Harwin M22520/2-01 User manual

Harwin North America

Harwin North AmericaHarwin North America

Harwin North America

Harwin Europe

Harwin EuropeHarwin Europe

Harwin Europe

Harwin Asia

Harwin AsiaHarwin Asia

Harwin Asia

T:

T:T:

T: +1 603 893 5376 F:

F:F:

F: +1 603 893 5396 T:

T:T:

T: + (0) 23 9231 5 5 F:

F:F:

F: + (0) 23 9231 590 T:

T:T:

T: +65 6 779 909 F:

F:F:

F: +65 6 779 3868

E:

E: E:

E: misbost[email protected] W:

W:W:

W: www.harwin.com E:

E:E:

E: [email protected] W:

W:W:

W: www.harwin.com E:

E:E:

E: [email protected] W:

W:W:

W: www.harwinasia.com

IS-01 Issue: 7 Date: 08.10.15 C/Note: 13121 Page 1 of

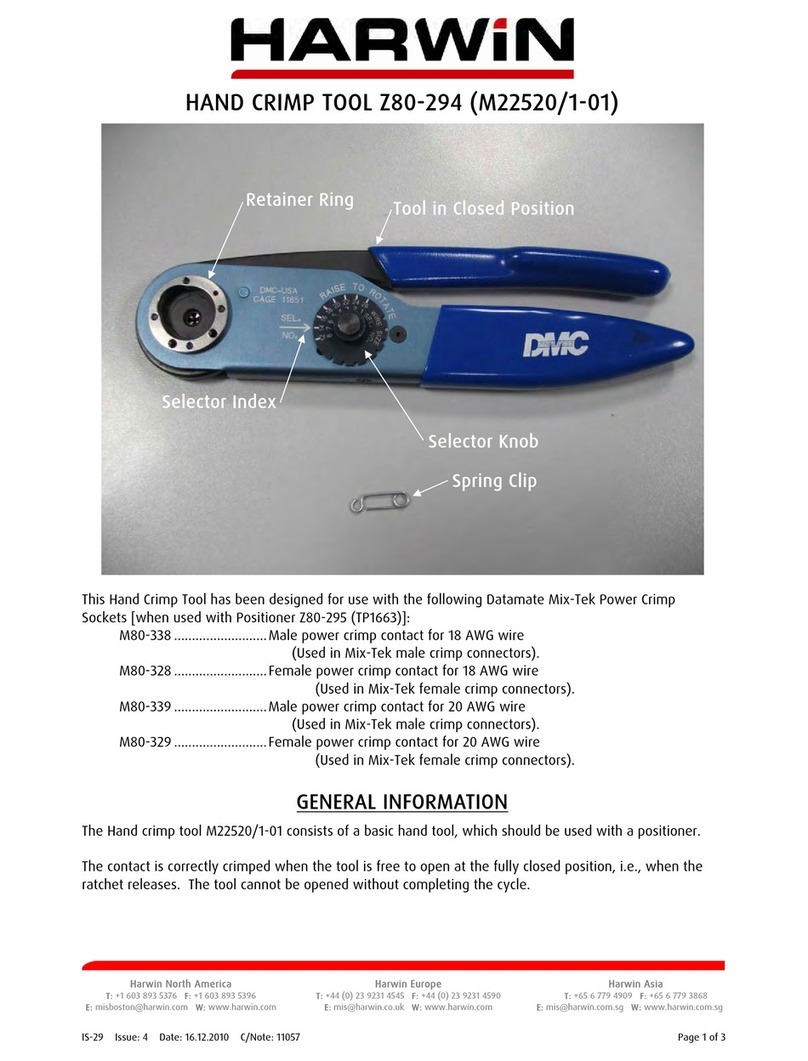

HAND CRIMP TOOL M22520/2

HAND CRIMP TOOL M22520/2HAND CRIMP TOOL M22520/2

HAND CRIMP TOOL M22520/2-

--

-01

0101

01

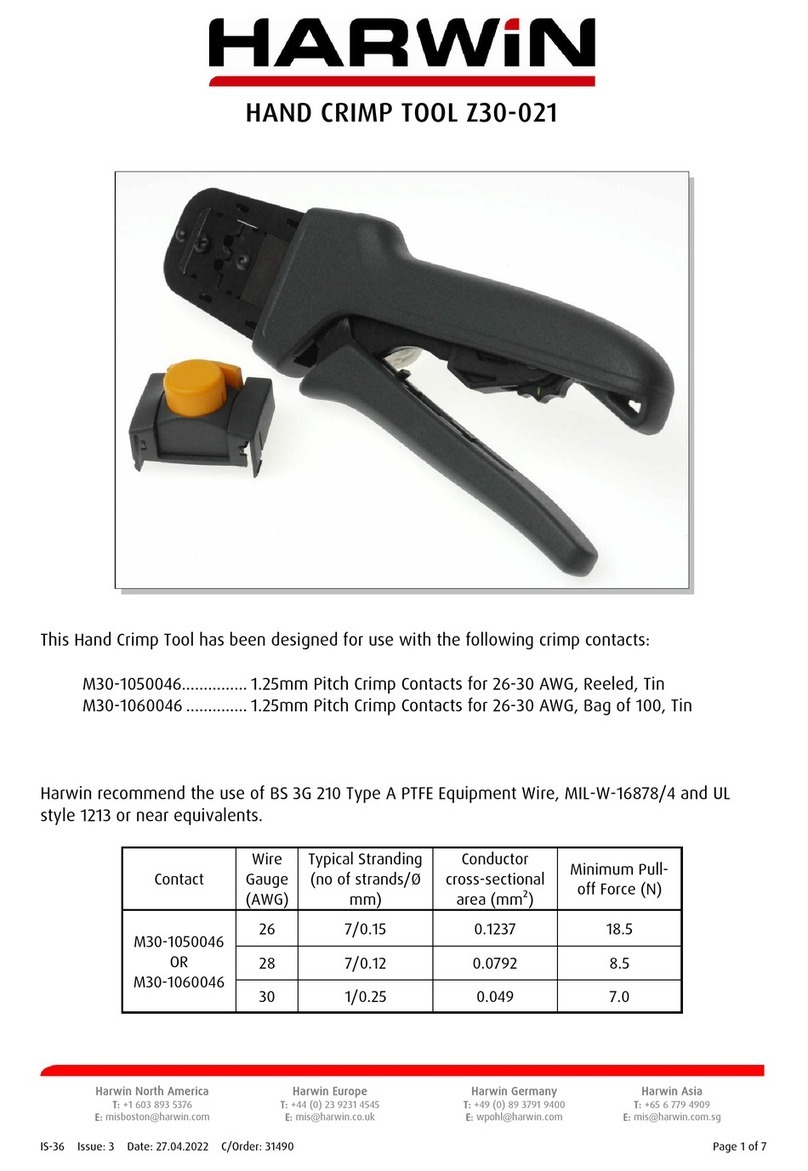

This Hand Crimp Tool has been designed for use with the following

This Hand Crimp Tool has been designed for use with the followingThis Hand Crimp Tool has been designed for use with the following

This Hand Crimp Tool has been designed for use with the following

Crimp Contacts:

Crimp Contacts:Crimp Contacts:

Crimp Contacts:

Datamate

DatamateDatamate

Datamate

Signal

SignalSignal

Signal

C

CC

Crimp

rimp rimp

rimp S

SS

Sockets (when used with Positioner T57 7):

ockets (when used with Positioner T57 7):ockets (when used with Positioner T57 7):

ockets (when used with Positioner T57 7):

M80-01100XX .................. Large bore Female crimp contact for 22 AWG wire

(used in all L-Tek, J-Tek and Mix-Tek female crimp connectors).

M80-01300XX .................. Small bore Female crimp contact for 2 -28 AWG wire

(used in all L-Tek, J-Tek and Mix-Tek female crimp connectors).

M80-01900XX .................. Extra small bore female crimp for 28-32 AWG wire

(used in all L-Tek, J-Tek and Mix-Tek female crimp connectors).

M80-0 000XX ................. Large bore Male crimp contact for 22 AWG wire

(used in L-Tek male crimp connectors).

M80-0 100XX .................. Small bore Male crimp contact for 2 -28 AWG wire

(used in L-Tek male crimp connectors).

M83-01100XX...................Large bore Female crimp contact for 22 AWG wire

(used in all L-Tek, J-Tek and Mix-Tek female crimp connectors).

M83-01300XX..................Small bore Female crimp contact for 2 -28 AWG wire

(used in all L-Tek, J-Tek and Mix-Tek female crimp connectors).

Data

DataData

Datamate Signal Crimp Pins

mate Signal Crimp Pinsmate Signal Crimp Pins

mate Signal Crimp Pins

can also be crimped (when used with Positioner Z80

can also be crimped (when used with Positioner Z80can also be crimped (when used with Positioner Z80

can also be crimped (when used with Positioner Z80-

--

-193):

193):193):

193):

M80-19 00XX .................. Large bore Male crimp contact for 22 AWG wire

(used in J-Tek and Mix-Tek male crimp connectors).

M80-19500XX .................. Small bore Male crimp contact for 2 -28 AWG wire

(used in J-Tek and Mix-Tek male crimp connectors).

Datamate

Datamate Datamate

Datamate and M300 Power Crimp Contacts

and M300 Power Crimp Contactsand M300 Power Crimp Contacts

and M300 Power Crimp Contacts

can also be crimped (when used with Positioner Z80

can also be crimped (when used with Positioner Z80can also be crimped (when used with Positioner Z80

can also be crimped (when used with Positioner Z80-

--

-

058):

058):058):

058):

M80-05500XX .................. Power Female crimp contact for 18-20 AWG

(used in M80-716 and M80-719 series).

M300-00100 5 ................ Power Female crimp contact for 18-20 AWG

M300-00200 5 ................ Power Female crimp contact for 22 AWG

M300-10100 5 ................. Power Male crimp contact for 18-20 AWG

M300-10200 5 ................ Power Male crimp contact for 22 AWG

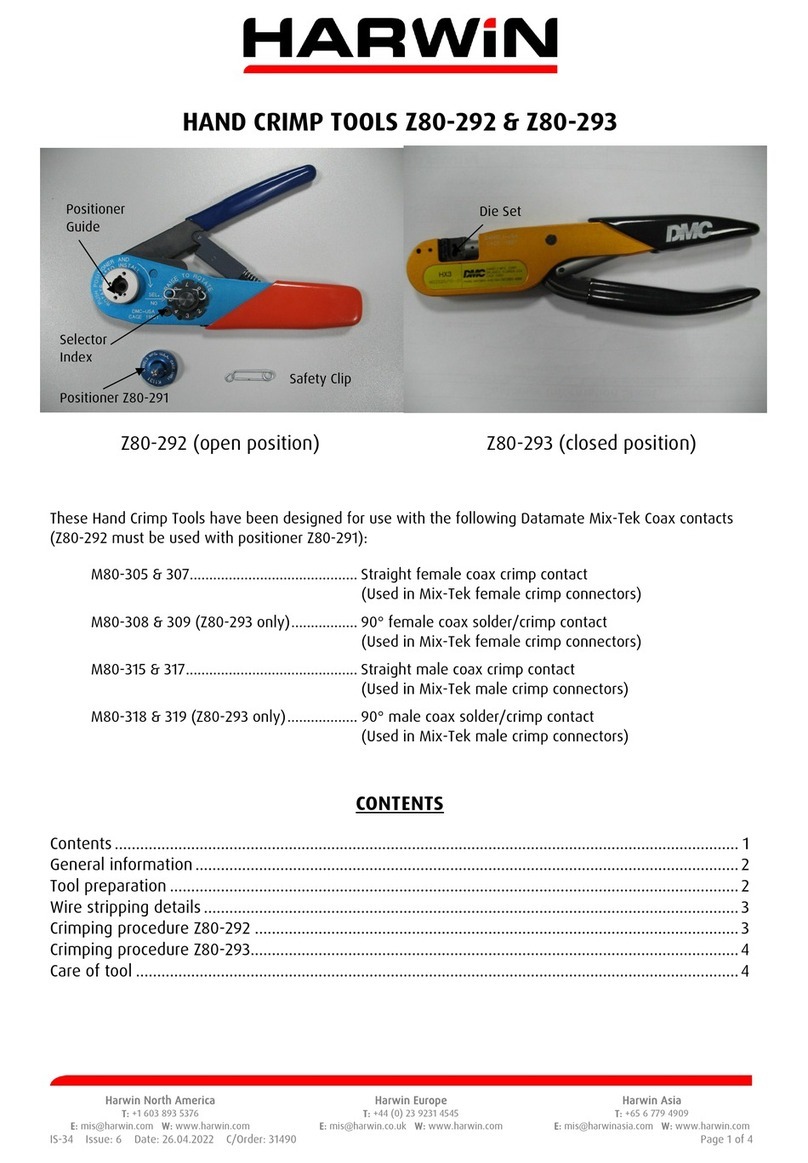

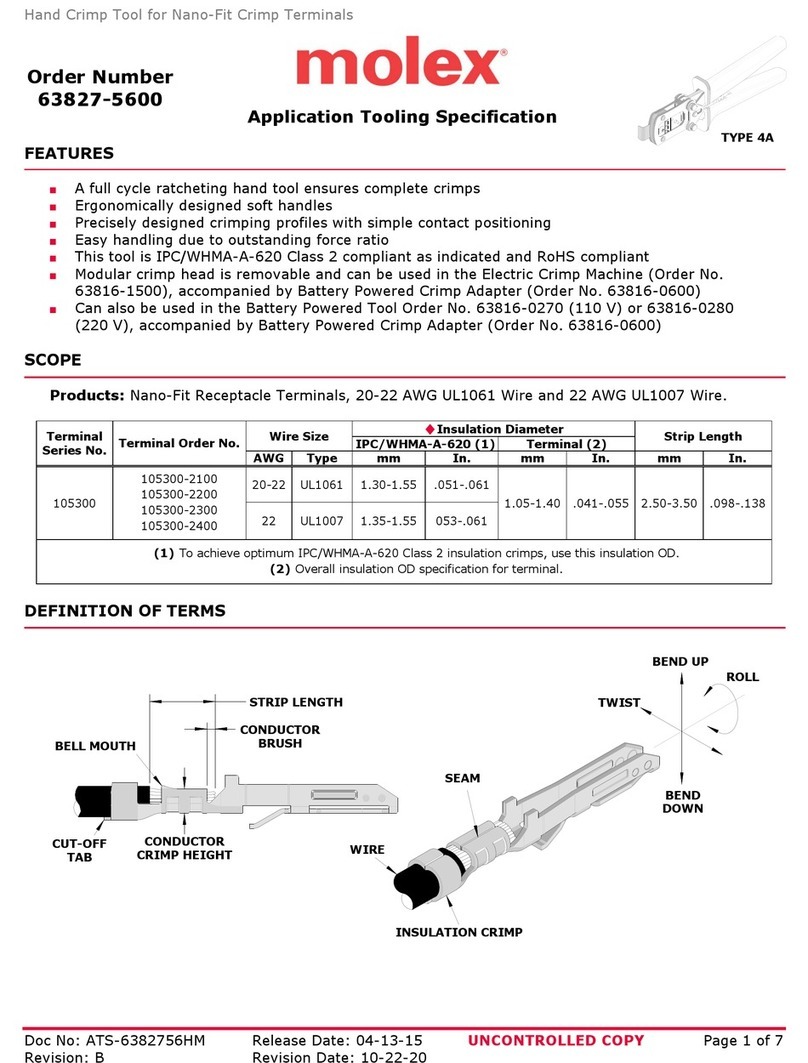

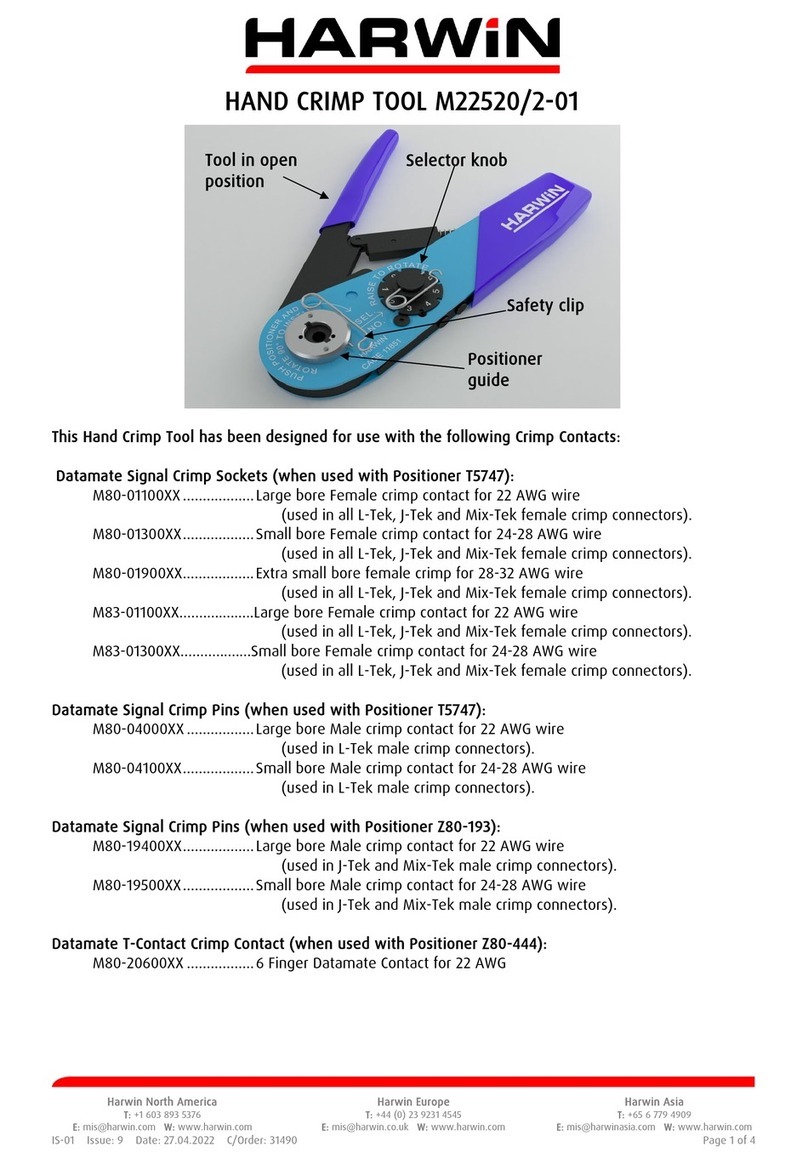

Tool in open

Tool in open Tool in open

Tool in open

position

positionposition

position

Selector knob

Selector knobSelector knob

Selector knob

Safety clip

Safety clipSafety clip

Safety clip

Positioner

Positioner Positioner

Positioner

guide

guideguide

guide

Harwin North America

Harwin North AmericaHarwin North America

Harwin North America

Harwin Europe

Harwin EuropeHarwin Europe

Harwin Europe

Harwin Asia

Harwin AsiaHarwin Asia

Harwin Asia

T:

T:T:

T: +1 603 893 5376 F:

F:F:

F: +1 603 893 5396 T:

T:T:

T: + (0) 23 9231 5 5 F:

F:F:

F: + (0) 23 9231 590 T:

T:T:

T: +65 6 779 909 F:

F:F:

F: +65 6 779 3868

E:

E: E:

E: misbost[email protected] W:

W:W:

W: www.harwin.com E:

E:E:

E: [email protected] W:

W:W:

W: www.harwin.com E:

E:E:

E: [email protected] W:

W:W:

W: www.harwinasia.com

IS-01 Issue: 7 Date: 08.10.15 C/Note: 13121 Page 2 of

Crimp Contacts Continued:

Crimp Contacts Continued:Crimp Contacts Continued:

Crimp Contacts Continued:

K series Power Crimp Sockets can also be crimped (when used with Positioner ZK3609-00):

K3606- 6 ......................... Power Male crimp contact for 18 AWG.

K3607- 6 ......................... Power Female crimp contact for 18 AWG.

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

GENERAL INFORMATION

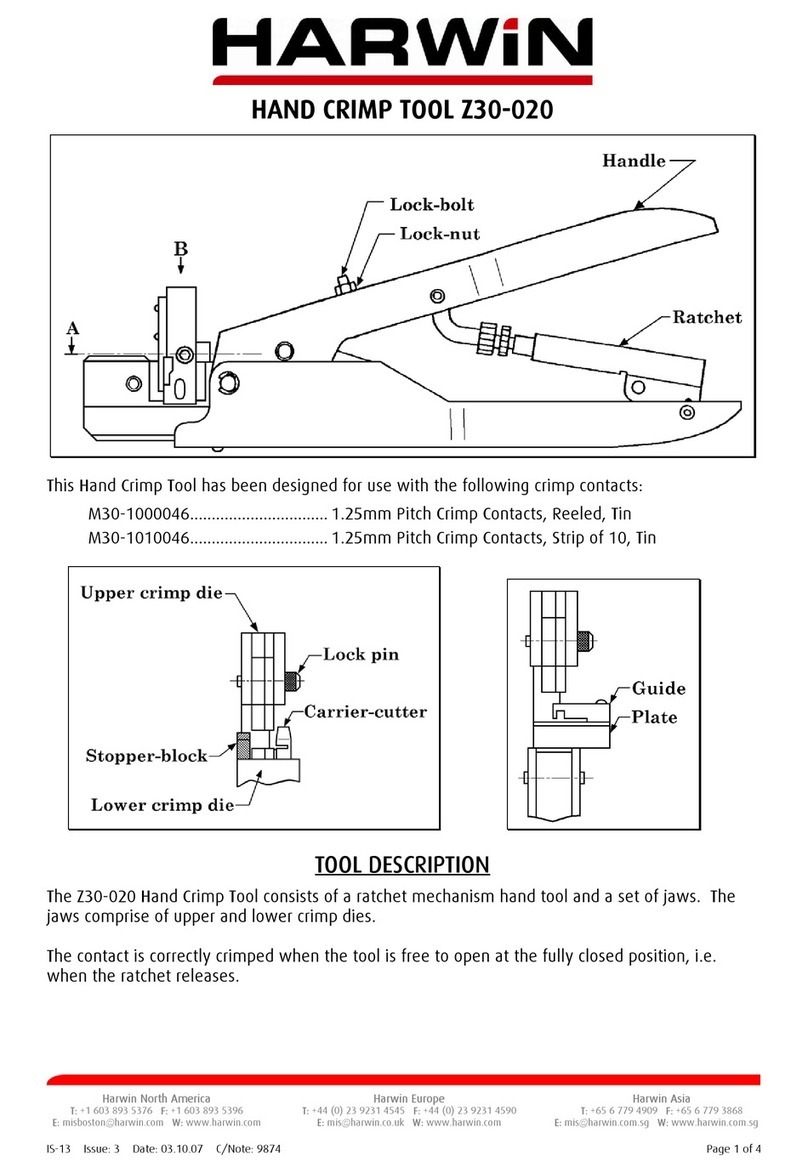

The Hand crimp tool M22520/2-01 consists of a basic hand tool, which should be used with a

positioner.

The contact is correctly crimped when the tool is free to open at the fully closed position, i.e.,

when the ratchet releases. The tool cannot be opened without completing the cycle.

TOOL PREPARATION

TOOL PREPARATIONTOOL PREPARATION

TOOL PREPARATION

1. Check that the tool is in the open position. Remove the safety clip from the positioner

guide (do not discard).

2. Insert the Positioner into the positioner guide and turn it 90° in the direction shown on the

tool, until the bayonet pins lock.

3. Install the safety clip back into the positioner guide (optional).

. Check Table 1 for the correct crimp tool setting of the wire size you wish to crimp.

5. Remove the safety clip from the selector knob (do not discard).

6. Lift and turn the selector knob until the correct crimp tool setting is lined up with the “Sel.

No.” arrow. Lower the selector knob, ensuring the locating peg lines up with a notch.

7. Install the safety clip back into the selector knob.

Harwin North America

Harwin North AmericaHarwin North America

Harwin North America

Harwin Europe

Harwin EuropeHarwin Europe

Harwin Europe

Harwin Asia

Harwin AsiaHarwin Asia

Harwin Asia

T:

T:T:

T: +1 603 893 5376 F:

F:F:

F: +1 603 893 5396 T:

T:T:

T: + (0) 23 9231 5 5 F:

F:F:

F: + (0) 23 9231 590 T:

T:T:

T: +65 6 779 909 F:

F:F:

F: +65 6 779 3868

E:

E: E:

E: misbost[email protected] W:

W:W:

W: www.harwin.com E:

E:E:

E: [email protected] W:

W:W:

W: www.harwin.com E:

E:E:

E: [email protected] W:

W:W:

W: www.harwinasia.com

IS-01 Issue: 7 Date: 08.10.15 C/Note: 13121 Page 3 of

CRIMPING PROCEDURE

CRIMPING PROCEDURECRIMPING PROCEDURE

CRIMPING PROCEDURE

1. Ensure that the wire to be crimped is within the specified range of sizes for the contact and the

crimp tool. Failure to use the specified wire size will result in poor quality crimps and possible tool

damage.

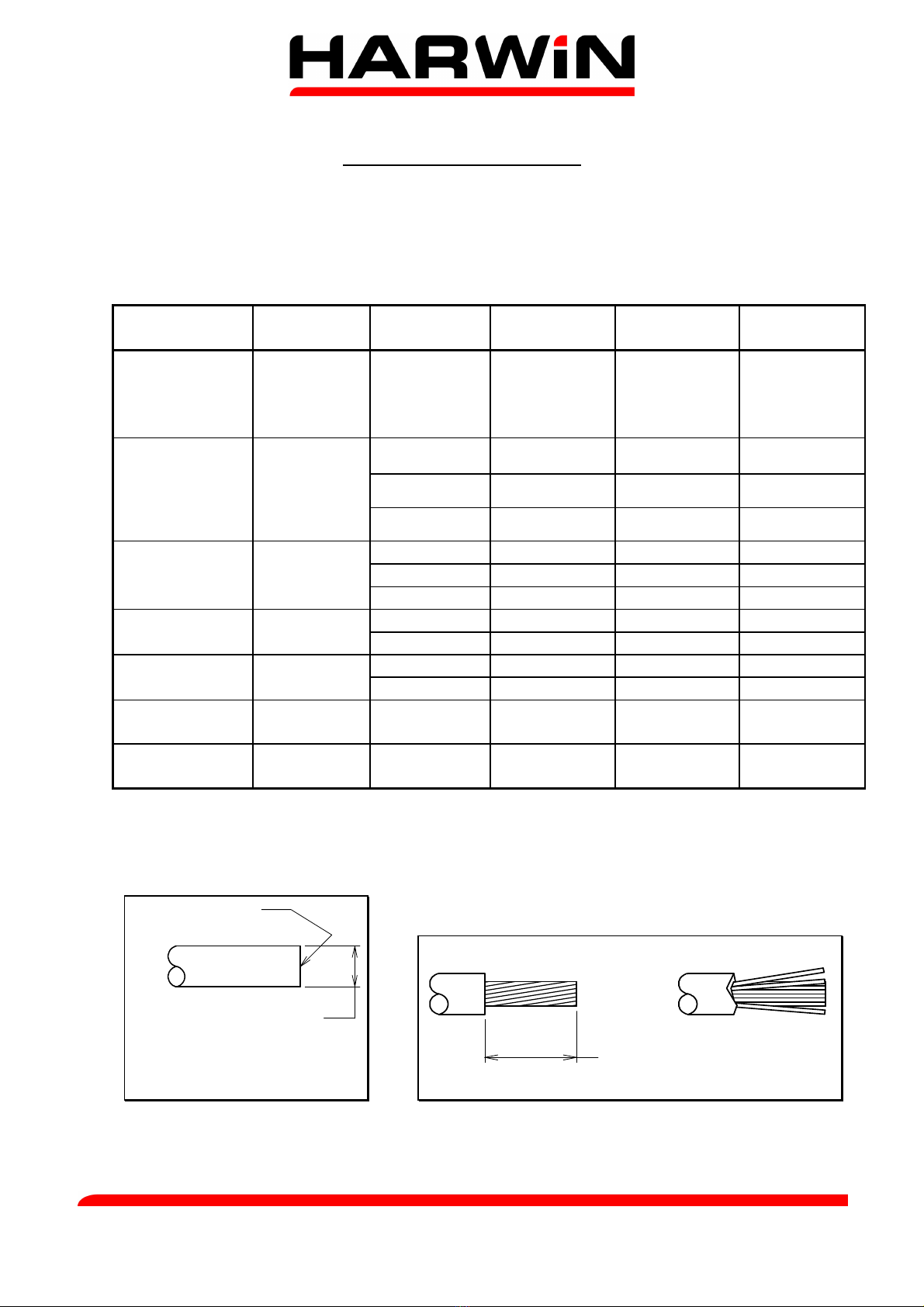

Table 1

Contact

ContactContact

Contact

Crimp Type

Crimp TypeCrimp Type

Crimp Type

Wire Gauge

Wire Gauge Wire Gauge

Wire Gauge

(AWG)

(AWG)(AWG)

(AWG)

Stranding

Stranding Stranding

Stranding

(mm)

(mm)(mm)

(mm)

Crimp Tool

Crimp Tool Crimp Tool

Crimp Tool

Setting

SettingSetting

Setting

Minimum

Minimum Minimum

Minimum

pull

pullpull

pull-

--

-of

ofof

off force

f forcef force

f force

M80-01100XX

M83-01100XX

M80-0 000XX

M80-19 00XX

Datamate

Large Bore 22 19/0.15 6 50N

M80-01300XX

M83-01300XX

M80-0 100XX

M80-19500XX

Datamate

Small Bore

2 7/0.2 6 N

26 7/0.15 6 25N

28 7/0.12 6 12.5N

M80-01900XX

Datamate

Extra small

bore

28 7/0.12 5 12.5N

30 1/0.25 7N

32 7/0.08 N

M80-05500XX Datamate

Power Crimp

20 19/0.2 8 85N

18 19/0.26 8 1 0N

M300-00100 5

M300-10100 5

M300 series

Large Bore

20 19/0.2 8 80

18 19/0.25 8 1 0

M300-00200 5

M300-10200 5

M300 Series

Small Bore 22 19/0.15 8 50

K36XX- 6 K Series

Power Crimp 18 Variable 8 1 2N

2. Cut the end of the cable to be terminated so that there is a clean cut end (Figure A). Strip the cable

to the correct length (Figure B) using a PTFE Wire stripper, preferably with adjustable rotating cutter.

This should result in all the strands lying together neatly. If the lay of the strands is disturbed, it

may be re-imposed with a slight twist.

Clean cut

Ø0.75mm max 28-32 AWG

Ø1.10mm max 22-28 AWG (M80)

Ø1. 0mm max 22 AWG (M300)

Ø1.80mm max 18-20 AWG

RIGHT

WRONG

2.00 ±0.15mm

M80

/300

Series

3.75 ±0.25mm K Series

Figure A Figure B

3. Position the crimp contact fully into the positioner, with the crimp barrel uppermost.

Harwin North America

Harwin North AmericaHarwin North America

Harwin North America

Harwin Europe

Harwin EuropeHarwin Europe

Harwin Europe

Harwin Asia

Harwin AsiaHarwin Asia

Harwin Asia

T:

T:T:

T: +1 603 893 5376 F:

F:F:

F: +1 603 893 5396 T:

T:T:

T: + (0) 23 9231 5 5 F:

F:F:

F: + (0) 23 9231 590 T:

T:T:

T: +65 6 779 909 F:

F:F:

F: +65 6 779 3868

E:

E: E:

E: misbost[email protected] W:

W:W:

W: www.harwin.com E:

E:E:

E: [email protected] W:

W:W:

W: www.harwin.com E:

E:E:

E: [email protected] W:

W:W:

W: www.harwinasia.com

IS-01 Issue: 7 Date: 08.10.15 C/Note: 13121 Page of

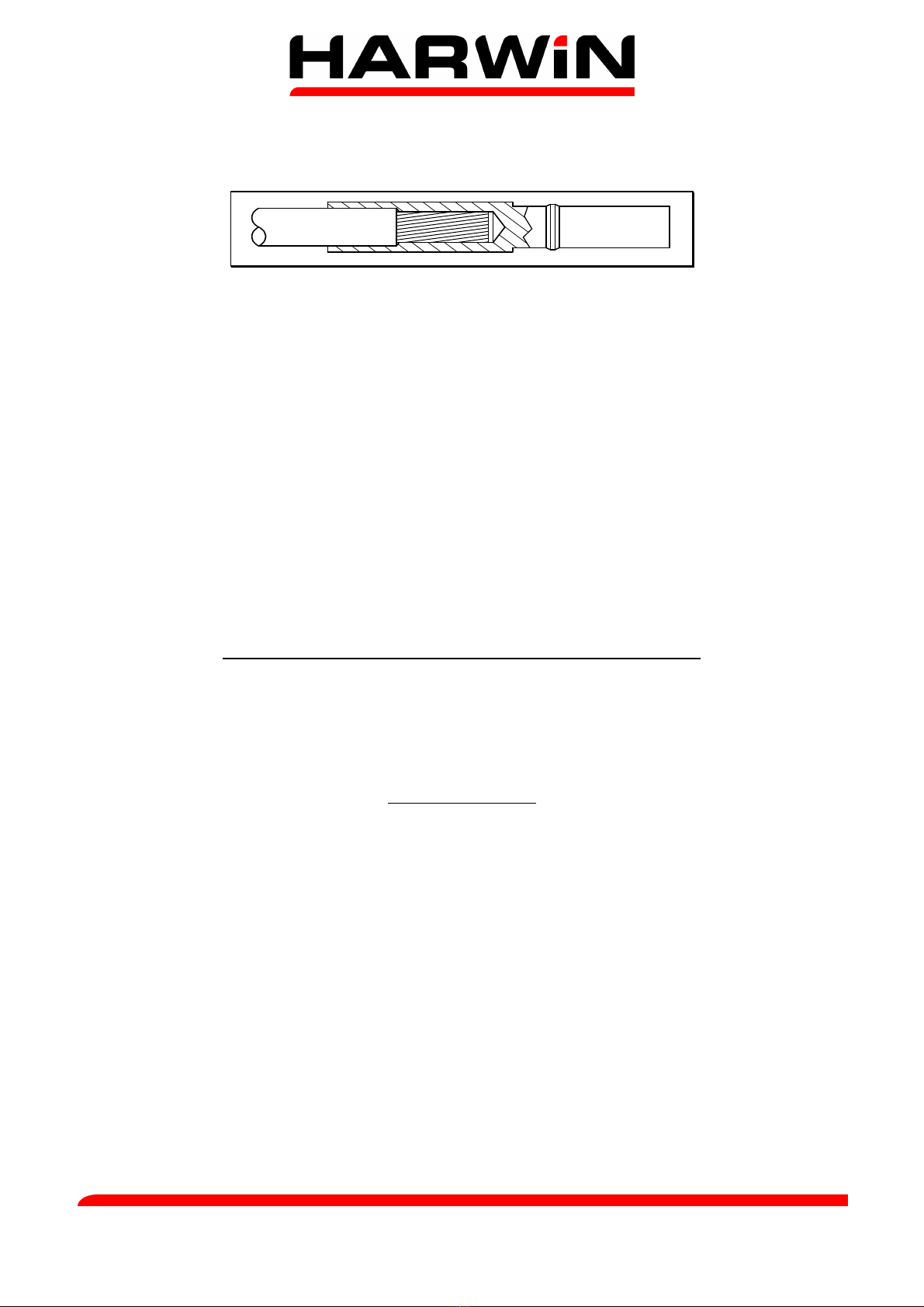

. Load the terminated end of the cable into the crimp barrel of the contact. Ensure the wire is fully

inserted, with all strands in place (see Figure C).

Figure C

5. Squeeze the handles of the crimp tool fully together, until ratchet releases. The handle will return to

the open position. Remove the crimped contact and wire. Check that there is no exposed or stray

wire, and that the insulation is fully within the end of the crimp barrel.

Note: The cross hole on the crimp barrel, although not an inspection hole (it is designed to assist

with plating processes) may give approximate guidance to the location of the conductor. After

crimping the contact, the indent may overlap this hole.

6. Crimp joints should be checked for:

a) Correct combination of cable, tool setting and crimp termination.

b) Correctness of form and location of crimp.

c) Freedom of fracture, rough edges and flash.

d) Adequate insertion of all conductor strands in the crimp barrel.

e) Absence of damage to the conductor or the insulation.

CONTACT

CONTACT CONTACT

CONTACT ASSEMBLY

ASSEMBLY ASSEMBLY

ASSEMBLY TO HOUSING

TO HOUSING TO HOUSING

TO HOUSING PROCEDURE

PROCEDUREPROCEDURE

PROCEDURE

M80 Series parts are assembled using Assembly Tool Z80-280 and Instruction Sheet IS-25.

M300 Series parts are assembled using Assembly Tool Z300-902 and Instruction Sheet IS- 0.

K Series parts are assembled using the Assembly Tool ZK3610-00 and Instruction Sheet IS-22.

CARE OF TOOL

CARE OF TOOLCARE OF TOOL

CARE OF TOOL

There is virtually no maintenance required for the M22520/2-01 tool. However, it is good practice to keep

the indenter tips free of residual colour band deposits and other debris. A small wire brush may be used

for this purpose.

We strongly recommend that you:

1. DO NOT

DO NOTDO NOT

DO NOT immerse tools in any cleaning solution.

2. DO NOT

DO NOTDO NOT

DO NOT spray oil into tool to lubricate.

3. DO NOT

DO NOTDO NOT

DO NOT attempt to disassemble tool or make repairs.

This is a precision crimp tool and should be handled as such.

Other Harwin Crimping Tools manuals

Harwin

Harwin Z20-320 User manual

Harwin

Harwin Z80-294 User manual

Harwin

Harwin M22520/2-01 User manual

Harwin

Harwin Z22-020 User manual

Harwin

Harwin Z80-255 User manual

Harwin

Harwin Z125-900 User manual

Harwin

Harwin Gecko-MT Z125-903 User manual

Harwin

Harwin Z30-021 User manual

Harwin

Harwin M22520/2-01 User manual

Harwin

Harwin Gecko Z125-900 User manual