Bastian Solutions Shoe Sorter Manual

Installation and Maintenance Manual

Model: Shoe Sorter

Effective October 2019

Rev. A1

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

2

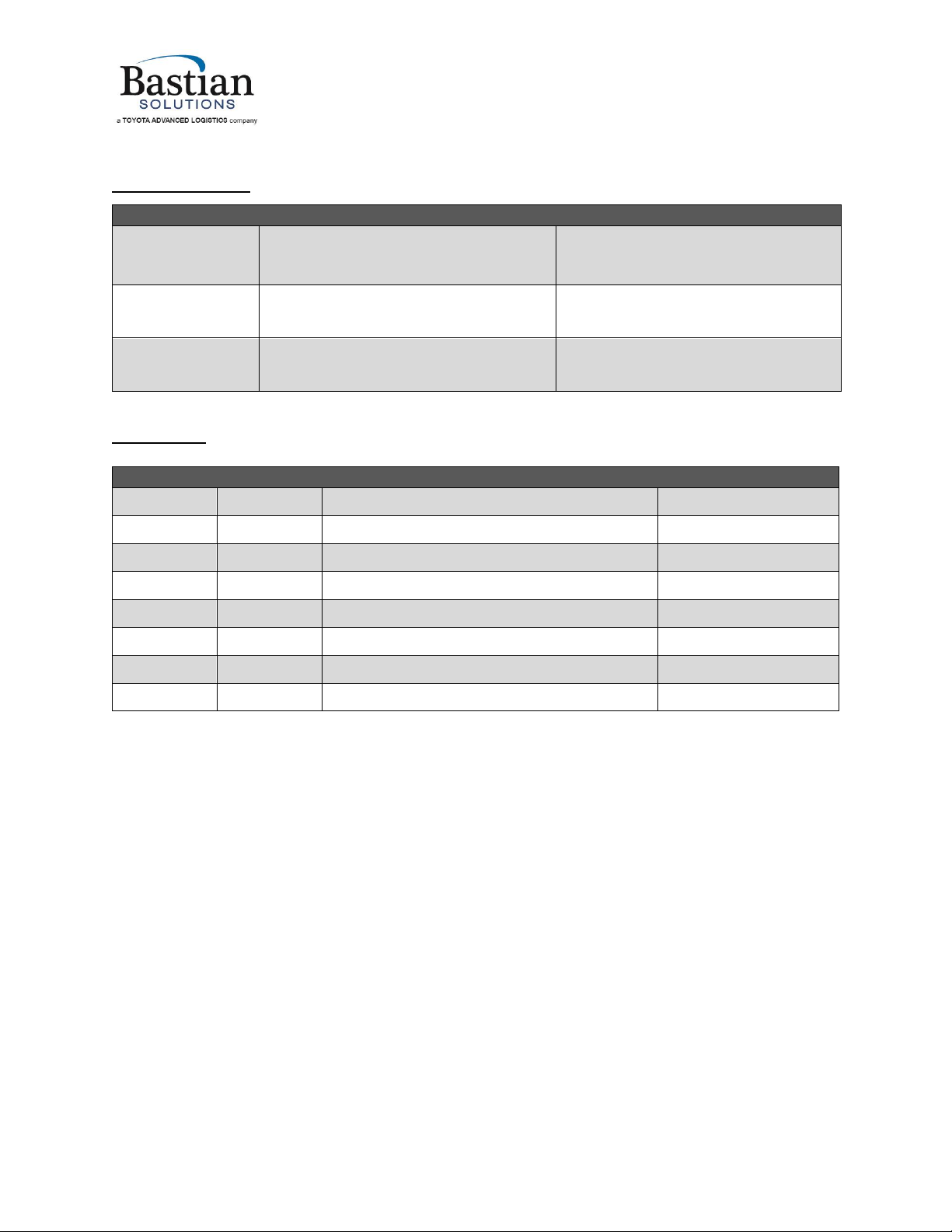

Contributions

Revisions

ROLE

NAME

TITLE

Author

Ben Baker

Senior Design Engineer

Checker

Sam Osterhout

Project Engineer

Approver

Chris Perry

Engineering Manager

DATE

REVISION

REVISION DESCRIPTION

AUTHOR

10/21/2019

A1

Initial document creation

Ben Baker

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

3

Term and Acronym Definitions

TERM/ACRONYM

DEFINITION

AC

Alternating current

Accumulation

The collection or staging of multiple cartons, cases, or totes of product on conveyor.

Back pressure

Pressure against carton(s) in the direction of carton flow resulting from weight of densely

accumulated cartons.

BF

Between frame; this refers to the distance between conveyor bed side frames.

BHCS

Button head cap screw

BOM

Bill of Materials

BRBDC

Belted Roller Bed Direct Current; DC roller conveyor format driven by brushless DC servo

motors.

Carton or Case

Term for conveyable items generally contained in cardboard boxes.

CB

Carriage bolt

CCW

Counter-clockwise

CW

Clockwise

DC

Direct current

DC Card

A control card used to power and control the logic used when operating a MDR in DC

conveyor applications.

Diffuse

A photoeye format that houses both the emitter and receiver and senses an object when

the light beam is reflected back to the sensor. This type of photoeye is a standalone unit

and does not use reflectors.

Discharge

The point where cartons, cases, or totes exit a conveyor or similar unit used in a material

handling system.

Divert

(noun) A conveyor unit used to change the direction of a carton, case, or tote in a

controlled manner. (verb) To change the direction of a carton, case, or tote in a

controlled manner.

Drive Pulley

A motor-driven pulley used to transmit rotational energy to linear motion in AC belts.

E-stop

A highly visible button or pull cable designed to shut down equipment in the case of an

emergency.

ETO

Engineered to Order; Orders requiring custom Engineering

FAT

Factory Acceptance Testing

Flange

A feature in sheet metal consisting of a face and bend connected to an existing face

along a straight edge.

Gapping

The separation of cartons, cases, or totes which are initially in contact with one another.

Generally done by progressively increasing the speed of consecutive zones, forcing

cartons, cases, or totes to "pull a gap."

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

4

TERM/ACRONYM

DEFINITION

Guide Rail

Mechanism used to maintain the desired position of conveyable cartons, cases, or totes

on their respective conveying surface.

HHCS

Hex head cap screw

HMI

Human-Machine Interface; an operating console or control panel of a conveyor system.

HTL

High Threshold Logic. In the context of an encoder, a differential push-pull output

intended to operate on 24VDC.

ID

Inner diameter of a circular, cylindrical or arced body.

Idler Roller

Cylindrically-shaped material handling component that is unpowered and used to

support a belt.

Infeed

The point where cartons, cases, or totes enter a conveyor or similar unit used in a

material handling system.

LOTO

Lockout Tagout

Mark Number

A numeric or alphanumeric term used to uniquely identify a conveyor bed or collection

of beds (of similar model type) within a material handling system.

Match

A mark made on mating conveyor assemblies to assist in identifying orientation and

placement within a system.

MDR

Motorized drive roller; DC powered conveyor roller with an internally mounted motor

which may be controlled via internal or external commutation.

MSD

Master specification document; a document used to describe a product's intended

capabilities, appearance, and interaction with users.

NO

Normally Open

OAW

Overall width of any given conveyor bed.

OD

Outer diameter of a circular, cylindrical, or arced body.

O-Ring

A plastic ring with a circular cross section used for power transmission in DC conveyor

applications.

OSHA

Occupational Safety and Health Administration

OTD

On-Time Delivery

Photoeye

Device used to detect the presence of an object-such as a carton, case, or tote-by use of

an emitter and receiver (not necessarily in the same unit as one another).

PM

Project Management (or Project Manager)

PO

Purchase Order

PPE

Personal protective equipment

Proximity Sensor

(“Prox”)

A sensor able to detect the presence of nearby objects without any physical contact.

Typically an inductive sensor that detects nearby electrically conductive (metal) objects.

Pulley

Mechanical device used to change the direction of the belt in a conveyor system, to drive

and/or tension the belt.

Reflector

A reflective component needed for retroreflective photoeyes to receive transmitted light

or radiation when no object is in front of the photoeye.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

5

TERM/ACRONYM

DEFINITION

Retroreflective

Of or relating to a surface or device that reflects light or other radiation back to its

source.

Return Idlers

Belt-routing rollers on the underside of any given AC conveyor.

RLSDC

Roller Live Spur Direct Current; DC roller conveyor powered by live MDRs and configured

as a spur.

Roller

Powered or unpowered cylindrically-shaped material handling component used for

mechanical power transmission, a conveying surface, and/or support for a belted

conveying surface.

Shingling

Event in which surfaces of adjacent cartons, cases, or totes are forced to lift off the

conveyor due to elevated uneven carton, case, or tote back pressure.

Shoe

A sliding element that engages with cartons, cases, or totes to divert from a shoe sorter

onto a spur.

Side Cover

A PVC cover used to conceal and protect electrical components and wiring from foreign

debris and moving obstacles.

Side Frame

Structural member used to support rotating components needed for conveyor beds.

Singulation

The active separation of cartons, cases, or totes.

Skatewheel

Small unpowered wheels used to replicate nearly frictionless guidance or support of

conveyable cartons, cases, or totes.

Skew

A format of DC conveyor where one end of all rollers are shifted one roller position to

provide an angled conveying surface for left or right justification of cartons, cases, or

totes.

SKU

Stock Keeping Unit; Product and service identification code for a product (i.e. bar code).

Slug

Collection of two or more cartons, cases, or totes that are in contact with one another.

Snub Roller

A roller or pulley mounted to increase the arc of contact between a belt and drive pulley.

Additionally, this can be used to change the direction of the return belt travel.

Sorter

Any piece of conveyance equipment used to divert a series of cartons, cases, or totes

simultaneously.

Splice Assembly

A five-component assembly-consisting of a plate (or formed plate), two bolts, and two

nuts-that is used to secure a piece of guide rail to an adjacent piece of guide rail, or a

side frame to an adjacent side frame. This is used to provide additional structural rigidity

and ensure relative position of components is maintained.

SPST

Single Pole Single Throw; a type of electrical switch.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

6

TERM/ACRONYM

DEFINITION

Spur

A format of DC conveyor used to create linear transitions into intersecting lines of

conveyor positioned at a non-perpendicular angle. Typically includes 30deg and 22deg

configurations.

Tail Pulley

A non-driven pulley located at the tail end of the conveyor.

Takeup Pulley

Pulley with an adjustable position used to eliminate unnecessary slack in a belt.

Takeup Screws

Adjustment screw used to adjust the position of a takeup pulley.

TOCS

Top of Conveying Surface; this refers to the elevation of the conveying surface with

respect to the floor on which the conveyor is sitting. Interchangeable with TOR but

applicable to non-roller conveyors as well.

TOR

Top of roller; this refers to the elevation of the conveying surface with respect to the

floor on which the conveyor is sitting.

Track

To adjust the position of conveyor components in such a way that engourages proper

belt alignment on a system.

Tracking Bands

Thin plastic bands installed on head or secondary drive roller to help keep DC format

conveyor belts tracked.

UHMW

Ultra-high molecular weight polyethylene

VFD

Variable Frequency Drive. An electronic variable-speed control for an AC induction

motor.

Waterfall

Method of overlapping guide rail such that cartons, cases, or totes cannot catch on

downstream guide rail.

Wiz Nut

A serrated flange nut used to cut into the surface of the component it is tightened

against.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

7

Table of Contents

1Introduction ................................................................................................................. 11

2OSHA And Safety.......................................................................................................... 11

3Model: Shoe Sorter....................................................................................................... 11

4Receiving...................................................................................................................... 12

4.1 Mark Numbers..................................................................................................................12

4.2 Skid Contents....................................................................................................................13

4.3 Skid Documentation..........................................................................................................13

5Installation................................................................................................................... 14

5.1 Mechanical Installation .....................................................................................................14

5.1.1 Bed Section Placement ..........................................................................................................................14

5.1.2 Floor Support Installation ......................................................................................................................14

5.1.3 Section Fastening and Rail Alignment....................................................................................................15

5.1.4 Spur Installation.....................................................................................................................................17

5.1.5 Chain Installation ...................................................................................................................................19

5.1.6 Slat Installation ......................................................................................................................................21

5.1.7 Initial Startup Procedure........................................................................................................................23

5.1.8 Setting Infeed Conveyor ........................................................................................................................23

5.1.9 Setting Discharge Conveyor...................................................................................................................27

5.1.10 Installing Guards and Guiderail..............................................................................................................28

5.1.11 Installing Side Covers .............................................................................................................................29

5.1.12 Setting Oiler Flow...................................................................................................................................30

5.2 Electrical Installation.........................................................................................................32

5.2.1 Drive Motor Settings..............................................................................................................................32

5.2.2 Components requiring 3 phase AC power connections.........................................................................33

5.2.3 Components requiring 24VDC power connections................................................................................33

5.2.4 Components requiring 48VDC power connections................................................................................34

5.2.5 List of Sensors (discrete)........................................................................................................................34

5.2.6 Communication between system PLC and divert control box...............................................................36

6Operation..................................................................................................................... 38

6.1 Startup Procedure.............................................................................................................38

6.2 Troubleshooting Faults......................................................................................................39

7Maintenance ................................................................................................................ 40

7.1 Slat and shoe repair, replacement, and service ..................................................................40

7.2 Divert switch repair, replacement, and service...................................................................41

7.3 Chain Adjustment..............................................................................................................41

7.4 Recommended Preventative Maintenance Schedule..........................................................42

Appendix 1 Section Weights........................................................................................... 44

Appendix 2 Oiler System Recommended Flow Rates and Lubrication Intervals ............... 46

Appendix 3 General Arrangement Drawings................................................................... 47

Appendix 4 Electrical Schematics for Divert Control Box................................................. 70

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

8

List of Figures

Figure 1-Shoe Sorter Section Types and General Arrangement.................................................................11

Figure 2-Mark Number Stickers..................................................................................................................12

Figure 3-Skid Sticker....................................................................................................................................13

Figure 4-Floor Support Installation Detail ..................................................................................................15

Figure 5-Bed Section Fastening Detail ........................................................................................................16

Figure 6-Typical Spur Positioning................................................................................................................18

Figure 7-Spur Mounting Detail....................................................................................................................18

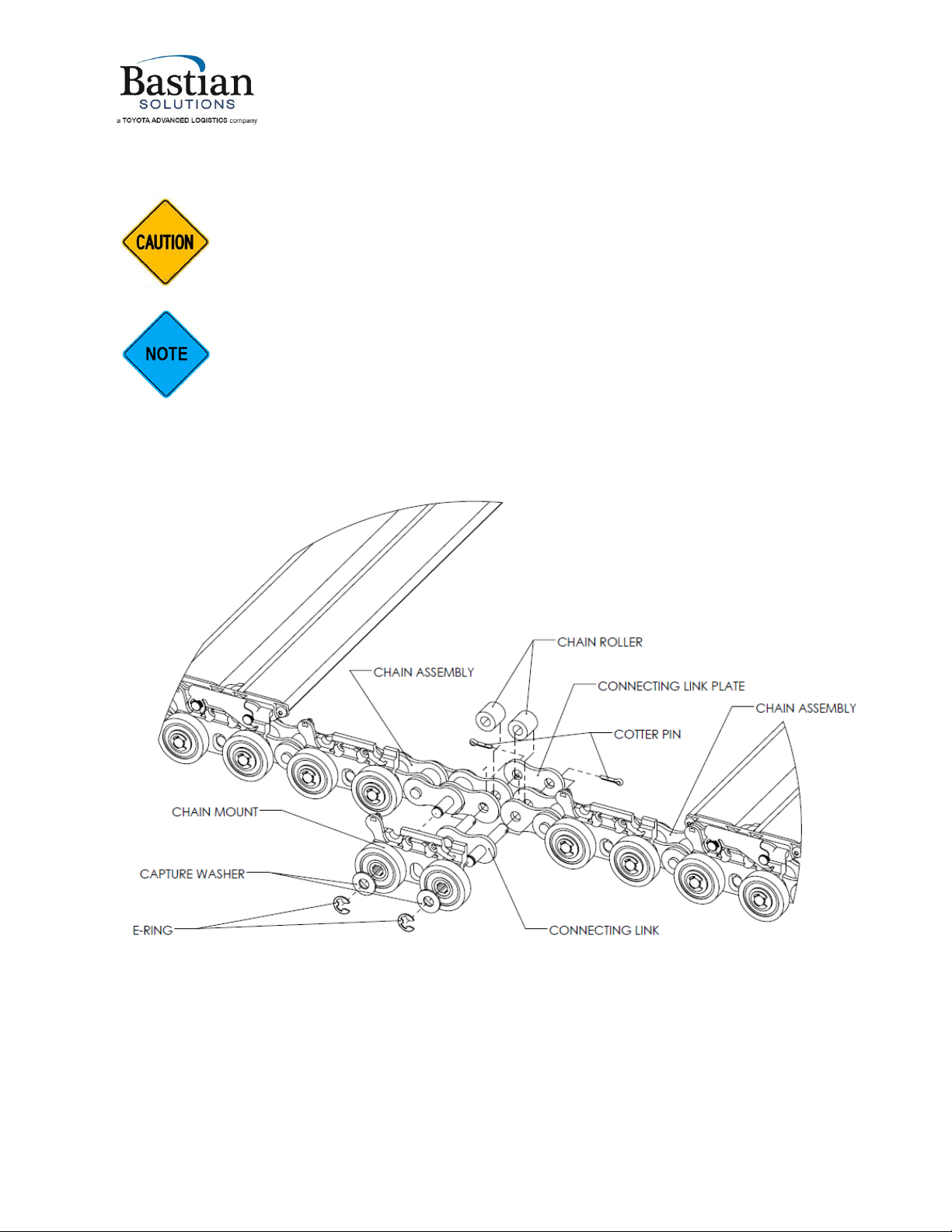

Figure 8-Chain Connection Detail ...............................................................................................................19

Figure 9-Slat Installation Detail...................................................................................................................21

Figure 10-Spring Clip Seating Detail............................................................................................................22

Figure 11-Knife Edge Installation Positioning .............................................................................................24

Figure 12-Knife Edge Nosebar Positioning Detail .......................................................................................25

Figure 13-Side View of Knife Edge Conveyor..............................................................................................26

Figure 14-Belt Tracking by Adjusting Snub Rollers .....................................................................................27

Figure 15-Discharge Transition Assembly Positioning Detail......................................................................28

Figure 16-Chain Guard, Guiderail, and Side Cover Installation...................................................................29

Figure 17-Oiler Pump and Flow Adjustment Panel.....................................................................................32

Figure 18-General Arrangement, Shoe Sorter Slat and Chain Exploded View, Sheet 1 of 1 ......................47

Figure 19-General Arrangement, Shoe Sorter Divert Section, Sheet 1 of 2 ...............................................48

Figure 20-General Arrangement, Shoe Sorter Divert Section, Sheet 2 of 2 ...............................................49

Figure 21-General Arrangement, Shoe Sorter Divert Switch, Sheet 1 of 3.................................................51

Figure 22-General Arrangement, Shoe Sorter Divert Switch, Sheet 2 of 3.................................................52

Figure 23-General Arrangement, Shoe Sorter Divert Switch, Sheet 3 of 3.................................................53

Figure 24-General Arrangement, Shoe Sorter Divert Receiver and Shoe Return, Sheet 1 of 1 .................54

Figure 25-General Arrangement, Shoe Sorter Tail, Sheet 1 of 2 ................................................................55

Figure 26-General Arrangement, Shoe Sorter Tail, Sheet 2 of 2 ................................................................56

Figure 27-General Arrangement, Shoe Sorter Drive, Sheet 1 of 2 .............................................................57

Figure 28-General Arrangement, Shoe Sorter Drive, Sheet 2 of 2 .............................................................58

Figure 29-General Arrangement, Shoe Sorter Discharge Transition, Sheet 1 of 1.....................................60

Figure 30-General Arrangement, Shoe Sorter Oiler, Sheet 1 of 1 ..............................................................62

Figure 31-General Arrangement, Shoe Sorter Chain Guide Fastening Detail, Sheet 1 of 1........................63

Figure 32-General Arrangement, Shoe Sorter Debris Sensor Detail, Sheet 1 of 1 .....................................64

Figure 33-General Arrangement, Shoe Sorter Knife Edge, Sheet 1 of 2.....................................................66

Figure 34-General Arrangement, Shoe Sorter Knife Edge, Sheet 2 of 2.....................................................67

Figure 35-General Arrangement, Shoe Sorter Induction Gapper, Sheet 1 of 1..........................................69

Figure 36-Electrical Schematic for Divert Control Box, Sheet 1 of 7...........................................................70

Figure 37-Electrical Schematic for Divert Control Box, Sheet 2 of 7...........................................................71

Figure 38-Electrical Schematic for Divert Control Box, Sheet 3 of 7...........................................................72

Figure 39-Electrical Schematic for Divert Control Box, Sheet 4 of 7...........................................................73

Figure 40-Electrical Schematic for Divert Control Box, Sheet 5 of 7...........................................................74

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

9

Figure 41-Electrical Schematic for Divert Control Box, Sheet 6 of 7...........................................................75

Figure 42-Electrical Schematic for Divert Control Box, Sheet 7 of 7...........................................................76

List of Tables

Table 1-List of Sensors ................................................................................................................................34

Table 2-Divert Box I/O Mapping .................................................................................................................37

Table 3-Recommended Preventative Maintenance Schedule ...................................................................42

Table 4-List of Section Weights...................................................................................................................44

Table 5-List of Drive Motor Weights...........................................................................................................45

Table 6-Oiler Pump Runtime (in seconds) Per Lubrication Interval............................................................46

Table 7-Recommended Lubricant Flow Rates and Lubrication Intervals ...................................................46

Table 8-BOM for GA-SHOE-36-120-0001....................................................................................................50

Table 9-BOM for GA-SHOE-MW-88-0001...................................................................................................59

Table 10-BOM for GA-SHOE-MW-88-0002.................................................................................................61

Table 11-BOM for GA-SHOE-MW-120-0002...............................................................................................65

Table 12-BOM for GA-SHOE-MW-48-0001.................................................................................................68

Reference Documents

MANUFACTURER

DOCUMENT TITLE

DOCUMENT

NUMBER

URL

Teknic, Inc.

ClearPath MC/SD User

Manual Rev.3.05

N/A

https://www.teknic.com/files/downloa

ds/clearpath_user_manual.pdf

Teknic, Inc.

AC ClearPath-MC/SD User

Manual Rev.3.06

N/A

https://www.teknic.com/files/downloa

ds/ac_clearpath-mc-sd_manual.pdf

The Diamond

Chain Company

Diamond Chain

Maintenance Guide

11255_201903

https://www.diamondchain.com/wp-

content/uploads/2017/03/

catalogs/maintenance-guide/

maintenance-guide.pdf

The Diamond

Chain Company

Diamond Series Product

Catalog

DC1000-201905

https://www.diamondchain.com/wp-

content/uploads/2018/01/2019_

Diamond_Chain_Catalog_links.PDF

The Diamond

Chain Company

Roller Chain Wear Gauge

Instructions

DCWG-2013

N/A

ABB Motors and

Mechanical, Inc.

(formerly Baldor

Electric

Company)

Instruction Manual for

DODGE® Setscrew,

Eccentric Collar, D-Lok, H-E

Series, E-Z Kleen, Ultra

Kleen and Food Safe

Mounted Ball Bearings

MN3016

https://www.baldor.com/mvc/

DownloadCenter/Files/MN3016

ifm Efector, Inc.

Operating instructions

Retro-reflective sensor

(OGP7xx)

80284283 / 00

https://www.ifm.com/mounting/

80284283UK.pdf

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

10

MANUFACTURER

DOCUMENT TITLE

DOCUMENT

NUMBER

URL

Insight

Automation

EZ24 Family Reference

Manual

PR-1100

https://www.pulseroller.com/files/NA/

Control%20Literature%20&%20

Drawings/EZ-24/Users%20Manual%20

and%20Specifications/Users_Guide.pdf

SEW Eurodrive

Operating Instructions (AC

Motors DR..71-315, DRN63-

315, DR2..63-80)

24745332/EN

https://download.sew-eurodrive.com/

download/pdf/24745332.pdf

SEW Eurodrive

Assembly and Operating

Instructions (Gear unit

series R..7, F..7, K..7, K..9,

S..7, SPIROPLAN® W)

21932786/EN

https://download.sew-eurodrive.com/

download/pdf/21932786.pdf

Bijur Delimon

International

SureFire II Lubricator

Automatic, Oil & Fluid

Grease, Single Phase

36410

http://www.bijurdelimon.com/

fileadmin/products/docs/bdius/

Datasheets/36410_LUB_SureFire-II-PDI-

SLR_DS-R2.pdf

Bijur Delimon

International

Operators Manual

Controller,SureFire II (Single

Phase PDI - SLR(24VDC,

115VAC & 230VAC))

36412

http://www.bijurdelimon.com/

fileadmin/bdide/downloads/36412_

SureFire-II_Controller_OM_2017_

1_GB.pdf

Bijur Delimon

International

SureFire II Lubricator Quick

Start Manual

71070

http://www.bijurdelimon.com/

fileadmin/products/docs/bdius/

Operator-Manuals/71070_SureFire-II-

Quick_Start_QS-R3.pdf

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

11

1Introduction

Thank you for choosing ZiPline Conveyor. The following manual serves as a guide for installation, part

replacement, and general maintenance for your material handling equipment. It is important to read the

manual and follow any instructions as it provides important safety information for personnel and will

maximize the longevity of the conveyor.

The information contained in this manual applies only to the products described. Uses, activities, or

processes related to installing or maintaining the equipment that are not explicitly described in this

manual are considered out of scope. Please contact Bastian Solutions ZiPline Conveyors for any

questions or support that is not clearly addressed in this document. ZiPline Conveyor is not responsible

for misuse of the equipment described in this manual or misuse of information in this manual. If you

have any questions, contact ZiPline Conveyor Customer Service or Support at

ZiPlineSupport@BastianSolutions.com.

2OSHA And Safety

ZiPline Conveyor is not responsible for ensuring that conveyors used in a system abide by OSHA

standards. Safety is of primary importance to our company, but as a product distributor we ask that

system integrators and end users conform with all applicable OSHA standards. We encourage that all

warnings in this manual are followed to avoid unnecessary risk.

3Model: Shoe Sorter

The ZiPline Shoe Sorter is a slat conveyor with movable shoes that slide laterally on the slats when

diverted by rails below the conveying surface. The shoe sorter is used for high-speed, high-volume

primary sortation, and is optimized for conveyance of cartons and totes.

Figure 1-Shoe Sorter Section Types and General Arrangement

Figure 1 shows a side view of an example shoe sorter. Product flows over an induction conveyor,

containing at least a knife edge transition belt, but commonly also containing one or more gapper

conveyors to set correct product spacing. The product then flows across the sorter, which contains one

or more divert sections. Each divert section will mate to a spur and a takeaway conveyor line. Products

that do not get diverted will continue down the length of the sorter onto discharge conveyor.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

12

4Receiving

Upon delivery of any ZiPline Conveyor, please review and check the following:

•The quantity of items received against the Bill of Lading.

•Complete a visual inspection of equipment to determine any damage that may have occurred

during shipping. If damage is present, document with pictures.

•Review Mark Number information and layout locations. More information can be found in

subsection 4.1.

If there are any missing or damaged components contact your ZiPline Conveyor representative with as

much detail as possible. If you are unsure of your ZiPline Conveyor representative, please contact

Customer Service at ZiPlineSupport@BastianSolutions.com.

4.1 Mark Numbers

A mark number is a specific number given to a piece of equipment. A mark number is usually made up of

a single product line (RZPDC, RLVDC, BZPDC, etc.) but can contain many bed section lengths. They can

range from two inches to hundreds of feet in length. The mark number is used to help identify where

the piece of equipment will go within the system layout.

Every bed section of conveyor will have (2) stickers. One sticker on the infeed end of the bed, and one

sticker on the discharge end of the bed. Each sticker will contain the following information:

•ZiPline Project Number and Name

•Model Type

•Mark Number

•Match

•Piece

•Flow

Figure 2 shows the stickers that would appear on an RZPDC that has two bed sections.

•The Match field on the stickers is used to indicate if two bed sections are to be spliced to one

another.

•As shown in Figure 2 the stickers where the two beds splice together both contain Match: 1.

•The Piece field defines the bed section number within the mark.

•The flow refers to the direction of product flow along the conveyor system.

Figure 2-Mark Number Stickers

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

13

4.2 Skid Contents

Skids will contain varying combinations of conveyor sections, support structures, accessories, and

pertinent hardware. For protection of product integrity during shipping, accessories and supports may

be delivered on separate, but labeled skids.

4.3 Skid Documentation

All shipments will contain a Bill of Lading for the delivery company, a skid label, and a skid

manifest. Skid labels have the contents of each shipped item located on the skid. Figure 3 shows

a sample of a skid label. These stickers are placed on the surface of each skid.

Figure 3-Skid Sticker

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

14

5Installation

Ensure that your conveyor equipment has been securely fastened to the floor or other mounting surface

before full operation occurs.

Consideration should be given to floor point loading prior to installation to ensure

proper support of equipment. See Appendix 1 for section weights.

5.1 Mechanical Installation

5.1.1 Bed Section Placement

1. Lay out chalk lines on floor for placement –See the system layout/installation drawings.

2. Lift the drive section off the skid using the provided lifting eyes on the frame

3. Set the drive section in position. Refer to the system layout/installation drawing and Figure 1.

DO NOT pick up or move drive section using the lifting eyes on the motor or

gearbox. Damage to the gearbox or drive shaft may result.

On larger units, the motor may be shipped separate from the drive unit. See SEW

Eurodrive Gear Unit Assembly and Operating Instructions section 4 for installation

instructions.

Secure the drive unit to the floor before installing the motor. Heavy gearmotors

may cause the drive unit to become unbalanced or tip during installation.

4. Adjust the foot bolts on the drive so all four feet are in contact with the floor and the drive section is

level and aligned to the chalk lines.

5. Check that the height of the drive section matches the specified height on the system layout

drawing (the top of the frame is 3/8” below the final slat surface)

6. If the drive section is out of square, use the provided tension rod for squaring adjustment

7. Set each section and bolt them together, working backwards from the drive to the tail. See Figure 5

for details on fastening the sections together. Hand tighten only at this stage.

8. Check square on each section and check the straightness of the sorter before securing to the floor.

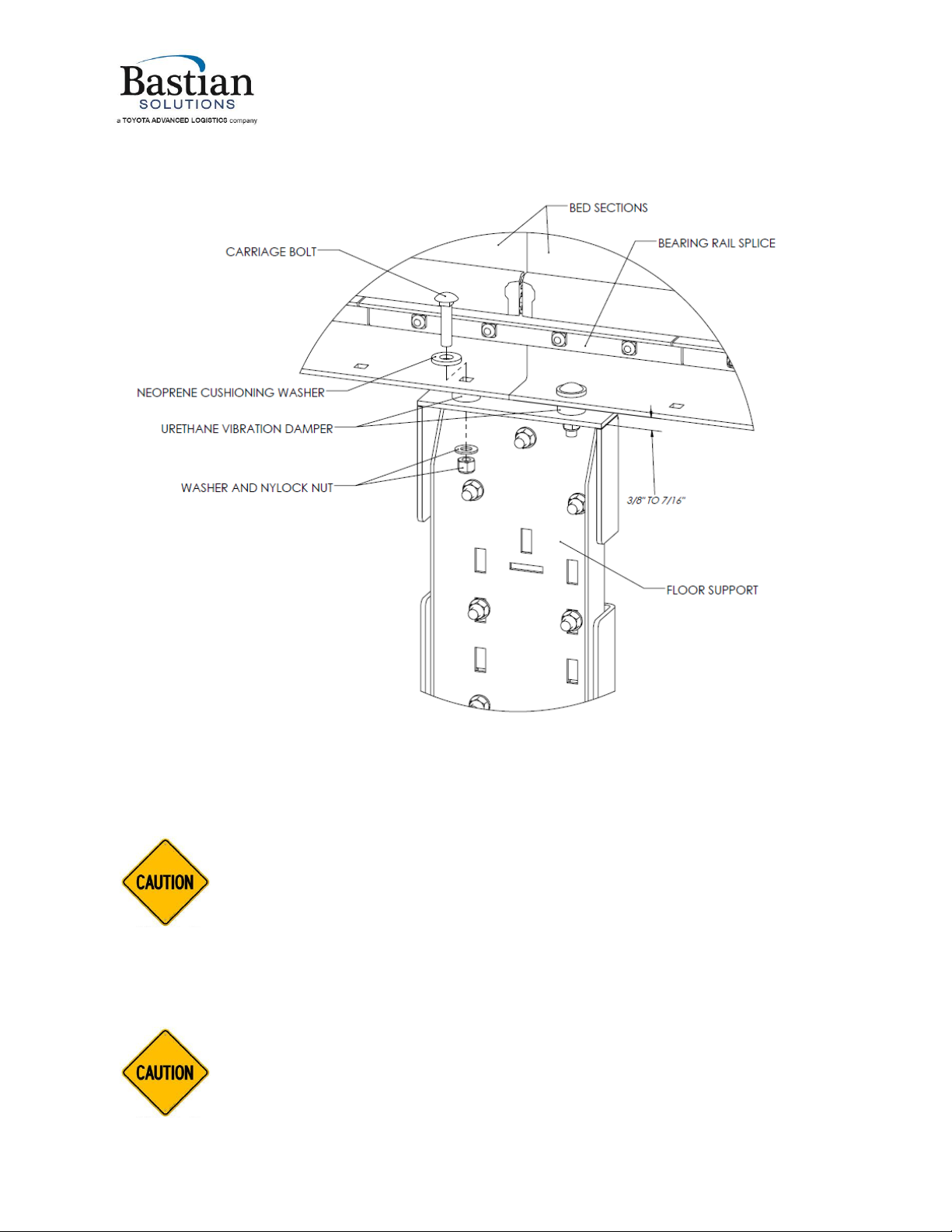

5.1.2 Floor Support Installation

1. See Figure 4

2. Place a thin black neoprene washer between the bolt head and the flange of the sideframe.

3. Place a green urethane vibration damper between the sideframe and the floor support.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

15

Figure 4-Floor Support Installation Detail

4. Adjust the urethane vibration damper to 3/8” to 7/16” tall (1/8” to 1/16” compression).

5. Adjust the top of conveying surface height by adjusting the floor support.

Do not use vibration dampers for height adjustment. Excessive compression can

damage the vibration dampers and will increase vibrations transmitted into the

floor supports.

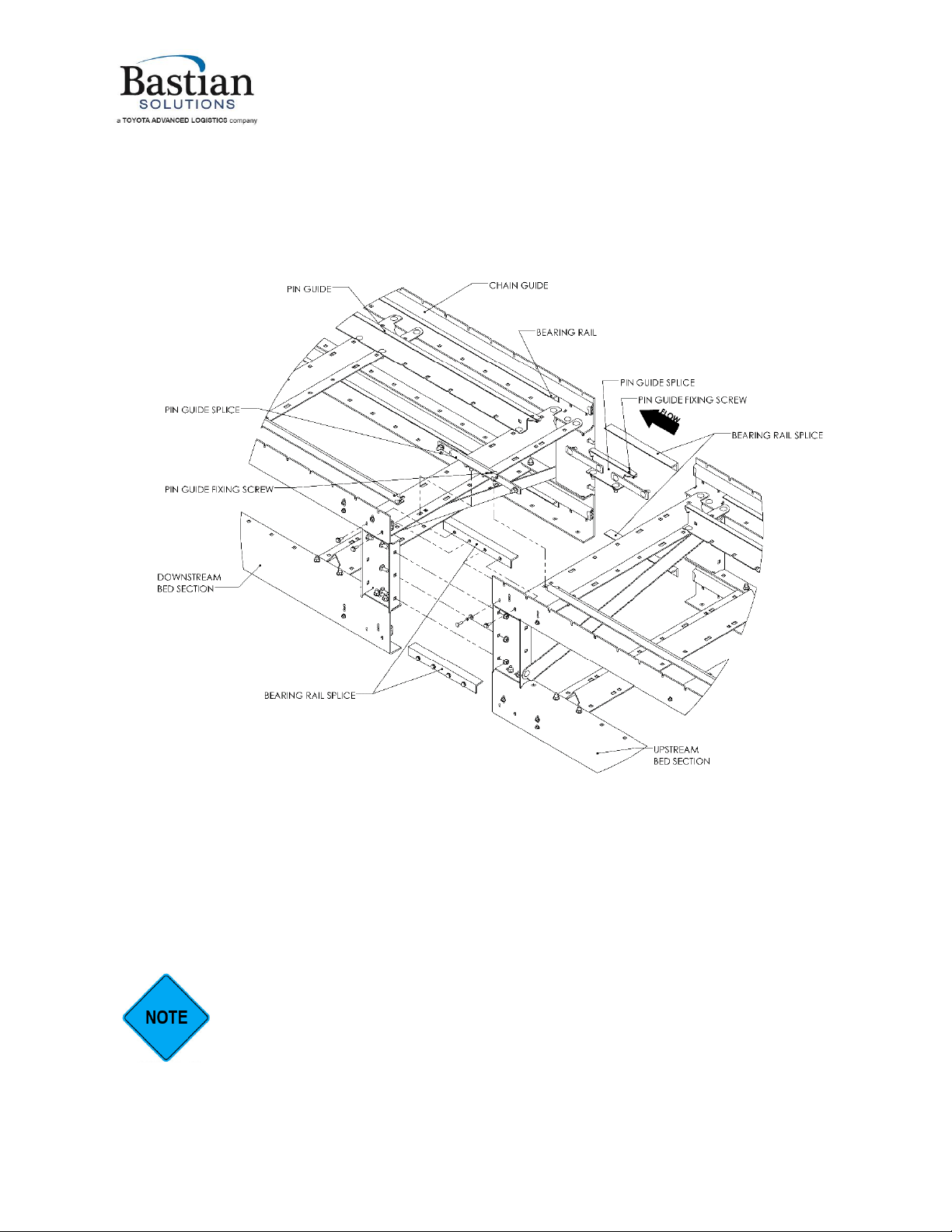

5.1.3 Section Fastening and Rail Alignment

1. See Figure 5 for details on fastening sections together.

2. Use of a laser level is recommended to set the sorter straight and level.

The sorter must be level front-to-back, side-to side, and all sections must be aligned

straight to within the tolerances specified in step 3. Misalignment can cause noisy

operation and/or damage to the chain, bearings, and slats.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

16

3. Lateral straightness tolerances must be within +/- 1/2 inch per 100 feet. Check each bed section

joint to ensure there are no bumps or discontinuities (use a laser to sight from the drive to the tail).

4. Ensure the drive and tail shafts are level by placing a precision level directly on the respective shafts.

See Diamond Chain Maintenance Guide section 1 for chain alignment tolerances.

Figure 5-Bed Section Fastening Detail

5. Place a straightedge across the gap in the bearing rail between each bed section, and install the

bearing rail splice so that it mates with the installed bearing rail on both the upstream and

downstream ends.

a. If there are any bumps created by misalignment where the bearing rail ends meet, it will cause

excessive noise during operation and, if the misalignment is severe, can damage the chain

mount bearings over time.

The bearing rail splice can also be used for pulling sections together (aligning) left-to-

right. Ensure the section splice bolts are loose enough to allow movement before

pulling the sections together.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

17

6. Place a straightedge across the gap in the pin guide between bed sections, and install the pin guide

splice so that it mates with the installed pin guide on both the upstream and downstream ends. The

pin guide and pin guide splices should be approximately centered in their mounting slots.

a. If there are any bumps created by misalignment where the pin guide ends meet, it will cause

excessive noise during operation and, if the misalignment is severe, can damage the pin guide

covers and the slat mounts over time.

The pin guide fixing screw is always on the upstream end with respect to chain flow.

It is important to maintain this orientation, or the plastic cover could come off and

cause damage.

7. Once the sections are straight and level, fully tighten all section splice bolts and secure to the floor

or decking.

a. Tighten 1/4”-20 fasteners to 8.4 ft-lb.

b. Tighten 3/8”-16 fasteners to 31 ft-lb.

c. Fastening hardware to secure the floor supports to the floor or decking is not provided by

ZiPline. Consult the hardware manufacturer for appropriate torque values.

Ensure the securing method is appropriate for the application. Installations in seismic

zones will generally require an independent seismic review. ZiPline does not provide

general-purpose recommendations for concrete anchors or other fastening methods,

since fastening requirements depend on the site-specific details of the mounting

surface.

8. Verify straightness and level again once all sections are fully secured and all bolts are tightened.

Adjust the section positioning as needed if any sections have moved out of alignment.

5.1.4 Spur Installation

1. The spur mounting brackets share mounting bolts with the chain guards. Spur locations use a chain

guard piece painted standard silver color instead of safety yellow.

2. Attach the spurs to the sorter by bolting the spur to the slots in the mounting brackets using 3/8”

carriage bolts.

3. Spur locations are adjustable left-to-right using the provided slots.

4. Locate spurs per the system installation drawing. See Figure 6 for typical spur positioning. Spur

alignment is given relative to the divert rail and the positions of installed shoes.

5. Set spurs approximately 3/8” lower than the sorter TOCS using the spur jack bolts.

6. Tighten spur mounting bolts once spur is in its final position. See Figure 7.

a. Tighten 3/8”-16 fasteners to 31 ft-lb.

The provided adjustment travel is intended for optimizing the spur location relative to

the divert rail. Moving the spur a large distance may cause problems diverting large

packages, depending on the system layout.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

18

Figure 6-Typical Spur Positioning

Figure 7-Spur Mounting Detail

2” APPROXIMATELY

1 3/8” APPROXIMATELY

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

19

5.1.5 Chain Installation

Run power to the main drive motor and verify the motor rotation direction before

installing the chain. Running the sorter backwards can cause damage to slats, chain, and

sorter internal components.

The “missing bearing”fork sensor on the first divert section is easy to damage when

installing the chain. This sensor is shipped separately for this reason; recommend

installing the sensor only after completing the chain installation.

1. The chain comes pre-assembled with chain mounts.

2. The chain is shipped and tagged in matched pairs (right and left)

a. Right and left sides of the sorter are determined by facing in the direction of product flow.

Figure 8-Chain Connection Detail

3. Always keep the matched pairs across from each other. Keep the tags on the chain until it is installed

in the sorter.

4. Lay out a matched pair of chain and hold it together with one slat approximately every two feet,

starting at the drive sprocket and working backwards.

Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Man ual: Shoe S orter

Published October 2019

Rev.A1

20

a. See Section 5.1.6 for instructions on slat installation.

5. Join the chain sections with a connecting link, then install the chain mounts over the connecting link

section. See Figure 8.

6. Once the chain is installed on top of the sorter, use the drive sprocket to help pull the chain around.

7. Two options to turn the drive sprocket manually are:

a. The flat on the drive shaft (use a 1-1/8” open end wrench with a cheater bar or other long

handle extension)

b. Remove the fan cover and rotate the fan of the drive motor by hand (this method is slower, but

it requires lower torque due to the mechanical advantage of the gearbox)

The drive must be locked out during chain install—do not use the drive motor to

advance the chain during installation. Death or serious injury could result.

8. Attach ropes to the free end of the chain to help pull the chain through the catenary (force should

be transmitted through the drive sprocket; the ropes are to correctly guide the free end).

DO NOT pull on the slats or chain mounts. Damage to the slats or chain mounts could

result. Fasten any pulling devices (winches, come-alongs, etc.) directly to the chain,

with the use of a suitable spreader bar to ensure the force is exerted directly along

the length of the chain.

There will be, by design, one matched pair of chains that is a shorter length than the

others. This pair has been factory-cut to the appropriate length for the sorter

installation. As with all matched chain pairs, this pair must be kept directly across

from each other.

9. Install the short length chain pair last.

10. Depending on the sorter length and the chain weight, making the last chain splice may require the

use of come-alongs, ratchet straps, or other mechanical pulling devices to generate enough slack to

insert the last connector link.

11. Apply no more than 800 lbs of pulling force to each chain end (1600 lbs total).

12. If needed, adjust the position of the tail shaft (only if the chain cannot be assembled otherwise) to

gain extra slack. Ensure the tail shaft remains square to the sorter frame. See Figure 25 and Figure

26 in Appendix 3.

13. Once the chain installation is complete, install the “missing bearing”sensor on the first divert of the

sorter.

a. See Figure 21, Figure 22, and Figure 23 in Appendix 3 for drawings showing the mounting

details, location, and alignment of the pin sensor and “missing bearing” sensor.

b. The “missing bearing”sensor must be positioned 4-1/2” behind the pin sensor.

c. See Section 6.2 for detailed troubleshooting information on the “missing bearing”sensor.

Other manuals for Shoe Sorter

1

Table of contents

Other Bastian Solutions Industrial Equipment manuals