WARNING! DO NOT use the wrench if damaged or thought to be

faulty.

Ensure all workshop safety rules, regulations and conditions are

complied with when using this wrench.

Maintain correct balance and footing. Ensure the floor is not

slippery and wear steel toe-capped non-slip shoes / boots.

Always wear eye protection when using the wrench.

Keep children and unauthorised persons away from the working

area.

Ensure that all hand tools, sockets and extensions are not

damaged, use of such items may result in personal injury.

Apply the torque slowly and grip the centre of the handle.

DO NOT apply load to the end of the handle.

DO NOT subject the wrench to excessive force or shocks.

DO NOT use the wrench to break fasteners.

DO NOT use the wrench as a hammer or lever bar.

DO NOT use extensions on the handle as this may result in

damage to the wrench and/or cause personal injury.

DO NOT drop or throw the wrench.

DO NOT use the wrench unless you have been instructed in its use

by a qualified person.

DO NOT leave the wrench in any place exposed to excessive heat,

humidity or direct sunlight.

DO NOT use organic solvents such as alcohol or thinners to clean

the wrench.

DO NOT use this wrench in water. (not waterproof). If the wrench

gets wet, dry it immediately.

DO NOT Over-torque (110% of Max. torque range) could cause

damage or loss of accuracy.

DO NOT use or store the wrench near a magnet.

DO NOT expose the wrench to dust or sand as this could cause

serious damage.

DO NOT apply excessive force to the LCD panel.

After use clean with a soft dry cloth and store in a safe, dry,

childproof location.

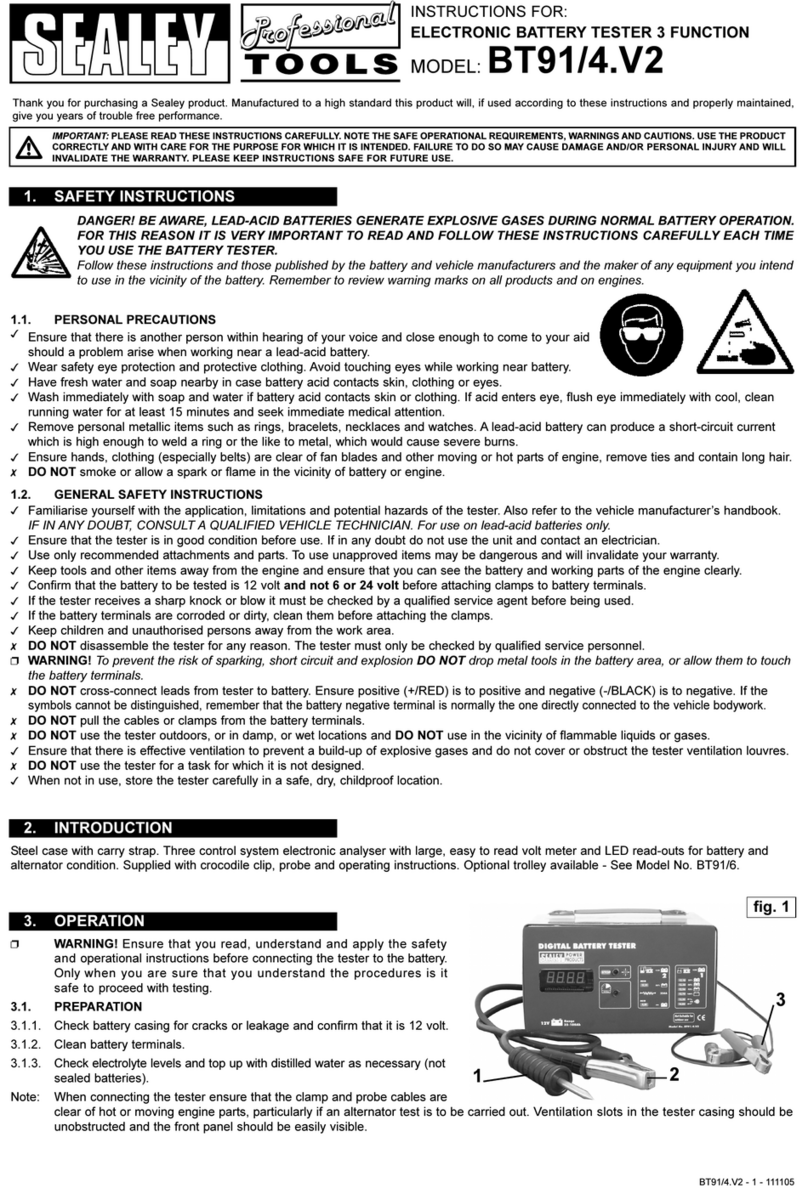

Rugged and resilient digital torque wrench suitable for workshop and

factory use. LCD read-out with LED/audible alarm indicates achieved

and target torque levels. Track peak and working torques using simple

push button menu. Selectable read-out in Nm, lb.ft, lb.in or kg.cm.

Reversible Chrome Vanadium ratchet allows torque reading in either

direction. Accurate to ±3% CW and ±4% CCW between 20% and

100% of wrench’s stated capacity. Tested in accordance with EN ISO

6789. Supplied with certificate and storage case.

Thank you for purchasing a Sealey Product. Manufactured to a high standard this tool will, if used according to these instructions and properly

maintained, give years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS,

WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS

INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE

WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

INSTRUCTIONS FOR:

1/2” SQ DRIVE DIGITAL

ELECTRONIC TORQUE

WRENCH 40-200Nm

MODEL No: STW298

1. SAFETY INSTRUCTIONS 2. INTRODUCTION & SPECIFICATION

STW298 Issue No: 1 - 02/06/09

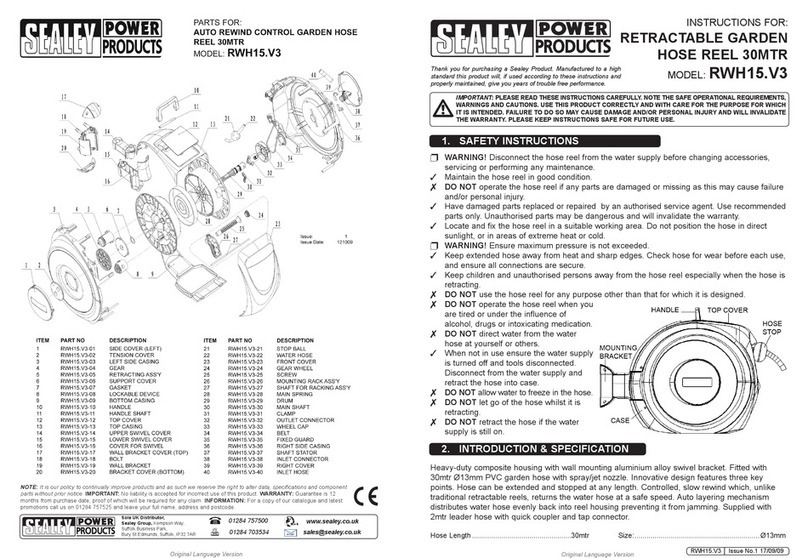

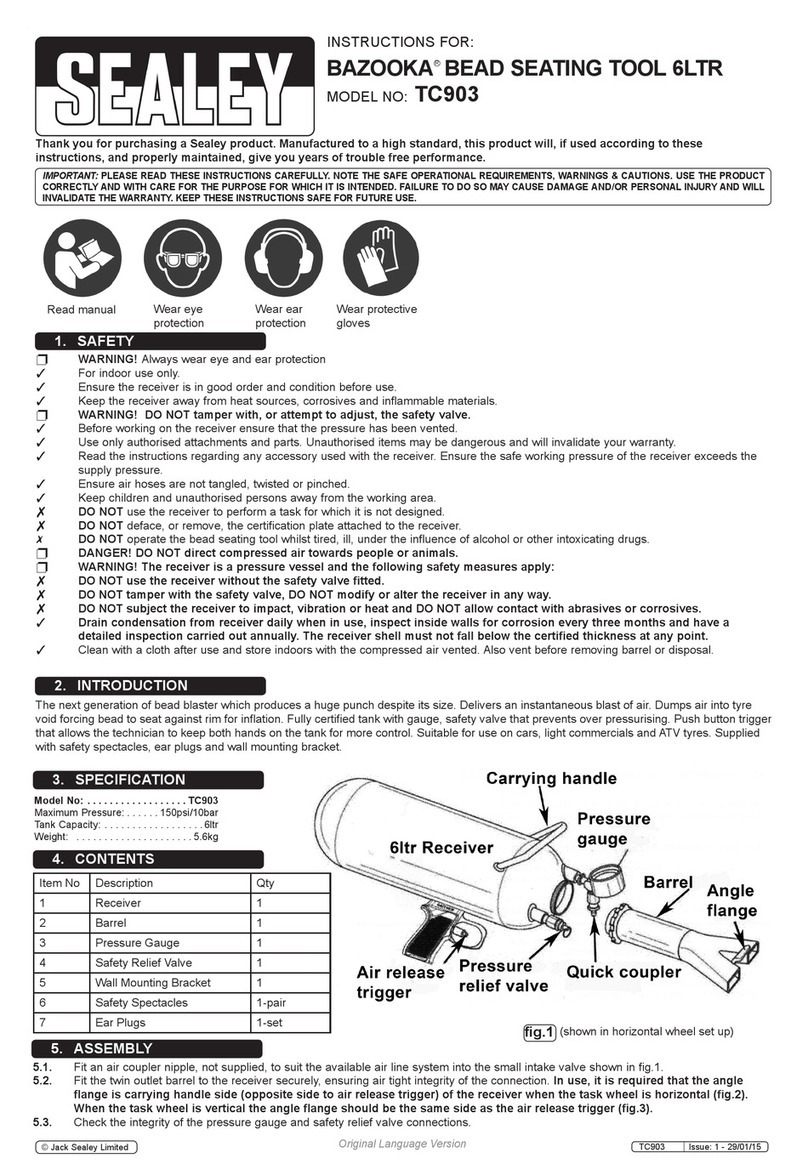

2.1 MAIN FEATURES

Digital torque value readout.

+/- 3% accuracy CW and +/- 4% accuracy CCW operation.

Peak-hold and track mode selectable.

Buzzer and LED indicator for the pre-settable target torque.

Engineering units (N-m, ft-lb, in-lb, kg-cm) selectable.

Auto Sleep after about 5 minutes idle.

Compatible with rechargeable batteries.

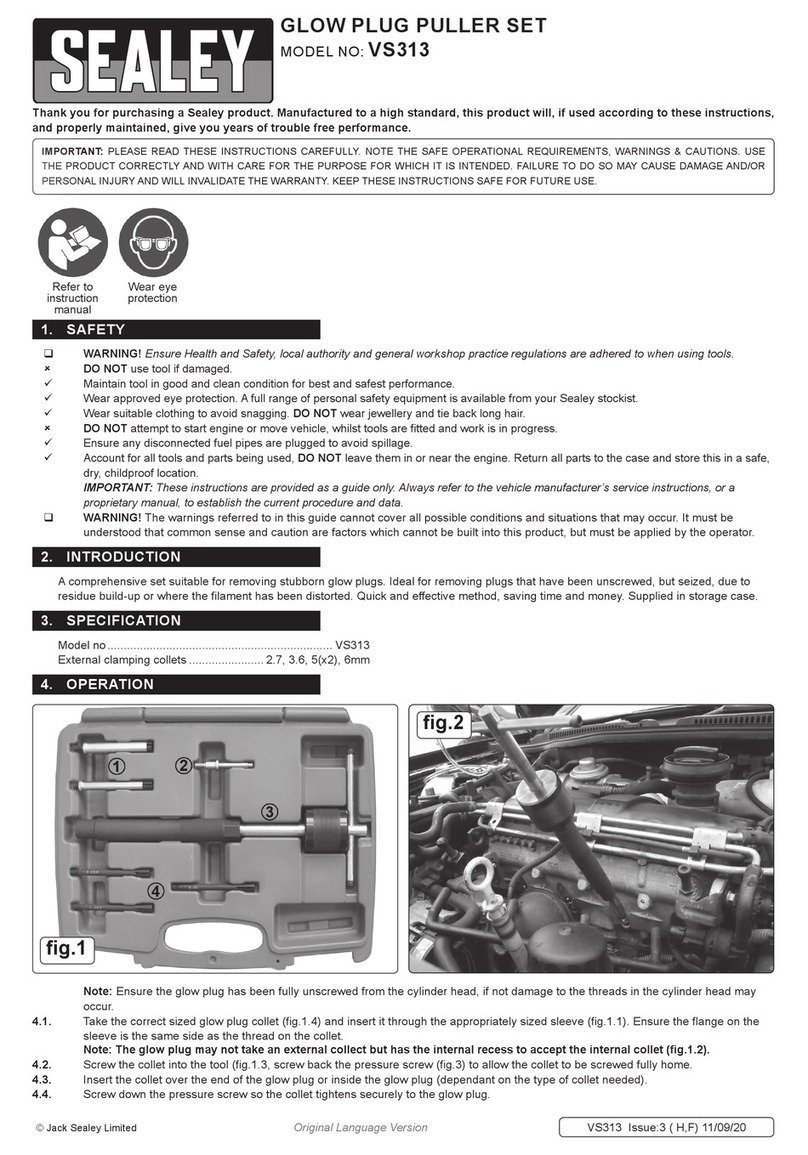

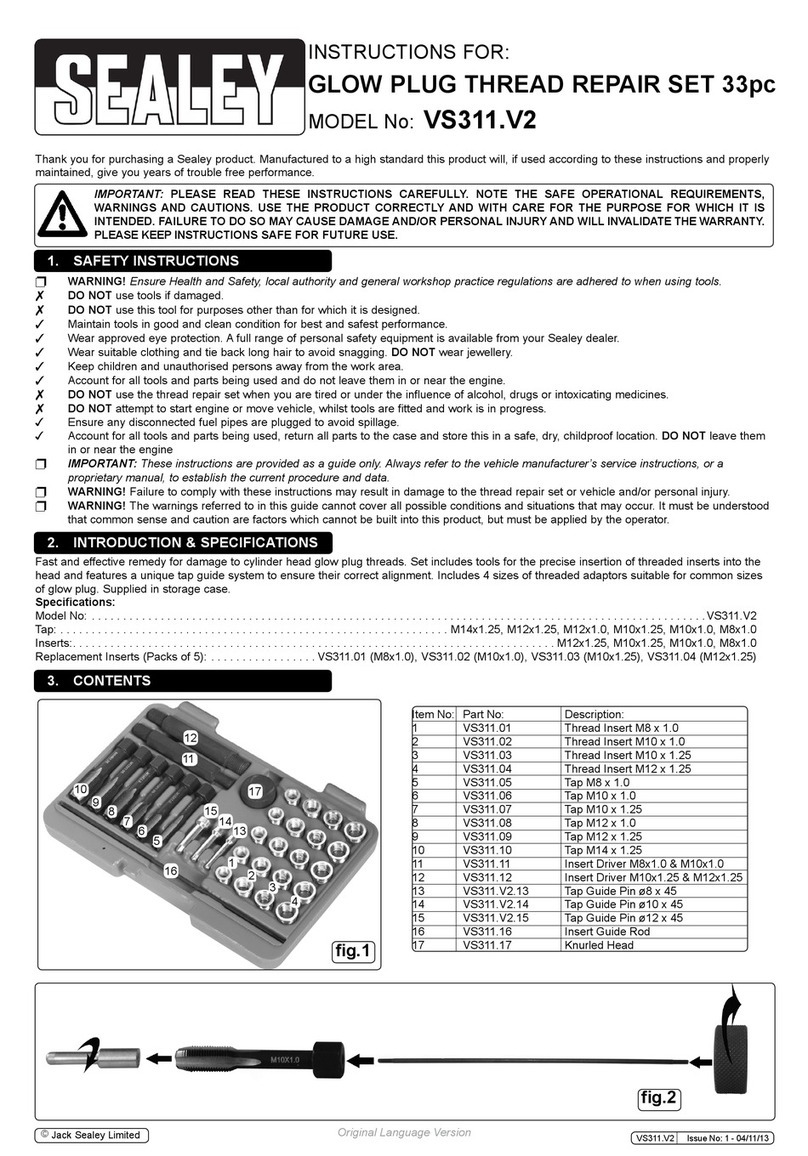

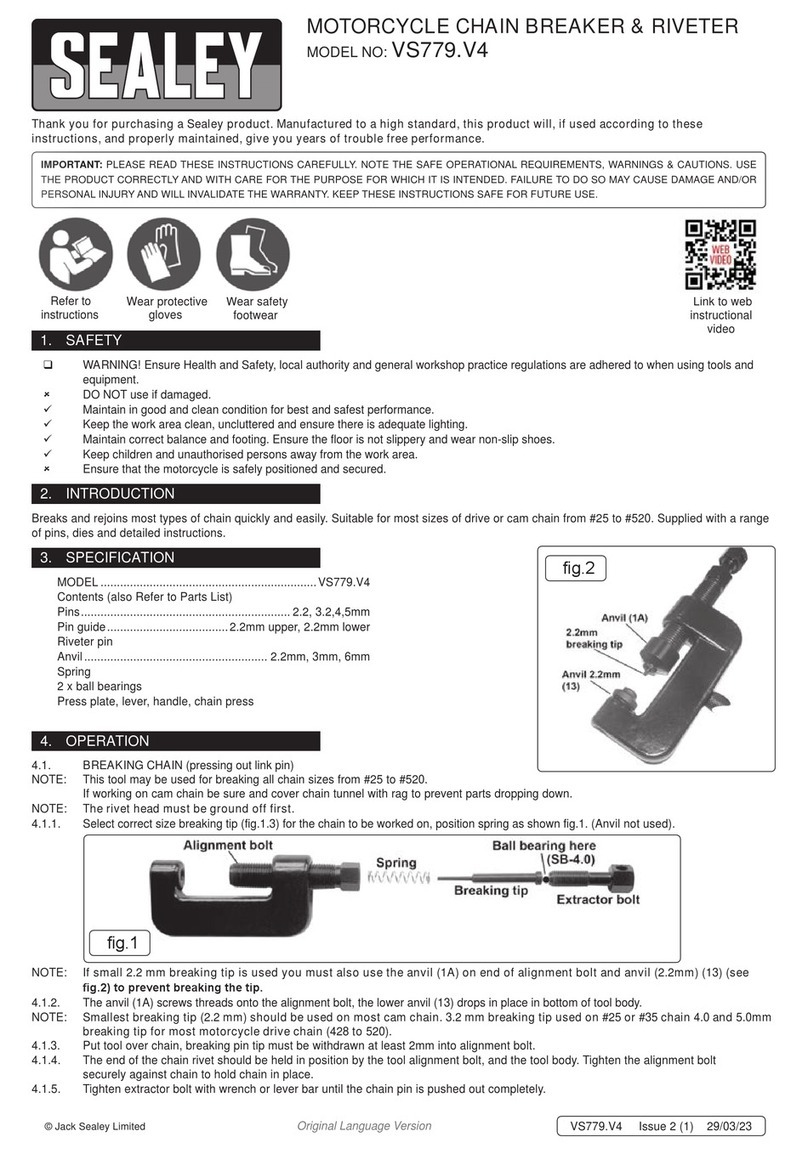

2.2 NAMES AND FUNCTIONS OF PARTS

10. LED Indicator

11. Torque Value

12. Unit (N-m, ft-lb, in-lb, kg-cm)

13. Up/Down Button

14. Peak hold/Track mode

15. Power on/Clear Button

16. Unit/Setting Button

1. Round Head Ratchet

2. LCD Readout

3. Buzzer

4. Communication Port

5. Button

6. Battery Compartment

7. Battery Cover

8. Ratchet Drive

9. Anti-slip Handle