Release: 02.0 2017-01-13 Page 3

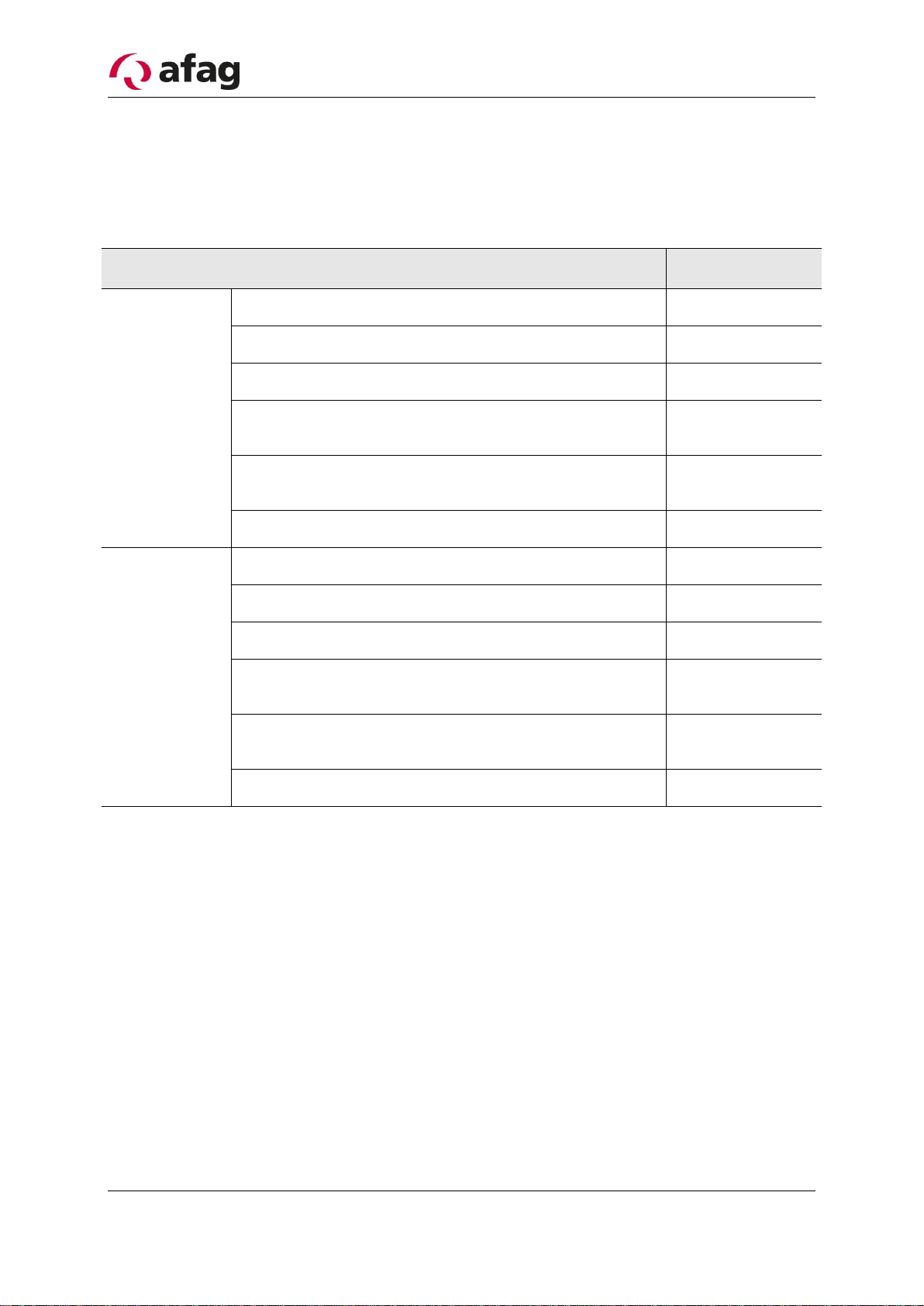

Table of Contents

1Declaration of installation for a complete machine........................................ 5

2Safety instructions............................................................................................ 6

Explanation of symbols and instructions .............................................................................................. 6

Basic safety instructions ...................................................................................................................... 7

2.2.1 Electrical Connection.................................................................................................................. 7

2.2.2 Danger zones ............................................................................................................................. 7

Intended use ....................................................................................................................................... 8

Obligations of the operator ................................................................................................................. 8

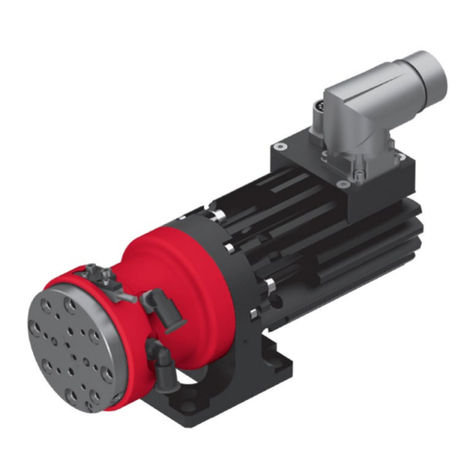

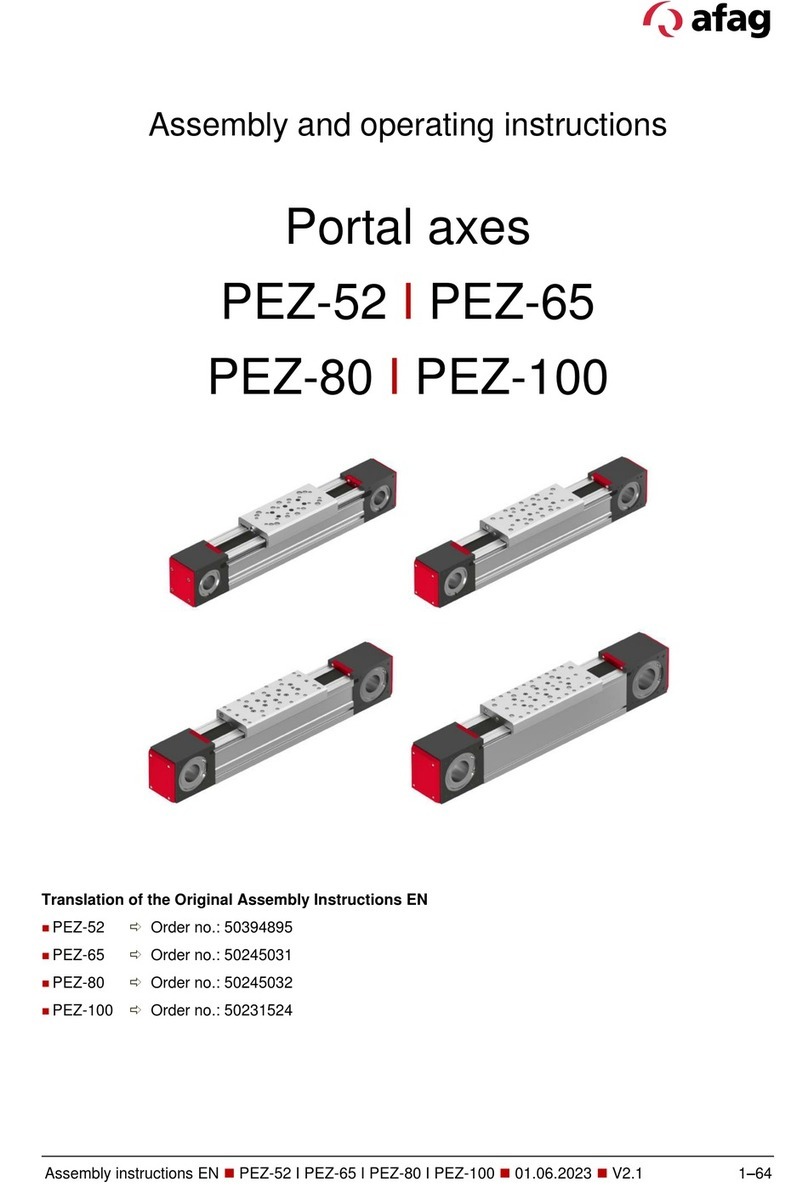

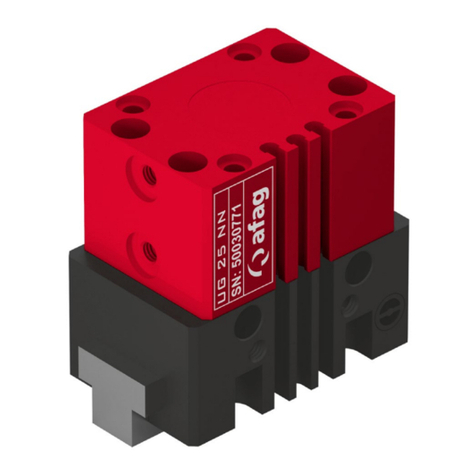

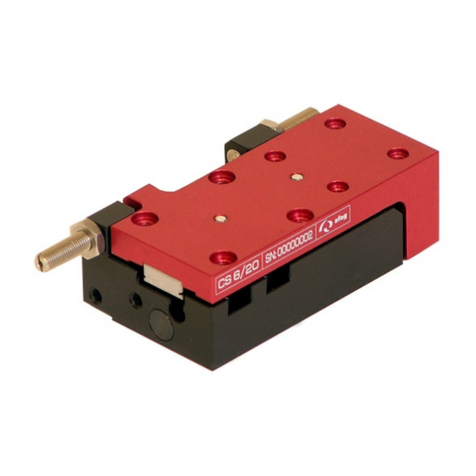

3Description of the device................................................................................ 10

General............................................................................................................................................. 10

Function description .......................................................................................................................... 11

Technical data................................................................................................................................... 12

Electrical/Control Components .......................................................................................................... 16

4Installation instructions.................................................................................. 17

Transport .......................................................................................................................................... 17

Assembly of the device ...................................................................................................................... 17

4.2.1 Drilling pattern for assembly .................................................................................................... 17

4.2.2 Dismantling adaptor plate........................................................................................................ 18

4.2.3 Assembly of the flex sockets..................................................................................................... 19

4.2.4 Assembly of the adaptor plate on the mounting level............................................................... 19

4.2.5 Assembly of aflex on the adaptor plate..................................................................................... 19

Connection of the device ................................................................................................................... 20

Power supply..................................................................................................................................... 20

Connection of the control .................................................................................................................. 21

5Software description....................................................................................... 23

Installation of the Software ............................................................................................................... 23

User groups....................................................................................................................................... 24

Start page ......................................................................................................................................... 25

5.3.1 Control unit States ................................................................................................................... 26

5.3.2 Advanced display Administrator ............................................................................................... 29

5.3.3 Connection set-up.................................................................................................................... 30

Main menu........................................................................................................................................ 30

Control interface ............................................................................................................................... 34

5.5.1 Aflex control panel ................................................................................................................... 34

5.5.2 Aflex configurations ................................................................................................................. 37

5.5.3 Control unit power output ....................................................................................................... 39

5.5.4 Simulation of the external control ............................................................................................ 40

Sub menu controller .......................................................................................................................... 43