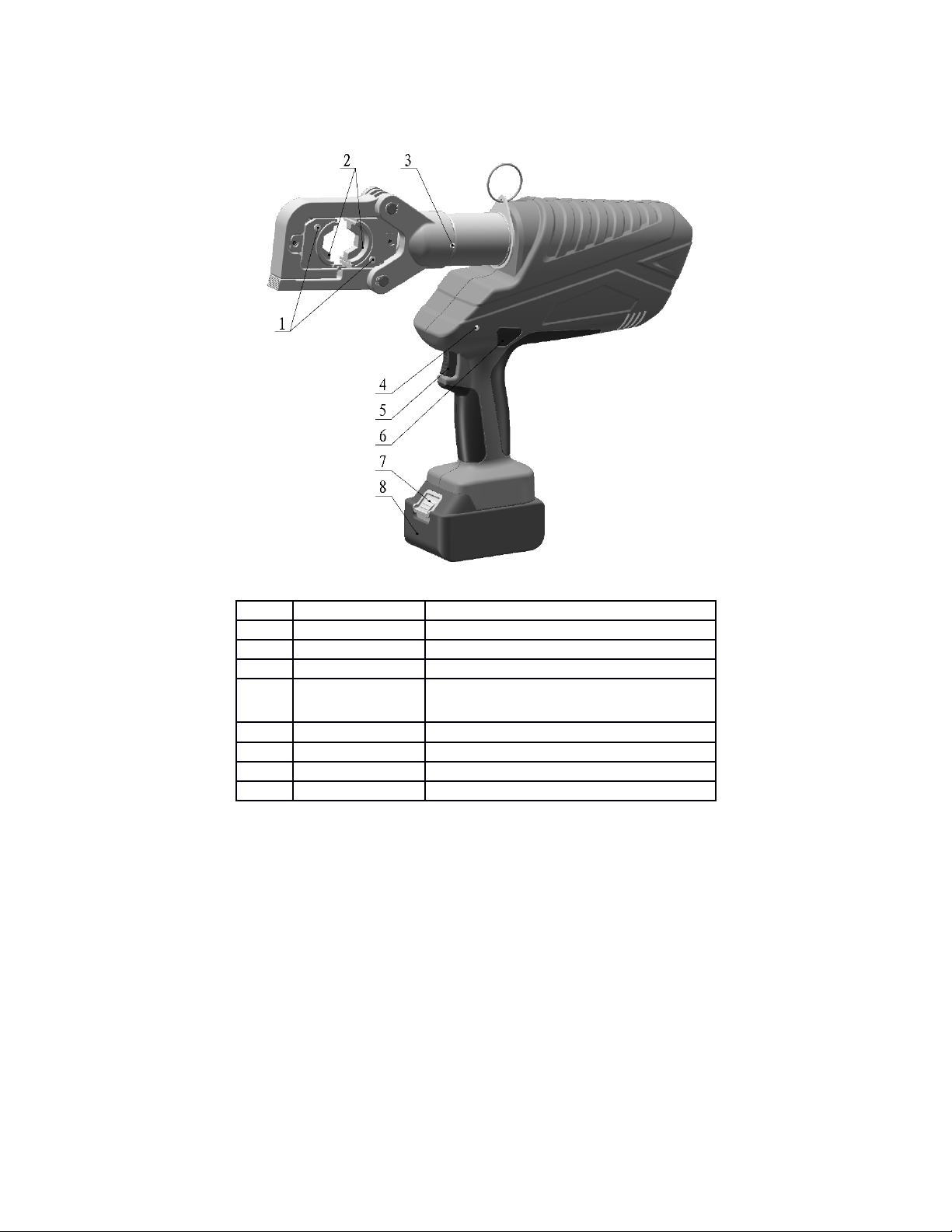

No Name Function

1 Blinding clip Lock or take out the crimping dies

2 Crimping dies emovable crimping dies

3 Stop screw Prevent the head back out

4Indicator(LED

)

Show work condition / discharge reminder

5 Start button Start machine and crimping

6 eset button eset piston

7 Battery lock Lock or take out battery

8 Battery Chargable lithium ion battery

www.barton-tools.com

Function description

1. Microcomputer control system: automatic pressure monitoring and double safety protection in t e process of crimping,

automatic reset and stop motor rotation after finis ing t e crimping.

2. Automatic reset function: automatic pressure relief ydraulic device, w en t e pressure relay reac es t e maximum, t e

piston (lower die seat) automatically returns to t e original position.

3. Manual reset function - in case of error during crimping, t e piston (lower die seat) can be returned to its original position

by manual reset.

4. Miniature bipolar ydraulic system: t e piston (lower die older) pus es forward rapidly during t e process of crimping

low pressure, and slowly pus es forward after t e die contacts t e terminal

5. 330°Free rotating clamp ead -- suitable for a wide range of Angle applications

6. W en t e power is switc ed on, t e battery is low and t e crimping process is wrong, t e microcomputer control

system will give out sound and red LED flas ing signal (see table1).

7. T e overall structure of t e tool is compact and ergonomic. T e non-slip rubber for t e and- eld part and t e optimized

center of gravity design make t e operation easier.

8. Hig -performance lit ium-ion battery provides more powerful power source, no disc arge memory, ultra-low power

consumption standby design can guarantee up to 6 mont s, and equipped wit over-disc arge protection to extend t e battery life

9. Temperature sensor: W en works for a long time, it will be eat. W en t e temperature exceeds 60℃, it will stop

automatically and a warning will appear to protect t e tool from being burned. After t e temperature drops, it can continue to work .

www.barton-tools.com

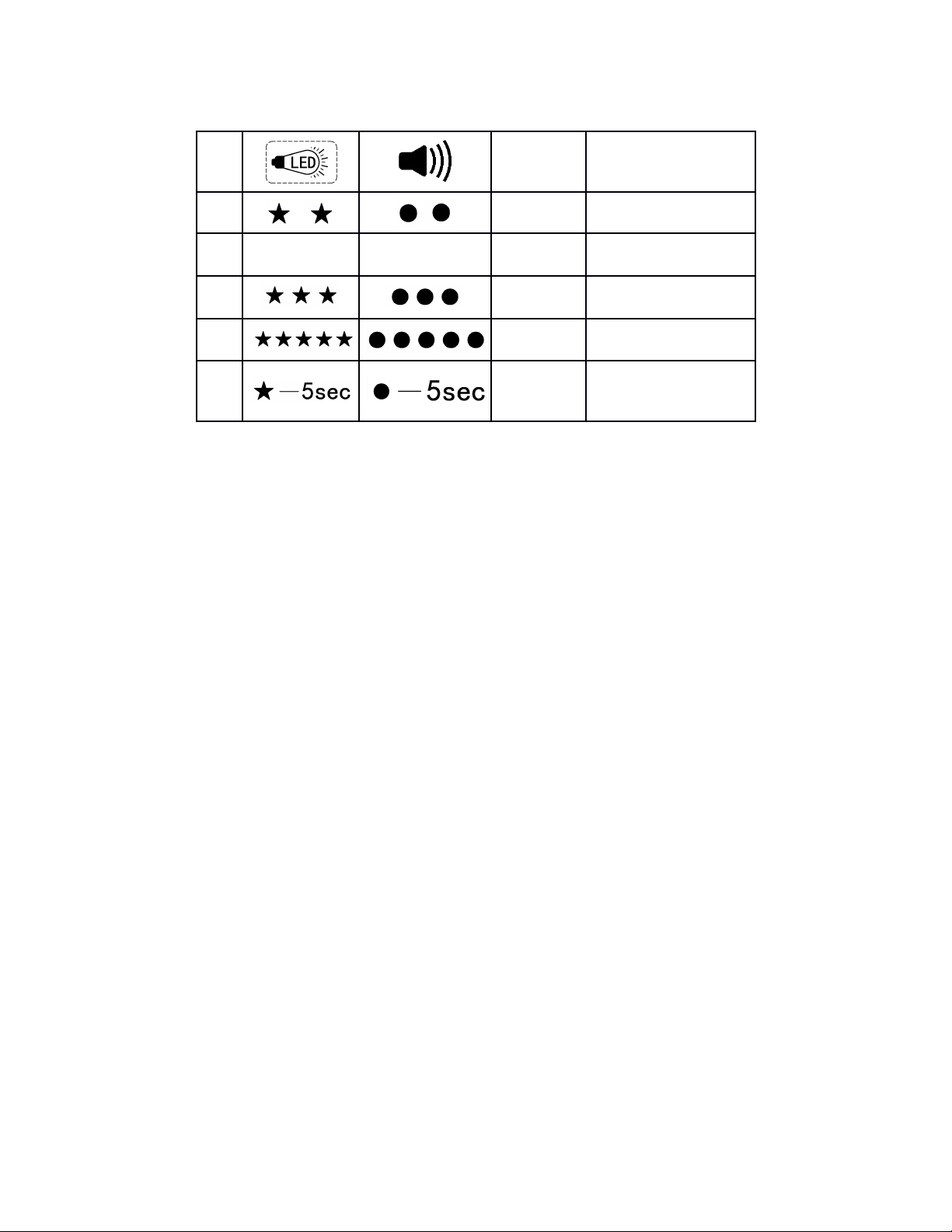

Table 1:Signal indication and meaning

No Signal Meaning

1 Self check self check system

normal

2The system has fault

should recheck

3Temprature

warning

The temprature is high

, cool down

4Charge

remider Remind charging

5

Power

shortage

alarm

Battery run out,charge

at one

Usage and precautions

Before using, c eck carefully w et er t e c arger cover, battery cover, working ead and cover are in

good condition, and w et er t e battery connection is reliable to ensure safety.

www.barton-tools.com

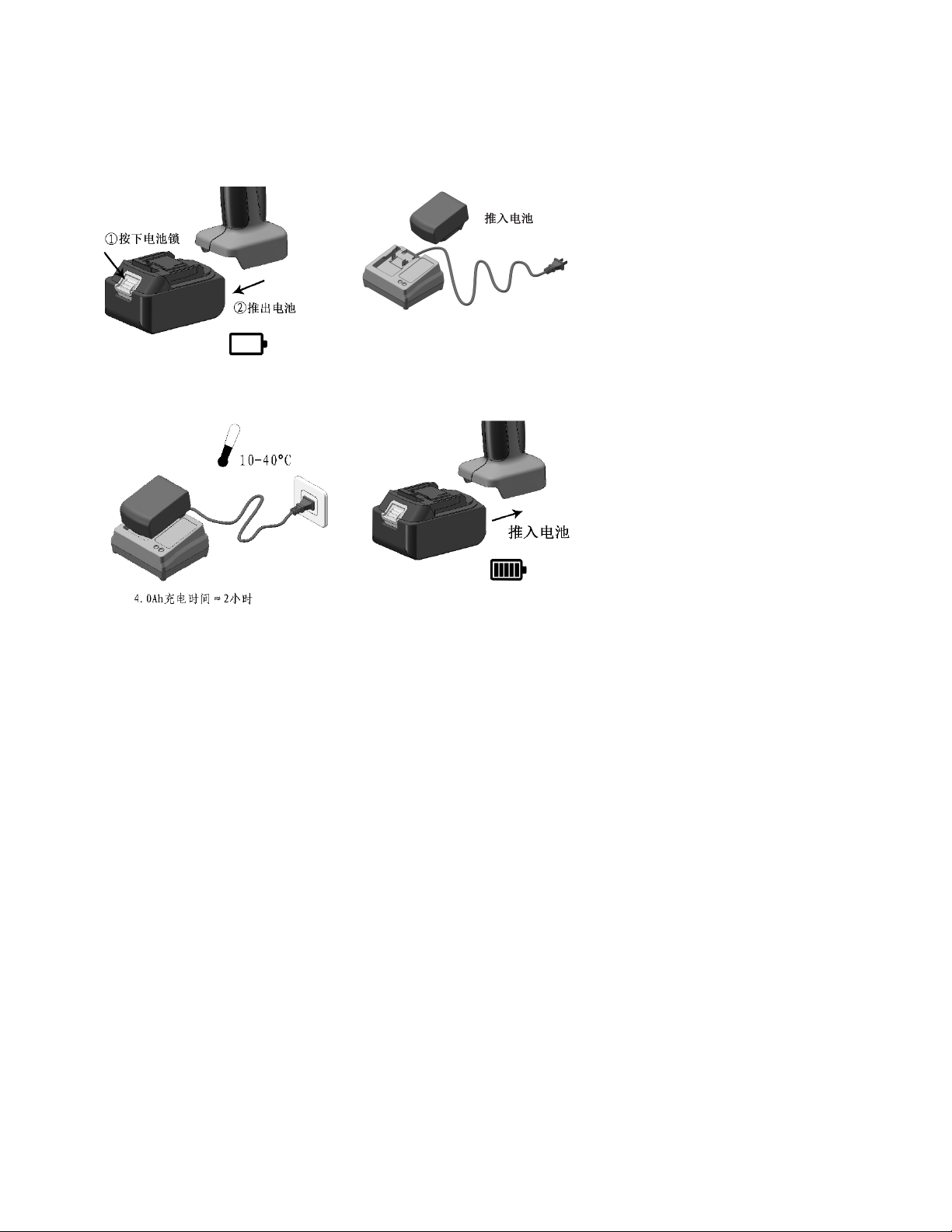

Charging

1 2

3 4

Attention:

1. A battery can be c arged and disc arged undreds of times, but eventually fails. Replace t e battery if t e number of times.Please

c arge t e battery in time, do not completely consume t e battery, w ic will lead to permanent failure of t e lit ium battery

2. W en tools are not used for a long time, t e battery will generate self-disc arge. Take out t e battery and c arge it fully every quarter

2. Don't connect t e two poles wit wires, it is easy to cause sparks. Burn or even explode.

3. Do

not

use

damaged

batteries

or

c arge

as

t is

increases

t e

risk

of

electric

s ock.

4. Do not burn batteries under any circumstances, ot erwise t ey may explode

5. W en c arging t e battery, do not use any object to cover t e c arger, so t at t e c arger can not eat ,ot erwise it can be easy to

cause a fire

6. Disconnect t e c arger w en not in use. T is will reduce t e risk of injury to c ildren and untrained person

7. Do not use t e c arger in wet conditions and do not expose yourself to rain or snow, w ic can increase t e risk of electric s ock

8. Do not disassemble batteries and c argers wit out permission. If any fault occurs during use, please and it over to professionals or

manufacturers

for

maintenance

until

t e

problem

is

solved

www.barton-tools.com

1 2

3 4

www.barton-tools.com

56

Warning:

1. Do not ammer or knock any part of t e tool. Before operation, c eck w et er any damage, aging, missing parts, inaccurate

adjustment or parts stuck or any ot er adverse factors t at may endanger safety and normal operation . Ensure t at t e switc can

operate effectively wit out any stuck p enomenon. If any problems are found, discontinue use immediately until t e problem resolved.

2. T e limit block and screw on t e clamp ead are to prevent t e clamp ead from falling off or popping out. Do not remove it by

yourself!

3. Remove any grease and dust, especially from andles and control components, to prevent sliding off during use.

4. Built-in safety valve after strict pressure test before leaving t e factory, users must not adjust wit out aut orization! If t e pressure is

insufficient, please and t e tool to t e maintenance personnel and pass t e pressure test before using

5. Do not crimp w en t ere is no mold in t e jaw of t e working pliers. Ot erwise,t e tools may be damaged and personal injury

Warning:In t e process of extending t e piston, do not put fingers or any part of uman body into t e jaw of t e

working pliers to avoid accidents

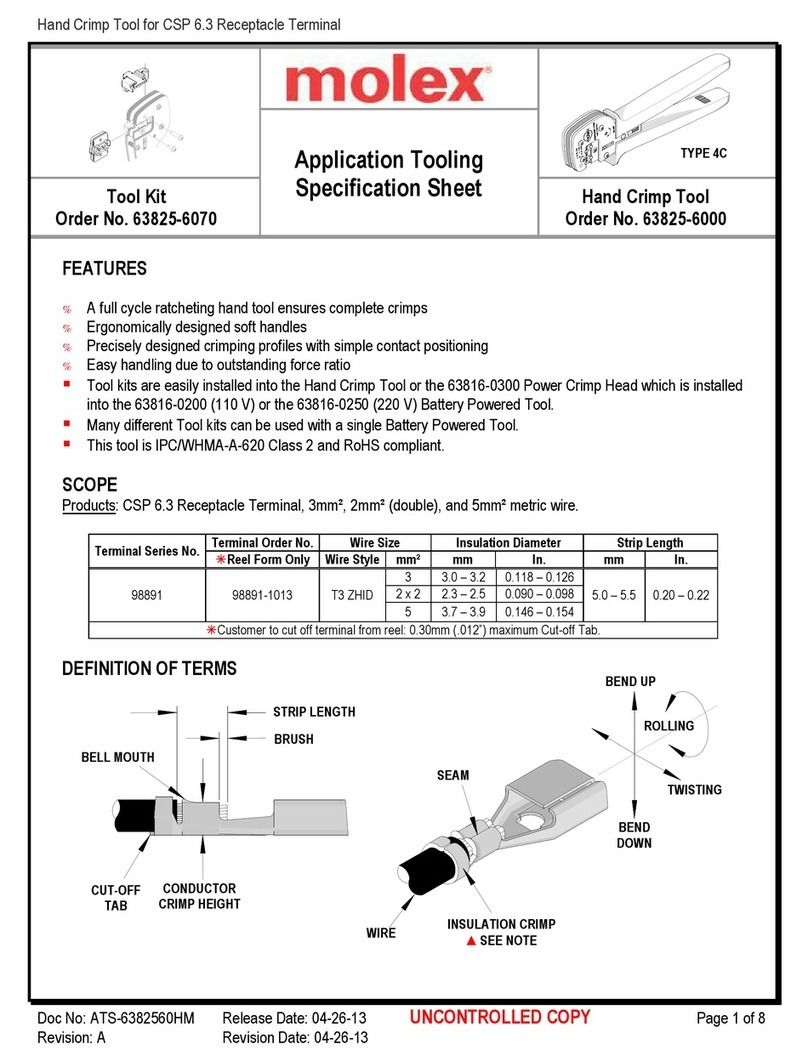

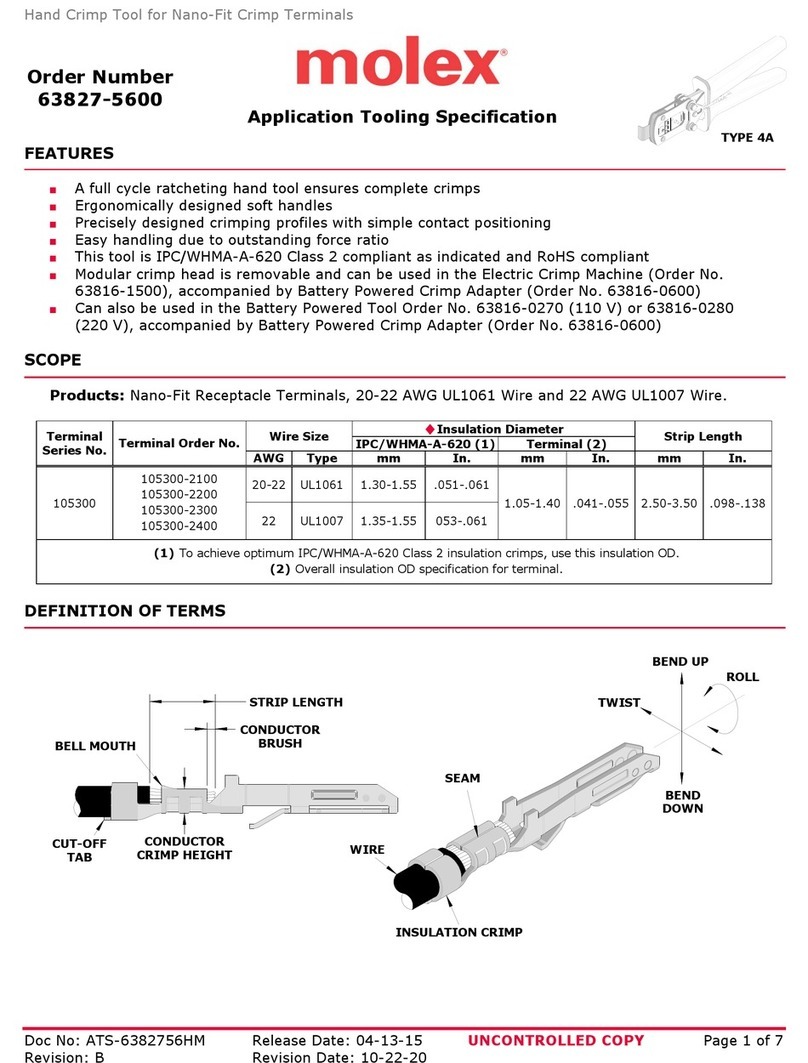

Crimping dies

Matched standard crimping die(Hex)(mm2):

16、25、32、50、70、95、120、150、185、240、300

T e corresponding mold specifications are printed on t e side of t e arc

If t ere are different specifications of wires and terminals to be crimped, please contact wit us ,we can customize different sizes and

special s apes of crimping dies for users

Note: Please select proper crimping die according to wire specification and corresponding copper/aluminum

terminal. Improper selection of crimping die may lead to loose crimping between wire and copper/aluminum

terminals or a large number of flanges.

www.barton-tools.com

Maintenance and Service

1. T e tool is a product wit excellent design and tec nology, it is not allowed to disassemble internal parts at all, all t e failure caused

by users' unaut orized disassembly or improper use of t e damage, no longer wit in t e scope of warranty service, but for users to

make paid repair (only c arge parts cost).

2. Keep dry. Rain, moisture, and various liquids or moisture can corrode tool ousings, metal surfaces, and electronic routes. If t e tool

is wet, take out t e battery and reinstall t e battery after completely dried

3.

Do not store in too cold or too ot places.

Too muc cooling or over eating can deform plastic part. s orten t e life of electronics and

damage batteries.

4.

Do not use strong c emical cleaners or strong detergents to clean

To ensure t e service life,replace t e ydraulic oil in t e tool once a year

6. If t e tool is not in use for a long time, reset t e piston to t e bottom, wipe t e tool surface, smear rust-proof grease on t e metal

surface of t e crimping die and t e tool, take out t e battery, and store it in t e tool box

7. Sealing components are worn. If ydraulic oil leaks after a period of use, contact t e dealer or manufacturer for professional

maintenance personnel to replace t e sealing components.

5.

www.barton-tools.com

This manual suits for next models

2

Table of contents

Other BARTON TOOLS Crimping Tools manuals

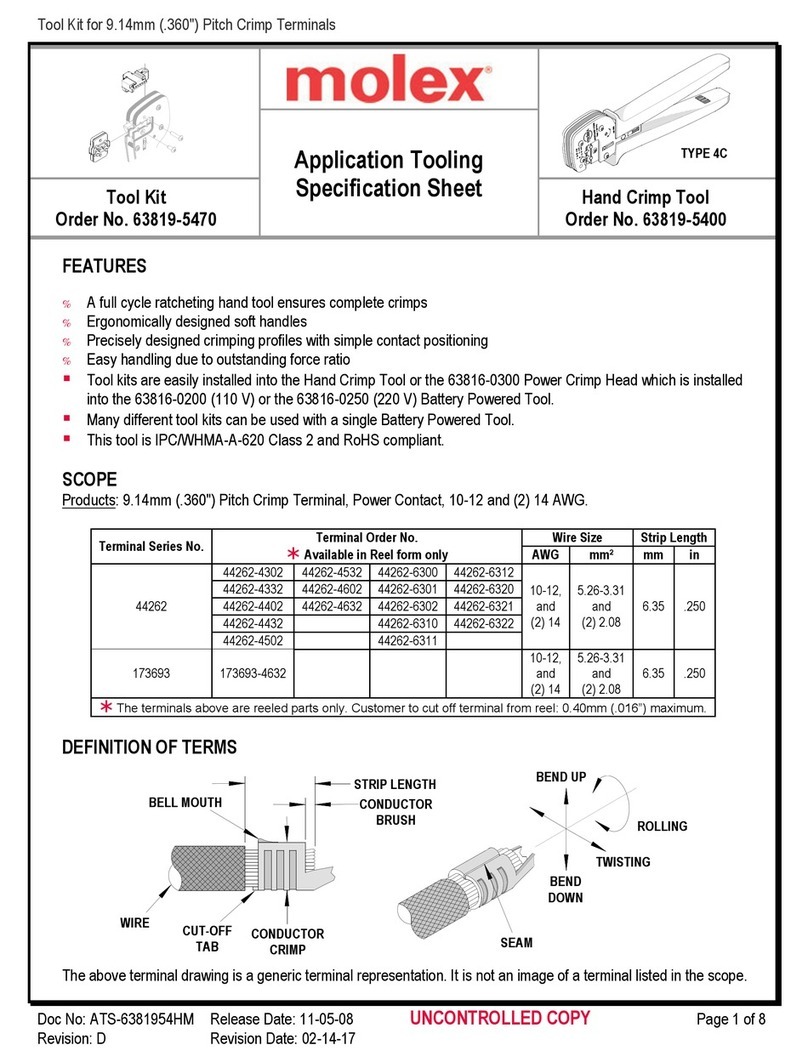

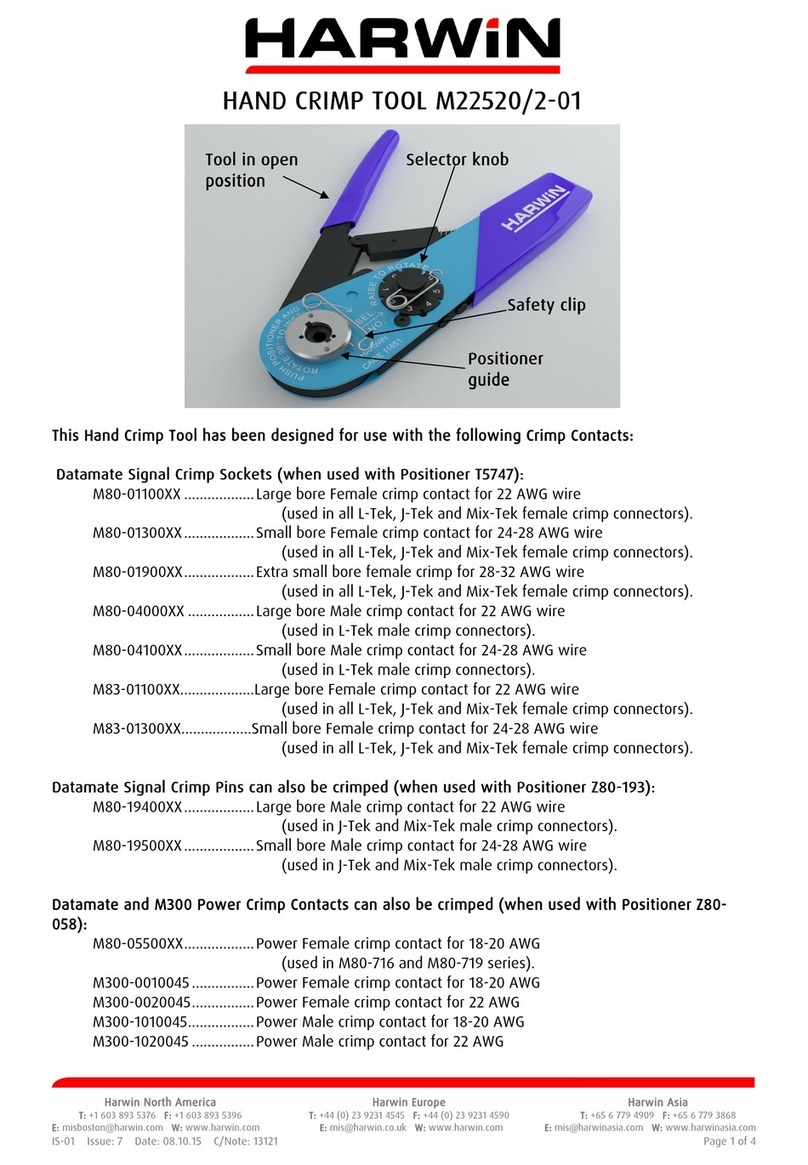

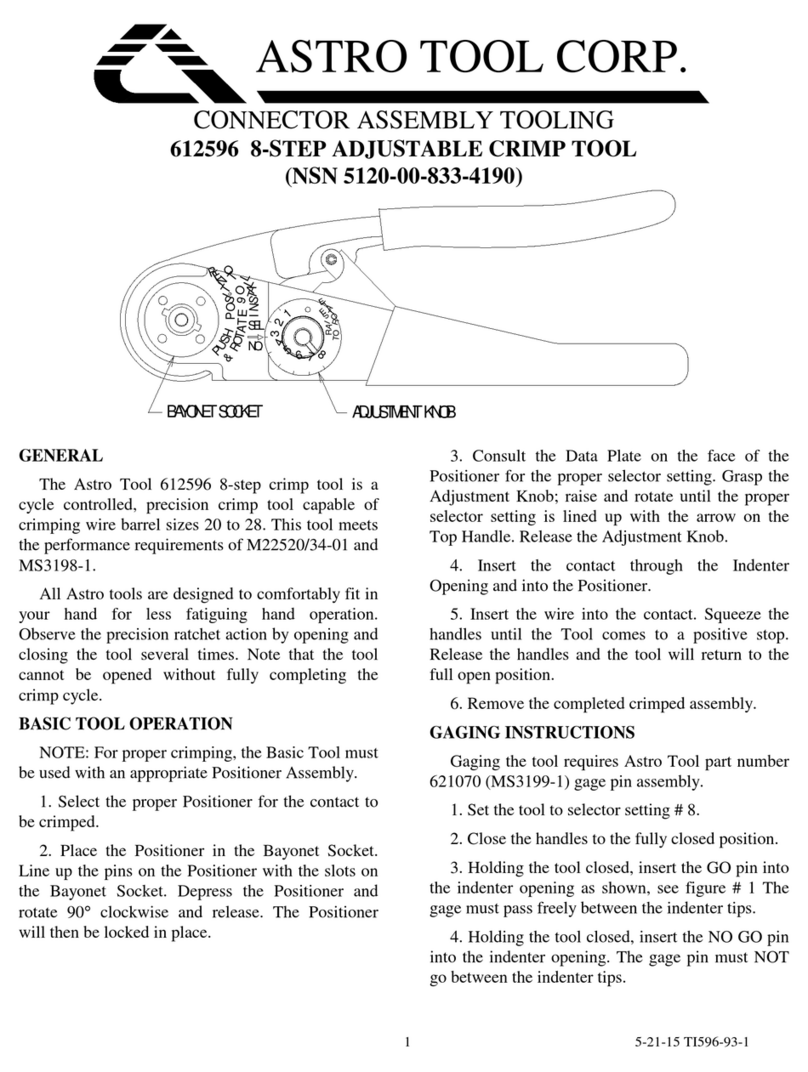

Popular Crimping Tools manuals by other brands

Cembre

Cembre B1500 Operation and maintenance manual

Gates

Gates MobileCrimp 4-20 Safety and operating manual

APP

APP 1309 Series Operation & maintenance instructions

molex

molex 105300 Series quick start guide

Cembre

Cembre B1350-CA Operation instructions

HARTING

HARTING 09 69 82 5140 Series Assembly instructions