Table of Contents

1Introduction ................................................................................................................... 6

2OSHA and Safety ............................................................................................................ 6

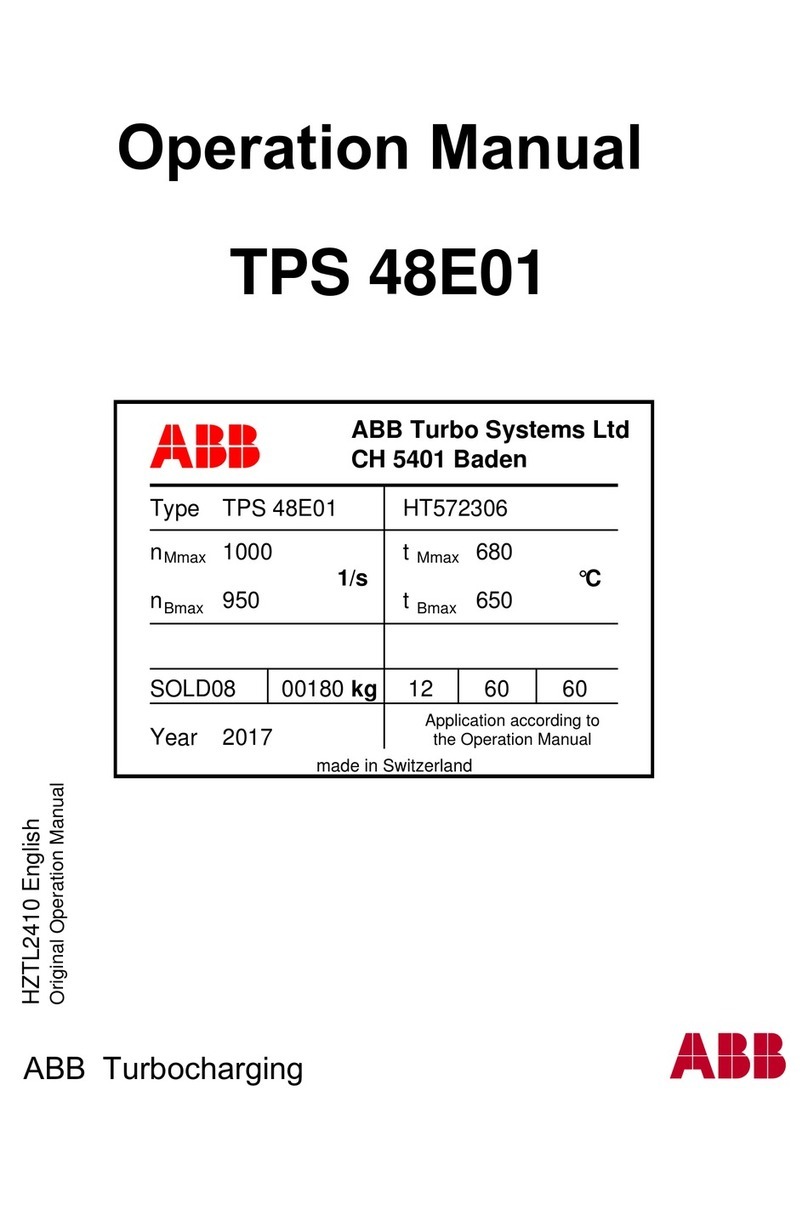

3Model: BRBDC................................................................................................................ 7

4Receiving........................................................................................................................ 8

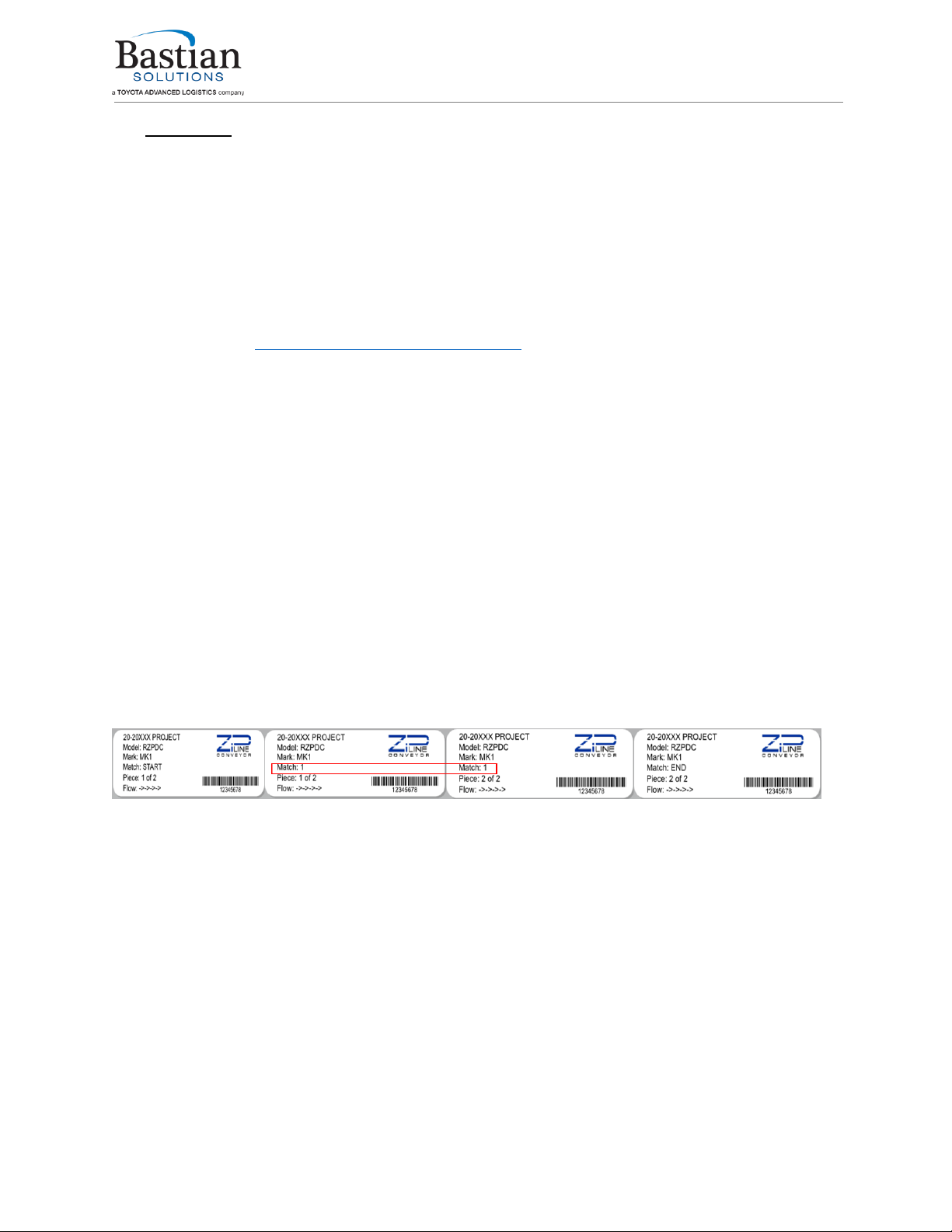

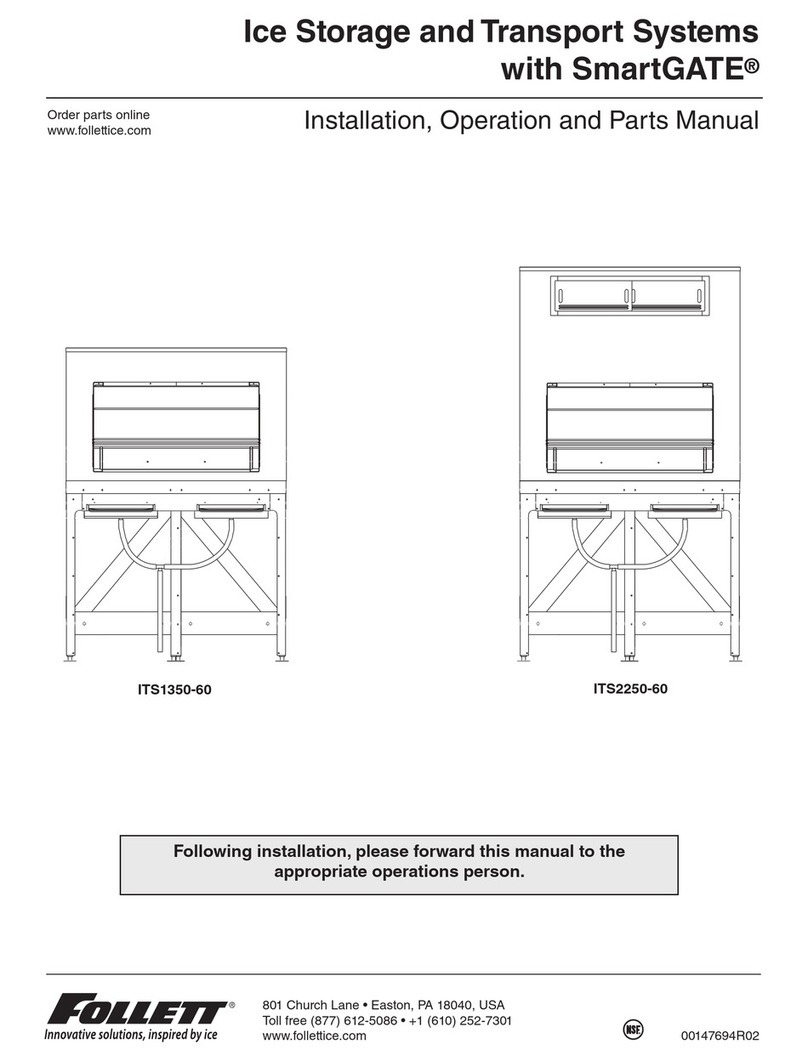

4.1 Mark Numbers....................................................................................................................8

4.2 Skid Contents......................................................................................................................8

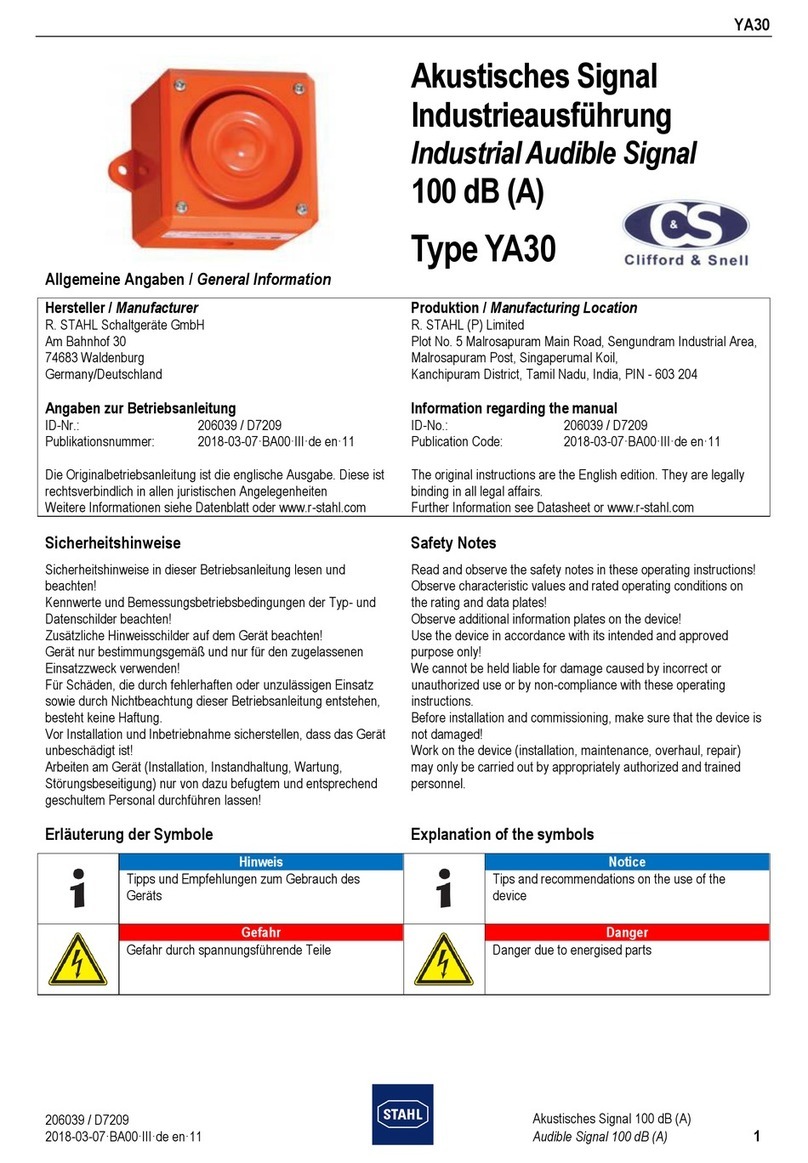

4.3 Skid Documentation............................................................................................................9

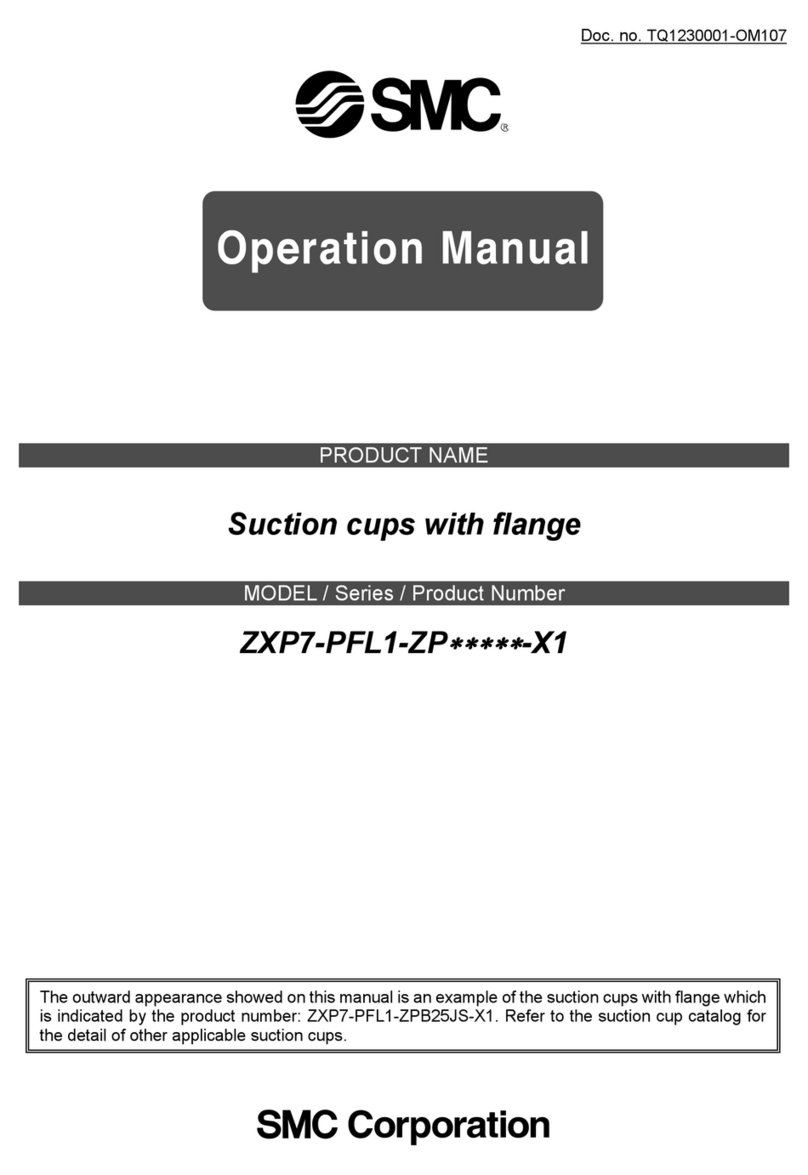

5Installation................................................................................................................... 10

6Maintenance and Operation......................................................................................... 11

6.1 Safety During Operation....................................................................................................11

6.2 Maintenance Schedule ......................................................................................................11

6.2.1 Mechanical Service ................................................................................................................................12

6.2.2 Electrical Service ....................................................................................................................................12

6.2.3 Replacing Idler Rollers ...........................................................................................................................12

6.2.4 Replacing Head Roller............................................................................................................................15

6.2.5 Replacing Motor ....................................................................................................................................16

6.2.6 Replacing Drive Band .............................................................................................................................18

6.2.7 Tracking Belt ..........................................................................................................................................19

6.2.8 Tracking Drive Band ...............................................................................................................................20

7Troubleshooting and Repair.......................................................................................... 20

8Standard Spare Parts .................................................................................................... 21

List of Figures

Figure 1: Exploded View of BRBDC ...............................................................................................................7

Figure 2: Mark Number Stickers ...................................................................................................................8

Figure 3: Skid Sticker.....................................................................................................................................9

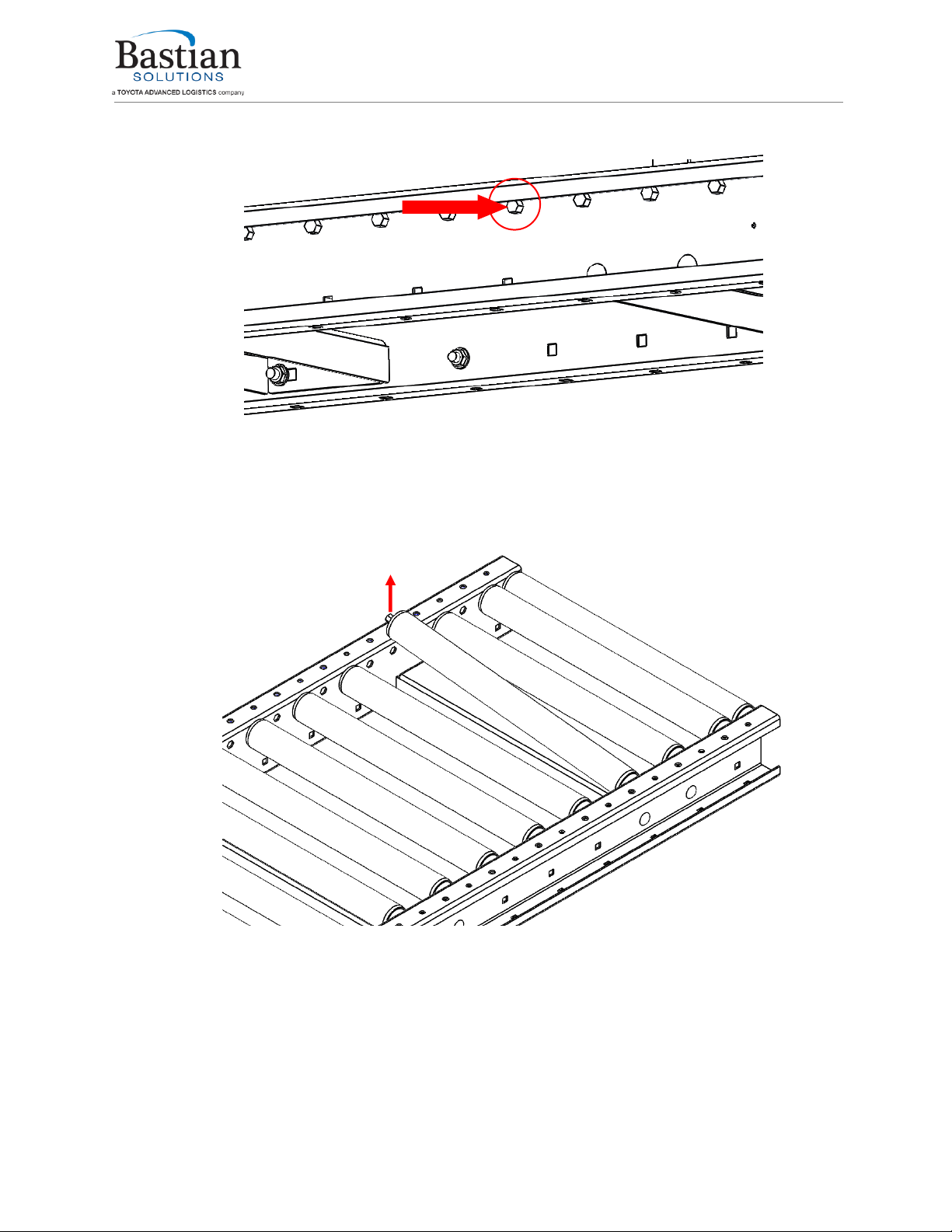

Figure 4: Fastening BRBDC to Floor Support ..............................................................................................10

Figure 5: Roller Removal.............................................................................................................................13

Figure 6: Removing Roller from Side Frame, Belt Hidden for Visibility ......................................................13

Figure 7: Top View of BRBDC, Belt Hidden for Visibility .............................................................................14

Figure 8: Underside View of BRBDC............................................................................................................15

Figure 9: Exploded View of Motor Mounting Assembly.............................................................................16

Figure 10: Exploded View of Motor and Pulley Assembly ..........................................................................17

Figure 11: Band Guard Assembly................................................................................................................18

Figure 12: Top View of BRBDC ....................................................................................................................19

Figure 13: BRBDC Spare Parts Exploded View ............................................................................................21