408-10043

3of 5

Rev C

5. Tighten the nut and close the handles until the

ratchet releases.

6. Remove and inspect the contact.

7. Make another sample crimp. If the contact is

straight, tighten the contact support screw. If the

contact is still being bent during crimping, repeat the

adjustment procedure.

5. CRIMPING PROCEDURE

This tool is provided with a crimp adjustment

feature. Initially, the crimp height should be verified

as specified in Figure 3. Refer to Section 6, Crimp

Height Inspection, and Section 7, RATCHET

Adjustment, to verify crimp height before using the

tool to crimp desired contacts and wire sizes.

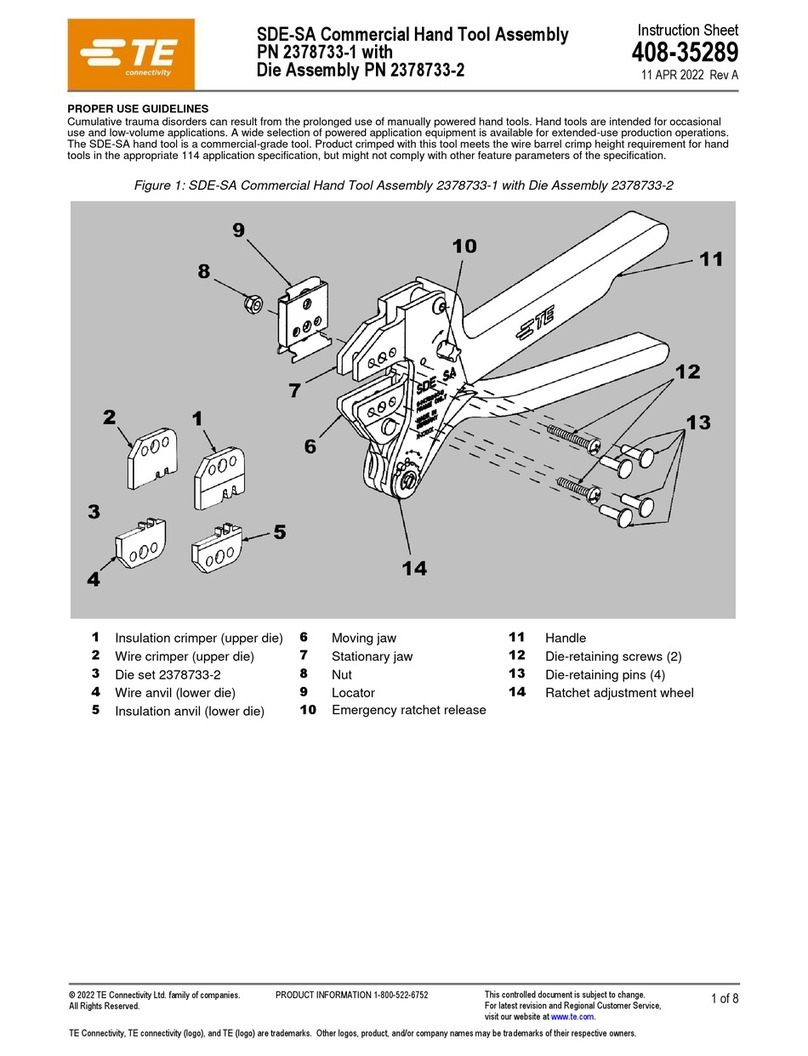

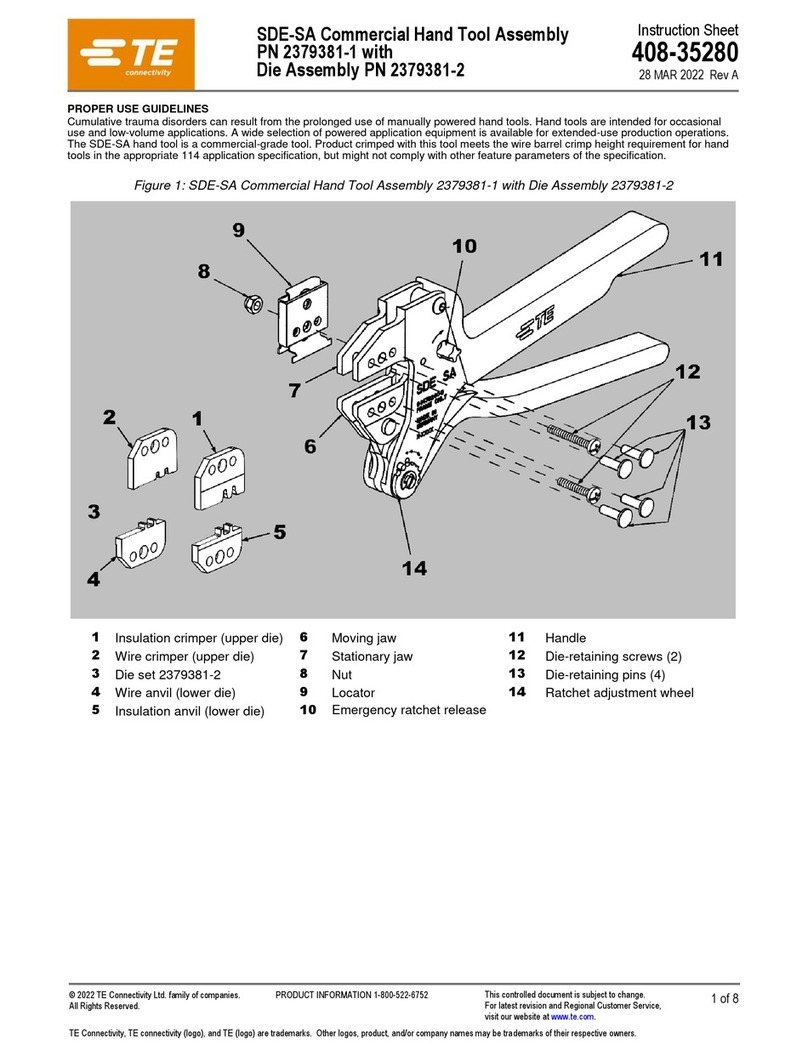

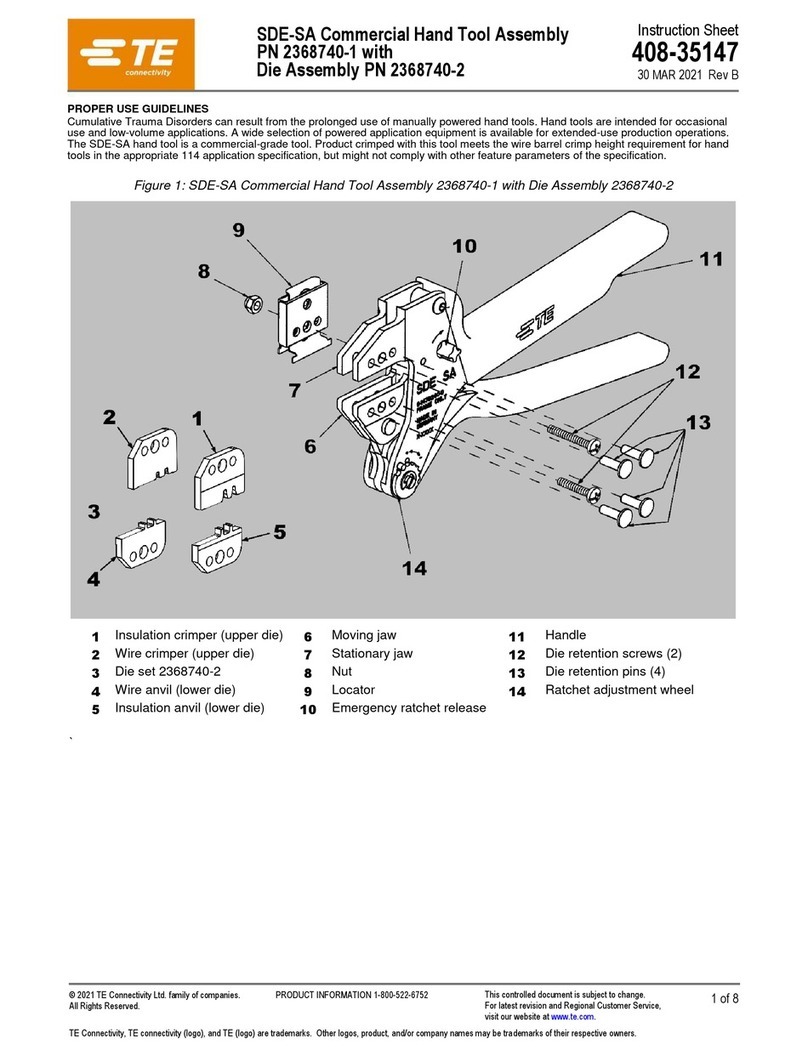

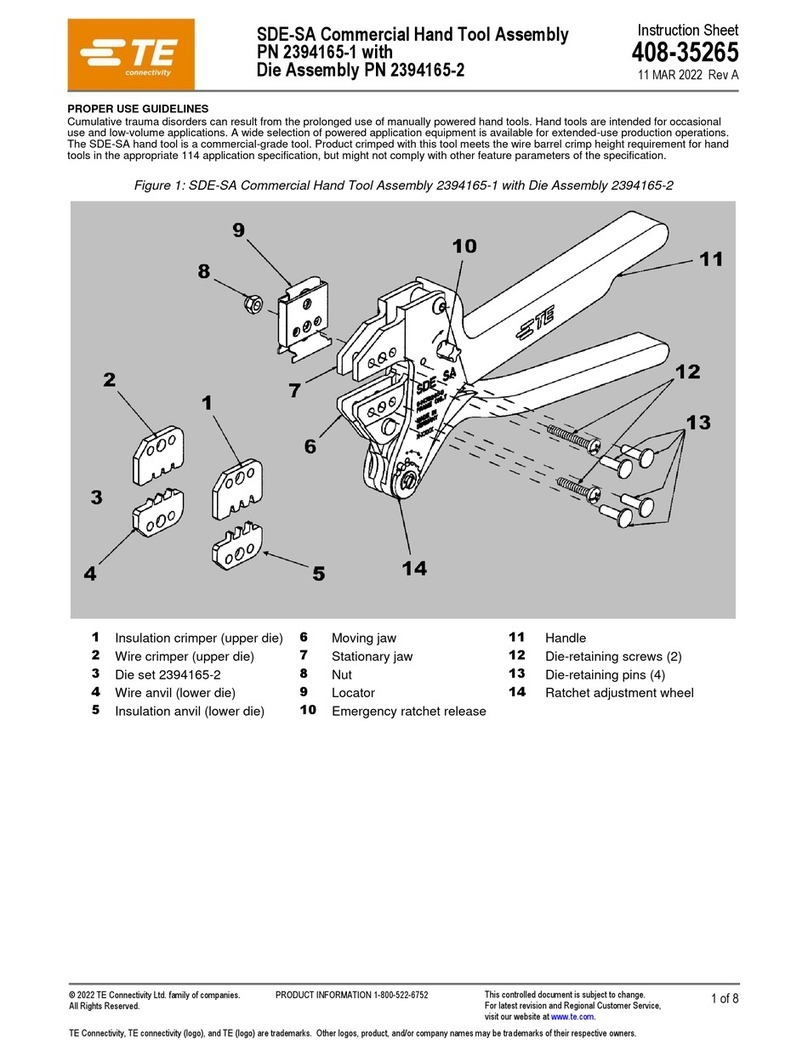

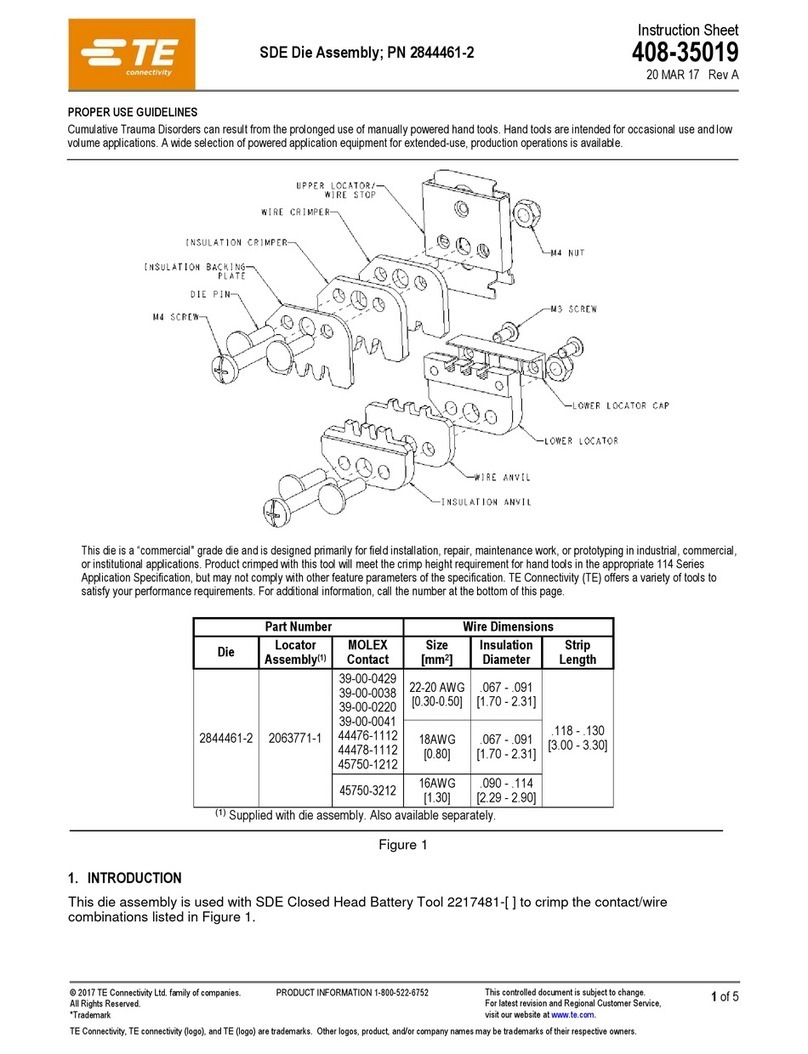

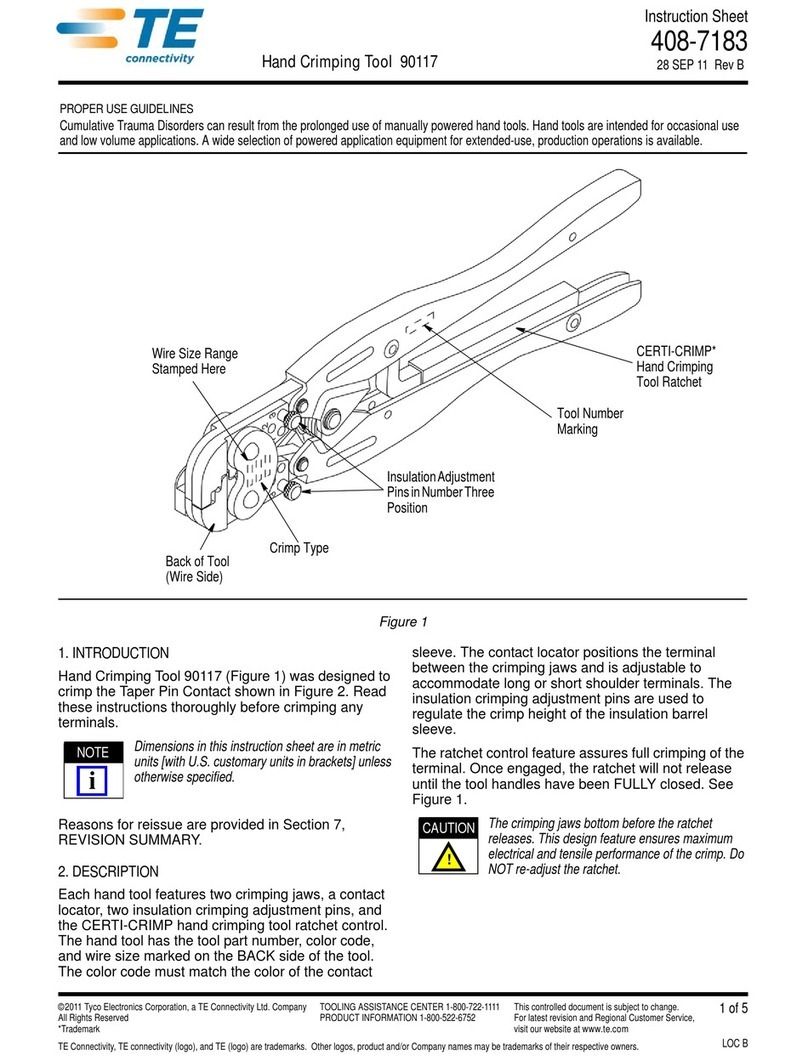

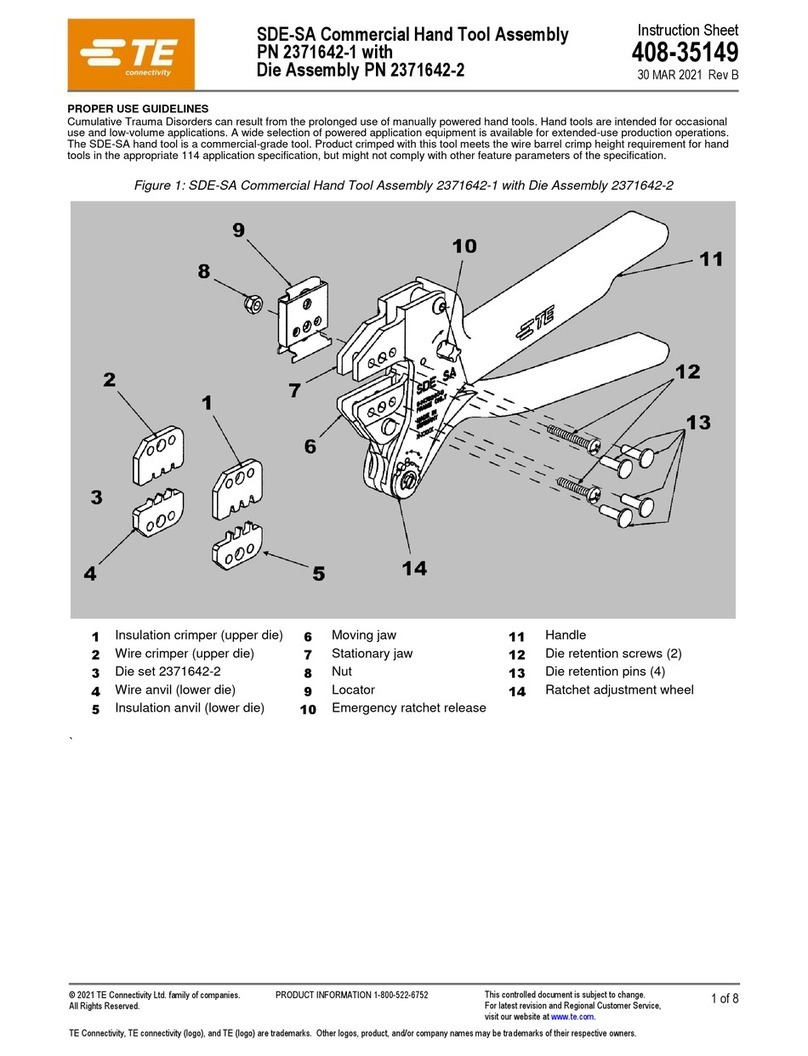

Refer to the table in Figure 1 and select wire of the

specified size and insulation diameter. Strip the wire to

the length indicated in Figure 1, taking care not to nick

or cut wire strands. Select an applicable contact and

identify the appropriate crimp section according to the

wire size markings on the tool. Refer to Figure 2 and

proceed as follows:

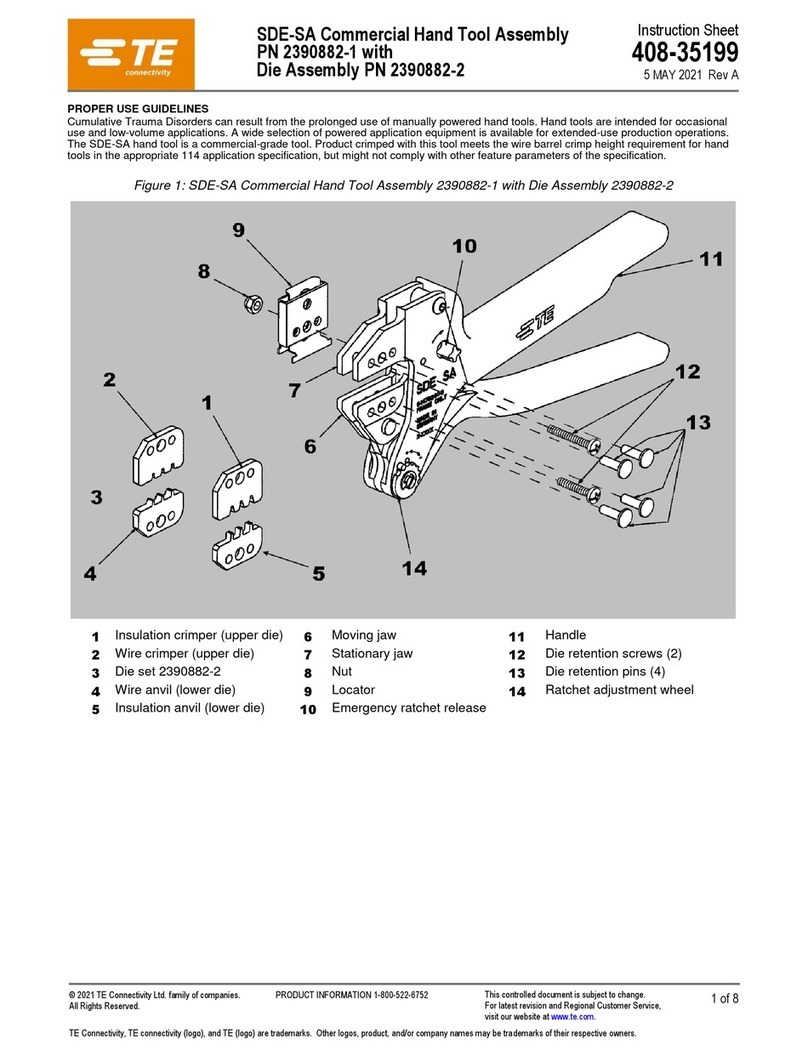

1. Hold the tool so that the back (wire side) is facing

you. Squeeze tool handles together and allow them

to open fully.

2. Holding the contact by the mating end, insert the

contact - insulation barrel first - through the front of

the tool and into the appropriate crimp section.

3. Position the contact so that the mating end of the

contact is on the locator side of the tool, and so that

the open “U” of the wire and insulation barrels must

face the top of the tool. Place the contact up into the

nest so that the movable locator drops into the slot

in the contact. Refer to Figure 2. Butt the front end

of the wire barrel against the movable locator.

Make sure that both sides of the insulation barrel

are started evenly into the crimping section. Do not

attempt to crimp an improperly positioned contact.

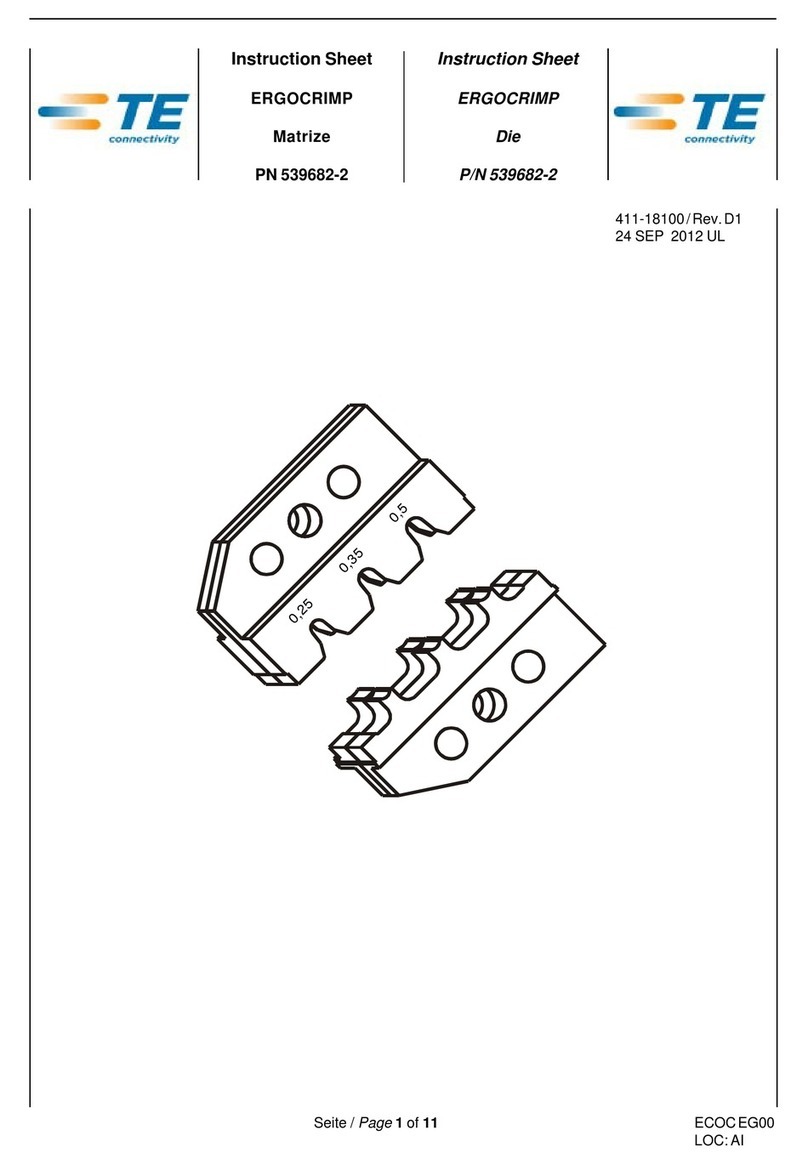

6. CRIMP HEIGHT INSPECTION

Crimp height inspection is performed through the use

of a micrometer with a modified anvil, commonly

referred to as a crimp-height comparator.

TE Connectivity does not manufacture or market

crimp-height comparators. Detailed information on

obtaining and using crimp-height comparators can be

found in Instruction Sheet 408-7424.

Proceed as follows:

1. Refer to Figure 1 and select a wire (maximum

size) for each crimp section listed.

2. Refer to Section 5, CRIMPING PROCEDURE,

and crimp the contact(s) accordingly.

3. Using a crimp height comparator, measure the

wire barrel crimp height listed in Figure 3. If the

crimp height conforms to that shown in the table,

the tool is considered dimensionally correct. If not,

the tool must be adjusted. Refer to Section 7,

RATCHET ADJUSTMENT.

Damaged product should not be used. If a

damaged contact is evident, it should be replaced.

Contacts must not be re-terminated.

Figure 3

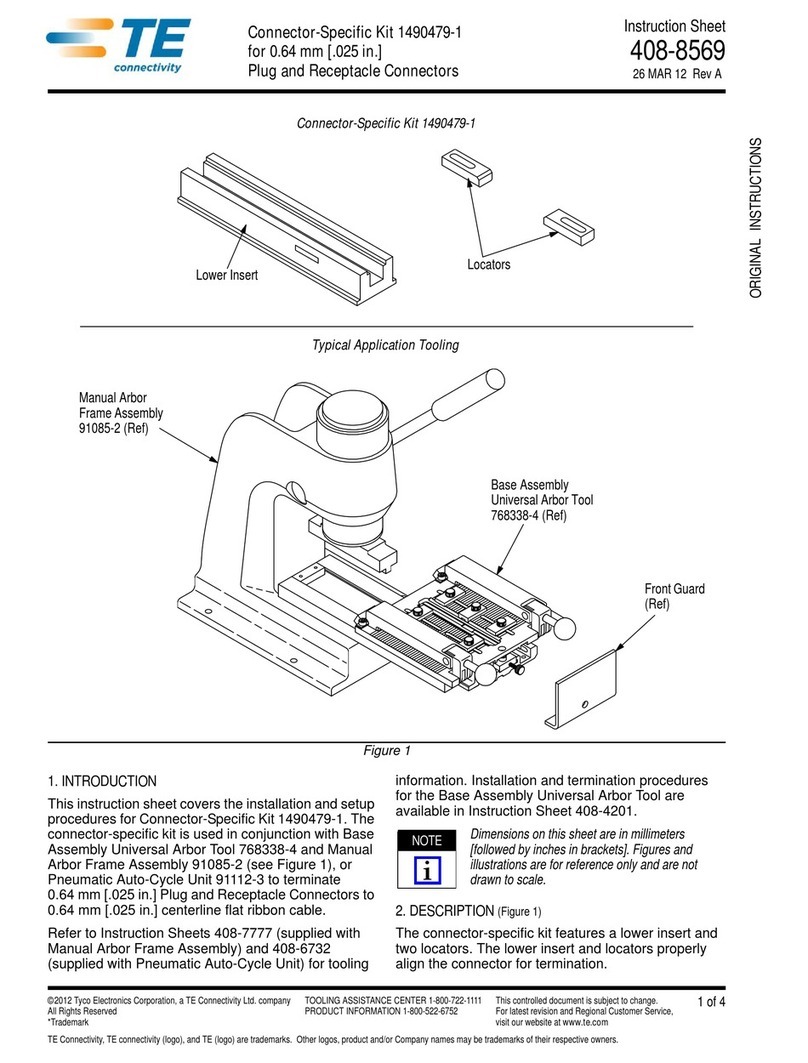

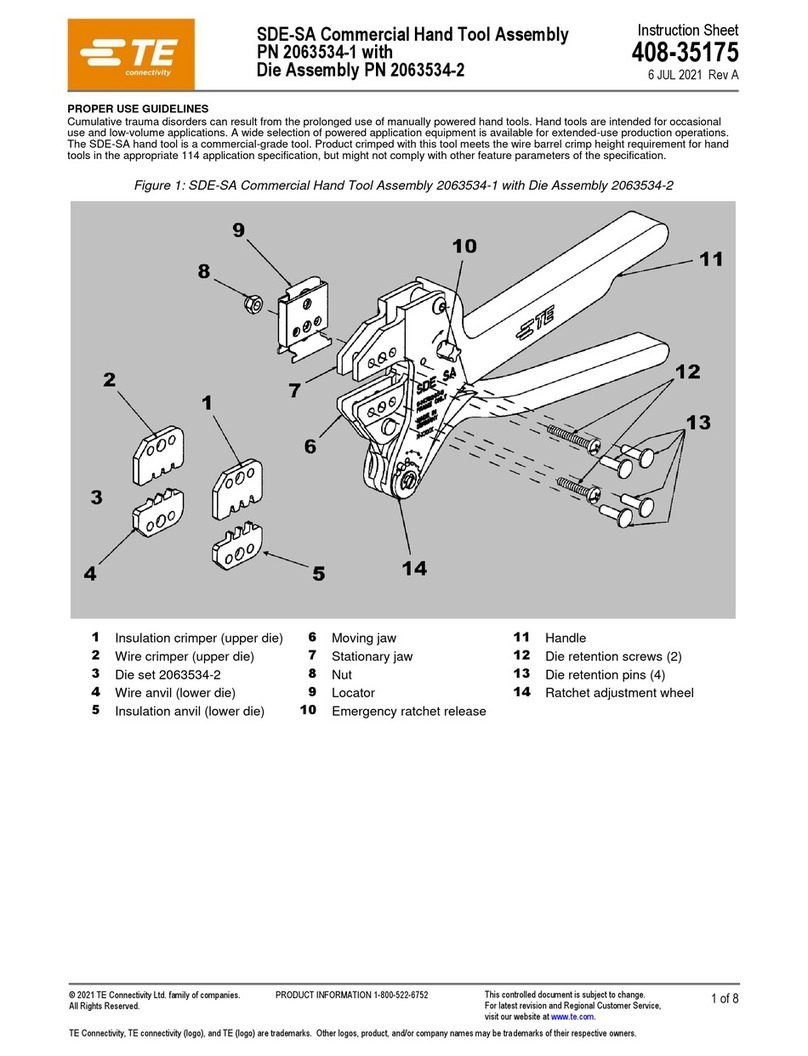

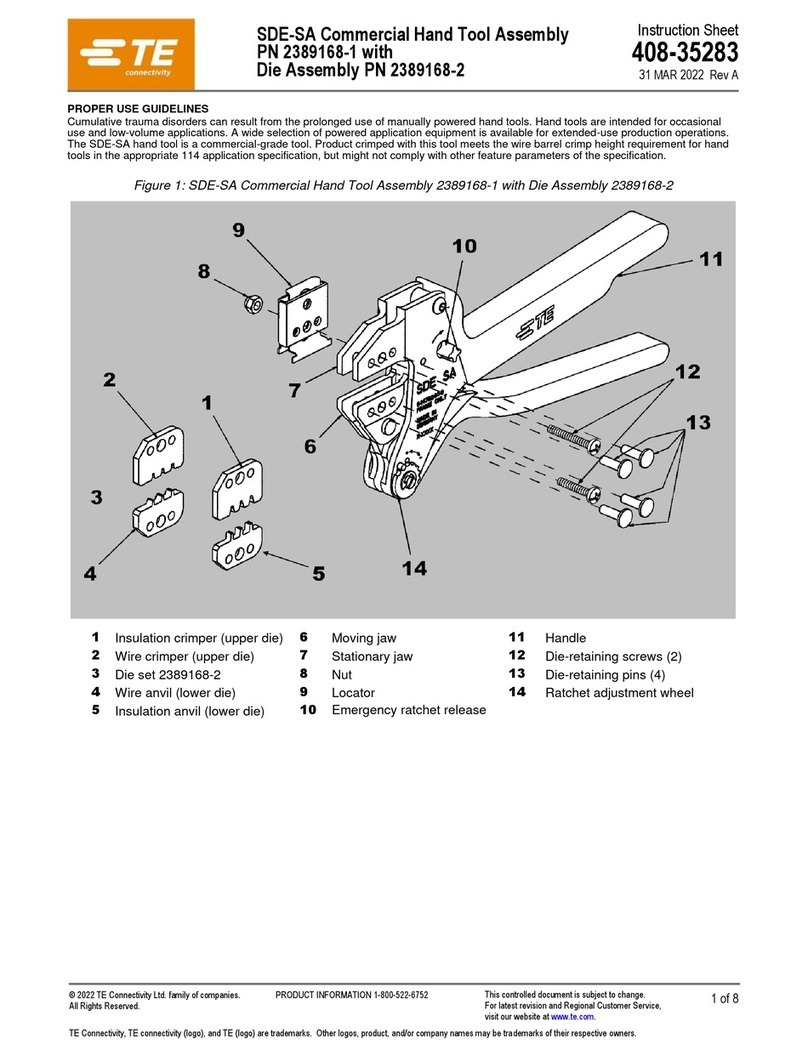

7. RATCHET ADJUSTMENT

Although the ratchet is preset prior to shipment, it is

important to verify the crimp height using a micrometer

or caliper. General use and subsequent wear may

cause the tool to go out of adjustment. It is

recommended that crimp height be inspected, and the

ratchet be adjusted, if necessary, on a regular basis.

Refer to Figure 4, and proceed as follows:

1. If the crimp height is larger than recommended,

remove the ratchet wheel adjustment screw and

rotate the adjustment wheel counterclockwise (+) to

a higher setting. Reinstall the screw. Repeat as

required.

2. If the crimp height is smaller than recommended,

remove the ratchet wheel adjustment screw and

rotate the adjustment wheel clockwise (-) to a lower

setting. Reinstall the screw. Repeat as required.

3. If the crimp cannot be made to conform to the

recommended crimp height, the tool or die set must

be replaced. See Section 9, REPLACEMENT.

Figure 4

WIRE SIZE

(AWG) CRIMP HEIGHT

Dimension “A” and Tolerance (±)

30-26 0.58 ±0.05 [.023 ±.002]

24-22 0.74 ±0.05 [.029 ±.002]

20 0.89 ±0.05 [.035 ±.002]

PositionPointon

Center of Wire

Barrel Opposite

Seam

Modified Anvil

“A”

Adjustment

Screw Ratchet

Adjustment

Wheel