BASHLIN BLCL 514 User manual

Important Safety

Information for Users of

Bashlin Climbers

and Accessories

No. BLCL 514, Rev. 4-21

- WARNING -

For your personal safety, this booklet must

be read and all of the information completely

understood before using these products.

Table of Contents

Important Safety Information ...................................................1

General Information for Bashlin Climbing Equipment .....................1

Climbers...........................................................................................2

Sizing Your Bashlin Climbers ...........................................................3

Climber Pads ....................................................................................3

Strap Climber Pad Attachment ........................................................3

Hook-n-Loop Pad Attachment .........................................................4

Wearing Hook-Loop Pads ................................................................5

Tips for Using Bashlin Climbers.......................................................5

Inspecting Your Bashlin Climbers and Pads....................................6

Using the Bashlin Gaff Gauge ..........................................................8

Maintenance of Bashlin Climbers ....................................................9

Sharpening the Gaffs on Your Bashlin Climbers..............................9

Shaping the Gaffs on Your Bashlin Climbers .................................10

Before Returning Your Climbers to Service ...................................10

Pole Cut Out Test............................................................................10

Replacing Bashlin Gaffs ................................................................. 11

Installing the New Bashlin Gaff ...................................................... 11

Replacing Bottom Straps on Bashlin Climbers .............................12

Inspecting and Shaping Bashlin 14T Tree Gaffs .......................12-13

Installing 89N Bottom Straps .........................................................14

Installing 87N Bottom Straps ....................................................14-15

Installing the Bashlin BHP Heel Covers .........................................16

Inspection Record ......................................................................18

*Se hable Espanol, (Para una versió espanola de este folleto de la

seguridad, contacta las Industrias de Bashlin S.a. por favor.)

Nous parlons Français (Pour une version française de ce livret

de sûreté, contacter les Industries de Bashlin Inc s’il vous plaît.)

Other languages upon request.

1

This information is intended for the user of the products indicated. It

must be included with the product, read and understood by the user

prior to placing this product into service. This equipment is to be used by

properly trained, professional workers. The information in this booklet,

manufacturer’s demonstrations, sales seminars, catalog information

or other promotional materials may be a part of but does not constitute

proper or complete training in the use of these products.

The user must inspect this equipment before each use. Any equipment

found to be worn out, damaged, subject to shock loading or in any way

questionable, must immediately be removed from service or accident,

injury and even death could result. Specic guidelines for inspection are

included in this information booklet.

General Information for Bashlin Climbing Equipment

These products are fabricated from leather and synthetic

woven materials and rated metal hardware. They are

assembled by riveting and/or sewing. The thread used in

assembly is of a contrasting color to permit easy inspection.

These products are manufactured in accordance with OSHA, ANSI, ASTM

F887 and/or CSA standards and are labeled as such. Please contact us

for information regarding specic applicable standards for each product.

Important Safety Information

- WARNING -

Bashlin equipment must not be altered. Altering or modifying these

products voids all warranties, may affect performance, and could

cause accident, injury or death to the user.

- WARNING -

Lack of proper training or the incorrect use and/or abuse of these

products may cause accidents, injury or death.

- WARNING -

Exposing the equipment to chemicals may produce a harmful

effect.Avoid using the equipment around moving machinery,

electrical hazards, sharp edges or abrasive surfaces.

- WARNING -

Shock loading is extremely damaging to climbing equipment.

Any belt, harness, pole strap, APL or climber that has

been shock loaded must be removed from service.

2

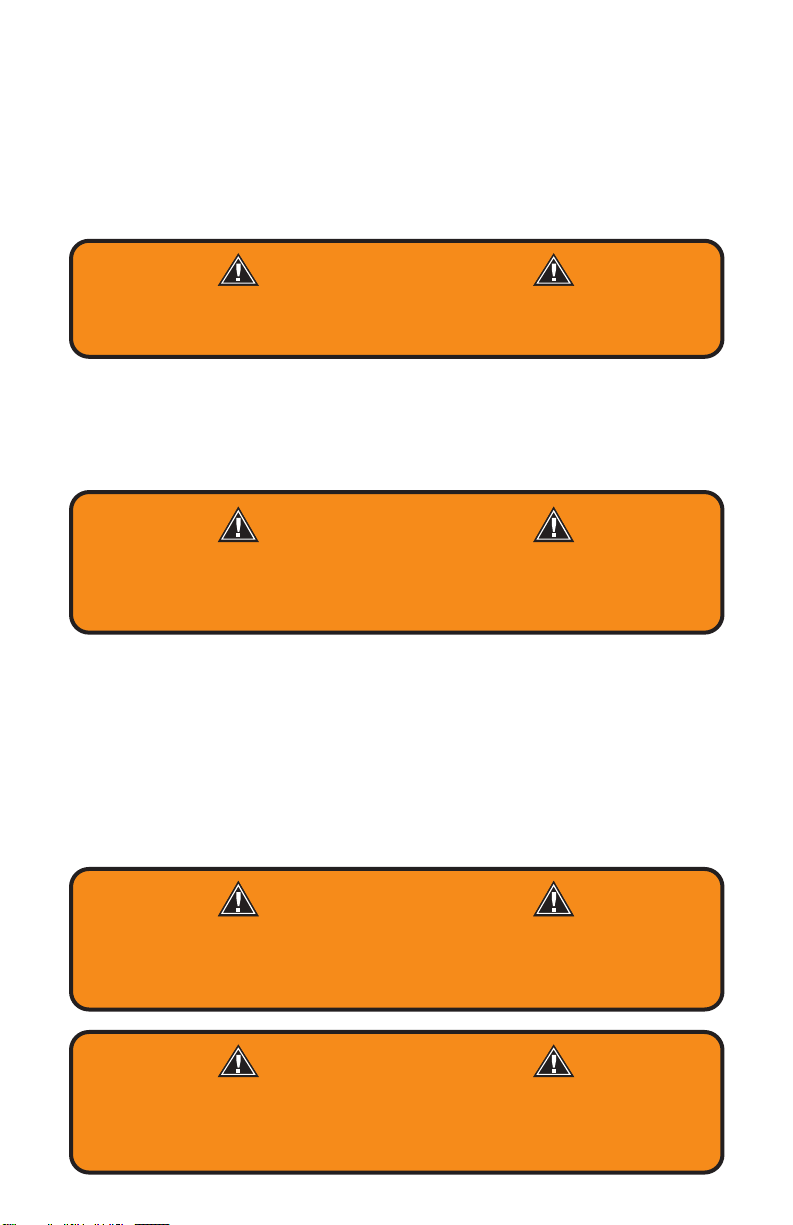

Climbers

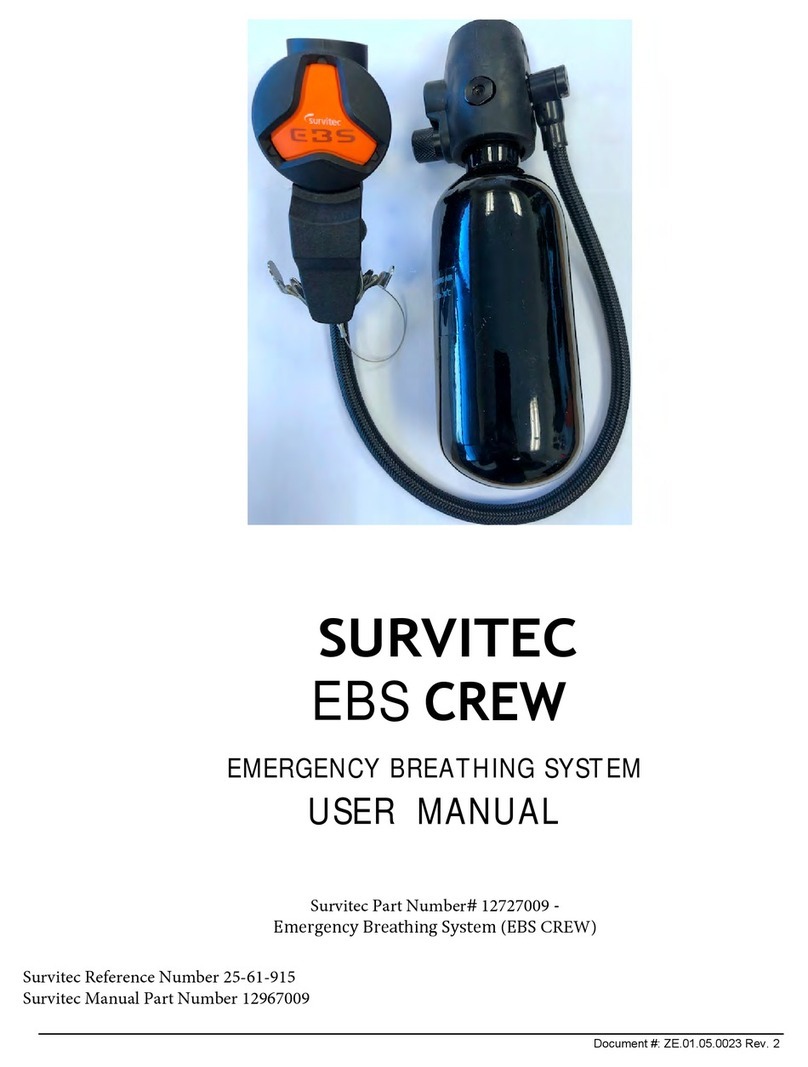

Your Bashlin climbers are known

the world over for their comfort and

superior performance. Whether your

choice is the popular BD14B, or one

of the rugged steel climbers, BD12 or

BD16, you have the proven Bashlin

17° angle gaff, roomy comfortable

stirrup and innovative offset design.

All Bashlin Pole Climbers come with

the following items standard; (A)

- 1 pair of climbers with the bottom

nylon straps installed

- 1 pair of gaff guards

- 1 pair of top slides with 4 screws

in a small packet

- 1 gaff gauge (Pole Climbers Only)

If any of these listed items

are not in your box, please

contact us immediately.

In addition, these climbers are sold

as sets and include the following

items designated by part number

- BD14B-1N Climbers with

bottom straps. (A)

- BD14B-2N Climbers with

bottom straps and top straps. (B)

- BD14B-3N Climbers with

bottom straps, top straps and

#110D pads. (C)

- BD14B-4N Climbers with

bottom straps, top straps and

#130D pads. (D)

- BD14B-5N Climbers with

bottom straps, top straps and

#140DS pads. (E)

A

B

C

D

E

3

Sizing Your Bashlin Climbers

For maximum comfort and performance,

the climber shank must be adjusted to t

your leg. This is done by performing the

following steps;

• Place the adjustable top slide on

the shank.

• Put your foot in the stirrup and move the

top of the adjuster to a point two ngers

below the bottom of the knee bone. (F)

• Holding the top slide in place, install one

of the screws, recheck the position, then

install the second screw.

• Adjust the second shank and tighten

screws.

• The shank should be low enough to

keep the pad from rubbing your knee

bone. If you are experiencing excessive

rubbing on the knee bone, lower the top

slide.

• The standard adjustment for Bashlin climbers per ASTM F887 is

14 3/4" to 18". If by adjusting your climbers to the proper height,

the top slide is in the last hole, or if the climbers are simply too

short, you must use the longer top slides, number 14ATSB, for

aluminum climbers or 16ATS for steel. Using the longer top slides

gives you a better t and reduces the exing of the shank section

of the climber, especially in the critical section 4-8" above the gaff.

(See Climber Inspection).

Climber Pads

Bashlin climber pads reduce the shin

discomfort caused by standing on

climbers for extended periods of time.

Strap Climber Pad Attachment

(110, 130, 140, 145 or 150 series pads)

Strap pads are held on your Bashlin

climbers with a 1" nylon strap that has

a tongue buckle closure. The strap is

normally oriented with the buckle close to

the front of the pad. The pad should wrap

around the front of your leg and inside of

the shank.

F

4

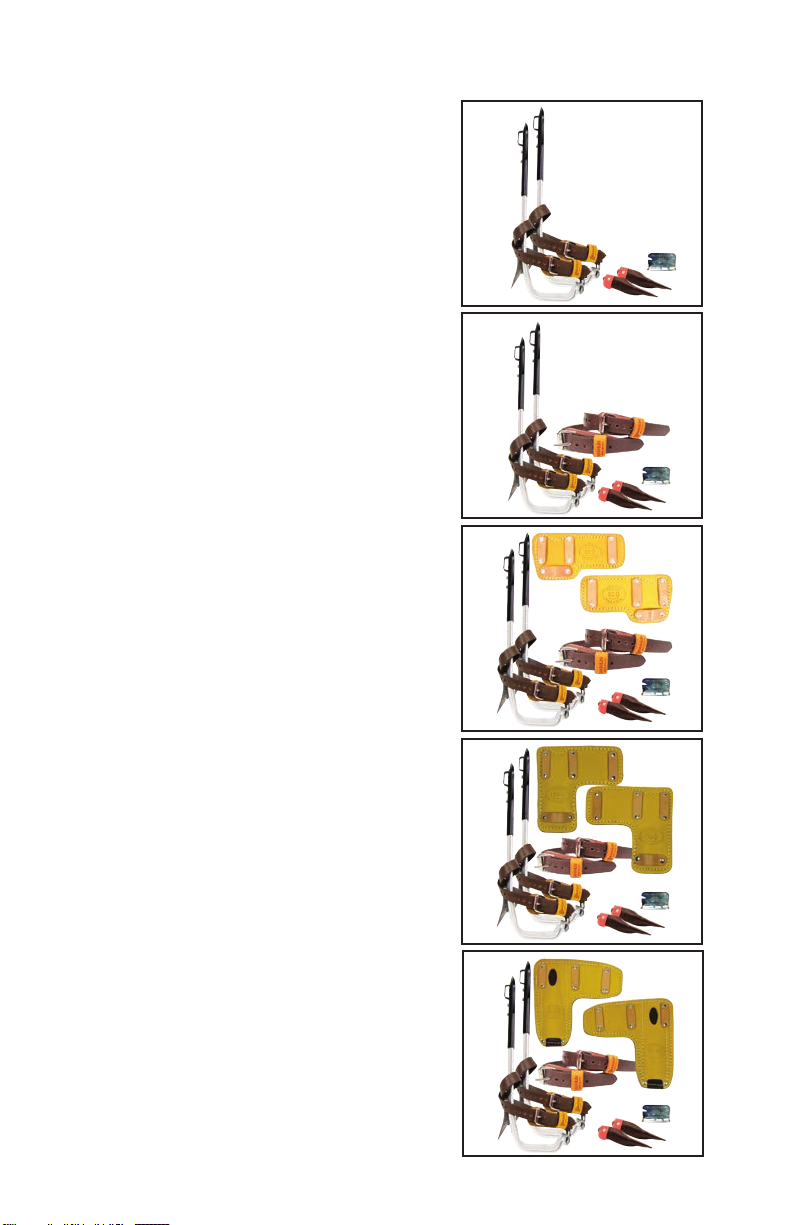

Hook-n-Loop Pad Attachment

(145ACV/BCV/FCV-145ACVW/BCVW/FCVW or 150V series pads)

• With the top slide secured to the climber, insert the shank into the

tunnel of the pad until the top slide loop is seated in the tunnel slot

or steel insert. Squeezing the tunnel will allow the climber to slide

in easier. (A)

• Feed the climber pad retaining strap through the top slide loop

and/or the steel insert and pull tight to secure the shank to the pad.

(B, C)

• To assist in sliding the strap through the loop, place a piece of paper

or other thin material over the end of the strap while sliding through

the top slide loop. A pair of pliers can be used to pull the strap. (D)

C D

B

A

5

Wearing Hook-n-Loop Pads

• Step into the climber and attach the

bottom strap securely to your boot. (A)

• Feed the free end of the pad with the

hook through the steel loop. (B)

• Pull the free end through the steel loop

until the pad is snug on your leg. (C)

• Secure the free end

around the pad, mating

the hook to the loop on

the body of the pad. (D)

• Check the security of

the climber and pad

by taking a step or two

on the structure you

are climbing before

ascending in them.

Tips for Using Bashlin Climbers

• Only use a Bashlin Gaff Gauge on Bashlin

Pole Climbers.

• Remove from service any climbers that have

come in contact with an electric arc.

• Never etch or scratch the critical section of

the climber shank, 4-8" above the gaff. Points

of stress will be created, and exing of the

shank will cause a

fracture and nally

premature failure

of the climber

shank. (A)

A, B

C D

A

6

• Bashlin BD14B forged aluminum alloy climbers are 30% lighter than

steel or titanium. Aluminum yields a better performing climber with

durability that is comparable to steel or titanium.

• Do not use aluminum alloy climbers with climbing boots that have a

steel heel guard. The heel guard wears deeply into the stirrup of the

climber and will require premature replacement of the shanks.

• Bashlin requires that any other manufacturer’s equipment used with

our products be made in accordance with the ASTM F887 Standards.

• Don’t violate safety rules.

• Keep dirt and debris cleared from the hook and loop material with a

soft brush. Debris can compromise the performance of the hook and

loop material, even causing the strap to release.

Inspecting your Bashlin Climbers and Pads

Your climbers must be inspected prior to each use.

Your climbers should be removed from service until repaired

or replaced if you nd any of the following:

• Climber straps that

are worn, cut, burned,

have elongated holes,

or loose buckles.

• Worn climber pads

that have broken rivets

or loops. (A)

• Hook-n-Loop pads

sleeve retaining strap is

damaged or missing.

• Hook-n-Loop closure will not stay secured, climber pad has broken

stitches, or steel loop on top slide is damaged or not secured to pad.

- CAUTION -

The average useful life of Bashlin

Climbing Equipment based on normal usage:

Tool Belts 5 - 8 years

Climbers 2nd set of gaffs

Pole Straps 1 - 4 years

A

7

• Climber shanks

Inspect critical area of the shank,

(4-8" above the gaff) for deep

scratches or cuts. Flex the shank

visually inspecting this area for any

cracks. (A) You can also run your

thumbnail along the edges to look to

nd any indentations or marks that could

indicate a crack in the shank section.

A crack will form prior to the shank

breaking. Close and regular inspection

could reveal the weakness before it

breaks in the eld.

• Stirrup

If the lettering is worn off the

foot tread of the BD14B climber,

carefully inspect for adequate

thickness. (B)

Compare the stirrup

section with a new

climber shank. (C)

The minimum measurement is

7/16" for continued use.

• Loose gaffs

• Short or improperly shaped

gaffs as determined by using

Bashlin’s No. 5 gauge.

Shanks should be replaced

when they no longer meet the

inspection criteria or when the

second set of gaffs wears out.

B

C

A

8

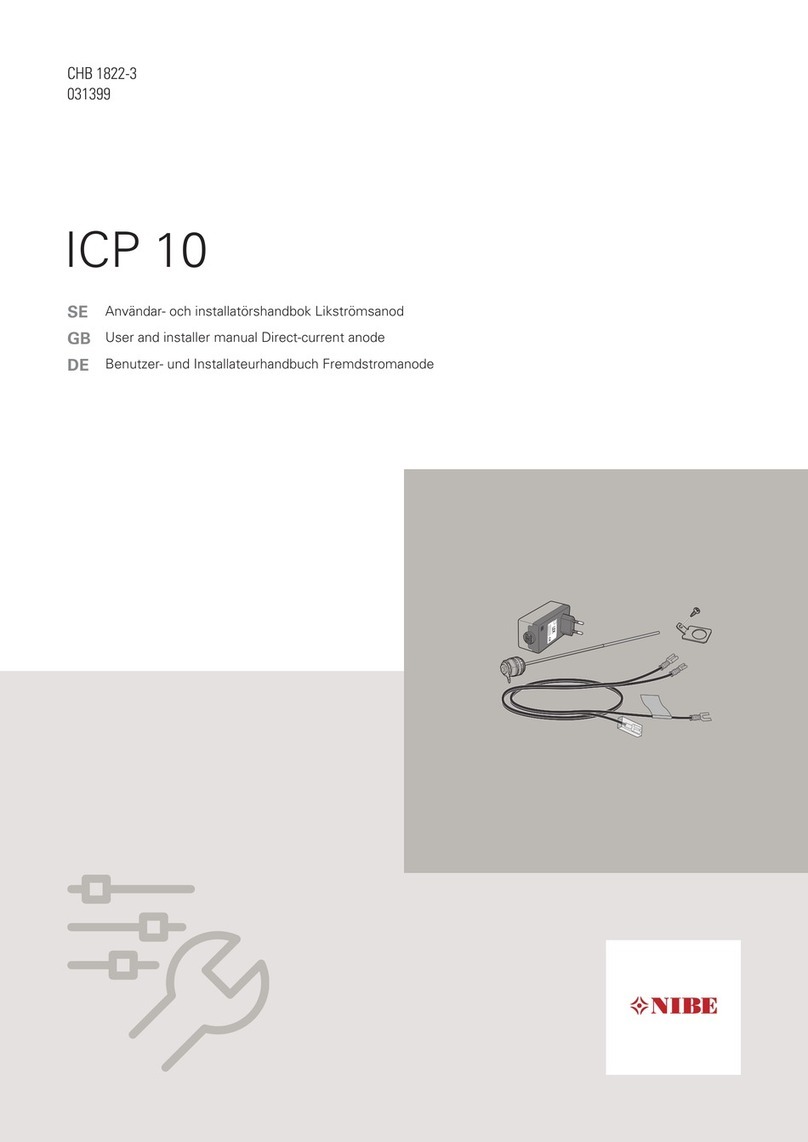

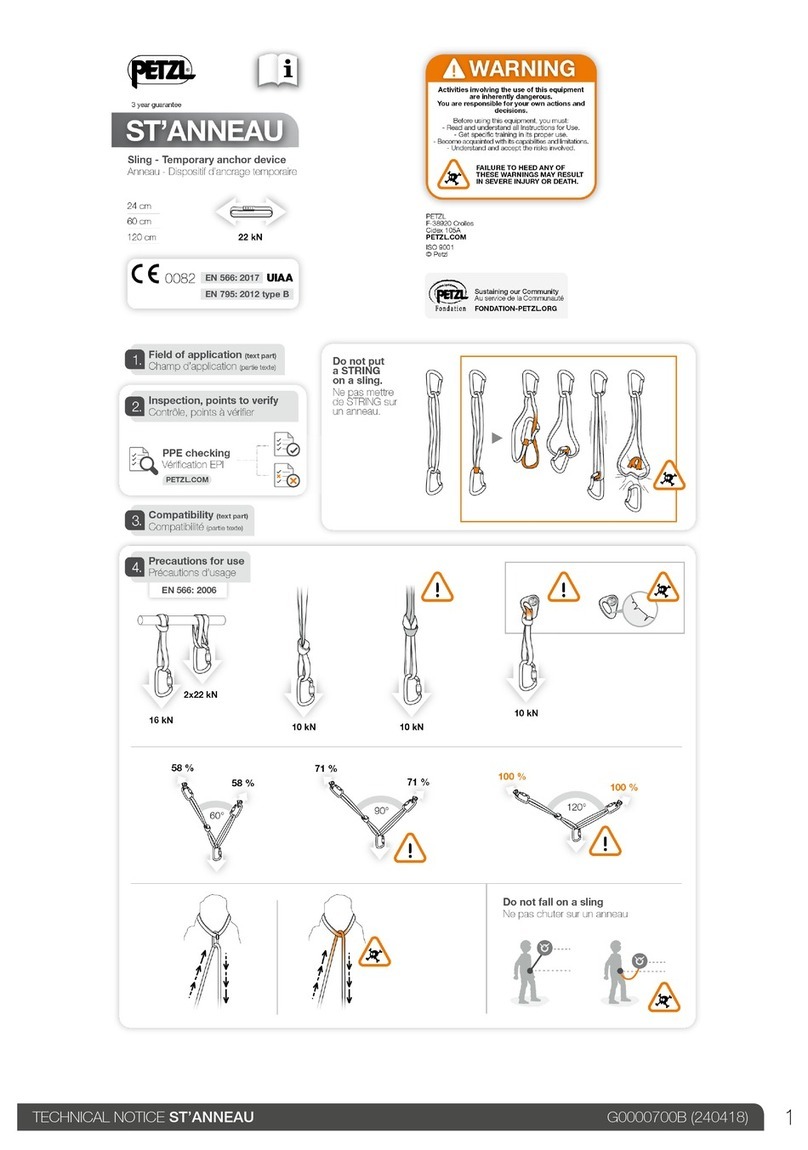

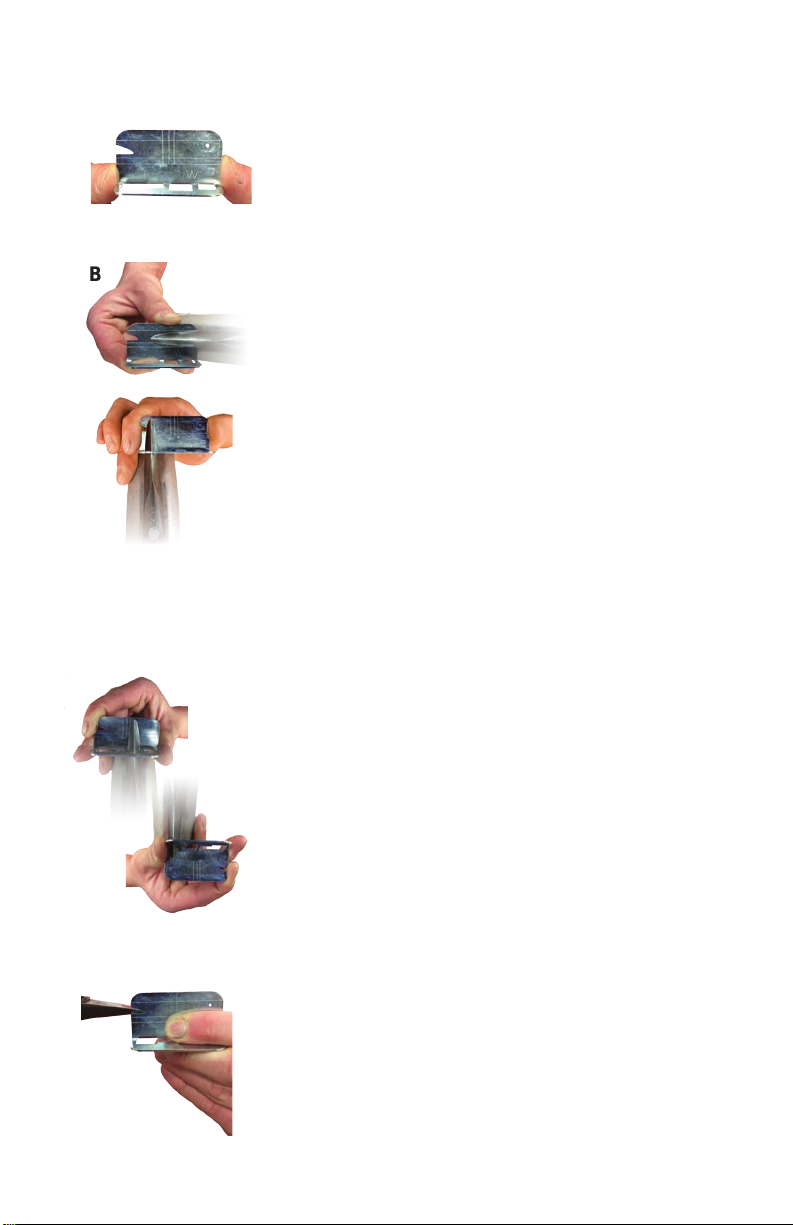

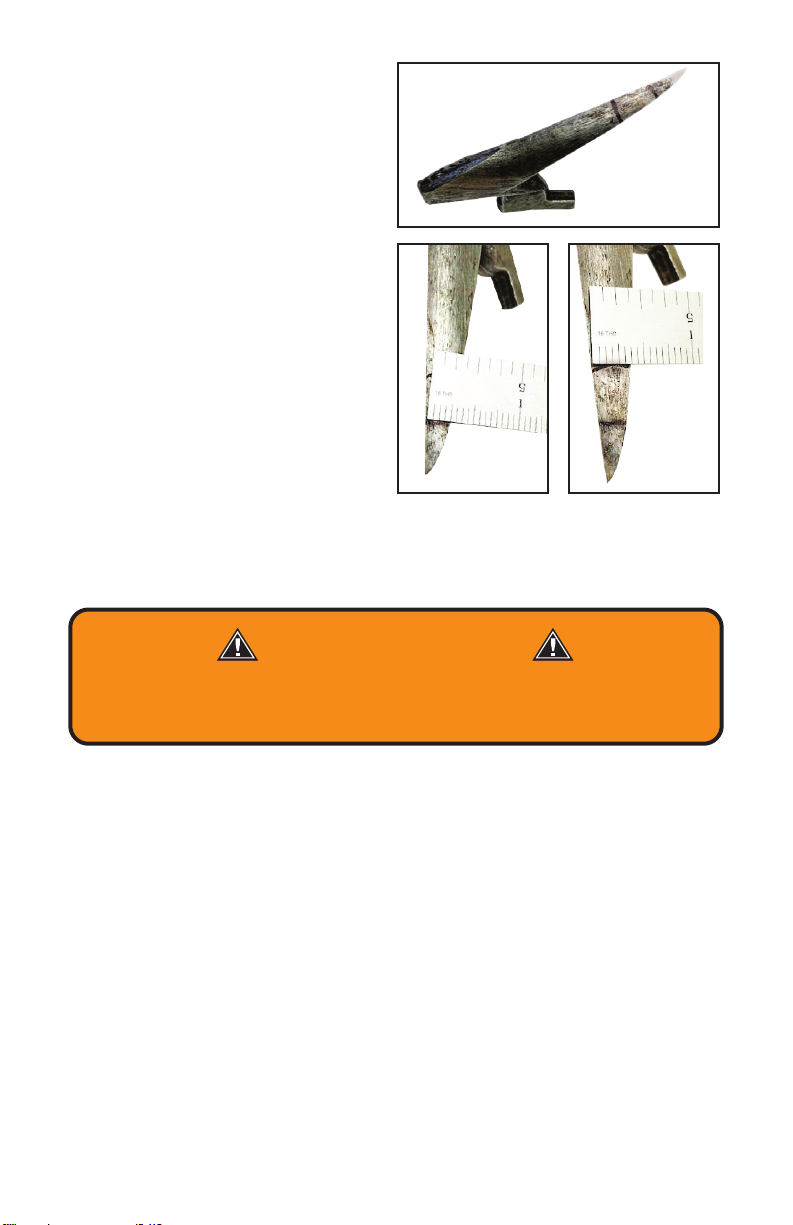

Using the Bashlin No. 5 Gaff Guage

A. Length

Place the gaff on the gauge as indicated in the

picture. The tip of the gaff should extend beyond

the line furthest from the edge, indicating the length

is at least 1 1⁄4". If the gaff is too short it must be

replaced.

B. Thickness

Insert the gaff into the larger portion of the section

of the gauge marked with a “T”. Make sure the

gaff is lying at against the gauge. When the gaff

is placed in the larger opening the cross section of

the gaff roughly 1" from the tip is being measured.

The tip should fall between the edge of the gauge

and the rst line. If it falls over the edge, it is too

thin and should be replaced. If it falls short of the

line, it is too thick and must be reshaped. Repeat

the procedure placing the gaff in the smaller portion

of the section marked with a “T”. Now the thickness

of the gaff is being measured at a point roughly 1⁄2"

from the tip. The end of the gaff should fall between

the two parallel lines above the “T”. If it is long,

replace the gaff. If it is short, shape the gaff. (See

Maintenance Section)

C. Width

Repeat the general procedure used to measure the

thickness of the gaff on the section of the gauge

marked with the “W”. Slide the gaff into the larger

portion of the “W” section. Make sure the gaff is

at on the gauge. The tip should fall between the

end of the gauge and the rst line. If it goes over

the edge, replace it. If it falls short, shape the gaff.

Continue the inspection by placing the gaff in the

smaller portion of the “W” section. Replace the gaff

or reshape it as is required by the gauge.

(See Maintenance Section)

D. Shape of the tip of the gaff

There is a small section cut out of the left side of

the gauge. This is used to determine if the tip of the

gaff is shaped correctly. Place the tip of the gaff in

the cut-out as indicated. The shape of the tip should

approximate the curve of the cut-out. The shape of

the tip can be conrmed by testing the tip using the

Pole Cut-Out Test shown on page 10.

A

B

C

D

9

E. Size of the tip of the gaff

There is a small hole in the gauge used to determine

if the tip of the gaff is thick enough. Simply place

the small hole on the right side of the gaff gauge on

the tip of the gaff. If the tip of the gaff protrudes far

enough through the hole that you can feel it, the tip

is too thin and may break during normal use. The

gaff should be removed from service.

Maintenance of

Bashlin Climbers

Your climbers, especially the straps

and pads should be cleaned and the

pads oiled regularly. Replace any old

or worn screws, sharpen and shape

your gaffs as needed.

Sharpening the Gaffs on

your Bashlin Climbers

Using wood blocks to protect the

shank, put the climbers in a vise with

the underside of the gaff exposed (A).

Place a 6" mill le across the gaff,

against the heel and draw it towards

you, following the rounded shape

of the gaff tip. Filing in this method

sharpens (B) the edges of the gaff

and maintains the correct shape of

the tip (C). If you prefer the edges to

be sharper, use a honing stone.

Bashlin’s No. 27 Gaff Shaping Kit has all

of the tools needed to maintain your gaffs

E

- WARNING -

Climbing equipment that does not meet inspection

criteria must be removed from service.

A

B

C

10

Shaping the Gaffs on your Bashlin Climbers

Block the climber in a vise and turn the climber over so the ridge of the

gaff is exposed. Using the 6" mill le, make smooth rounded cuts and

remove as much material as is needed to size the gaff to t correctly into

the gauge. Never le the ridge on the back of the gaff. Check the gaff on

the gauge, turn the climber over and sharpen the edges one more time.

Pole Cut Out Test

1. Wearing a pair of gloves, attach

the bottom strap of one of your

climbers.

2. Grasp the top of the shank and

touch the tip of the gaff against

the pole at a comfortable height

that will be easy to step into.

3. Holding the top of the shank

against the pole, step into the

stirrup. Steady yourself with your

other hand.

4. The properly shaped gaff should cut into the pole within an inch.

An improperly shaped gaff will break out of the pole.

For additional information regarding the care and maintenance

of pole climbing equipment, refer to the Lineman’s and Cableman’s

Handbook by Kurtz and Shoemaker, (Bashlin No. 831).

Your Climbers should

be eld tested before

returning to service.

11

Replacing Bashlin Gaffs

Tools needed include a vise, hammer,

2 blade type screwdrivers with1/4" and

1/2" blades, a 12" adjustable wrench.

You may need a 3/16" Allen Wrench.

1. Remove the adjustable top slide and

pad from the climber.

2. Holding the shank in one hand, strike

the gaff on the outside of the shank, at

the point where the large screw is in the

gaff. This will help loosen any corrosion

between the screw and the gaff. (A)

3. Place the climber shank in the vise,

placing the jaws on the gaff, with the

screw up and exposed. (B)

4. Use a square shank screwdriver that

completely lls the slot. (C) Hold the

screwdriver tightly in place and loosen

the screw using the wrench on the

shank. Avoid stripping the screw by

keeping constant pressure on the

screwdriver. If your gaff screw has a Hex

head screw you will need a 3/16" Allen

wrench. (C)

5. Remove the smaller screw completely.

6. Lightly tap the top of the gaff, then pull

the top away to remove it from the

shank. (D)

Installing the New Bashlin Gaff

1. Insert the gaff into the slot of the shank.

2. Drive the gaff into position. This is done

by either placing the lip of the gaff on a

hard edge, or placing the gaff in a block

of wood and driving the gaff into position

by striking the top of the shank with a

hammer. When the holes are aligned, it

is in the proper position.

3. Insert the large then the small screw,

and tighten.

4. Replace the top slide adjuster and pads.

B

A

C C

D

12

Inspecting and Shaping Bashlin Tree Climbers

No. 14 No. 14T

Bashlin Tree Climbers must be inspected prior to

each use. Please follow the inspection procedures

outlined on pages 6 and 7 in this booklet.

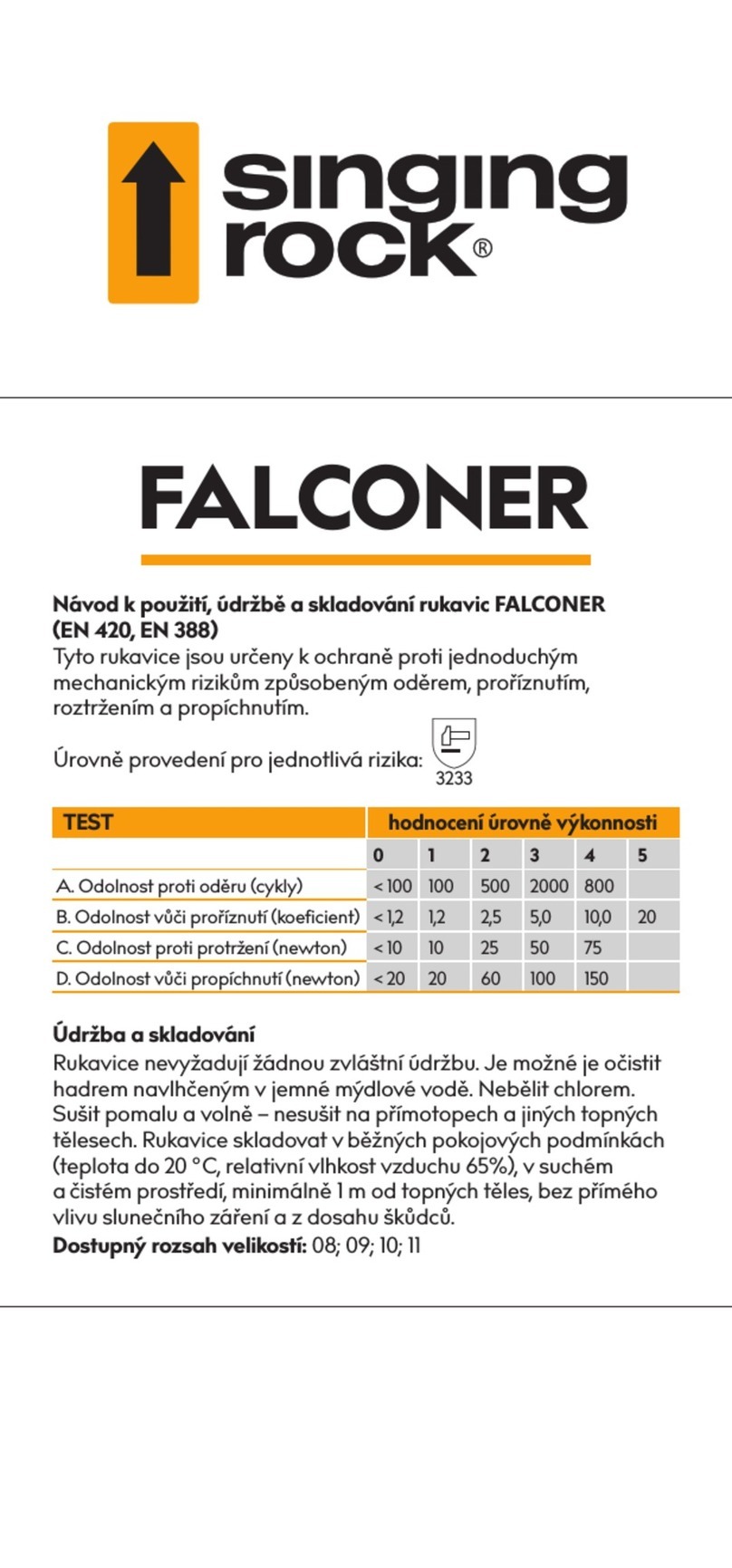

Inspecting Bashlin 14T Tree Gaffs

Length

Measure the bottom face of the gaff

from heel to tip (A). If the gaff is shorter

than 2-1/4", the gaff must be removed

from service.

Width

Mark two lines across the bottom face

of the gaff approximately 1/2" and 1"

from the tip of the gaff (B).

To verify width, measure across each mark.

The width of the gaff at the 1/2" mark should

be approximately 5/16" (C). The width at the

1" mark should be approximately 7/16" (D).

If either measurement is short, the gaff

is too narrow and must be removed from

service. If either measurement is long,

reshape the gaff.

Bashlin Tree Climbers are available in offset steel BD16BT, offset steel

with a twist BD16BCT, and lightweight aluminum BD14BT.

Bashlin No. 14T Tree Gaffs differ from the traditional No. 14 Pole Gaffs in

both length and shape as shown in the images above.

A

B

DC

13

Thickness

Continue the 1/2" mark and th 1"

mark up to the gaff spine on both

sides of the gaff. Marks should be

perpendicular to the bottom face of

the gaff (E).

To verify thickness, measure the

length of each mark. The thickness

of the gaff at the 1/2" mark should

be approximately 1/4" (F). The

thickness of the gaff at the 1" mark

should be approximately 3/8" (G).

Measure and evaluate both sides

of the gaff to ensure that neither

side is too thin.

If any measurement is short,

the gaff is too thin and must be

removed from service. If any

measurement is long, reshape

the gaff.

E

GF

Shaping your Bashlin Tree Gaffs

Block the climber in a vise as shown on page 10 in this booklet.

Using a 6" mill le, make smooth rounded cuts to shape the gaff.

Never le the ridge on the back of the gaff and remove only

as much material as needed to shape the gaff.

After you have reshaped your gaff use the Pole Cut Out Test on page 10.

If you need to replace your gaffs follow the instructions on page 11.

- WARNING -

Climbing equipment that does not meet inspection

criteria must be removed from service.

14

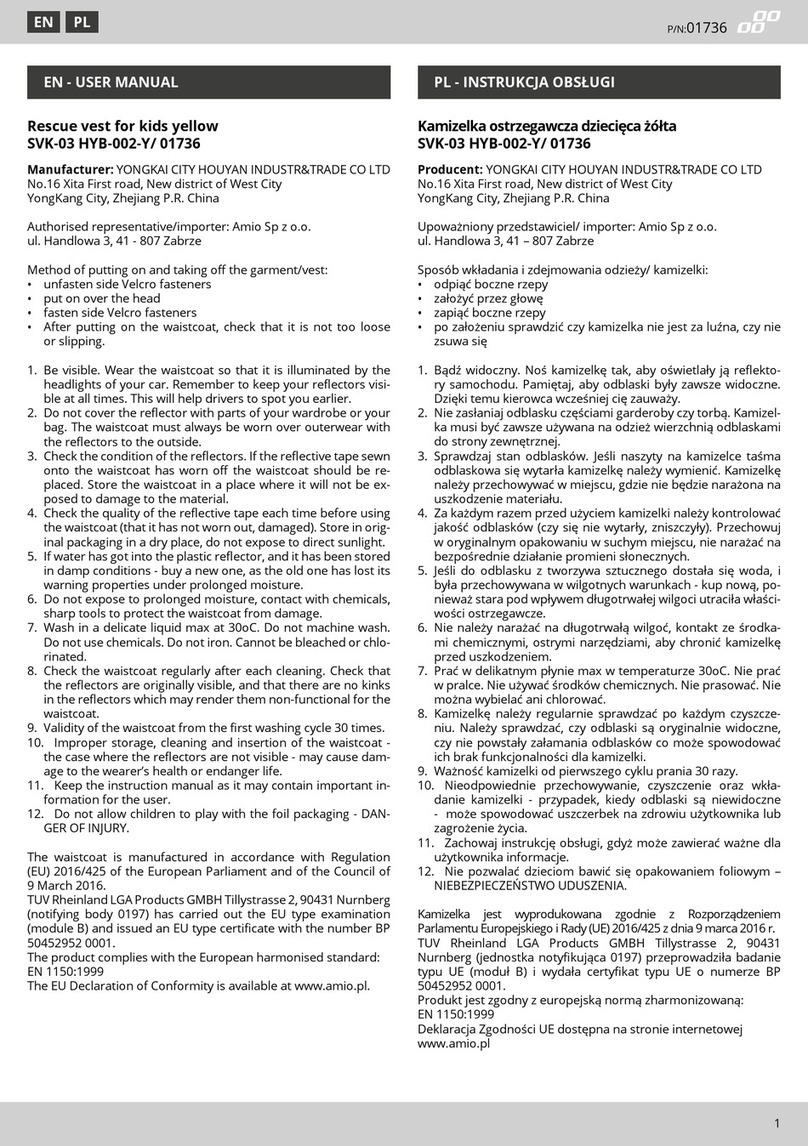

Replacing Bottom Straps on Bashlin Climbers

Your Bashlin Climbers come from the factory with bottom straps

installed. Over time they will wear out and require replacement. Before

replacing the straps, inspect your shanks per the instructions. If the

shanks are worn out, remove them from service and destroy them.

Only work on one shank at a time.

Use the other shank as a pattern for your work.

Installing 89N Bottom Straps

1. If your climbers have a triangle

ring, remove it using a hack saw

or bolt cutters. Inspect the lug

for cracks or excessive wear.

2. Block the climber in a vise with

lug exposed.

3. Using a screwdriver, open

the split ring and slide through

the hole. The buckle should

be toward the front of the

shank. (A)

4. Completely thread the ring

onto the shank.

5. Repeat the procedure on the

other shank.

Installing 87N

Bottom Straps

1. Inspect the triangle ring for

excessive wear, cracks, burns

or deformation. If there is any

question regarding the condition

of the ring, do not use it. Either

remove the shank from service

or if it is in otherwise good

condition, consider the use of

the 89N bottom strap assembly.

2. Remove and replace the long

strap. Tighten the screw-type

rivets (B).

B

A

A

87N Bottom

Strap Assembly

15

3. Remove the buckle

strap. Assemble the new

buckle assembly on the

shank using the other

shank as a pattern. It

is easiest to place the

leather keeper under

the strap, then insert the

screw-rivet in the hole

closest to the ring (C),

insert the second rivet

(D), and tighten both

screws.

4. Perform steps 1, 2, and 3

on the other shank.

5. Once you are certain

the assemblies on both

shanks are correct,

tighten all of the rivets,

and clip the ends off of

the screws (E). One at a

time, place the head of

the screw on a hard

surface and round off

the clipped ends of

the screw-rivets with

a hammer (F). This

will keep the rivet from

loosening up. A rivet

working loose may cause

an accident.

6. Finally, remove any

sharp edges on the

clipped end of the rivets

using a le, sand paper

or emery cloth.

C

D

F

E

16

Bashlin BHP Heel Covers are designed to help reduce injury to the

ankle and Achilles’s tendon while climbing. Made from PVC material that

is both durable and exible, these heel covers are sold in pairs marked

Left and Right and are compatible with most pole and tree climbers.

1. With the BHP

facing you, insert

the climber shank

through the tunnel

loop and slide it

down to the gaff. (A)

2. Push the climber

strap down through

the outside slot in

the cover and pull it

through (B).

3. Push the climber

strap down through

the outside slot in

the cover and pull it

through (C, D).

Installing Bashlin BHP Heel Covers

A

C

B

D

17

Inspection Record

Part Number ___________________ Date in Service ________________

Employee_____________________________________________________

Date of Inspection

This equipment must be inspected daily by the user.

Please feel free to copy this form.

Thank you for using Bashlin Products. For more information

or if you have questions please contact us:

Comments Inspected By

POBOX867 • 119W.PINEST. • GROVECITY,PA16127

Table of contents

Other BASHLIN Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Tractel

Tractel solsit 2000 Operating and maintenance manual

3M

3M Protecta AC202C-SA2 User instructions

elobau

elobau eloFlex 471EFR Series manual

NUOVA ELETTRONICA

NUOVA ELETTRONICA DSP LASER instruction manual

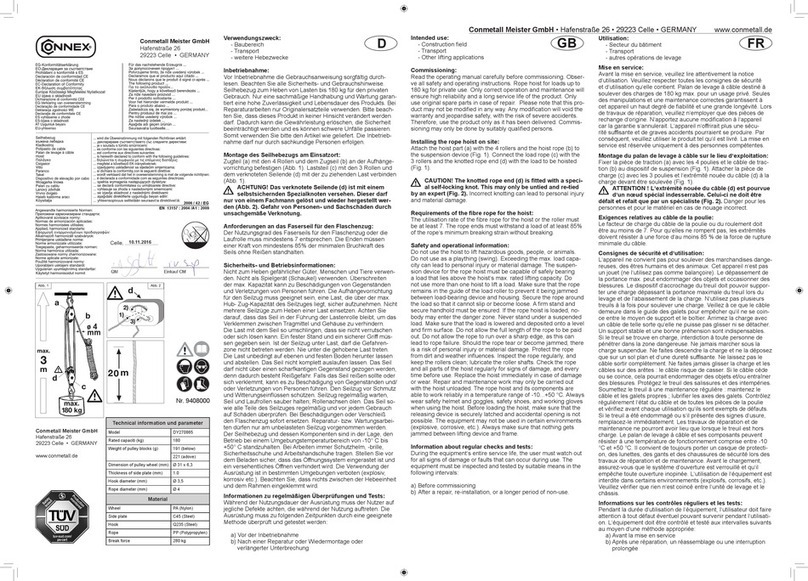

Conmetall Meister

Conmetall Meister Connex DY270865 manual

KStrong

KStrong Brute Series User instruction manual