BARTON TOOLS HHYD-400 D User manual

Battery Operated Crimping Tool

HHYD-400 D/E/U

Instruction Manual

For your safety, please carefully read this instruction manual and fully understand the information contained within. The owner and operator shall have

an understanding of this product and safe operating procedures before attempting to use this product

Save these instructions. Make sure this instruction manual is carried along during the entire life span of the tool.

Warning: Please do not disregard these instructions in order to avoid human injuries and environmental damages!

Techanical parameter

Output:110KN

Crimping range:Cu400mm2/ l300mm2

Working pressure:42mm

Hydraulic oil:15#Low pour point antiwear hydraulic oil approx 160ml

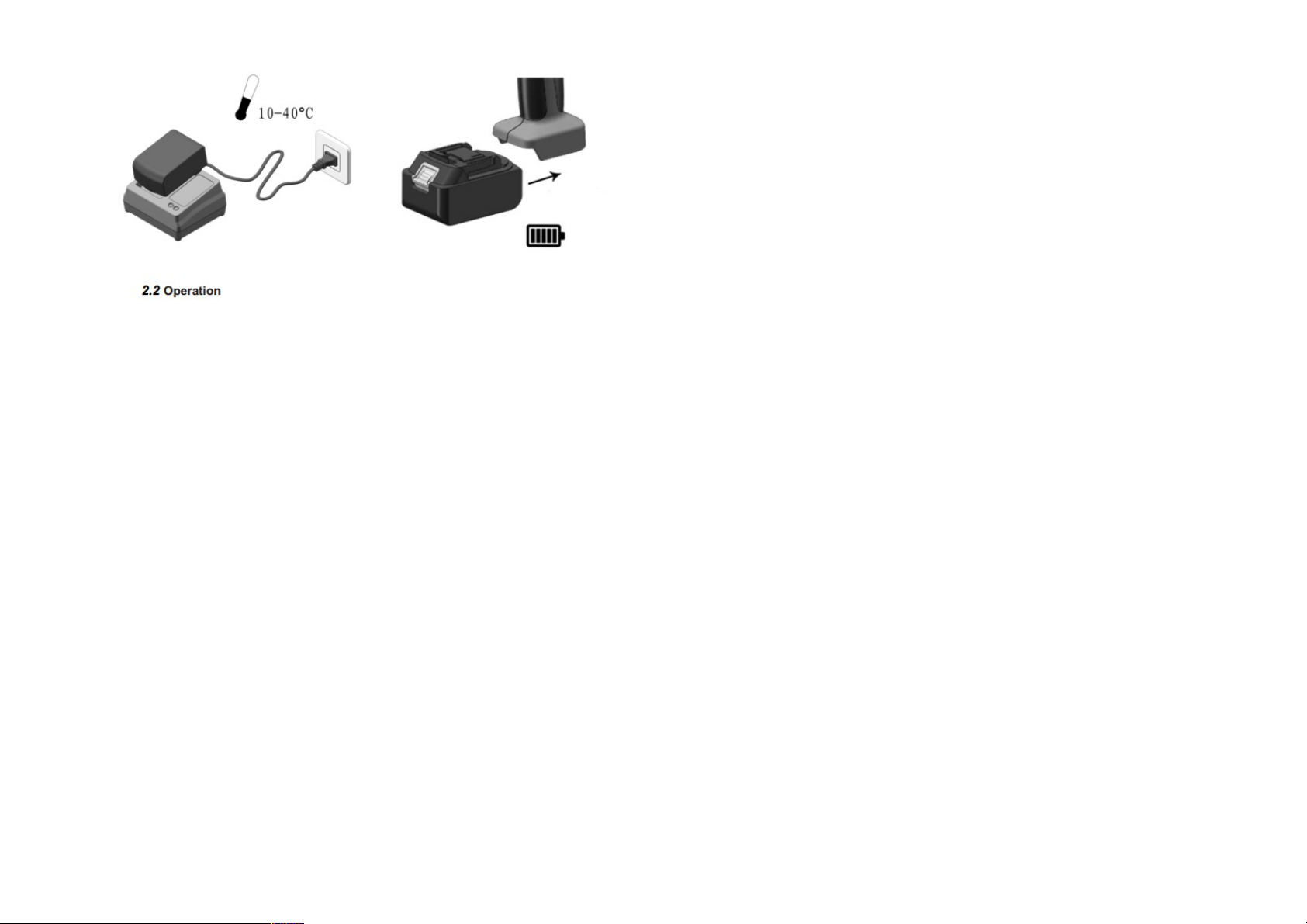

Enviroment temperature:-10℃~40℃

Battery :DC 18V 4 h h Li-ion

Crimping period:6~18s/cycle(depending on the end of lug size)

Battery capacity:approx 150 crimping cycles (Cu150mm2)

Charge power: C 100V~240V 50~60Hz

Charge time:2 hours

www.barton-tools.com

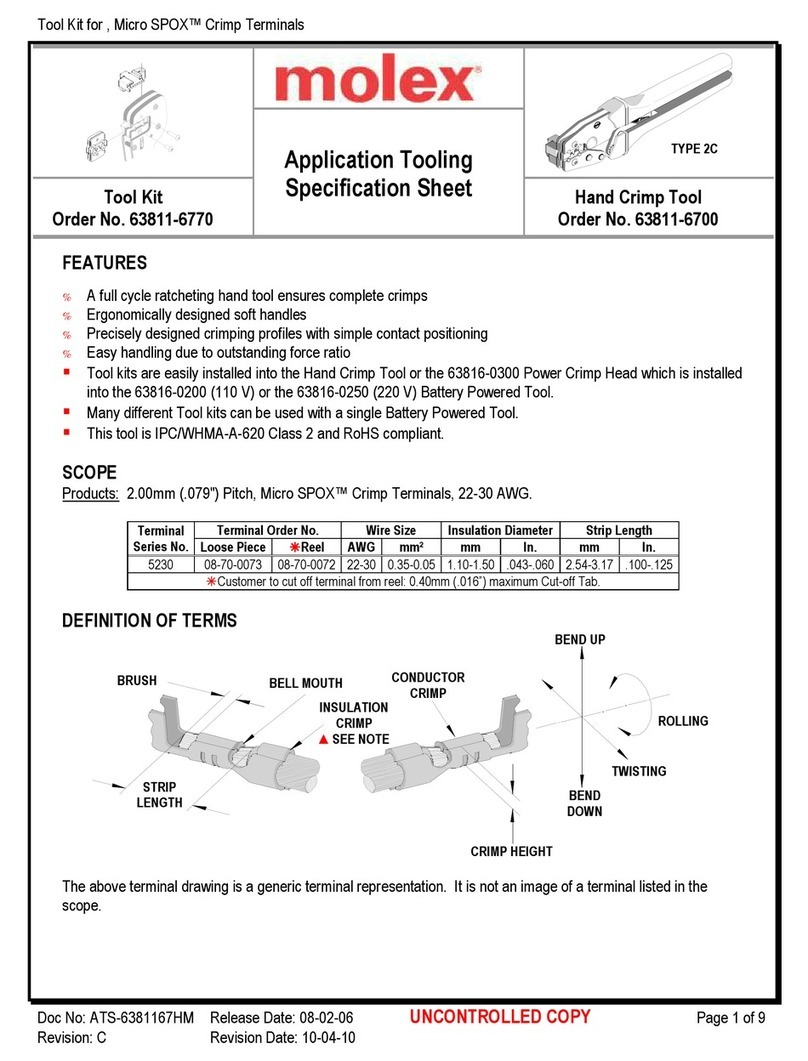

Product construction

Code Name Function

1 Die lock To lock and release the die

2 Die nterchangeable crimping dies

3 Stop pin Prevent the tong head from being

turned out and falling off

4 LED ndicator for battery charge control tool

functions and faults

5 Trigger Switch to start working cycle

6 Retract Button Retract the piston in case of error

7 Battery lock To lock and release the battery

8 Battery Rechargeable 18v/4.0ah li-ion battery

Function:

1. The tool is equipped with a microprocessor which shuts off the motor automatically after the crimp is completed, indicates service intervals and low battery

charges and performs internal checks sending out acoustical and optical warning signals in case of a detected fault.。

2. The hydraulic unit incorporates an automatic retraction which returns the piston into its starting position when the ma imum operating pressure is reached.。

3. A manual retraction allows the user to return the piston into the starting position in casr of effor or emergency。

4. The unit is equipped with a double piston pump which is characterised by a rapid approach of the dies towards the connector and a slow crimping motion.。

5. The crimping head can be smoothly turned by 330° around the longitudinal a is in order to gain better access to tight corners and other difficult working areas。

6. The tool features an integrated sensor which automatically identifies the system power status or achieved crimping force during every crimping operation.

When the tool is power-on, or when the battery is low, or when a deviation from the set operation pressure is identified, an acoustic signal sounds and a red display

flashes.(See chart 1)。

7. The tool is ergonomically designed with 2-component grip area and well balanced center of gravity。

8. High performance lithium ion battery - provide more powerful power source, no discharge memory effect, ultra-low power standby design

can guarantee up to 6 months storage time, at the same time, it is equipped with over discharge protection to prolong the service life of

battery。

9. Temperature sensor: the tool will generate heat when it works continuously for a long time. When the temperature exceeds 60 ℃, the tool

will stop automatically and give a fault prompt to protect the tool from being burned. The tool can continue to work after the temperature

drops。

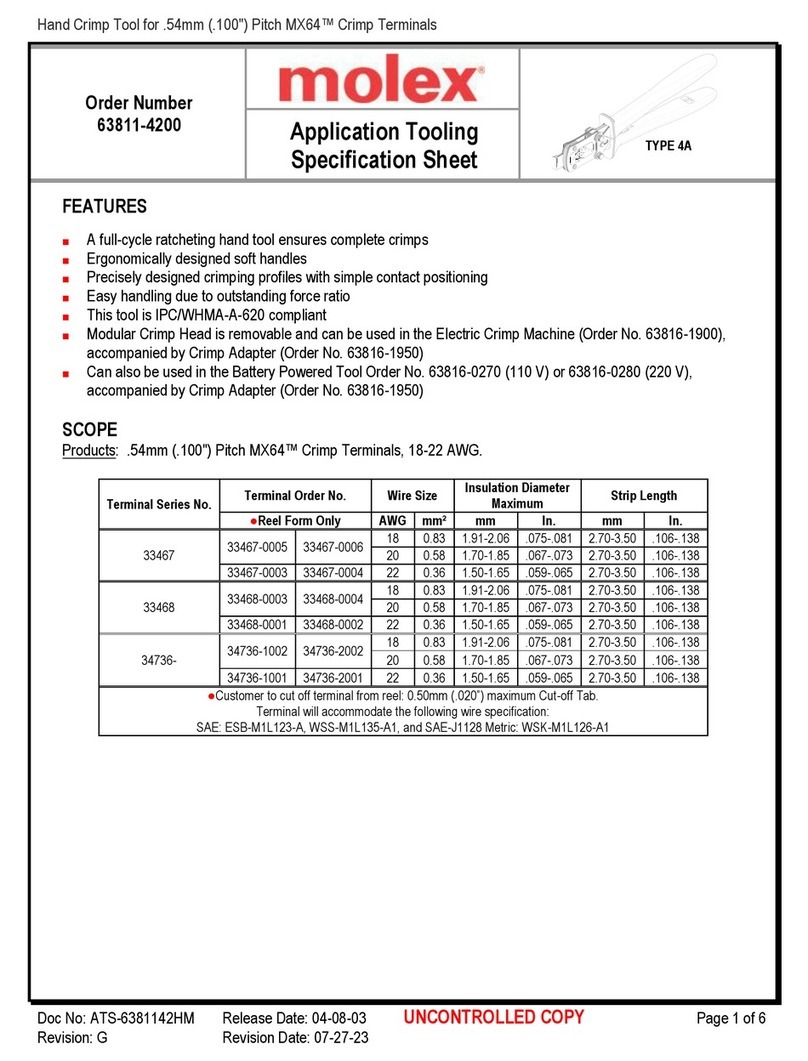

Chart 1:Signal indication and meaning

Code Signal Meaning

1Power on

self test

Selfcheck,normal

system

2

Thetoolisoverheated,st

op using it and wait

until it cools down

3Overheat

warning

The tools is

overheated,stop using

it and wait until itcools

4Charging

reminder

The battery is going

low,but can stillbeused

for a few cycles,it is

recommended to

charge up the battery

5 Battery out

the battery must be

charged immediately

after out of charge

Operation and Attention

Before use, please check the appearance and connection of the charger,

batteries, workhead and housing. Make sure the tool and components are

sound and safe prior to operation.

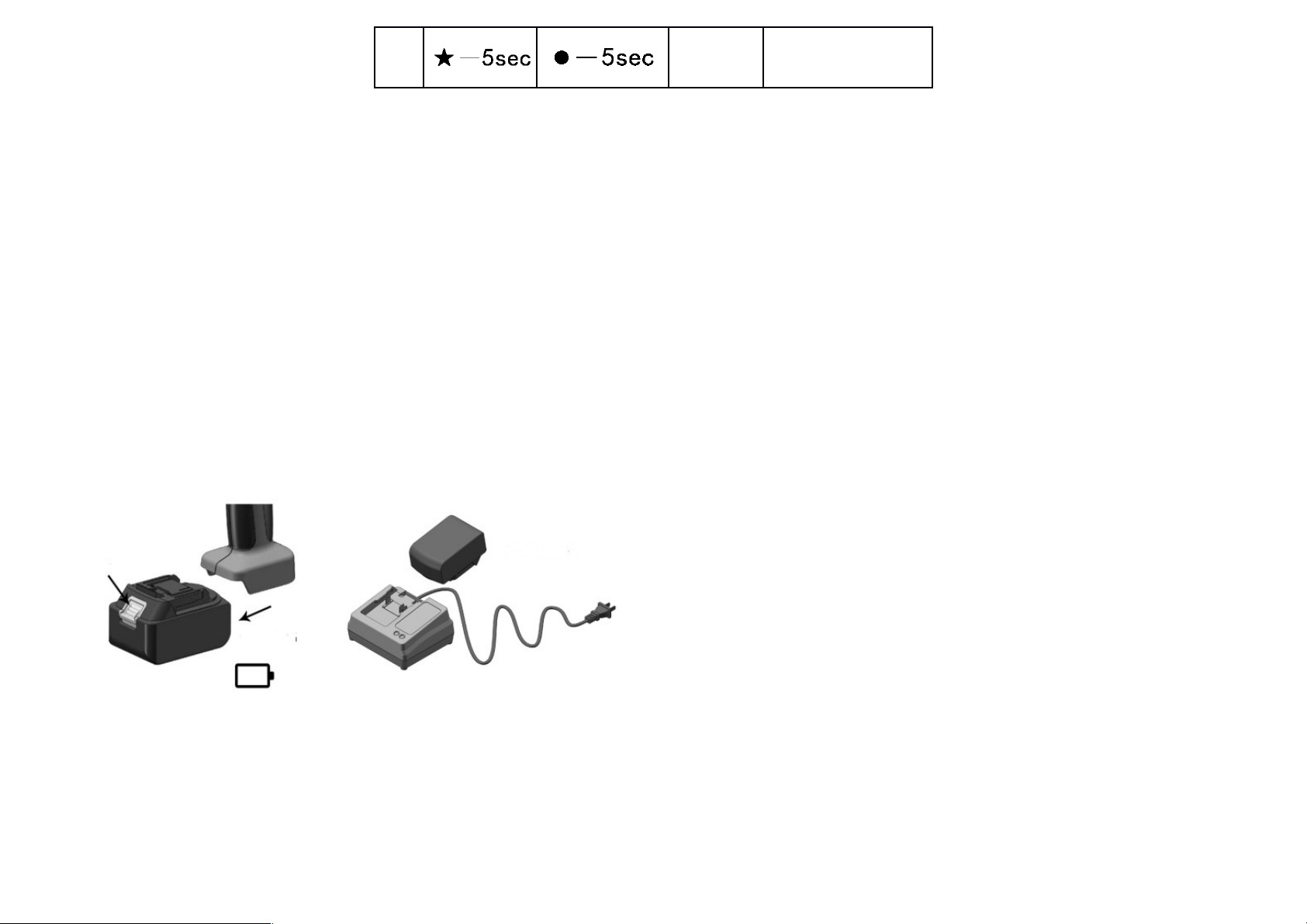

Battery

1 2

3 4

ttention:

Always charge the battery in time before it runs out. Depletion of battery leads to shortened service life, or even permanent failure.

Replace the battery when its service life comes to an end after hundreds of charge/discharge cycles.

If the tool is not to be used for long period, take off the battery from the tool,and charge the battery per 3 month

Operation:

Warning:

1. Any part of the tool shall not be hammered or knocked. Before operation, the tool must be checked for any damage, aging, lack of parts, inaccurate adjustment or stuck parts and

any other adverse factors endangering the safety and normal operation, so as to ensure that the switch can operate effectively without any jamming. f any problem is found, please

stop using it。

2. The stop block and screw on the tong head are to prevent the tong head from falling off or popping out. Do not remove it by yourself!

3. n particular, it can prevent the handle from sliding and falling during use。

4. The built-in safety valve is subject to strict pressure test before leaving the factory. The user must not adjust it without authorization! In

case of insufficient pressure, please hand over the tool to professional maintenance personnel and pass the pressure test before use

5. If there is no die in the working jaw, please do not carry out crimping operation, otherwise the tool will be damaged and personal injury may be

caused!

warning:In the process of extending the tool piston do not put any part of the human body such as fingers into the working jaw to avoid accidents!

Crimping dies

Standard crimping dies(HEX)规格(mm2):

16、25、35、50、70、95、120、150、185、240、300、400

The corresponding mold specifications are printed on the side of the arc.

If there are different specifications of wires and terminals to be crimped, please contact the relevant dealers or manufacturers. Manufacturers

can customize different sizes and special shapes of crimping dies for users.

ttn: ccording to the wire specification and the corresponding copper / aluminum terminal, select the crimping die reasonably. Improper selection of

crimping die will result in loose crimping between conductor and copper / aluminum terminals or a large number of flash edges

Service and maintenance

This product with excellent design and technology is not allowed to dismantle the internal parts at will. Any failure or damage caused by improper use caused by user's

unauthorized disassembly is no longer within the scope of warranty service, but it can be repaired for users with compensation (only the cost of parts is charged)。

1. Keep tools and spare parts dry. Rain, moisture and various liquids or moisture can corrode tool housings, metal surfaces, and electronic wiring. f the tool is wet, please take out the

battery and replace the battery after the tool is completely dry。

2. Do not store tools in places that are too cold or too hot. Supercooling or overheating will deform the plastic parts of the tool, shorten the life of electronic components and damage

the battery。

3. Do not use strong chemical cleaner or strong detergent to clean tools。

4. n order to ensure the service life of the tool, it is recommended to replace the hydraulic oil in the tool once a year.

5. When the tool is not used for a long time, please reset the piston to the bottom, wipe the surface of the tool clean, and evenly apply anti rust grease on the metal surface of the

crimping die and the tool, and take out the battery and put it into the toolbox for storage。

6. The sealing element is a wear and tear part. When the hydraulic oil leaks out after the tool is used for a period of time, please contact the dealer or manufacturer to replace the

sealing element by professional maintenance personnel。

www.barton-tools.com

This manual suits for next models

2

Table of contents

Other BARTON TOOLS Crimping Tools manuals

Popular Crimping Tools manuals by other brands

Greenlee

Greenlee GATOR EK622PLX Operation manual

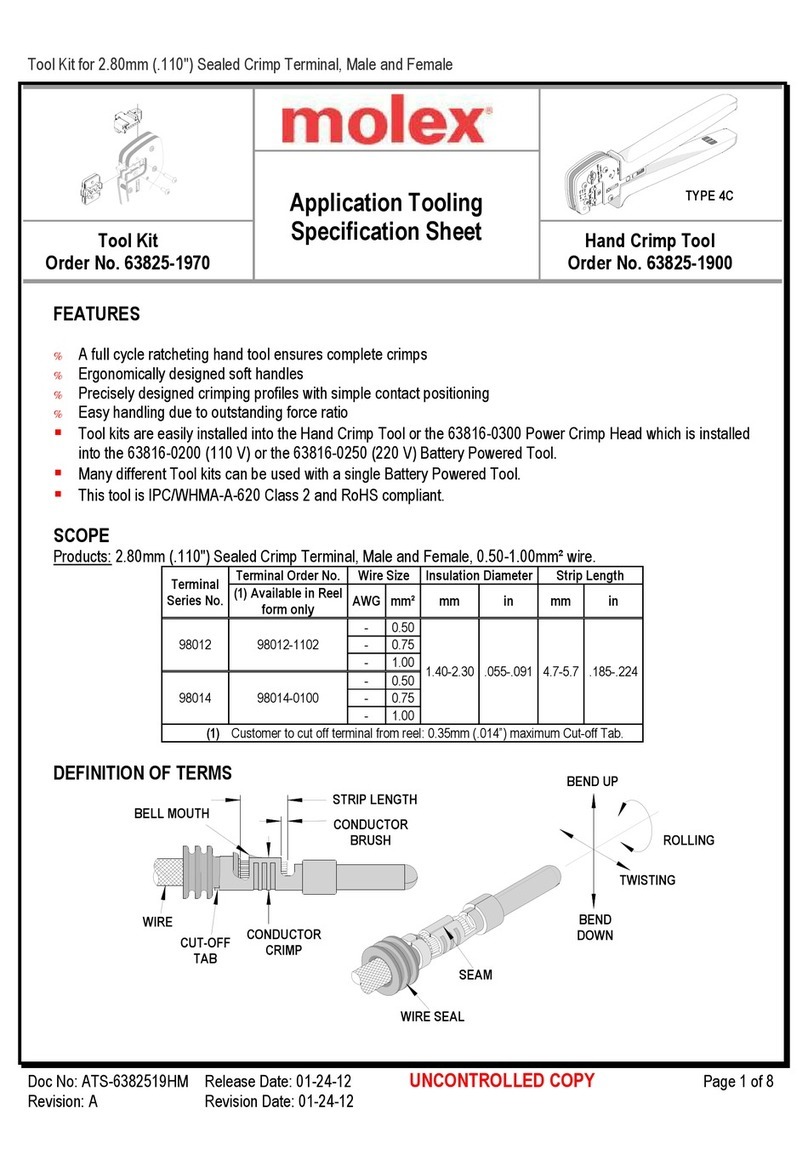

molex

molex 207129 Series Application Tooling Specification Sheet

Emerson

Emerson Klauke EK 135FTCFM manual

molex

molex 63825-1900 Specification sheet

Continental Refrigerator

Continental Refrigerator PC125-RCD quick start guide

haupa

haupa AC25-12 instruction manual