INSTRUCTION MANUAL FOR DISHWASHERS

Page 1 of 12

GB

CONTENTS

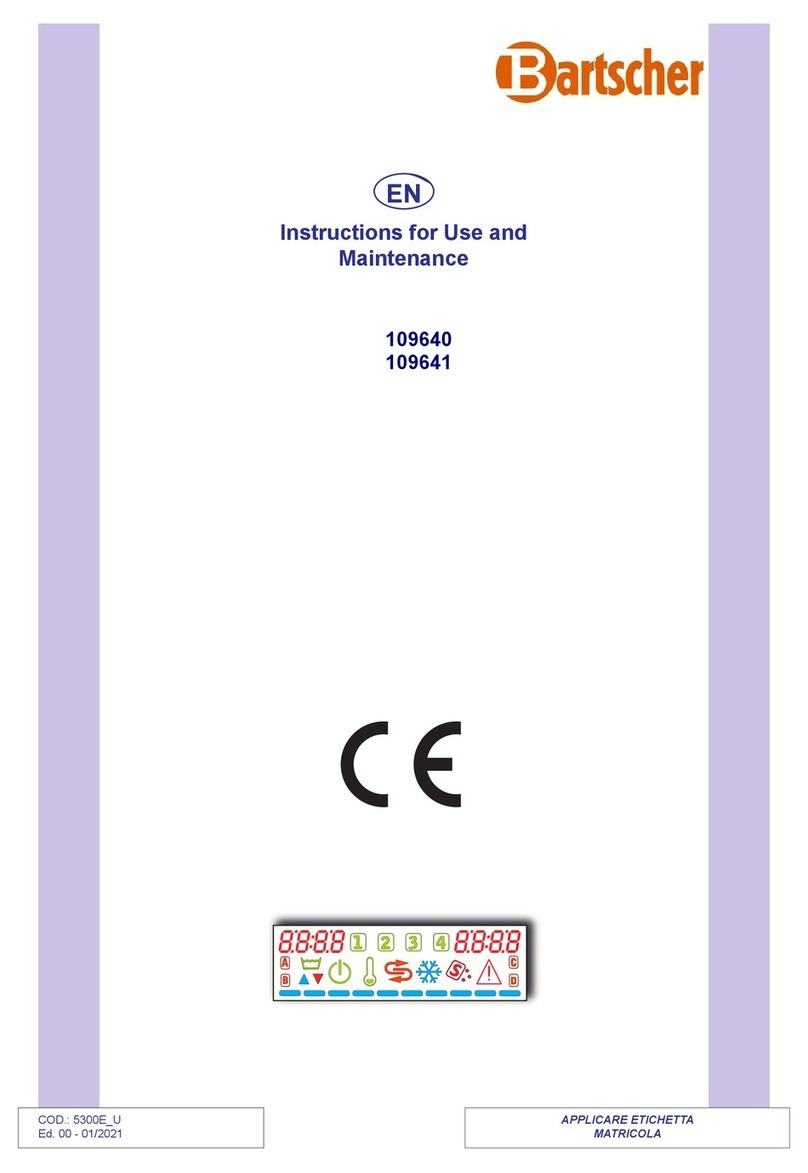

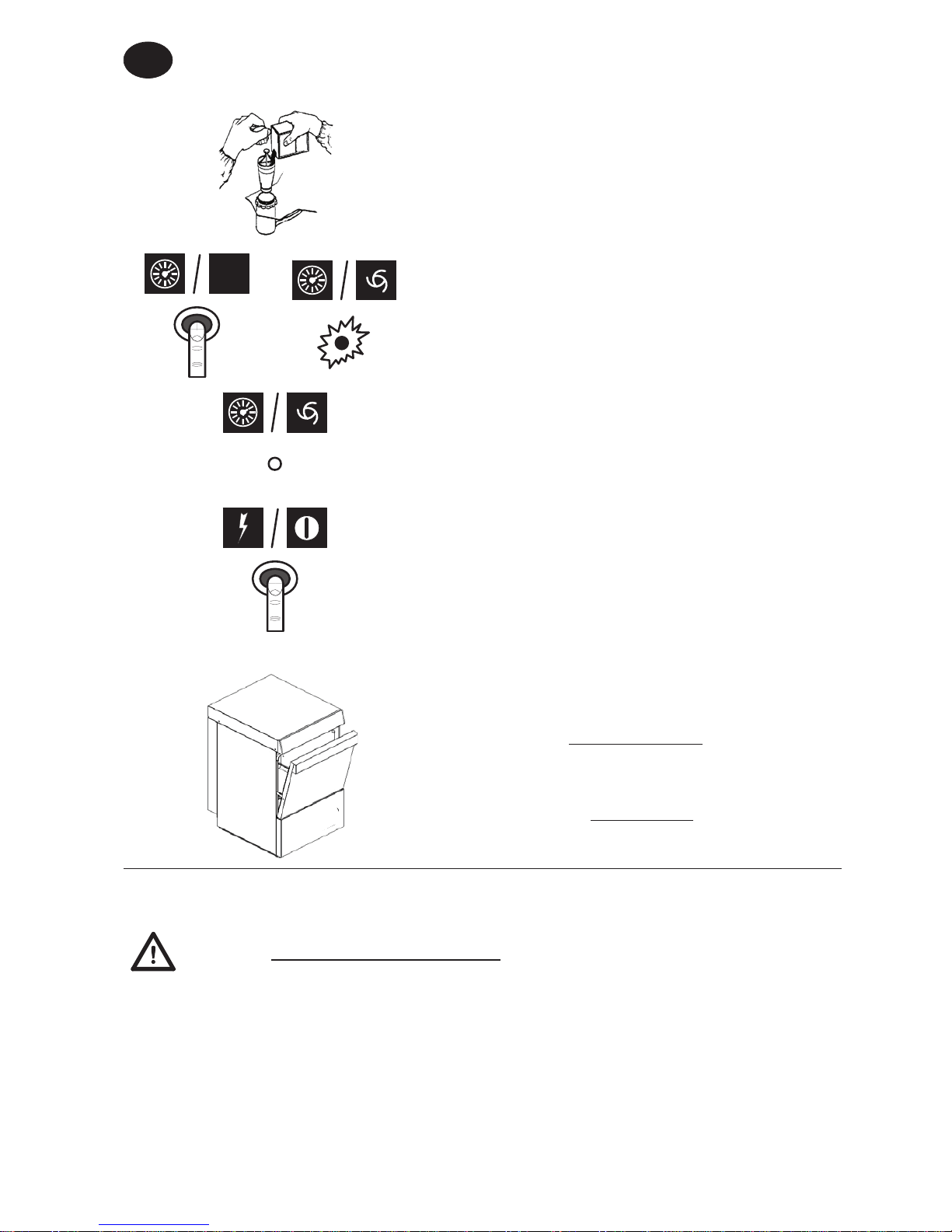

CHAP 1 PREFACE ..................................................................................................................... 2

CHAP 2 INSTALLATION ............................................................................................................ 2

2.1 UNPACKING ........................................................................................................................ 2

2.2 POSITIONING....................................................................................................................... 2

2.3 ELECTRICAL CONNECTION ................................................................................................... 3

2.4 PLUMBING CONNECTION ...................................................................................................... 3

2.5 CONNECTION TO THE DRAIN LINE ......................................................................................... 4

CHAP 3 RISKS AND IMPORTANT WARNINGS ....................................................................... 4

CHAP 4 USING YOUR APPLIANCE.......................................................................................... 5

4.1 SYMBOLS USED................................................................................................................... 5

4.2 STARTING UP...................................................................................................................... 5

4.3 LOADING AND WARMING UP................................................................................................ 5

4.4 WASHING CYCLE................................................................................................................. 5

4.5 TURNING OFF THE APPLIANCE............................................................................................. 6

4.6 DISCHARGING THE APPLIANCE............................................................................................. 7

4.6.1Models without discharging pump ............................................................................. 7

4.6.2Models with discharging pump .................................................................................. 7

4.7 REGENERATING THE ION EXCHANGE RESINS ....................................................................... 7

4.8 END OF SERVICE................................................................................................................. 8

CHAP 5 MAINTANANCE............................................................................................................ 8

5.1 HYGIENE AND CLEANING...................................................................................................... 8

5.2 ROUTINE MAINTENANCE (DAILY)........................................................................................... 8

5.3 WEEKLY MAINTENANCE....................................................................................................... 9

5.4 ANNUAL MAINTENANCE ..................................................................................................... 10

CHAP 6 ADJUSTMENTS AND SETTINGS.............................................................................. 10

6.1 DISPENSER....................................................................................................................... 10

6.1.1Rinse agent dispenser............................................................................................. 10

6.1.2Models with no detergent metering unit .................................................................. 11

6.1.3Models with detergent dispenser (available on request) ......................................... 11

CHAP 7 DEINSTALLATION ..................................................................................................... 12

CHAP 8 DISPOSAL .................................................................................................................. 12

8.1 CORRECT DISPOSAL OF THIS PRODUCT ............................................................................. 12

In legal terms, the manufacturer reserves the property of this document. It is forbidden to reproduce it or divulge it with any means

without prior written authorisation.

The manufacturer reserves the right to introduce changes in order to achieve the improvements it deems necessary without prior notice.