base engineering MEC EXCELA-WYND ME9000LH-17 User manual

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 1 Rev B12/1/21

BEFORE INSTALLING THE EXCELA-WYND HOSE REEL PLEASE READ THESE IMPORTANT INSTRUCTIONS

1. Place the laminated, tri-folded Excela-Wynd operating instructions (Form 1176-OP) from the ACCESSORIES BOX in the delivery truck

where it will be available to the driver, such as in the equipment binder or glove box.

2. The ME9000LH-17/25 Excela-Wynd hose reel must always be powered by a BASE Engineering VSC9000 variable speed controller.

3. A flexible connection must always be installed between fixed piping and the reel inlet.

4. To prevent damage to reel and reduce risk of injury, do not stack hose reels during transportation or storage.

5. The reel must be lifted as shown in the “Lifting and Setting” section of these instructions.

6. An anti-seize compound must be applied to the external threads of all fasteners when installing or servicing the hose reel. MEC

recommends using a Nickle-based (copper-free) anti-seize compound.

7. Use only Ø1” ID hose on the ME9000LH-17/25 Excela-Wynd hose reel.

8. Installation or service inconsistent with these instructions may damage the reel, increase the risk of injury or void the warranty.

BEFORE SERVICING THE EXCELA-WYND™HOSE REEL PLEASE READ THESE IMPORTANT SAFETY WARNINGS

WARNING! Risk of injury from

pinch points

– Keep hands and

fingers

away from hose guide.

WARNING! Risk of injury from

pinch

points – Do Not operate hose

reel without guards in place.

WARNING! Risk of injury from

pinch

/ sever points – Keep

fingers

away from inlet flange.

WARNING!

This product contains a

chemical known to the state of

California to

cause cancer and birth

defects or reproductive harm.

CONTENTS

INSTALLING REEL ………………………………………..… Page

Unboxing ……………………………………………………………

Locating Reel on Deck …………………..………………......

Lifting and Setting ……………………………………………...

Mounting to Deck …………………………………………..….

Connecting Inlet …………………………………………………

VSC9000 SPEED CONTROLLER ……………………………….

Enclosure ……………………………………………………………

Power …………………………………………………………………

Motor …………………………………………………………………

Sensor ……………………………………………………………..…

Test Mode ………………………………………………………….

CONFIGURING VSC9000 CONTROLLER .....................

Setting Hose Length ..............................................

Setting Hose Speed ...............................................

INSTALLING HOSE ...................................................

Removing / Replacing Optional Cover ..................

Connecting Hose to Riser ......................................

Installing Hose in Guide ........................................

Connecting Riser to Inlet Flange ...........................

Adjusting Carriage ................................................

Loading Hose ........................................................

2

2

2

3

3

3

4

4

4

4

4

4

5

5

5

5

5

6

6

7

7

8

SPECIFICATIONS ……….………………………………. Page

MATERIALS OF CONSTRUCTION ...........................

WARRANTY …………………………………………….………….

APPENDIX ………………………………………………............

Unboxing Instructions ……………………………………..

Controller Configuration Diagram ……………….…..

Operating Instructions ……………………………….…...

9

9

10

12

12

13

14

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 2 Rev B12/1/21

INSTALLING REEL

Unboxing - See 1176-UB unboxing instructions located on the shipping box or see “Unboxing” section in the Appendix.

Locating Reel on Deck - MEC recommends using the ME9000LH-17/25-DJ Drill and Piping Jig to properly position the reel on the

deck and allow piping to be fabricated prior to mounting the reel.

49 CFR Section 178.345-8 Accident Damage Protection requires that any part of the cargo tank motor vehicle which

contains lading during transit must be at least 6 inches horizontally forward of the vertical plane of the outboard surface of

the protection device (bumper).

To assure compliance and proper operation, the ME9000LH-17/25 Excela-Wynd hose reel must be positioned on the deck

and installed according to these instructions. Installation inconsistent with these instructions may cause damage to the

hose or hose reel and may void warranty.

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 3 Rev B12/1/21

Lifting and Setting Reel - Caution - The Excela-Wynd hose reel weighs approximately 300 pounds. Use a suitable mechanical fork truck,

hoist or crane to lift, move and set reel. Use a spreader bar and straps with a minimum working load of 500 lbs connected to the lift

points on the axle and inlet shown below to lift the reel and set it on the deck.

Note: The reel will rotate in the direction shown when lifted. Setting the reel on the deck will bring it back to level or it can be held

level manually as it is set.Do not lift by attaching to optional reel cover.

Mounting to Deck -WARNING - DO NOT use an impact driver to tighten mounting bolts. Use (4) SS carriage bolts, (4) SS backing

plates, (4) SS flat washers and (4) SS locknuts from the HARDWARE KIT and (2) Dielectric Mounts from the ACCESSORIES BOX.Install

reel as shown below with dielectric mounts between reel frame and deck and with backing plates below the deck.Install SS carriage

bolts through reel frame rail, dielectric mount, deck and backing plate. Apply anti-seize to threads of carriage bolts, install SS flat

washers and tighten SS locknuts securely.

Note: The off-center holes in the backing plate allow it to be installed when there is an obstruction that interferes with using the

center hole.

Connecting Inlet - A flexible connection as shown below must always be installed between fixed piping and the reel inlet.

An ME840SS or ME841SS series Type “A” 4-bolt flange kit (not included) must be used to connect to the reel inlet flange.

NOTE: Flanges available in Stainless Steel i.e. ME840SS-16F

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 4 Rev B12/1/21

VSC9000 SPEED CONTROLLER

Enclosure - Install the BASE Engineering controller enclosure according to the instructions provided with it in a location accessible for

service.

Power - Connect battery (+) and ground (-) according to the instructions and diagrams provided by BASE Engineering.

Motor - Connect motor leads to controller according to the instructions and diagrams provided by BASE Engineering.

Note - The motor lead corresponding to (+) for REEL IN is marked with red and the correct direction of rotation is shown below. If the

motor leads are inadvertently switched and the motor rotates in the wrong direction, sliding DIP switch 8 to “ON” will reverse the

polarity and direction of rotation eliminating the need to physically reverse the connections. See the Controller Configuration

Diagram in the Appendix or the decal inside the controller enclosure for details.

Sensor - Use the MEP801PC/30 extension cable from the ACCESSORIES BOX to connect the sensor to the VSC9000 controller terminal

block according to the instructions and diagrams provided by BASE Engineering, the Controller Configuration Diagram in the Appendix

or the decal inside the controller enclosure.

Note - Sliding DIP switch 6 to “ON” will override the sensor and closed loop speed control. This is useful when running the reel before

sensor connections are made or for diagnostics. With Sensor Override on, Reel-In operation will rotate the reel at the speed at which

the controller potentiometer is set. DIP switch “6” must be moved to “OFF” to return to normal operation. See the Controller

Configuration Diagram in the Appendix or the decal inside the controller enclosure for details.

Test Mode -Sliding DIP switch 7 to “ON” enables the sensor test mode. In test mode, the green LED on the controller turns on when

the sensor detects rotation. It is useful for confirming that the sensor and wiring are functioning as intended. DIP switch “7” must be

moved to “OFF” to return to normal operation. See the Controller Configuration Diagram in the Appendix or the decal inside the

controller enclosure for details.

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 5 Rev B12/1/21

CONFIGURING THE VSC9000 CONTROLLER

Hose Length - Note -Use only Ø1” ID hose on the Excela-Wynd model VSC9000 Excela-Wynd hose reel. Since the hose length and size

determine the number of wraps of hose on each layer, the controller must be set to match the installed hose length to assure proper

automatic speed changes and maintain the selected hose speed. The controller is factory set for a 150’ long Ø1” ID hose, so no

change is required when installing a 150’ long Ø1” ID hose. To set the hose length, slide the DIP switch corresponding to the length

below to ON. See the Controller Configuration Diagram in the Appendix or the decal inside the controller enclosure for details.

Hose Speed - Hose reel-in speed can be set to one of eight linear hose speeds ranging from 1.5 to 3.5 MPH. Company policy, seasonal

conditions or driver preference may dictate the required speed. The controller is factory set to a 2.9 MPH hose speed. To set the

hose speed, turn the potentiometer on the controller so the arrow points to the desired setting, below.See the Controller

Configuration Diagram in the Appendix or the decal inside the controller enclosure for details.

INSTALLING HOSE

Removing Cover, if installed - Pull both detent pins or remove locking screws, push the cover as shown to compress the spring loaded

plungers, move fixed posts away from mounting holes and lift cover off reel.

Replacing Cover - Insert plunger tips in holes in frame and level wind bracket, push cover to compress plungers, insert rear fixed post in

hole in frame and front fixed post in level wind bracket and replace both detent pins or locking screws.

Note -The cover (sold separately) ships from factory with both detent pins and locking screws installed.

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 6 Rev B12/1/21

Connecting Hose to Offset Riser - Remove the Offset Riser from the Accessories Box and make the NPT connection using

high quality PTFE sealant / tape and tighten securely.

Note -To improve level wind performance, align riser with curvature of hose, as shown.

Installing Hose in Gimbal Hose Guide - Using 3/4” wrenches,remove the nut, bolt and washers holding the gimbal roller,

remove the roller assembly and set aside. Remove the right rear vertical roller post assembly and set aside, being careful

to retain the internal tooth lock washer.

With riser connected to hose, route hose between vertical rollers and inside gimbal fork. Reinstall gimbal roller assembly

and hardware and tighten securely. Reinstall vertical roller post assembly, including lock washer, and tighten securely.

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 7 Rev B12/1/21

Connecting Offset Riser to Inlet Flange -Note -The riser flange bolts are captured with a locknut and shouldn’t be

removed to service the offset riser.

1. Remove the flange seal from the ACCESSORIES BOX and install it on the outlet flange.

2. Pass the offset riser and hose under the reel drum, position the keyhole slots over the mounting bolts and move it

down until the bolt heads clear the flange.

3. Move it fully forward until outlet and offset riser flanges are aligned

4. Push offset riser down to engage alignment boss making sure both flange faces are in contact.

5. DO NOT use impact drivers on riser bolts! Using a 1/4” hex drive and extension, tighten the flange bolts securely.

1-A 2-A 3-A 4-A 5-A

1-B 2-B 3-B 4-B 5-B

Adjusting Carriage - Using a 9/16” wrench, remove and retain the clutch rod cap. Pull and hold the clutch pin out, move the carriage to

the position shown and release clutch pin. If carriage doesn’t move freely, manually rotate reel until carriage moves freely.

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 8 Rev B12/1/21

Adjusting Carriage -Continued

Verify that the Gimbal hose guide is in the correct position and moves to the right when the drum is rotated in the direction shown

below. Readjust the carriage, if necessary. Replace the clutch rod cap and tighten securely.

Loading Hose - Connect a hose end valve to open end of hose. Pressurize hose and check for leaks at swivel inlet flange, riser flange,

riser / hose connection and hose end valve / hose connection. For improved level wind performance, remove twist due to coiling and

storage from hose before loading.

Use REEL IN to load the first layer of hose on reel with hose feeding straight into hose guide. Stop reel at end of layer to confirm even

placement on reel drum. If the first layer isn’t as shown below, pull hose off or loosen hose manually and adjust position of hose and

hose guide until the hose is tight to the drum and evenly spaced. Use REEL IN to load remaining hose onto reel. Replace cover, if

provided. Latch gimbal guide in the stowed position.Note - See “Rewinding Hose” section of Operating Instructions in Appendix.

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 9 Rev B12/1/21

SPECIFICATIONS

Swivel

Agency Approval: UL Listed

Pressure Rating: 400 PSI

Inlet Connection: MEC 4-Bolt Flange

Reel

Length: 16.5”

Diameter: 25.25”

Hose Capacity: 150 ft., Ø1” ID hose

Hose Connection: 1” Female NPT

Pressure Rating: 400 PSI

Motor

Construction: Totally Enclosed Explosion Proof

Agency Approval: UL Listed

Rating: Hazardous Location

Class I, Div I, Group D

Hp: 2/3

Voltage: 12 DC

Current: 75 Amps

Speed: 500 RPM

Drive Ratio: 12.25:1

Junction Box

Agency Approval: QPS Certified

Rating: Hazardous Location

Class I, Groups C &D

Class II, Groups E, F & G

Class III

Type 4 Enclosure

Volume: 35 Cubic Inches

No. of Hubs: 5

Hub Size: ¾” NPT

Dimensions

Width: 30.7”

Depth: 35.9”

Height: 27.9”

Weight: 270 lbs.

Shipping Weight: 310 lbs.

MATERIALS OF CONSTRUCTIONS

Wetted Surfaces

Swivel: CF8M stainless steel (316 SS)

Inlet Casting: CF8M stainless steel (316 SS)

Riser: CF8 stainless steel (304 SS)

Frame

Motor Plate: 3/16” stainless steel

Mounting Rails: 3/16” wall stainless steel

Tubing: 1-1/2” Square 11 Ga stainless steel

Stud Retainer: Tempered stainless steel

Mounting Hardware: Stainless steel

Backing Plates: Stainless steel

Gear Guard: Welded, polished stainless steel

Level Wind Cover: Welded, polished stainless steel

Spool

Reel Ends: Hardened, marine grade aluminum

Drum: Welded stainless steel

Axle: Stainless steel, 1-1/2” pipe

Reel Bearings: CF8 SS pillow block / split bronze

bushings with grease fitting

Drive-Train

Motor Gear: Hardened stainless steel

Gear Segments: Hardened, polished stainless steel

Level Wind Gear: Stainless steel

Motor Shaft: Stainless steel

Level Wind

Carriage: CF8 stainless steel (304 SS)

Mounting Brackets: CF8 stainless steel (304 SS)

Gimbal Bearings: (6) Sealed 25mm stainless steel

Roller Bearings: (26) Sealed 17mm stainless steel

Rod Roller Bearings: (12) Sealed 8mm stainless steel

Guide Rods: Hardened stainless steel

Rod Rollers: Hardened stainless steel

Drive Chain: Stainless steel

Drive Sprockets: Stainless steel

Shafts: Hardened stainless steel

Worm Screw: Hardened alloy steel

Worm Wheel: Bronze

Clutch Pins: Stainless steel

Connecting Pin: Stress proof 1144 alloy steel

Slider Bearings: Lubricated UHMW PE

Bearing Retainers: CF8 stainless steel (304 SS)

Hose Rollers: Hardened, anodized aluminum

Frame: Hardened, anodized aluminum

Fasteners: Stainless steel

Cover (Optional)

Mounting Rods: Stainless steel

Plate: 1/8” hardened, polished or powder

coated aluminum plate

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 10 Rev B12/1/21

WARRANTY INFORMATION ___________________

WARNING

Marshall Excelsior’s products are mechanical devices made of

materials such as rubber and metal, and are subject to wear, the

effects of contaminants, corrosion, and aging, and these devices will

eventually become inoperative. Regular inspection and

maintenance is essential. Marshall Excelsior’s products have a long

record of quality and service, and therefore LP-Gas dealers may

forget hazards that can arise from using aging devices that have

outlived their safe service life. The safe service life of these

products will be affected by the environment and the conditions of

their use. The LP-Gas dealer knows better than anyone what this

environment and the conditions of use are.

There are developing trends in state legislation and proposed

national legislation making the owner of products responsible for

replacing products before they outlive their safe service life. LP

Gas dealers should be aware of such legislation as it affects them.

All Marshall Excelsior products must be installed, inspected and

maintained by a trained and experienced professional adhering to

all installation instructions, product and safety warnings, local,

state, and federal regulations, codes and standards and any other

standards set by, but not limited to, NFPA, DOT or ANSI.

LP-Gas is a highly explosive and flammable gas that should never

be vented near a possible ignition source.

LIMITED WARRANTY

THIS WARRANTY for Marshall Excelsior manufactured products

is provided by Marshall Excelsior, Inc., 1506 George Brown Drive,

Marshall, MI 49068. Marshall Excelsior, unless otherwise

specified in writing, warrants to the original buyer that for a period

of three (3) years from the date of manufacture its products and

repair kits will be free from defects in material and workmanship

under normal service and use. This warranty covers manufacturing

defects only, and does not cover defects and product non-

compliance due to, misuse, alteration, neglect, accident, fire, or

other external causes, alterations, or repairs. This limited warranty

also does not cover normal wear and tear. During this warranty

period, if a defect arises in the product, and you follow the

instructions for returning the product, Marshall Excelsior will, at its

option, to the extent permitted by law, either (i) repair the product

using either new or refurbished parts, (ii) replace the product with a

new or refurbished product that is equivalent to the product that is

to be replaced, or (iii) refund to you all or part of the purchase price

of the product. This limited warranty applies to the extent permitted

by law, to any repair, replacement part or replacement device for

the remainder of the original warranty period or for ninety (90) days

whichever period is longer. All replaced parts and products for

which a refund is given shall become the property of Marshall

Excelsior. This is the only warranty or representation made by

Marshall Excelsior, and the sole basis for liability respecting

quality, performance, defects, repair, delivery, and replacement of

products and repair kits. The foregoing shall constitute Marshall

Excelsior’s sole liability.

Marshall Excelsior does not warrant any product or part that has

been altered, accidentally damaged, disassembled, modified,

misused, neglected, not properly maintained or installed. Marshall

Excelsior does not warrant cosmetic issues including but not limited

to dents, scratches, product discoloration, color fading or any other

imperfection that does not affect the functionality of the product.

Marshall Excelsior does not warranty any product or part not

installed according to Marshall Excelsior’s installation instructions

or installed in violation of any regulation or warning by state, local,

or federal regulators, or in violation of any standard or code set by,

but not limited to, NFPA, DOT or ANSI requirements. The

foregoing shall constitute Marshall Excelsior’s sole liability to

distributors, vendees and end users. NOTE: Warranty does not

include hose, as it is not manufactured by MEC.

LIMITATIONS

TO THE EXTENT PERMITTED BY LAW, THE WARRANTY

AND REMEDIES SET FORTH ABOVE ARE EXCLUSIVE AND

IN LIEU OF ALL OTHER WARRANTIES AND REMEDIES,

AND MARSHALL EXCELSIOR SPECIFICALLY DISCLAIMS

ALL STATUTORY OR IMPLIED WARRANTIES,

INCLUDING, BUT NOT LIMITED TO, WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE AND AGAINST HIDDEN OR LATENT DEFECTS.

IF MARSHALL EXCELSIOR CANNOT LAWFULLY

DISCLAIM STATUTORY OR IMPLIED WARRANTIES, THEN

TO THE EXTENT PERMITTED BY LAW, ALL SUCH

WARRANTIES SHALL BE LIMITED IN DURATION TO THE

DURATION OF THIS EXPRESS LIMITED WARRANTY AND

TO REPAIR OR REPLACEMENT AND SERVICE.

MARSHALL EXCELSIOR IS NOT RESPONSIBLE FOR

DIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM ANY BREACH OF

WARRANTY OR UNDER ANY OTHER LEGAL THEORY.

MARSHALL EXCELSIOR’S LIABILITY (EXCEPT AS TO

TITLE) ARISING OUT OF THE SALE, USE OR OPERATION

OF PRODUCTS OR REPAIR KITS, WHETHER ON CLAIMS

FOR BREACH OF WARRANTY, CONTRACT, NEGLIGENCE

OR OTHERWISE (INCLUDING CLAIMS OF

CONSEQUENTIAL OR INCIDENTAL DAMAGES) SHALL

NOT IN ANY EVENT EXCEED THE COST OF FURNISHING

OR REPLACEMENT OF THE DEFECTIVE PRODUCT OR

REPAIR KIT.

WARRANTY CLAIMS AND NOTICE

Warranty claims shall be made in writing to Marshall Excelsior’s

Home Office at 1506 George Brown Drive, Marshall, Michigan

49068 by the distributor, vendee or end user within twenty (20) days

of discovery of the defect and the product must be postmarked and

shipped F.O.B. origin to Marshall Excelsior’s Home Office within

thirty (30) days of the discovery of the defect. Marshall Excelsior

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 11 Rev B12/1/21

will not accept any products or repair kits that does not have a

Return Material Authorization (RMA) number from the Home

Office in Marshall, Michigan. After Marshall Excelsior has

inspected the product and deemed the product to be defective, at its

discretion, Marshall Excelsior will repair, replace or refund the

purchase price of the defective product or repair kit. If the buyer

does not comply with the above stated requirements the buyer will

waive unconditionally and absolutely any and all claims arising out

of the alleged defect.

COMPLIANCE

Marshall Excelsior manufactures all of our products to the highest

industry standards. All of our products meet or exceed the

requirements of the Compressed Gas Association (CGA), the

National Fire Protection Association (NFPA), American National

Standards Institute (ANSI), American Society of Mechanical

Engineers (ASME) or Underwriters Laboratories, Inc. (UL) where

indicated.

PRODUCT CHANGES

Marshall Excelsior reserves the right to change product specifi-

cations at any time. We are constantly evaluating our products and

incorporating engineering advances to ensure our products perform

and comply with changes in market conditions, government

mandates, and code changes. Marshall Excelsior shall not be

required to modify any equipment already sold or in service.

DETERMINING PRODUCT AGE

Marshall Excelsior products are mechanical devices that are subject

to wear, contaminants, corrosion, and aging of components made of

materials such as rubber and metal. Over time these devices will

eventually become inoperative. The safe service life of these

products will reflect the environment and conditions of use that they

are subjected to. Regular inspection and maintenance is essential.

Marshall Excelsior products have a long record of quality and

service, so LP-Gas dealers may forget hazards that can arise from

using aging devices that have outlived their safe service life. The

length of a device’s life is determined by the environment in which

it is used, and the LP-Gas dealer knows better than anyone about

this environment.

There are developing trends in state legislation and proposed

national legislation making the owner of products responsible for

re-placing products before they outlive their safe service life. LP-

Gas dealers should be aware of such legislation as it affects them.

To determine the product’s age, check the product for a date code

consisting of a series of letters and numbers.

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 12 Rev B12/1/21

APPENDIX - UNBOXING INSTRUCTIONS

1. REMOVE SCREWS FROM BOX

2. LIFT BOX OFF PALLET

3. USE A 3/4” WRENCH TO REMOVE

SHIPPING HARDWARE

4. REMOVE AND RETAIN ACCESSORIES BOX

5. KEEP ACCESSORIES BOX WITH REEL ACCESSORIES BOX CONTENTS

ACCESSORIES BOX

OPERATORS MANUAL INSTALLATION MANUAL SENSOR CABLE

MOUNTING HARDWARE DIELECTRIC MOUNTS RISER AND FLANGE SEAL

MANUAL CRANK MANUAL CRANK STORAGE POUCH

6. RECYCLE OR DISCARD: SHIPPING BOX, PALLET AND STEEL SHIPPING NUTS, BOLTS AND WASHERS

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 13 Rev B12/1/21

VSC9000 Controller Configuration Diagram

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 14 Rev B12/1/21

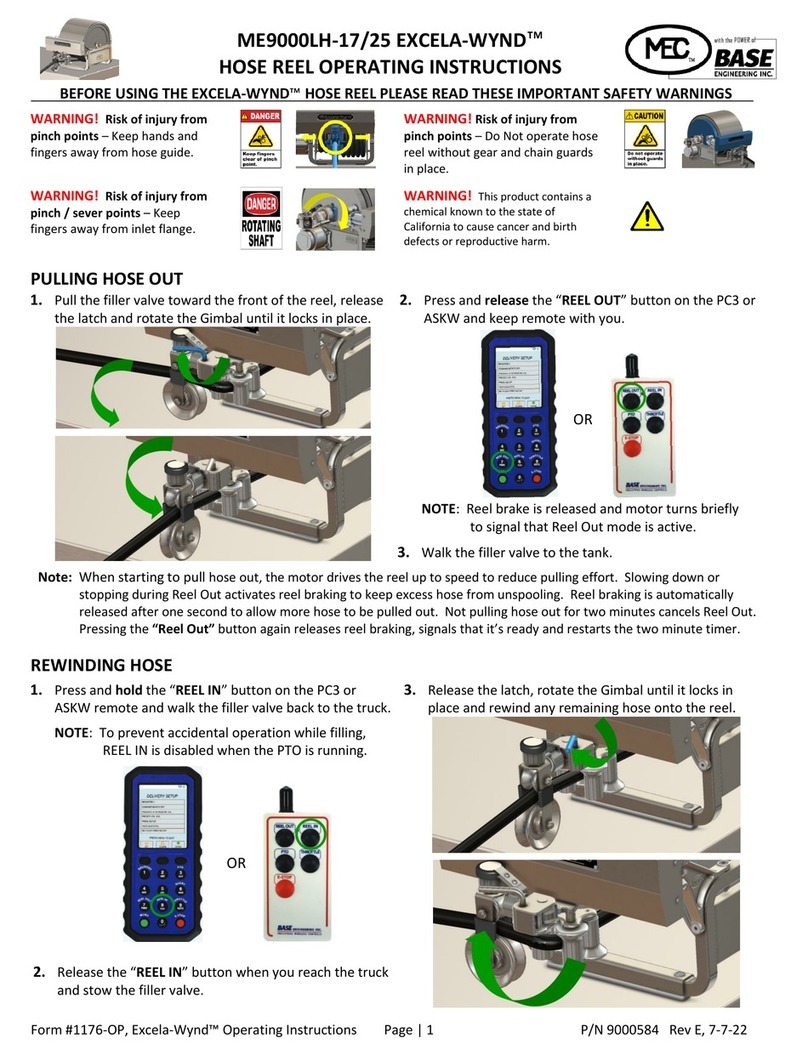

OPERATING INSTRUCTIONS

BEFORE USING THE EXCELA-WYND™HOSE REEL PLEASE READ THESE IMPORTANT SAFETY WARNINGS

WARNING! Risk of injury from

pinch points

– Keep hands and

fingers

away from hose guide.

WARNING! Risk of injury from

pinch points

– Do Not operate hose

reel without guards in place.

WARNING! Risk of injury from

pinch

/ sever points – Keep

fingers

away from inlet flange.

WARNING!

This product contains a

chemical known to the state of

California to cause cancer and birth

defects or reproductive harm.

PULLING HOSE OUT with HANDS-FREE REEL OUT™

1. Pull the filler valve toward the front of the reel, release

the latch and rotate the Gimbal until it locks in place.

2. Press and release the “REEL OUT” button on the PC3 or

ASKW and keep remote with you.

NOTE: Reel brake is released and motor turns briefly

to signal that Reel Out mode is active.

3.

Walk the filler valve to the tank.

Note: As hose is pulled out, the motor drives the reel up to speed for one revolution. Slowing down, stopping or not

pulling the hose for two minutes cancels Reel Out mode and turns reel braking on. Pressing the “Reel Out” button

again releases reel braking, turns the motor briefly to signal that Reel Out is active and restarts the two minute timer.

REWINDING HOSE

1. Press and hold the “REEL IN” button on the PC3 or

ASKW remote and walk the filler valve back to the truck.

2. Release the “REEL IN” button when you reach the truck

and stow the filler valve.

3. Release the latch, rotate the Gimbal until it locks in

place and rewind any remaining hose onto the reel.

OR

OR

ME9000LH-17/25 EXCELA-WYND™HOSE REEL (Patent Pending)

INSTALLATION AND OPERATING INSTRUCTIONS

Form #1176, Excela-Wynd™ Hose Reel IOM Page | 15 Rev B12/1/21

TIPS for Operating the EXCELA-WYND™Hose Reel

•Your service provider can adjust rewind speed between 1.5 and 3.5 MPH to match driver or seasonal needs.

•Avoid twisting the hose excessively to prevent binding on the reel and assure reliable automatic loading.

•If you have a loss of truck battery power to the reel controller while the hose is pulled out, such as when using the

emergency shut down, when the power is restored the hose reel speed controller may temporarily rewind at a different

speed. Once the hose is fully rewound on the reel, turning the truck ignition off and back on will reset rewind speed.

To raise the cover -

Pull the front detent

pin, push the front of

the cover to the left to

release it, and rotate

it upward. Latch and

pin cover when done.

To remove the cover -

Pull both detent pins,

push the cover to the

left to release it, and

lift it upward. Latch

and pin cover when

done.

To use the manual crank - (Remove crank from

storage pouch and remove red safety cap)

1) Insert the safety collar into the axle.

2) Push in and turn to engage drive pin.

When the hose is loaded, remove crank, replace

safety cap and place in storage pouch.

Note: Turning the truck ignition off releases the

reel brake making it easier to turn.

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSES AND SOLUTIONS

•The reel brake doesn’t release when pressing REEL OUT

•

The reel won’t turn at all when pressing REEL IN

•

The reel brake engages during REEL OUT or the reel stops

rewinding during REEL IN once you’re a distance from the truck

•The batteries in the remote may be too low to transmit or may

transmit only a short distance - Recharge or replace batteries.

•

The truck ignition may be off, removing power from the

controller - Make sure the ignition is on and the brake is set.

•

The ciruit breaker on the BASE Engineering controller enclosure

may have tripped - Check circuit breaker and reset, if tripped.

•The reel stops turning while pressing

REEL IN

(Rewind)

•An extremely high motor load may have triggered the over-

current protection - It will automatically reset after (5) seconds.

•

The hose may be stuck on an obstruction - Check for and clear

any obstructions.

•

The hose may have bound in the reel due to excessive twisting -

If the hose is bound or not evenly layered on the reel, pull out

any hose that is bound, remove excessive twist and rewind hose.

This manual suits for next models

1

Table of contents

Other base engineering Tools manuals