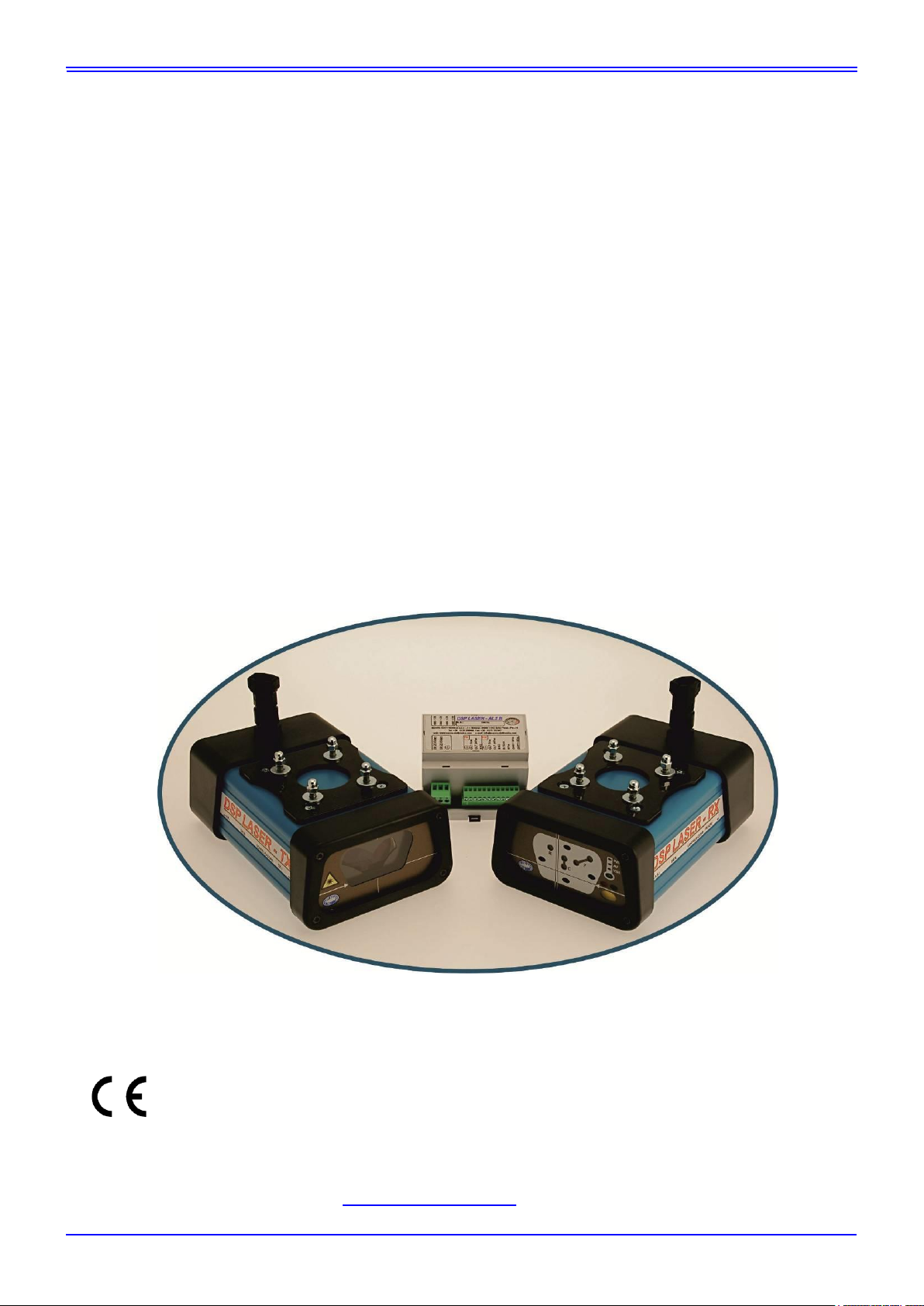

DSP LASER

4 DSPLSR01EN

5. Contents

1. Foreword..................................................................................................................... 1

1.1. General Information ............................................................................................ 1

2. Symbols used in the manual ..................................................................................... 2

3. Warranty...................................................................................................................... 3

4. Technical Service....................................................................................................... 3

5. Contents...................................................................................................................... 4

6. Safety precautions ..................................................................................................... 6

6.1. Signals of residual risks ...................................................................................... 6

6.2. Precautions......................................................................................................... 6

6.3. Dangers of electrical kind.................................................................................... 6

6.4. Prohibitions......................................................................................................... 6

6.5. Checks................................................................................................................ 6

6.6. Spare parts......................................................................................................... 7

6.7. Decommissioning................................................................................................ 7

7. Key .............................................................................................................................. 8

8. Planning safety measures ......................................................................................... 9

9. Introduction ...............................................................................................................11

9.1. Operating cycle of a bending press-brake..........................................................13

9.2. Foreseen use of the DSP LASER device...........................................................14

9.3. Operating principle.............................................................................................15

10. Requirements necessary for the correct use of DSP LASER........................16

10.1. Command circuit of the press-brake...................................................................16

10.1.1. Start and stop......................................................................................................16

10.1.2. Inhibition..............................................................................................................16

10.1.3. Operating modes ................................................................................................17

10.1.4. Check of overtravel or stop space......................................................................25

10.1.5. Interlock of restart ...............................................................................................28

11. Residual risks...................................................................................................29

11.1. Risks due to the Laser .......................................................................................29

11.2. Risks due to mechanical dangers.......................................................................29

11.2.1. Manual sheet support .........................................................................................29

11.2.2. Blanking ..............................................................................................................30

11.2.3. Installation and uninstallation of tools.................................................................31

11.2.4. Work organization...............................................................................................31

12. Signals and plate data......................................................................................32

12.1. Light indicators: scheme and functions...............................................................32

12.1.1. Display of the phase of stop space check ..........................................................32

12.1.2. Display of the alignment with four LEDs.............................................................33

12.1.3. Alignment LED....................................................................................................33